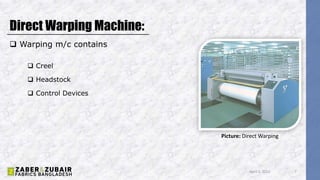

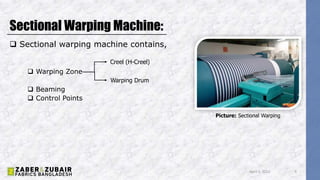

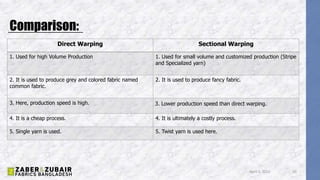

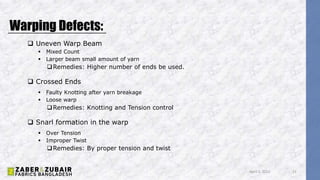

The document presents a detailed overview of warping in fabric manufacturing, defining it as the parallel winding of yarn onto a warp beam. It discusses three types of warping: direct, sectional, and ball warping, highlighting their applications, production capacities, and defects. Various remedies for common warping defects are also provided to enhance yarn quality.