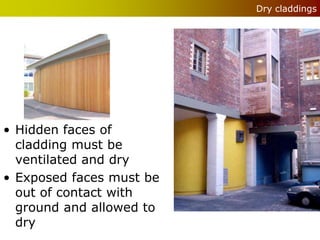

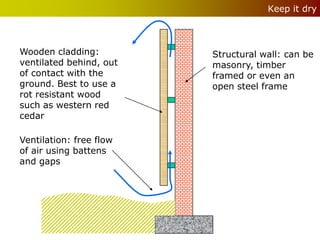

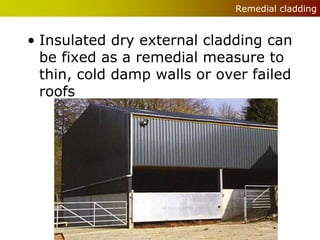

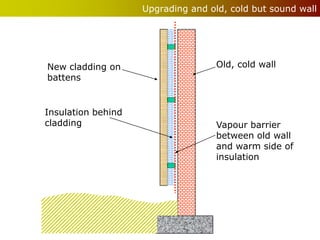

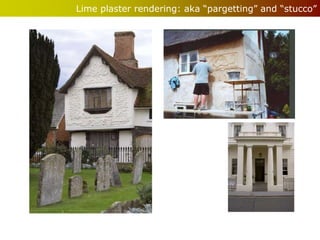

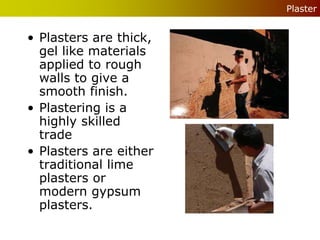

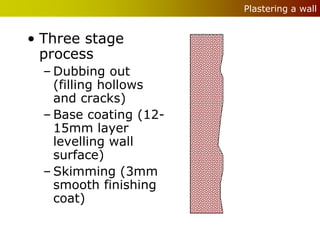

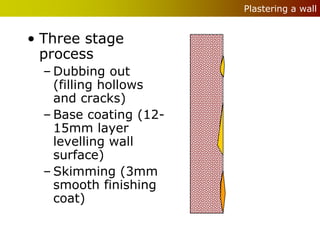

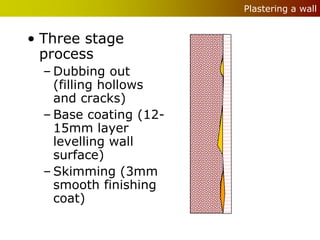

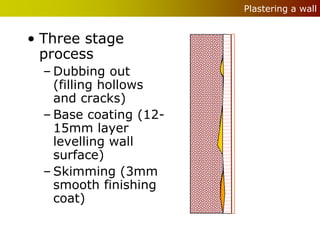

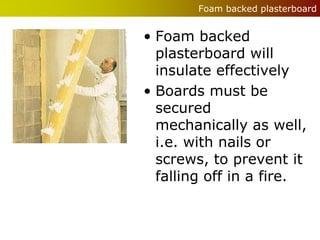

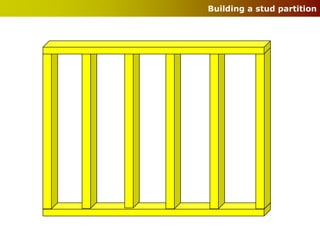

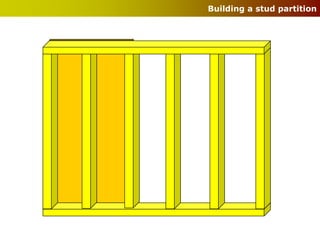

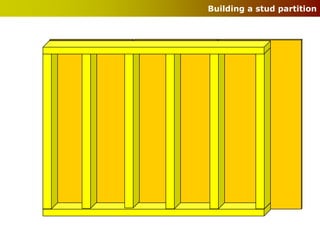

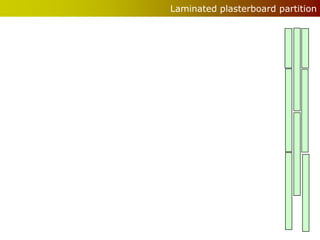

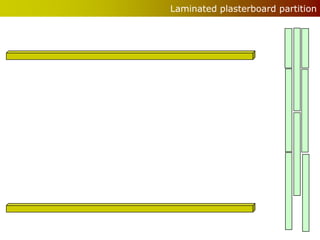

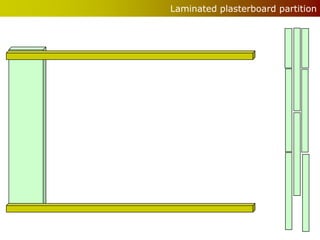

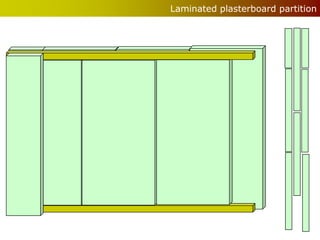

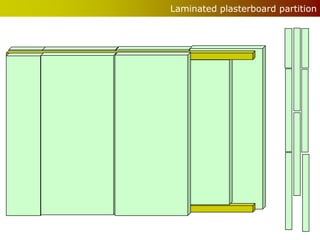

Partitions subdivide interior spaces and can be load-bearing or non-load bearing. Finishes can be thick, property-changing materials like plaster or thin, cosmetic materials like paint. External finishes include dry claddings like timber boarding and wet finishes like lime-based renders. Internal finishes include thick plaster or drywall with joint compound and paint. Proper installation of partitions and selection of appropriate finishes is important for interior construction.