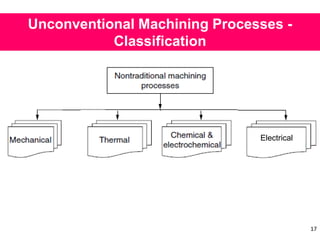

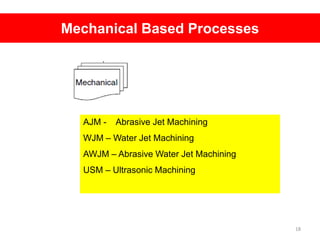

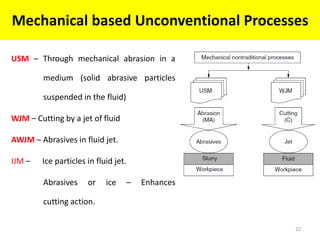

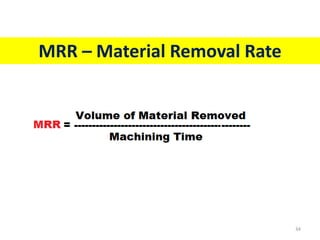

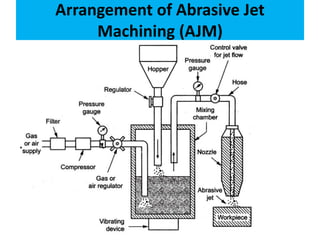

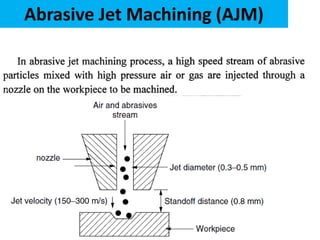

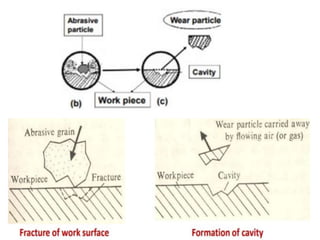

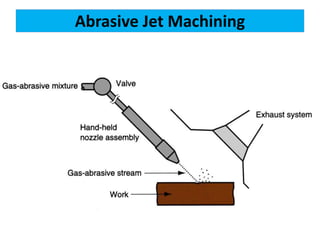

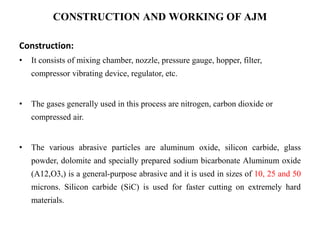

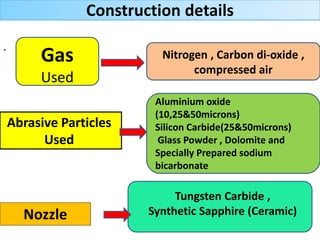

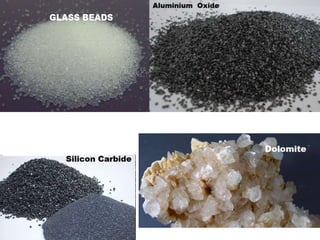

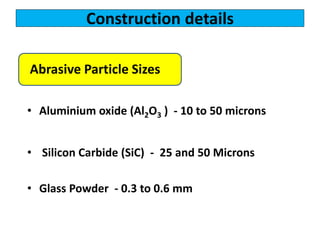

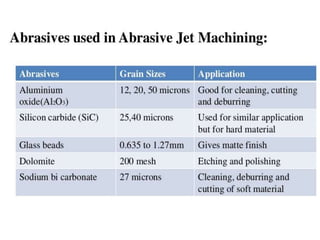

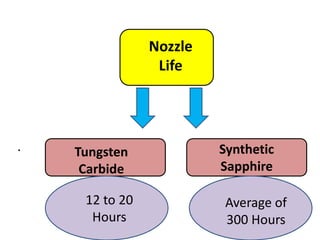

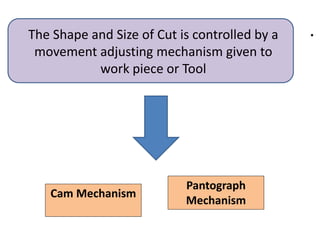

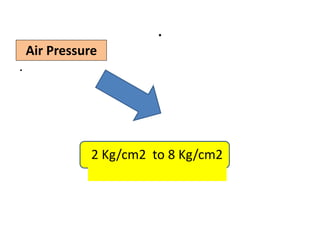

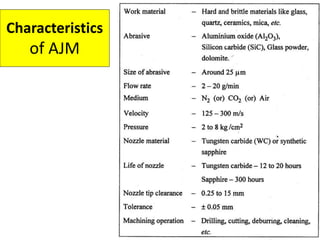

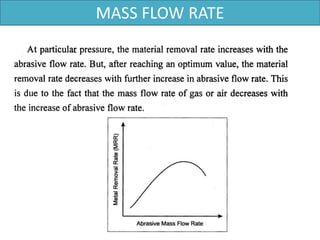

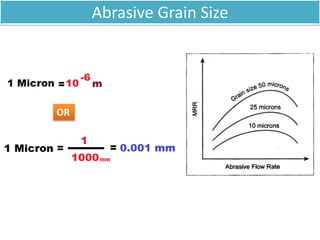

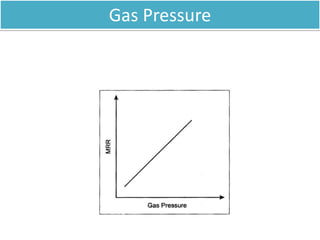

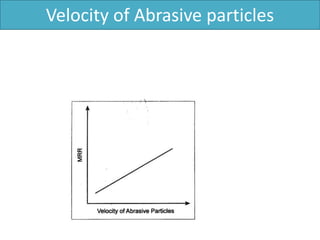

