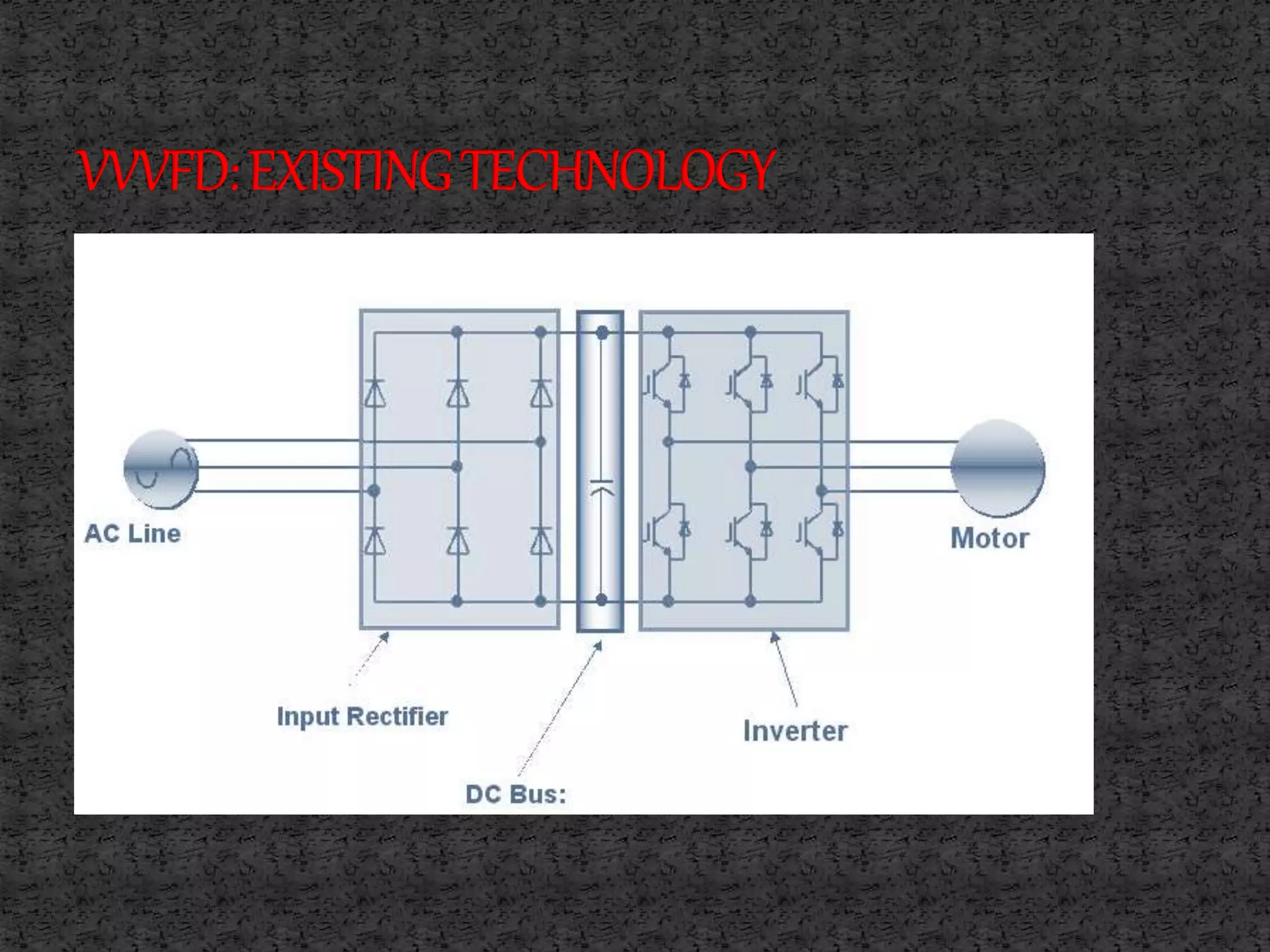

This document summarizes various methods for controlling the speed of three-phase induction motors. It discusses that induction motors are commonly used in industry but run at a constant speed. Speed control is needed to vary the motor speed based on process requirements. The main methods covered are stator voltage control, stator frequency control, stator current control, and V/F control. It provides details on how each method works and the advantages and disadvantages. Examples of industrial applications where speed control is used are also listed.