The document discusses the development and implementation of an internal model control (IMC) based PID controller for a nonlinear conical tank system, aiming to maintain desired fluid levels. It details the experimental setup, mathematical modeling, PID tuning methods, and compares the performance of conventional PID controllers with the IMC tuned PID controller. Results indicate that the IMC controller achieves better performance in terms of settling time and rise time.

![Asian Journal of Applied Science and Technology (AJAST)

Volume 1, Issue 2, Pages 224-228, March 2017

© 2017 AJAST All rights reserved. www.ajast.net

Page | 225

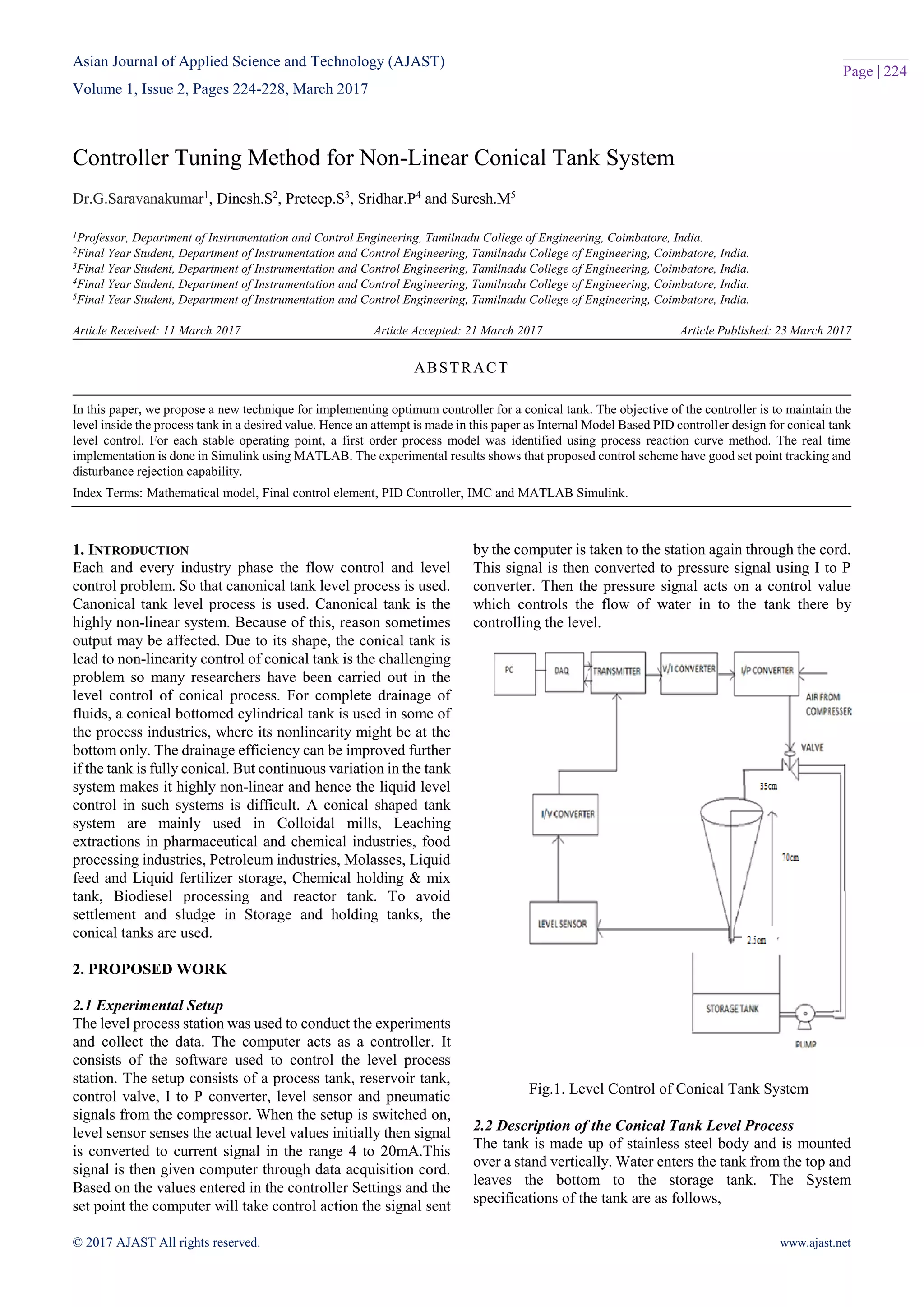

Technical Specification

Equipments Details

Conical tank Stainless steel body,

height– 70 cm, Top

diameter–35 cm

Bottom diameter

2.5cm

Differential Pressure

Level Transmitter

Differential Pressure

Level Transmitter

Pump Centrifugal 800LPH

Control Valve Size ¼ Pneumatic

actuated Type: Air to

open, Input 3-15PSI

Rota meter Range 0-600 LPH

3. MATHEMATICAL MODELLING

Where,

R=Radius of the tank [Constant]

H=Total height [Constant]

r=radius of the liquid level [Constant]

h=level of the water [variable]

Consider the tank with the angle .