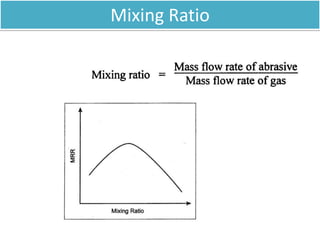

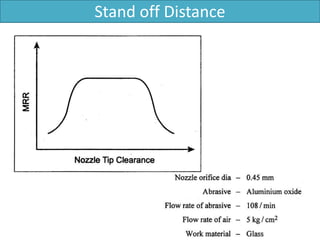

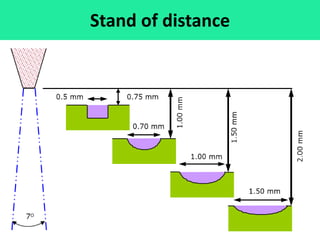

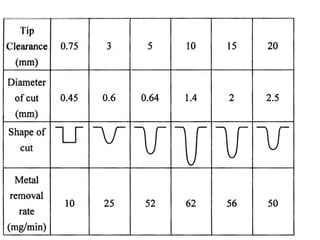

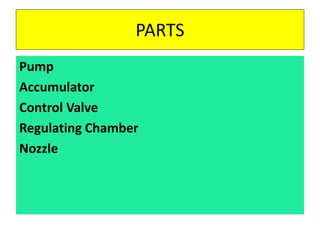

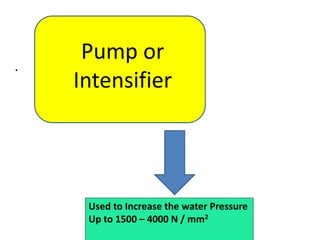

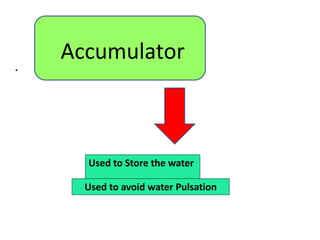

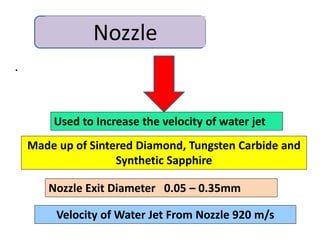

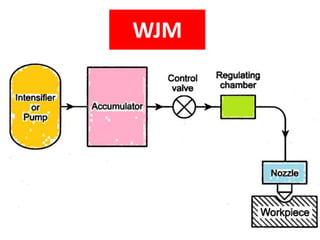

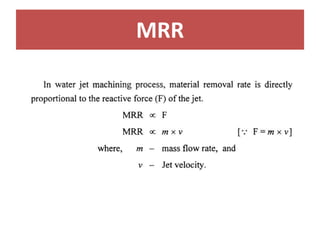

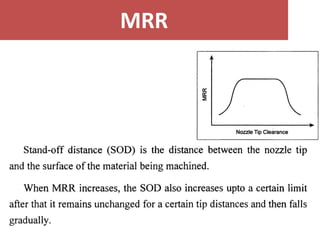

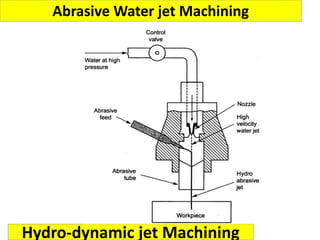

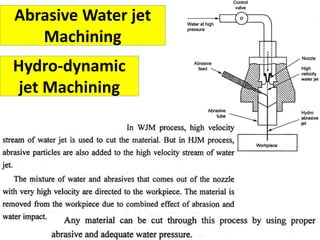

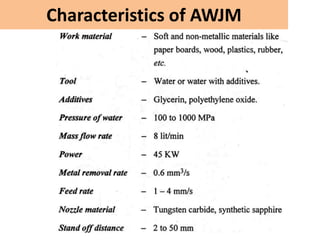

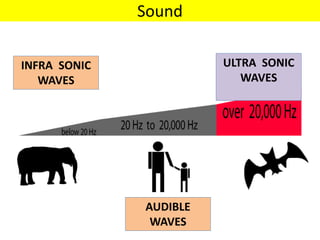

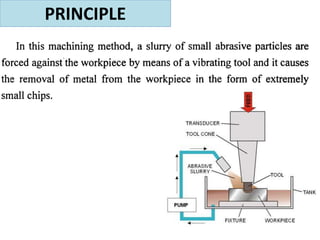

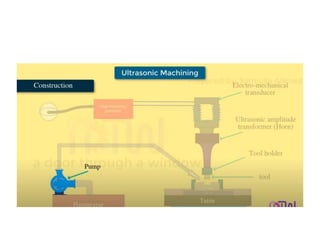

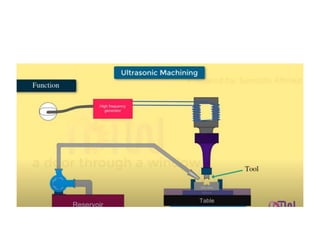

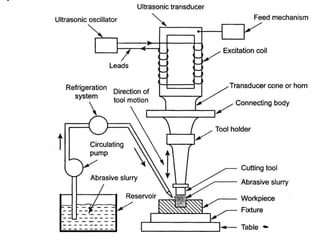

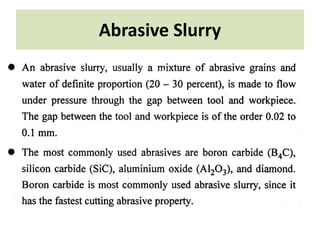

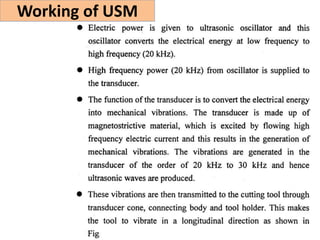

