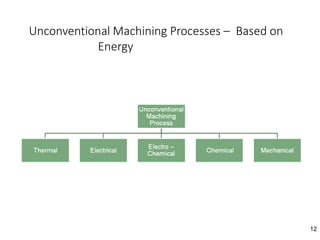

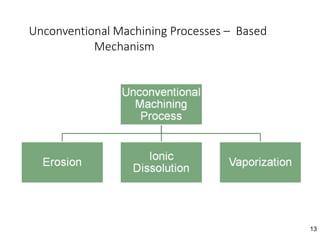

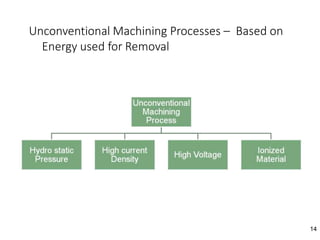

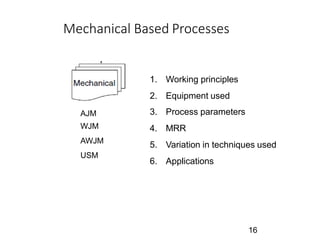

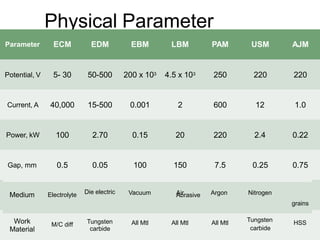

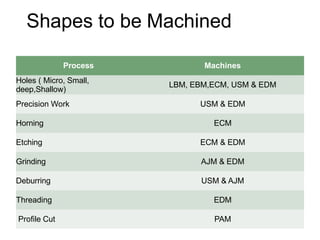

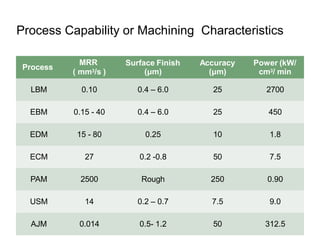

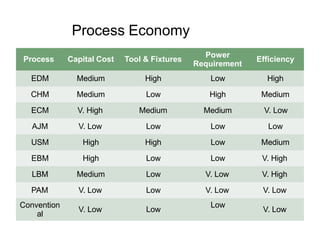

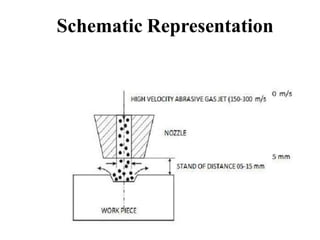

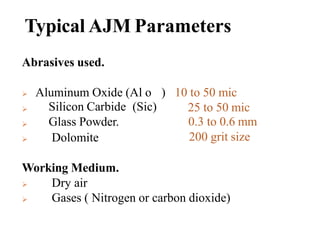

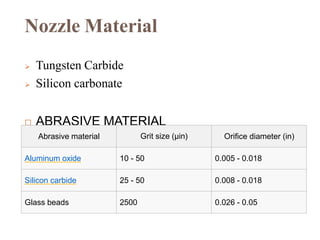

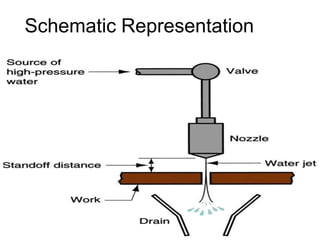

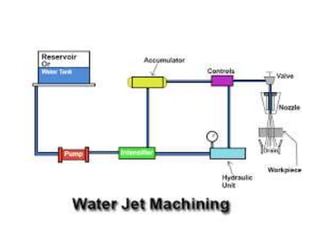

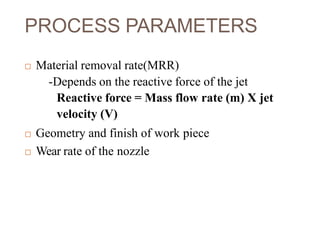

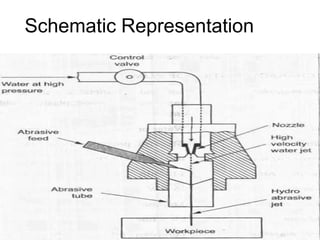

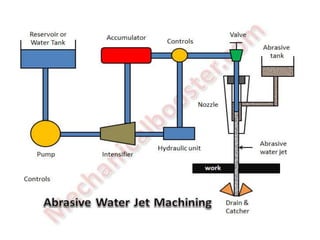

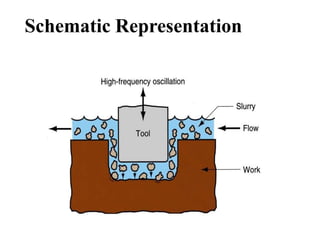

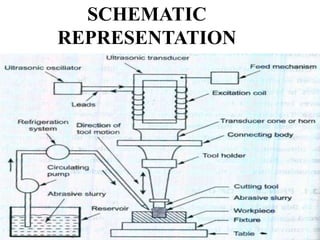

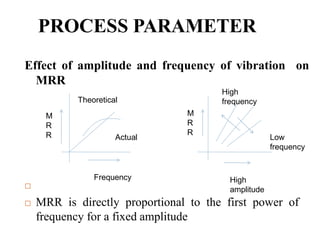

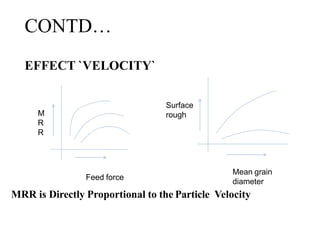

The document discusses various unconventional machining processes including abrasive jet machining (AJM), water jet machining (WJM), abrasive water jet machining (AWJM), and ultrasonic machining (USM). It provides an overview of the working principles, equipment used, process parameters, material removal rate, and applications of each process. Specifically, it explains that AJM uses a high-speed stream of abrasive particles to remove material, WJM uses a high-velocity water jet, AWJM adds abrasive particles to the water jet, and USM removes material using abrasive particles oscillated at ultrasonic frequencies. The document also discusses factors for selecting among these unconventional machining processes.