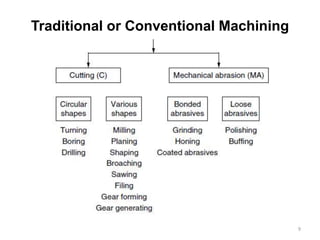

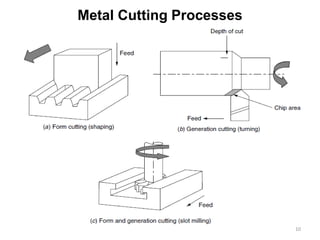

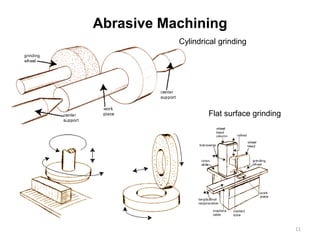

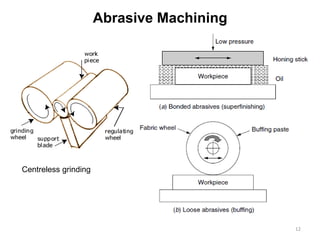

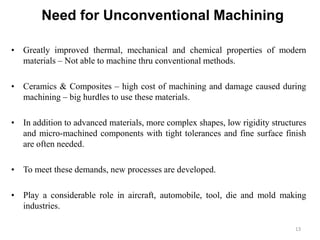

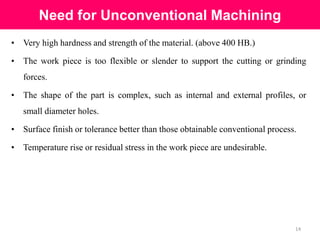

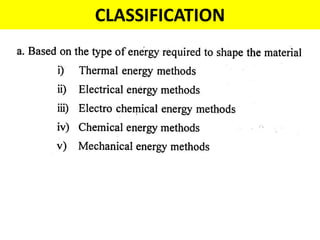

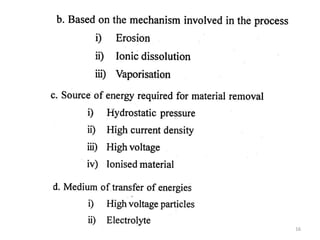

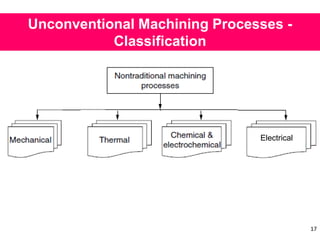

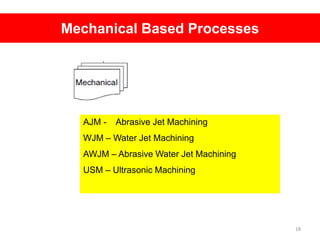

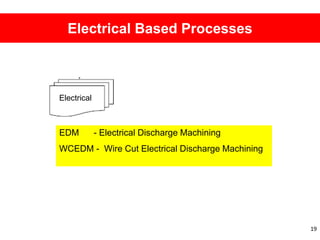

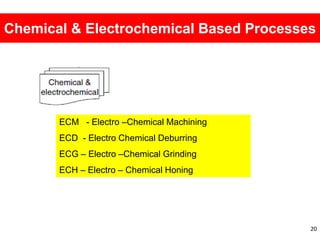

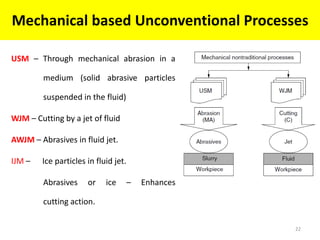

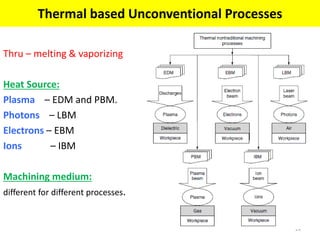

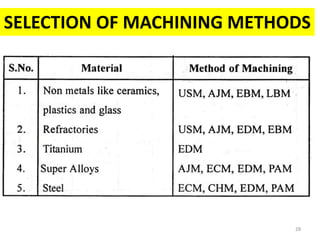

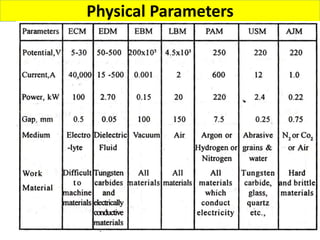