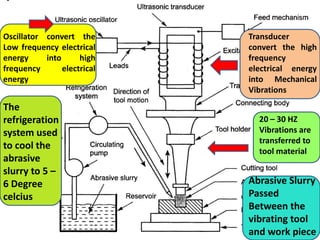

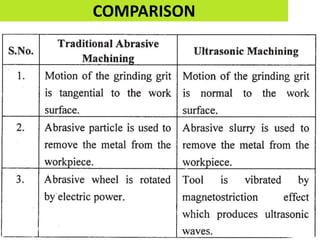

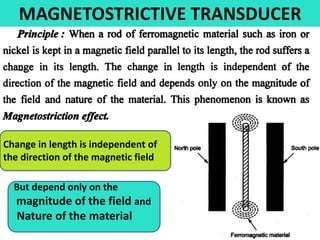

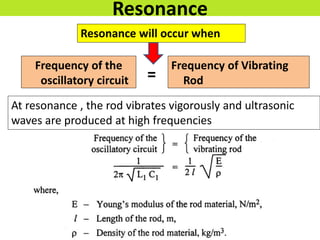

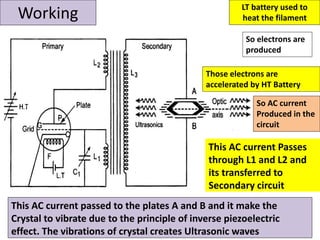

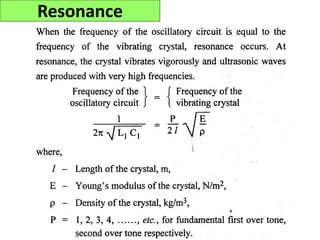

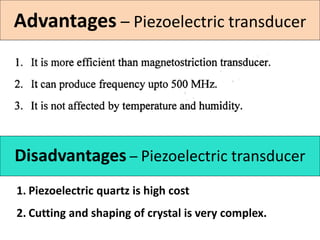

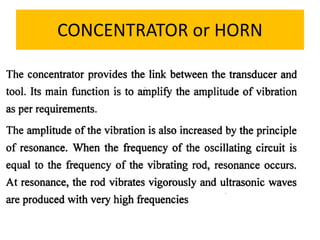

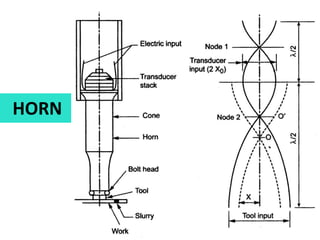

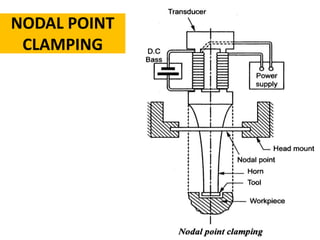

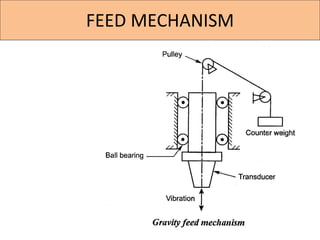

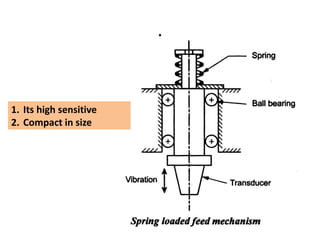

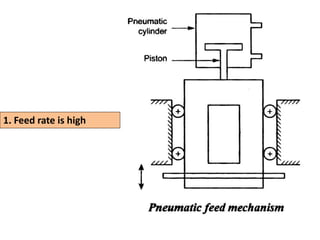

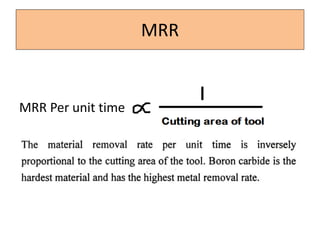

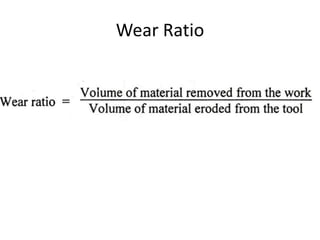

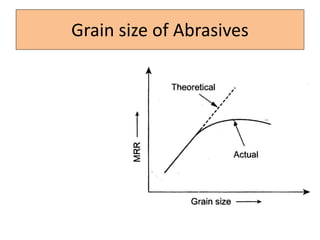

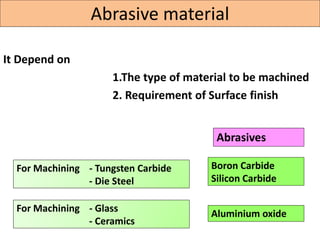

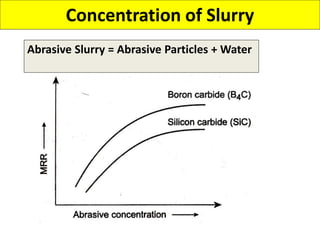

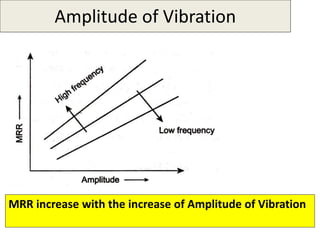

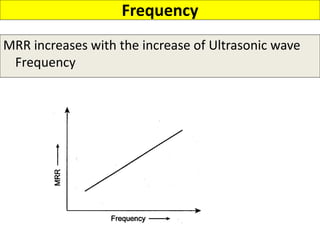

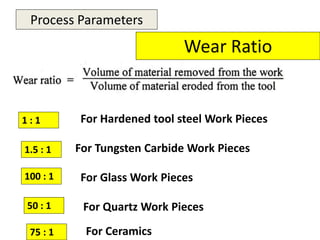

