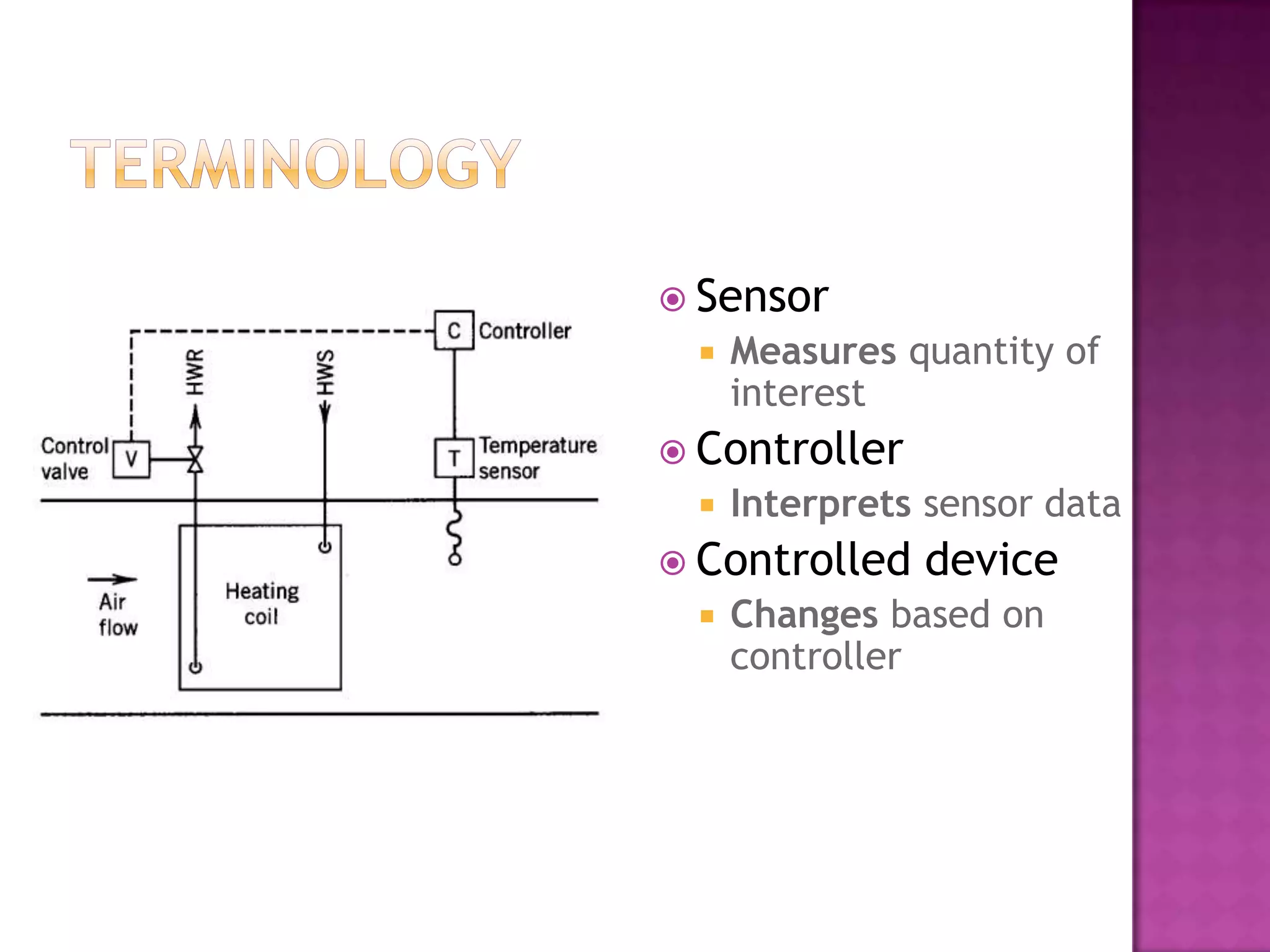

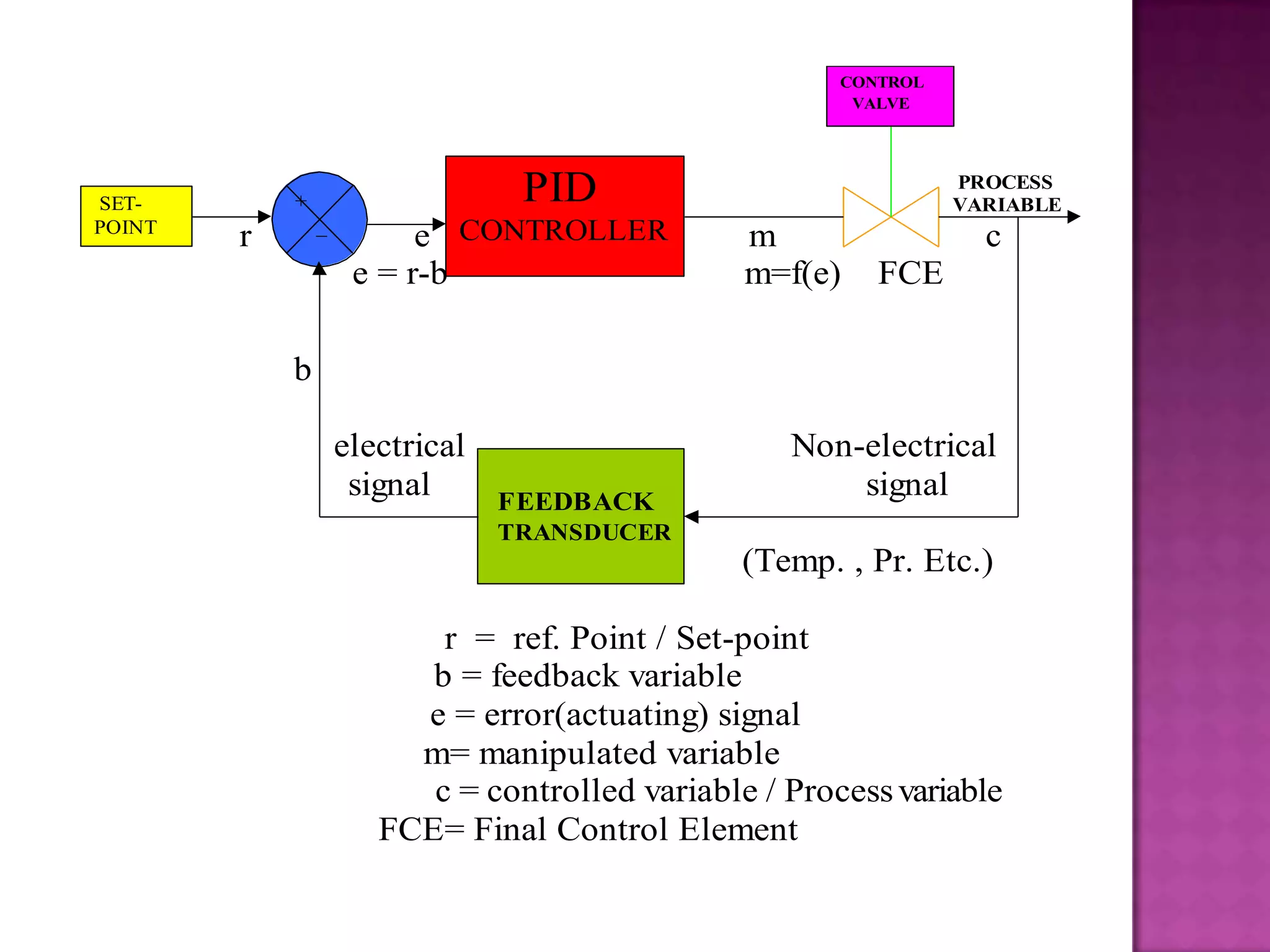