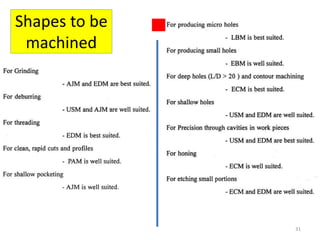

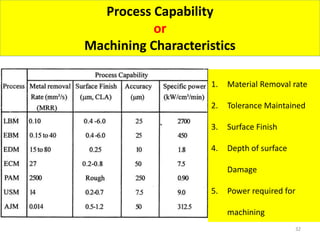

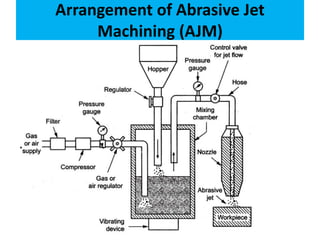

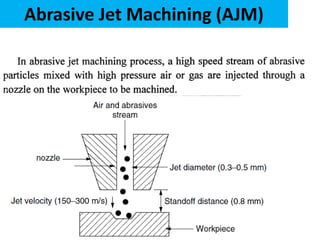

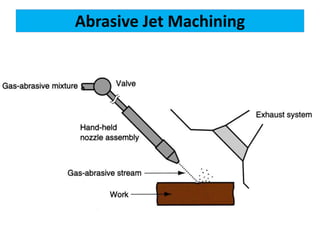

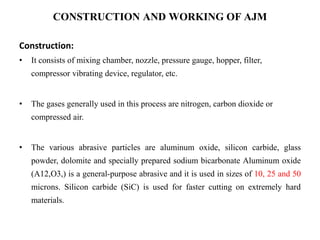

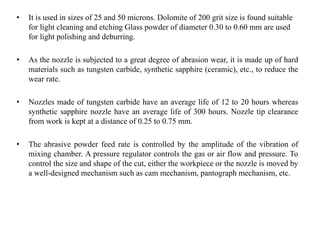

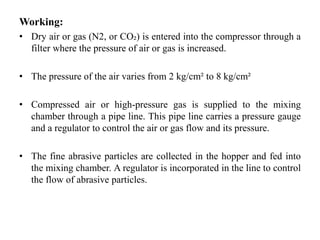

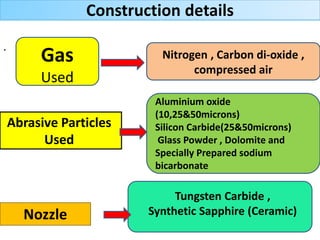

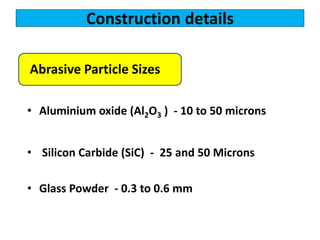

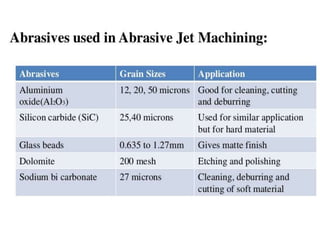

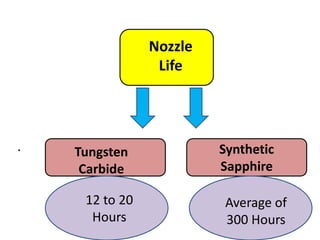

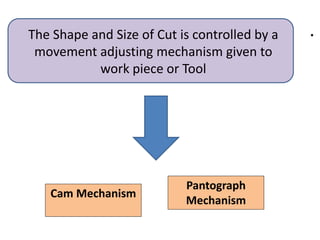

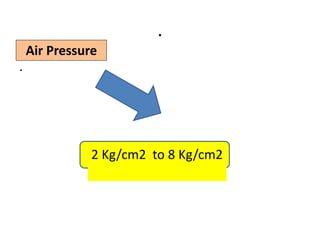

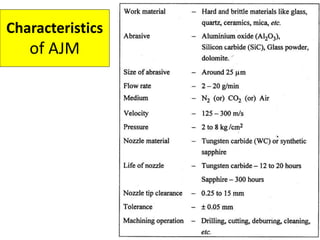

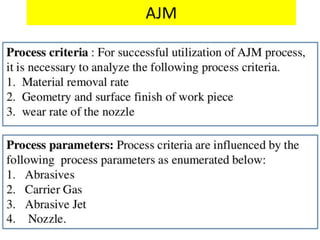