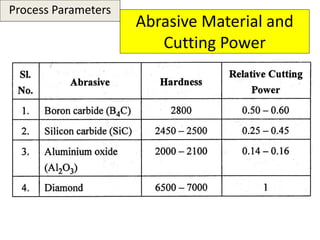

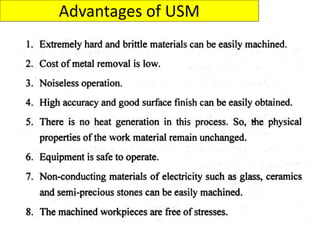

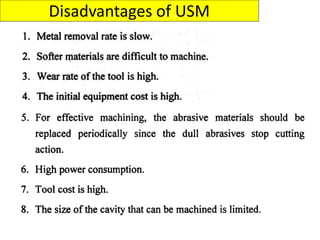

This document provides information on unconventional machining processes including mechanical energy based processes. It discusses abrasive jet machining where compressed air carries abrasive particles to impact and machine hard materials. Water jet machining uses high pressure water to cut. Abrasive water jet machining adds abrasives to the water jet. Ultrasonic machining uses high frequency vibrations and an abrasive slurry to machine hard brittle materials. Key parameters that affect the material removal rate in these processes are discussed such as abrasive grain size, gas/water pressure, and velocity. Advantages include ability to machine hard materials without heat, while disadvantages include low material removal rates and accuracy issues.