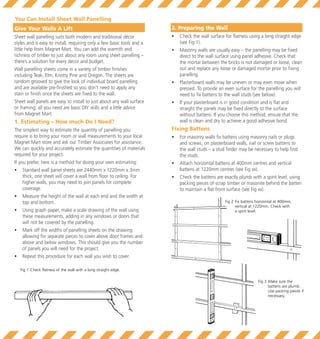

This document provides instructions for installing sheet wall panelling. It includes a list of required materials and tools, as well as steps for estimating quantities, preparing the wall surface, and fitting the wall panels using either nails or adhesive. Key points covered are checking for a flat surface, attaching horizontal and vertical battens, applying adhesive, and securing panels starting from the center and working outwards. The goal is to provide easy to follow guidance for giving walls a new look using wall panelling.