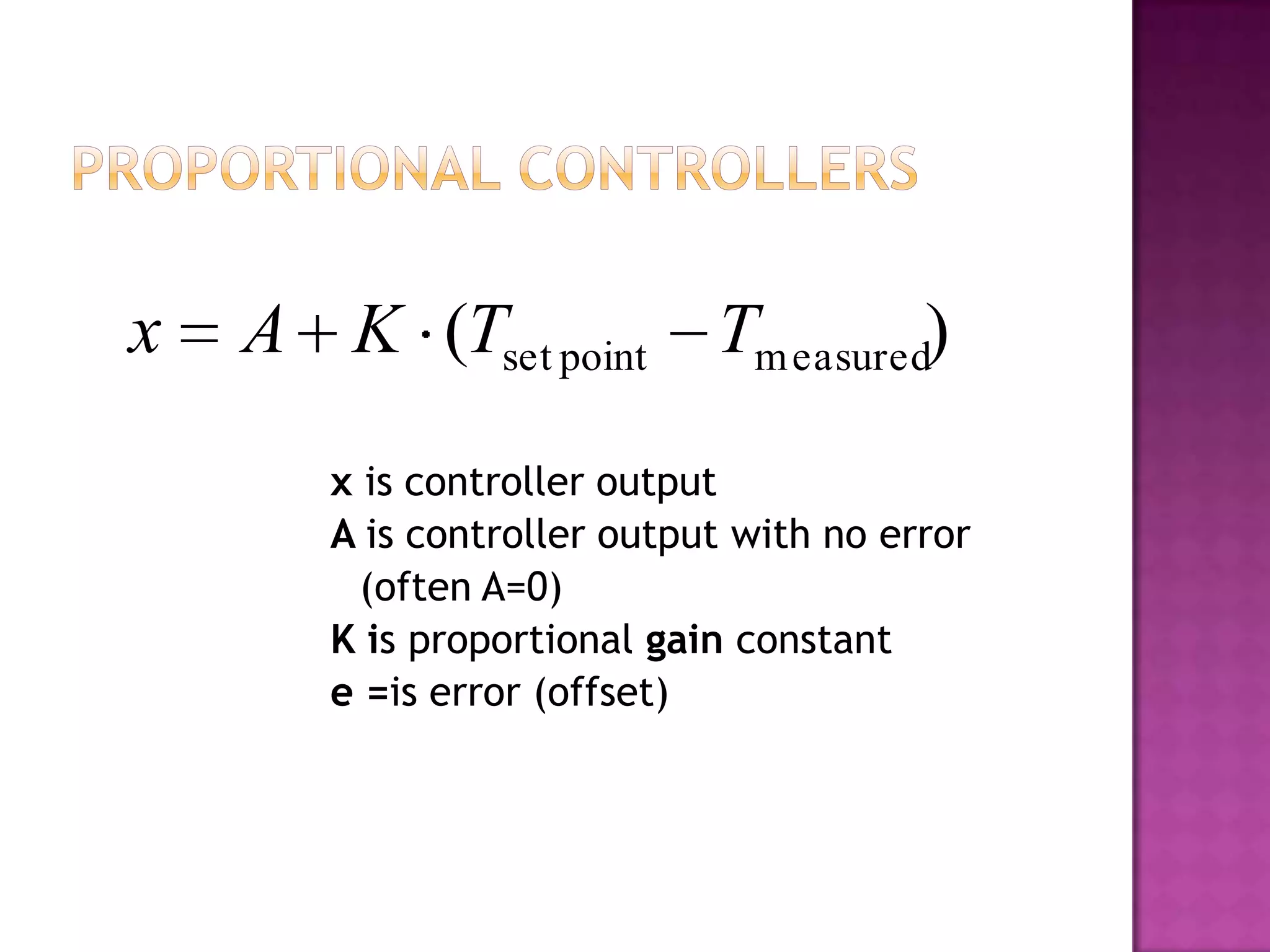

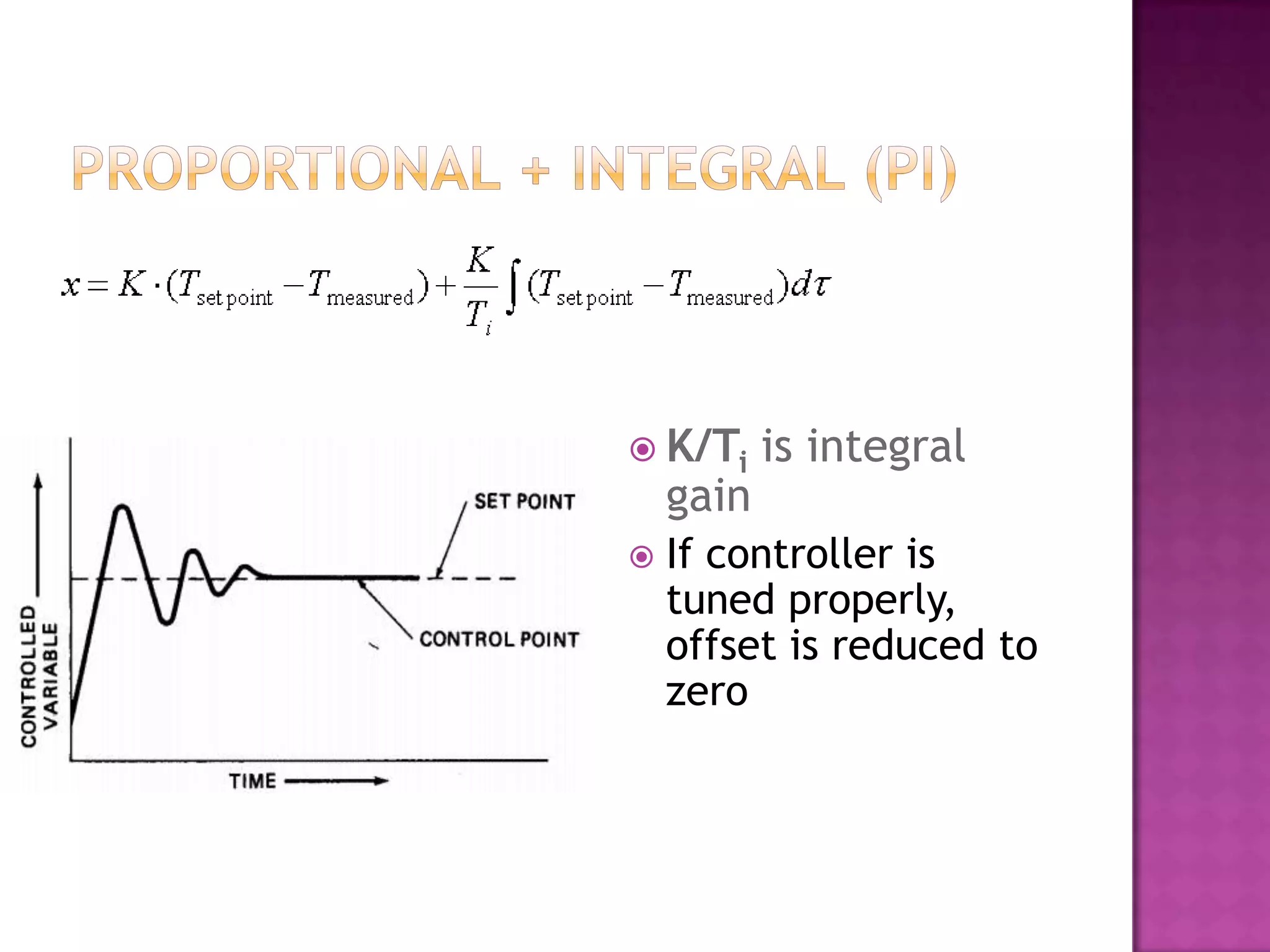

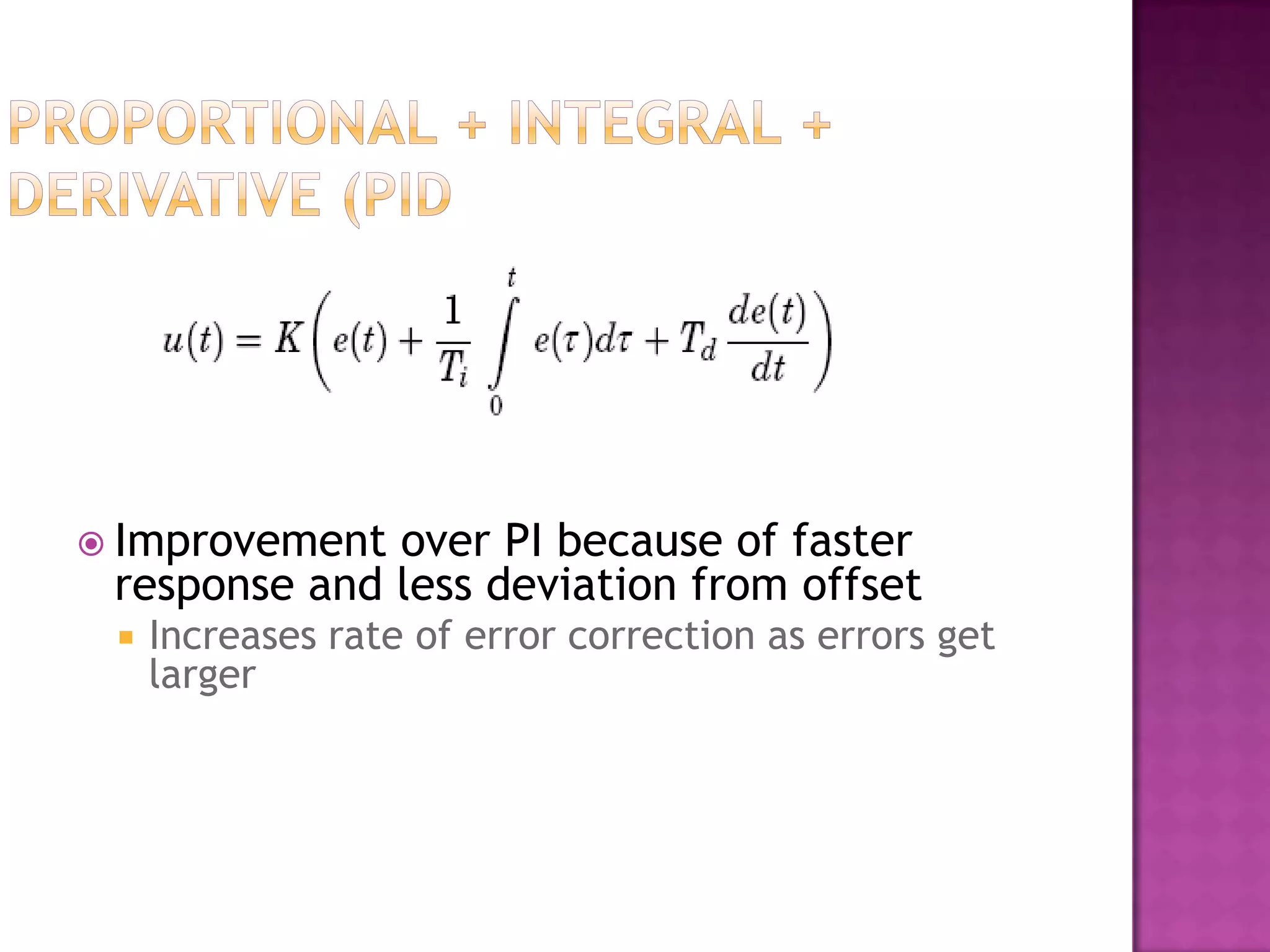