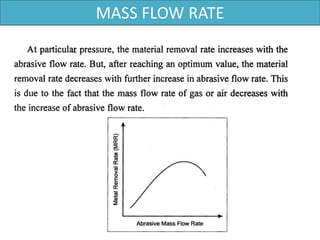

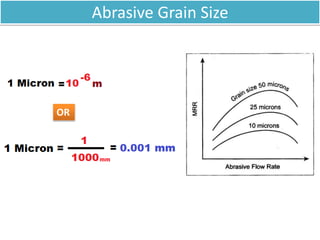

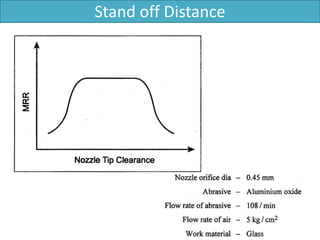

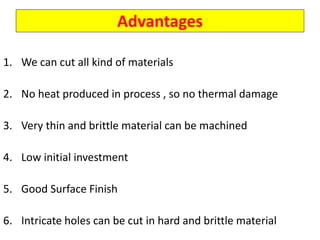

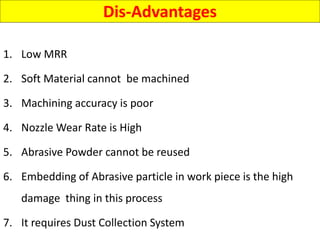

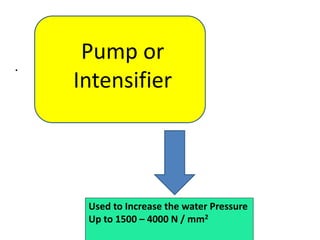

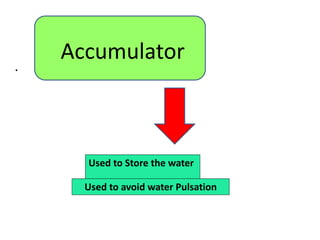

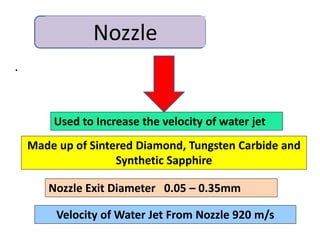

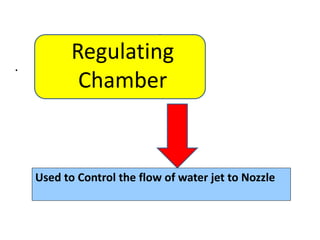

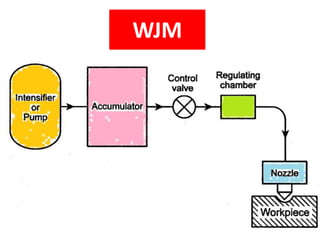

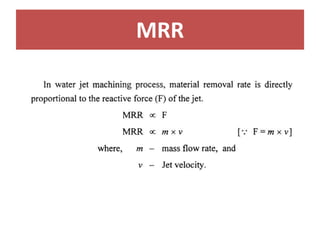

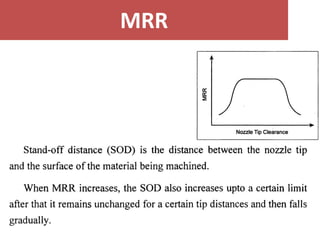

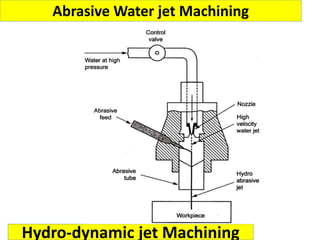

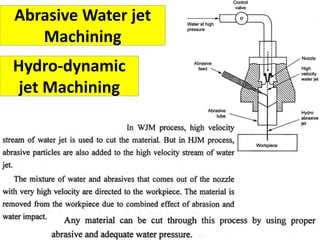

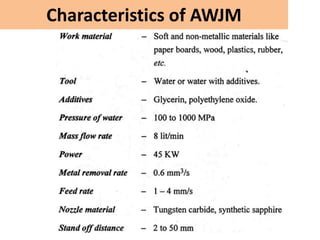

