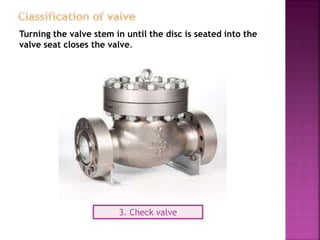

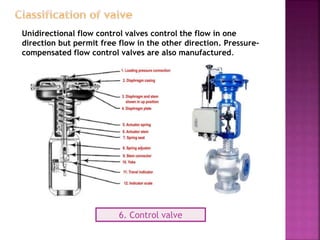

This document discusses different types of valves. It begins by defining a valve as a device that regulates, directs, or controls fluid flow. Valves are then classified based on their mechanical motion as either linear motion valves or rotary motion valves. Some common valve types are described, including globe valves, gate valves, ball valves, butterfly valves, and check valves. Globe valves are identified as good for regulating flow while gate valves are better for stopping and starting flow but not regulating. Ball valves use a ball to stop or start flow and butterfly valves are rotary valves used to control flow. Check valves are designed to prevent backflow.