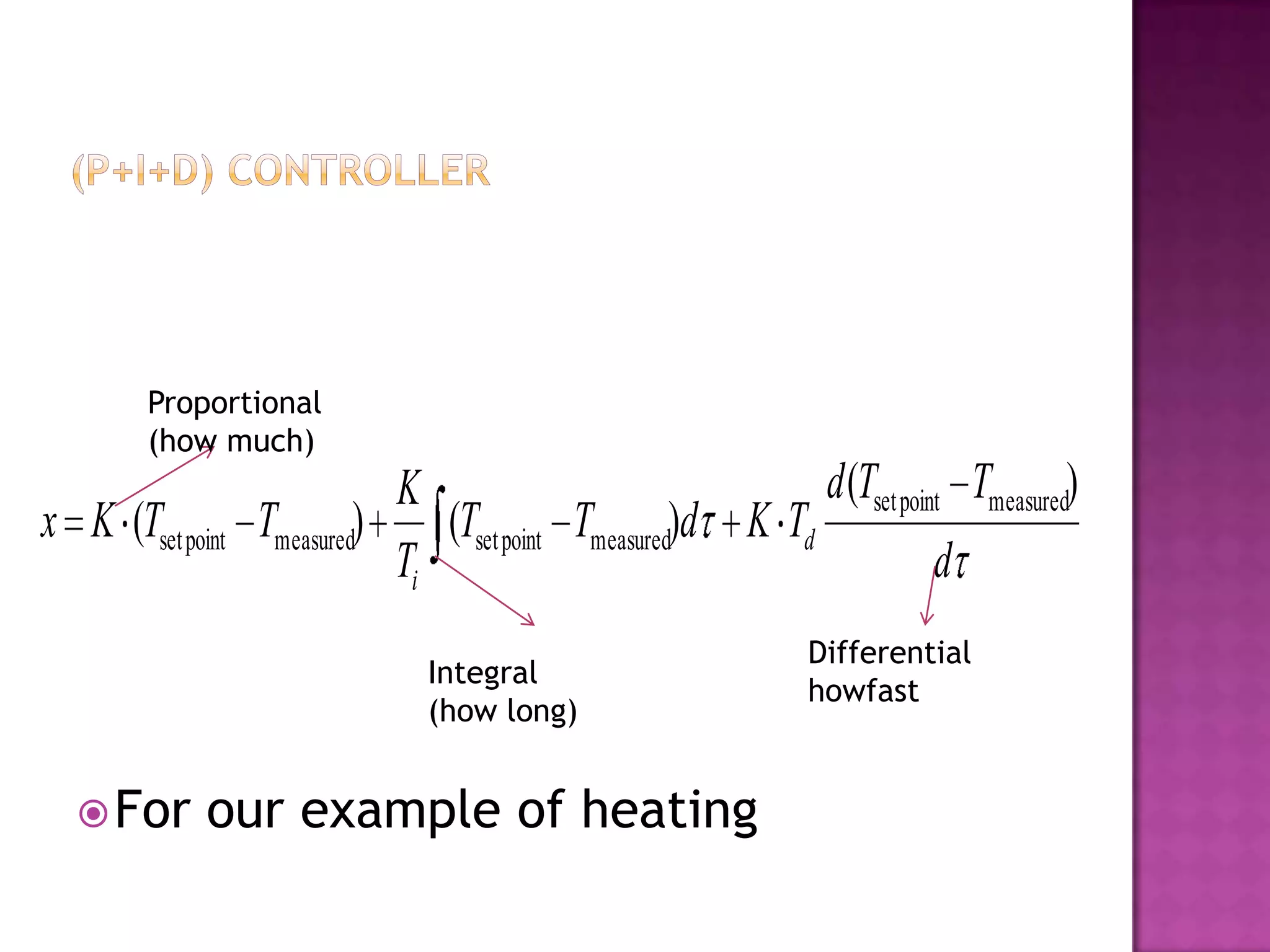

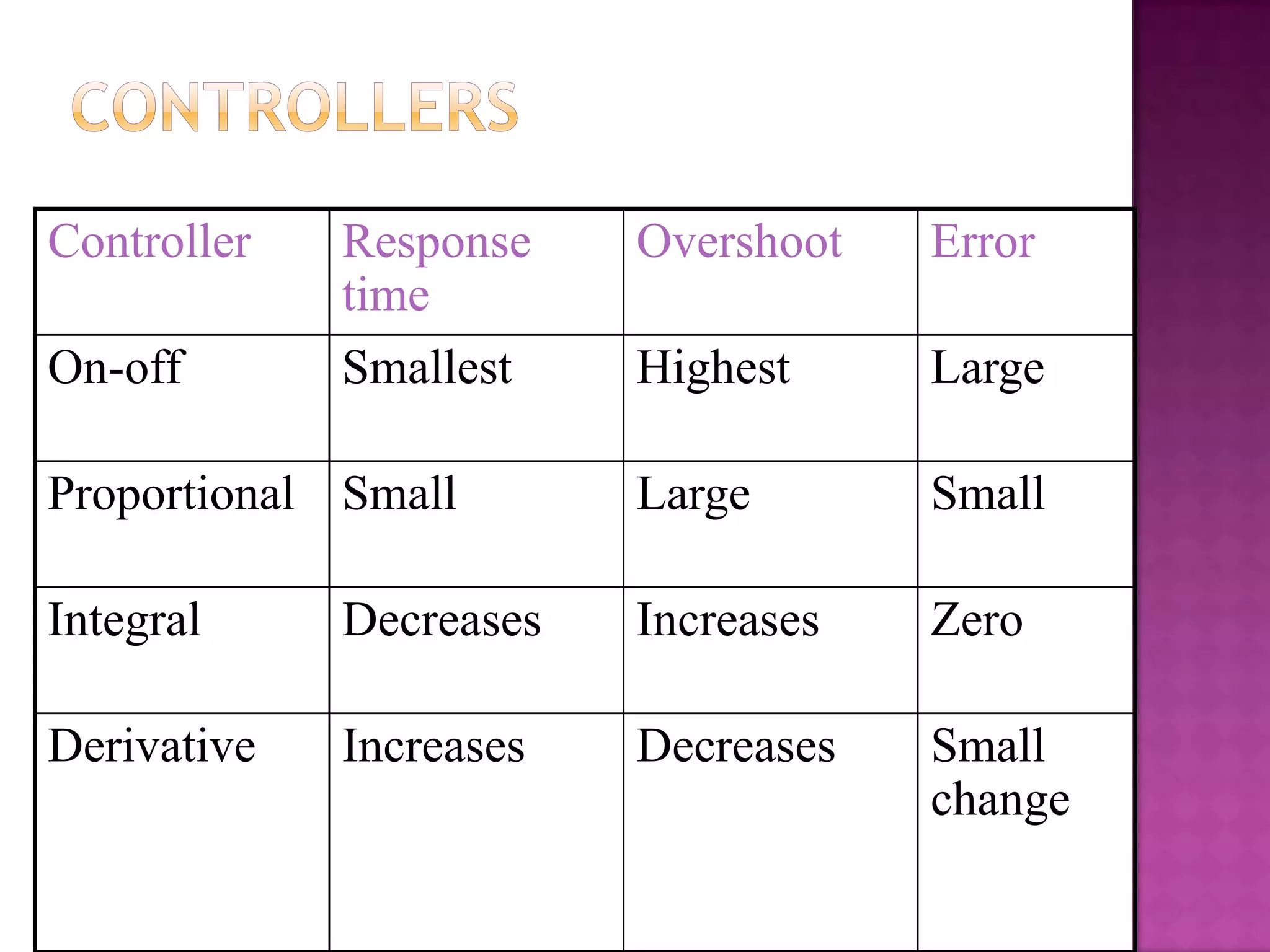