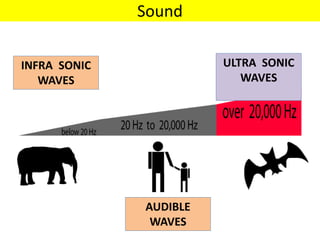

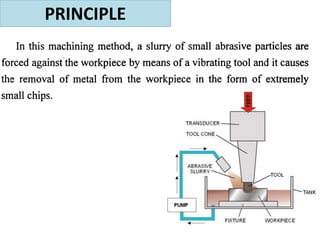

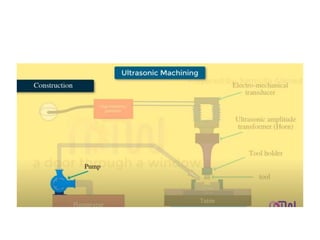

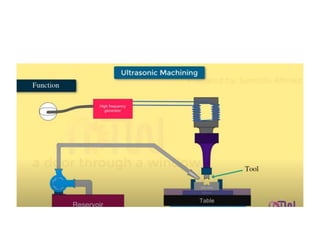

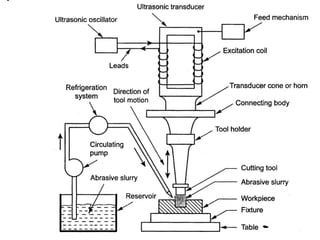

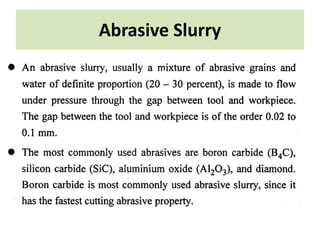

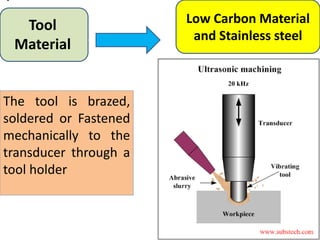

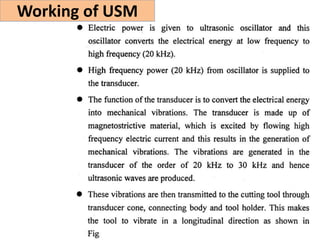

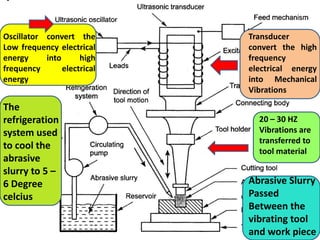

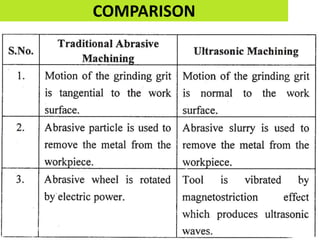

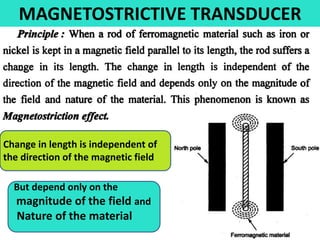

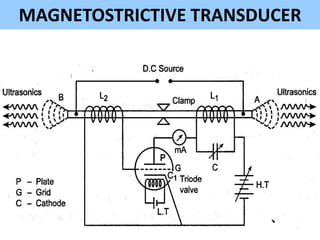

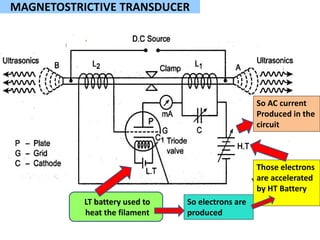

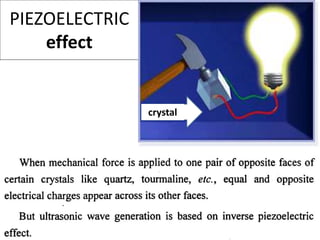

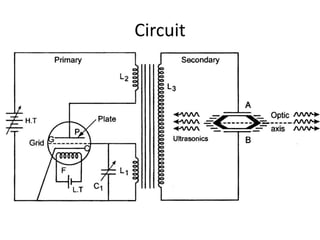

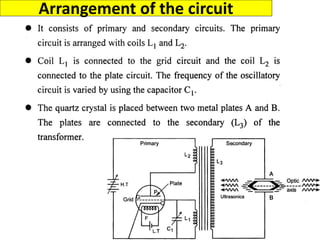

