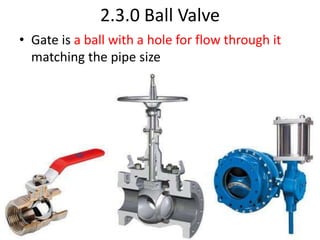

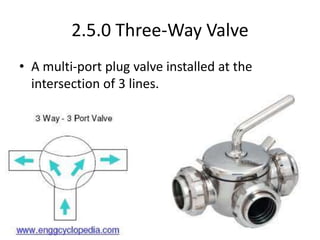

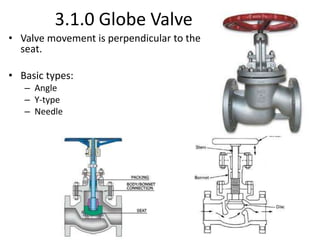

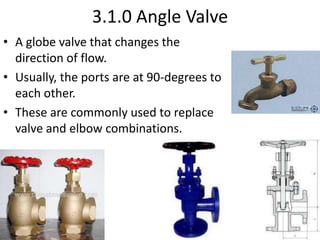

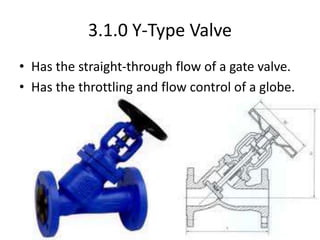

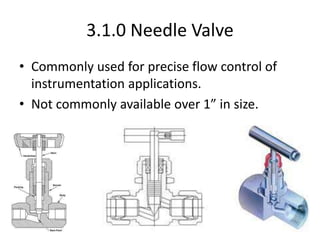

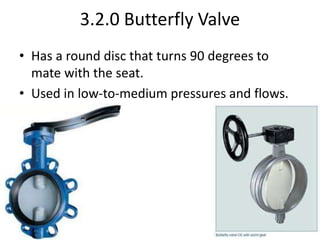

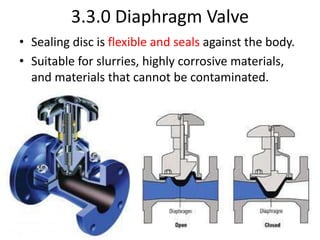

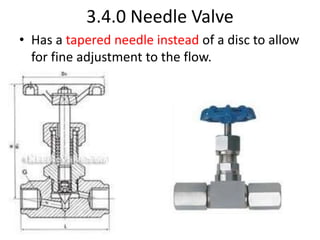

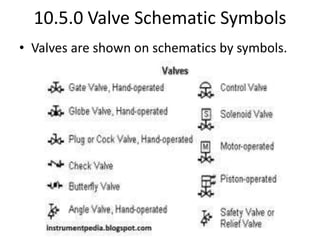

Valves control the flow of fluids through piping systems and come in many types for different applications. Valves are either on-off valves that completely stop or start flow, or control valves that can partially restrict flow to regulate it. Common on-off valves include gate, ball, plug, and knife valves. Control valves include globe, butterfly, and diaphragm valves. Valve selection depends on factors like pressure, temperature, fluid chemistry and the valve's intended function in the system. Proper installation, handling, and maintenance of valves is important for safety and performance.