= = =

r/h =R/H

r =R*h/H -------->1

Area =πr2

-------->2

Sub 1 in 2 and differentiating,

= [ ]2

2h -------->3

Volume of cone,V= -------->4

Differentiating the above equation

= [A ] -------->5

Sub 3 in 5

= [A+2 ] -------->6

By Newton’s law:

Fin-Fout= [A+2 ] -------->7

Fout =k -------->8

Fin – k

=

Sub Area in above equation,

=

= -

Let, =

= - =

= - -------->9

Taylor Series,

For linerisingFh-2

And in -------->9

F(h1Fin) = F(hs,Fins) – 2Fin hs

-3

(h - hs)+ hs

-2

(F-Fins) ---->10

= h-3/2

[Initially]

h-3/2

= hs

-3/2

- hs

-5/2

(h – hs) -------->11

Sub 11 and 10 in 9

= [F(hs , Fins) – 2Fin hs

-3

(h - hs) + hs

-2

(F - Fins)] – [hs

-3/2

- hs

-5/2

(h - hs) -------------->12

At initial and steady state condition,

= [-2Fins hs

-3

(h - hs) + hs

-2

(F - Fins) + hs

-5/2

(h –

hs)] ------------>13

Let y=(h - hs) and u = F - Fins sub in equ -----13

=-2 Fins

-3

y+ hs

-2

u+ hs

-5/2

y -------->14

------15

-------->16

-------->17

-------->18

Comparing 17 and 18,

C=

Applying laplace transform for equ----->18

The transfer function for the different height of the tank,

Model Height Transfer function

1 10 =

2 15 =

3 20 =

The transfer function of the model is,

The transfer of the sensor is,

The process transfer function is represented as,](https://image.slidesharecdn.com/2ajast47-170329001430/85/Controller-Tuning-Method-for-Non-Linear-Conical-Tank-System-2-320.jpg)

![Asian Journal of Applied Science and Technology (AJAST)

Volume 1, Issue 2, Pages 224-228, March 2017

© 2017 AJAST All rights reserved. www.ajast.net

Page | 228

Hardware implementation kit

Comparison Table

6. CONCLUSION

The nonlinearity of the conical tank is analyzed. Conventional

PID, Cohen and coon tuned PID controller and IMC Tuned

PID controller is implemented in simulation .Cohen and coon

tuned PID Controller and IMC tuned PID Controller results

are compared. IMC Tuned PID controller gives the better

performance. As far as the tuning of the controller is

concerned we have and optimum filter tuning factor λ

(lambda) value which compromises the effects of

discrepancies entering into the system to achieve the best

performance. Thus, what we mean by the best filter structure

is the filter that gives the best PID performance for the

optimum λ value. The PID and IMC controllers are designed

in such a way that the system is physically reliable. But due to

the presence of dead time, the performance of the system is

affected. The simulation results shows the IMC based PID

controller have minimum settling time and rise time in order

to reach steady state value when compare to conventional

controller. To avoid the minimum rise time advanced control

schemes such as Model Reference Adaptive Controller will

be implement in future.

REFERENCES

[1] Rajesh.T, Arun jayakar.S, Siddharth.S.G, “Design and

Implementation of IMC Based PID Controller for Conical

Tank Level Control Process”, in International Journal of

Innovative Research in Electrical, Electronics,

Instrumentation and Control Engineering in Sep 2014.

[2] Sukanya R. Warier, Sivanandam Venkatesh “Design of

controller based on MPC for a conical tank system”, IEEE

International Conference on Advances in Engineering,

Science and Management (ICAESM - 2012), March 30-31,

2012.

[3] Korkmaz, M. Aydogdu, O. Dogan, H. “Design and

performance comparison of variable parameter nonlinear PID

controller and genetic algorithm based PID controller

Innovations”, Intelligent Systems and Applications (INISTA),

2012 International Symposium.

[4] S.Nithya, N.Sivakumaran, T.K.Radhakrishnan and

N.Anantharaman, “Soft Computing Based Controllers

Implementation for Non-linear Process in Real Time”

Proceedings of the World Congress on Engineering and

Computer Science (WCECS), 2010, Vol – 2.

[5] Anand, S., Aswin, V., Kumar, S.R., “Simple tuned

adaptive PI controller for conical tank process”, Recent

Advancements in Electrical, Electronics and Control

Engineering 2011 International Conference.

Set point

(cm)

Controller overshoot Settling time

(sec)

15 PID 18% 60

IMC – PID 2.5% 25

20 PID 16% 38

IMC -PID 1.8% 21](https://image.slidesharecdn.com/2ajast47-170329001430/85/Controller-Tuning-Method-for-Non-Linear-Conical-Tank-System-5-320.jpg)