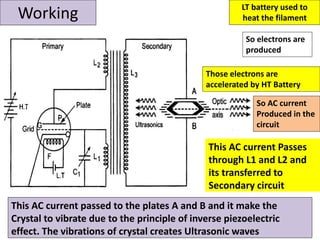

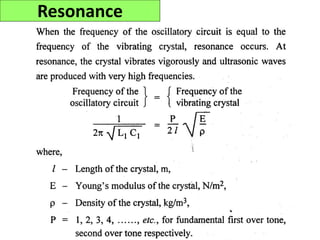

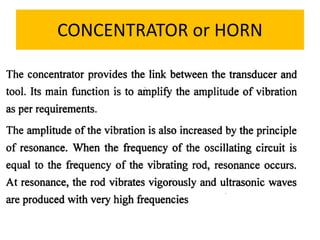

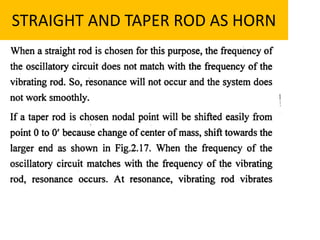

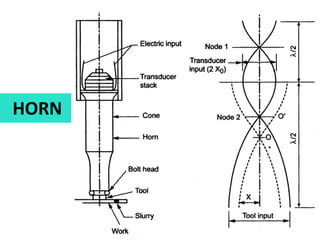

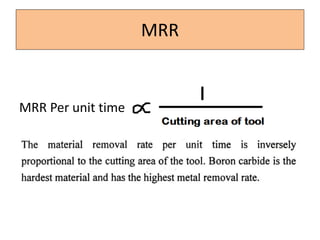

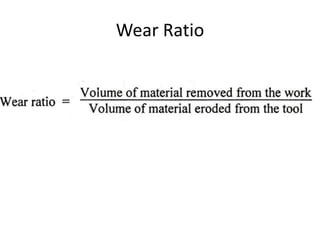

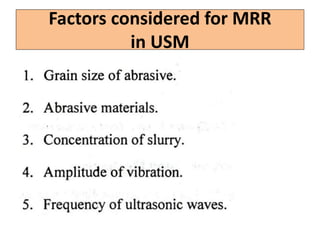

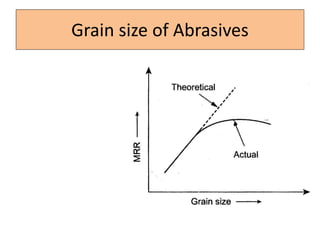

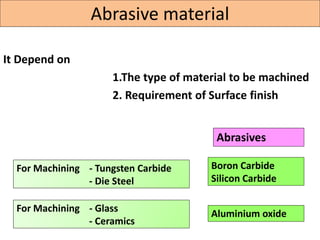

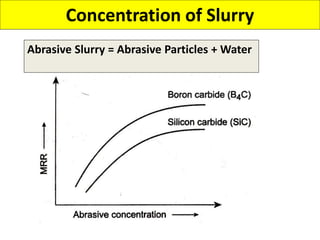

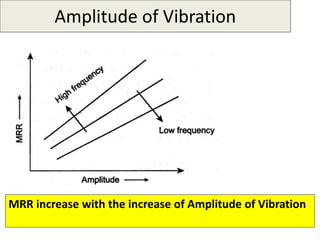

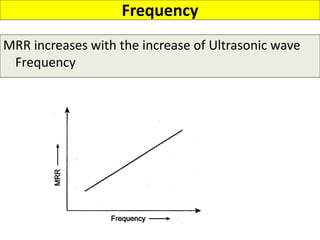

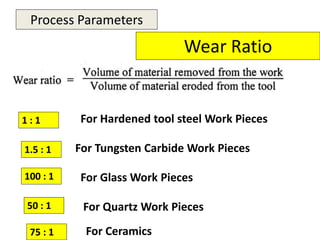

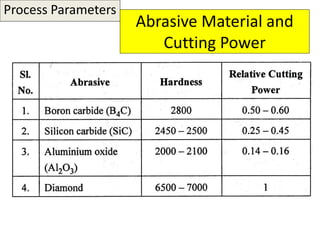

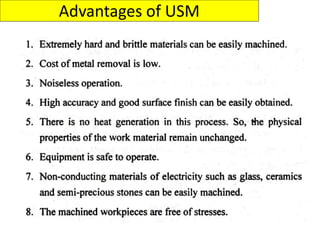

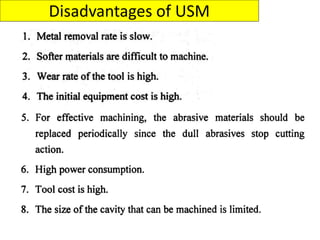

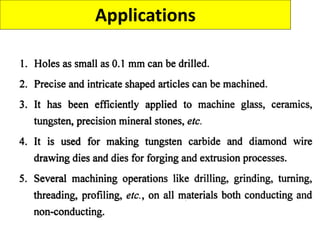

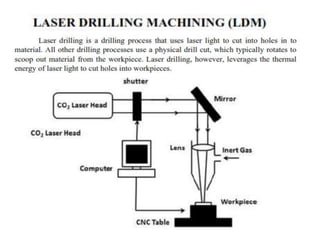

The document outlines unconventional machining processes, their classifications, advantages, and limitations, highlighting methods like abrasive jet machining (AJM), water jet machining (WJM), and ultrasonic machining (USM). It discusses the need for these techniques due to the limitations of conventional machining in handling advanced materials and complex geometries. Additionally, it details the working principles, equipment used, process parameters, and various applications in industries such as aerospace and automotive.