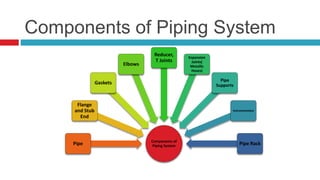

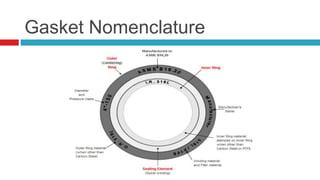

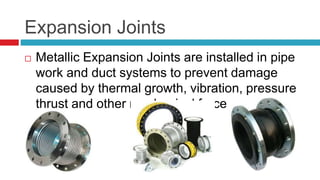

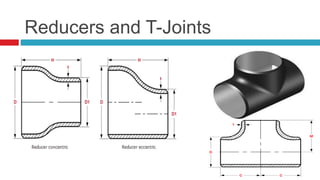

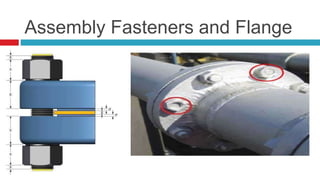

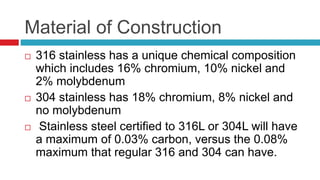

Piping systems are used to convey fluids such as liquids and gases from one location to another. The main components of a piping system include pipes, flanges, gaskets, elbows, reducers, expansion joints, supports, and instrumentation. Pipes are hollow tubes that fluids are conveyed through. Flanges connect pipes and allow for inspection or modification. Gaskets create seals between flanges. Piping materials include carbon steel, stainless steel, and alloys selected based on factors like temperature and pressure. Proper design of piping systems is important for safety and operational requirements.