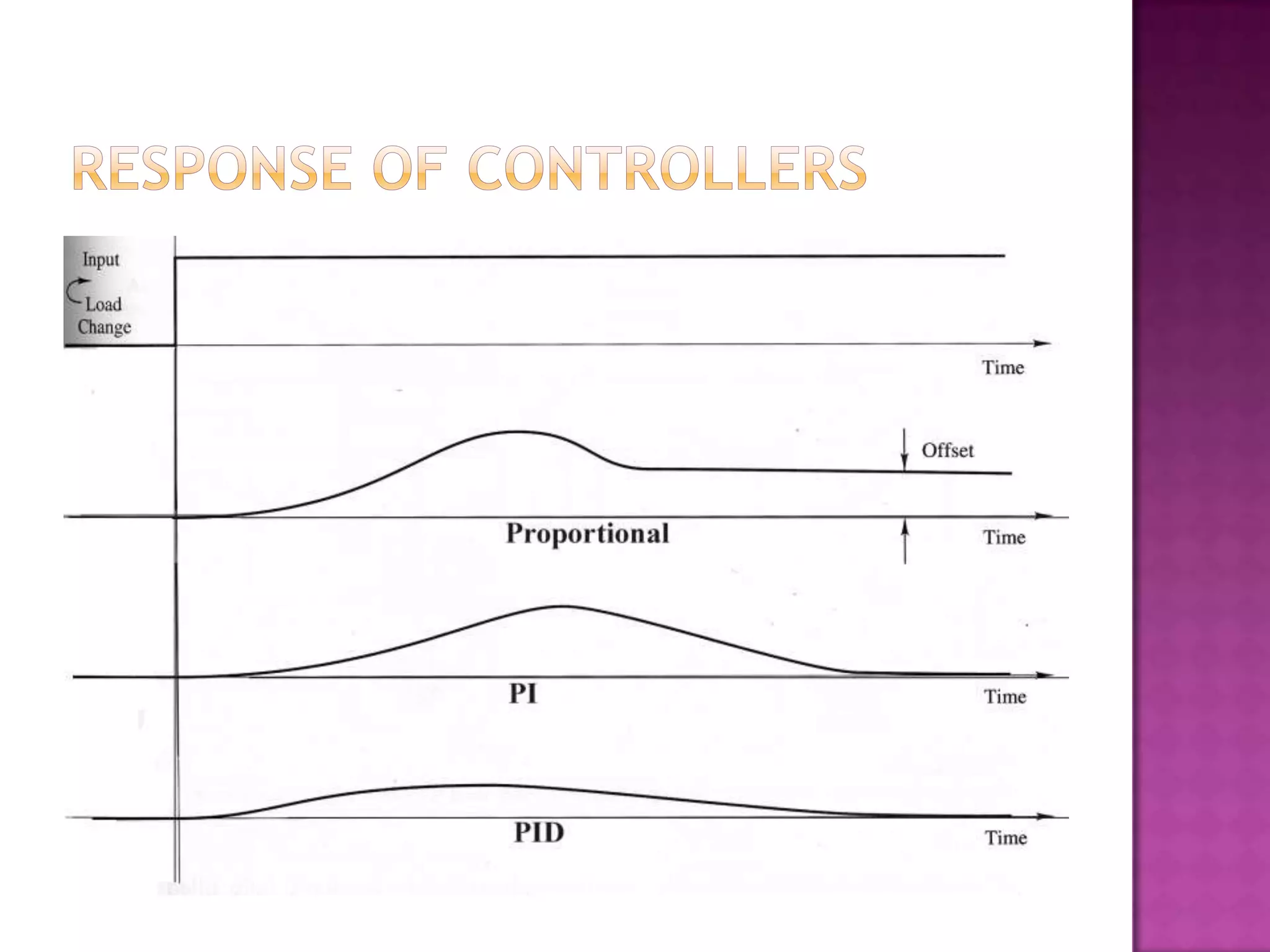

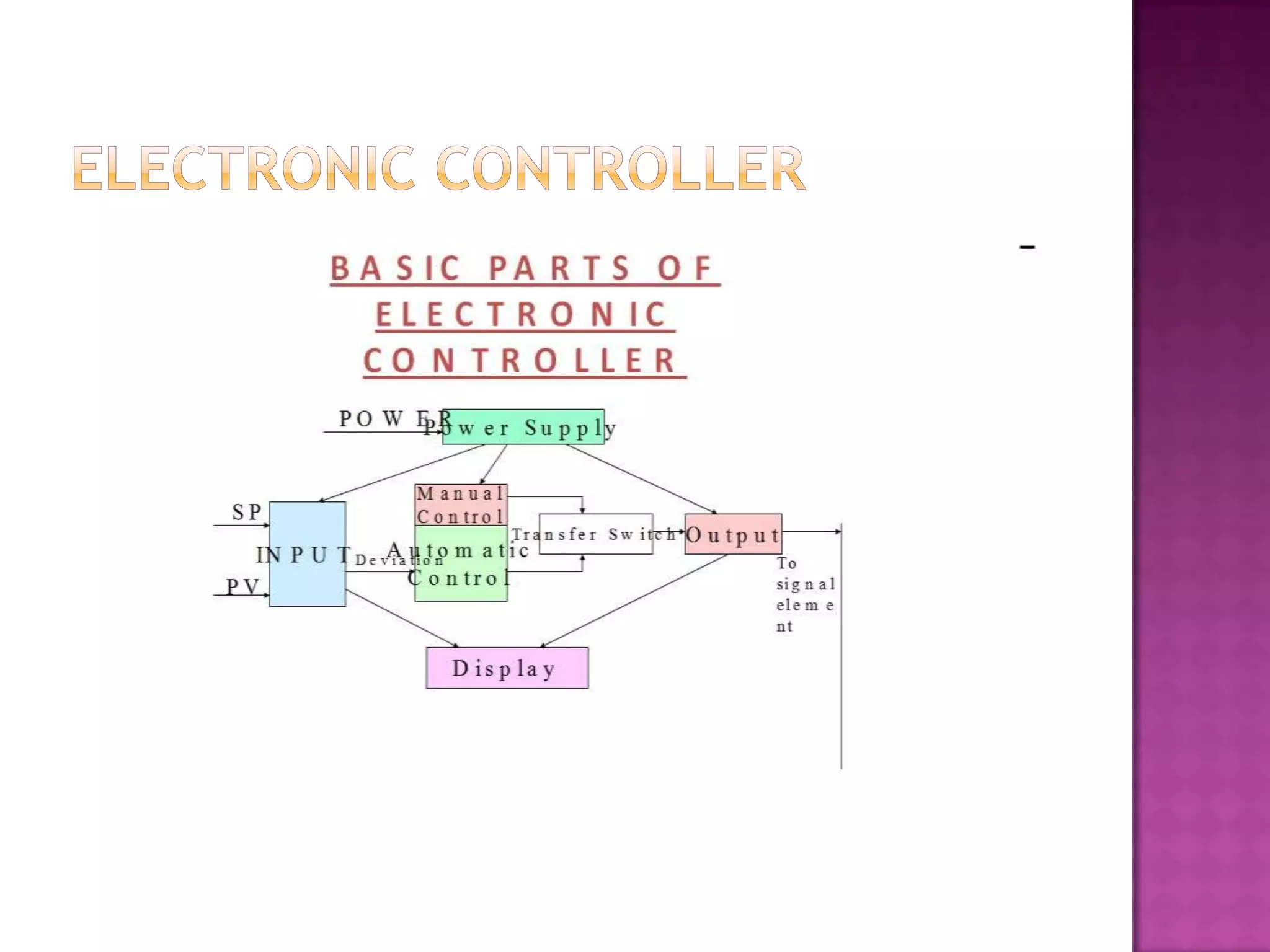

Controllers are devices that maintain process variables at set points by receiving input data, comparing the data to programmed set points, and signaling corrective action if needed. Controllers perform mathematical functions to compare input data to set points and may perform complex calculations or simple addition/subtraction. Controllers receive input, perform calculations, and produce an output signal to regulate the process.