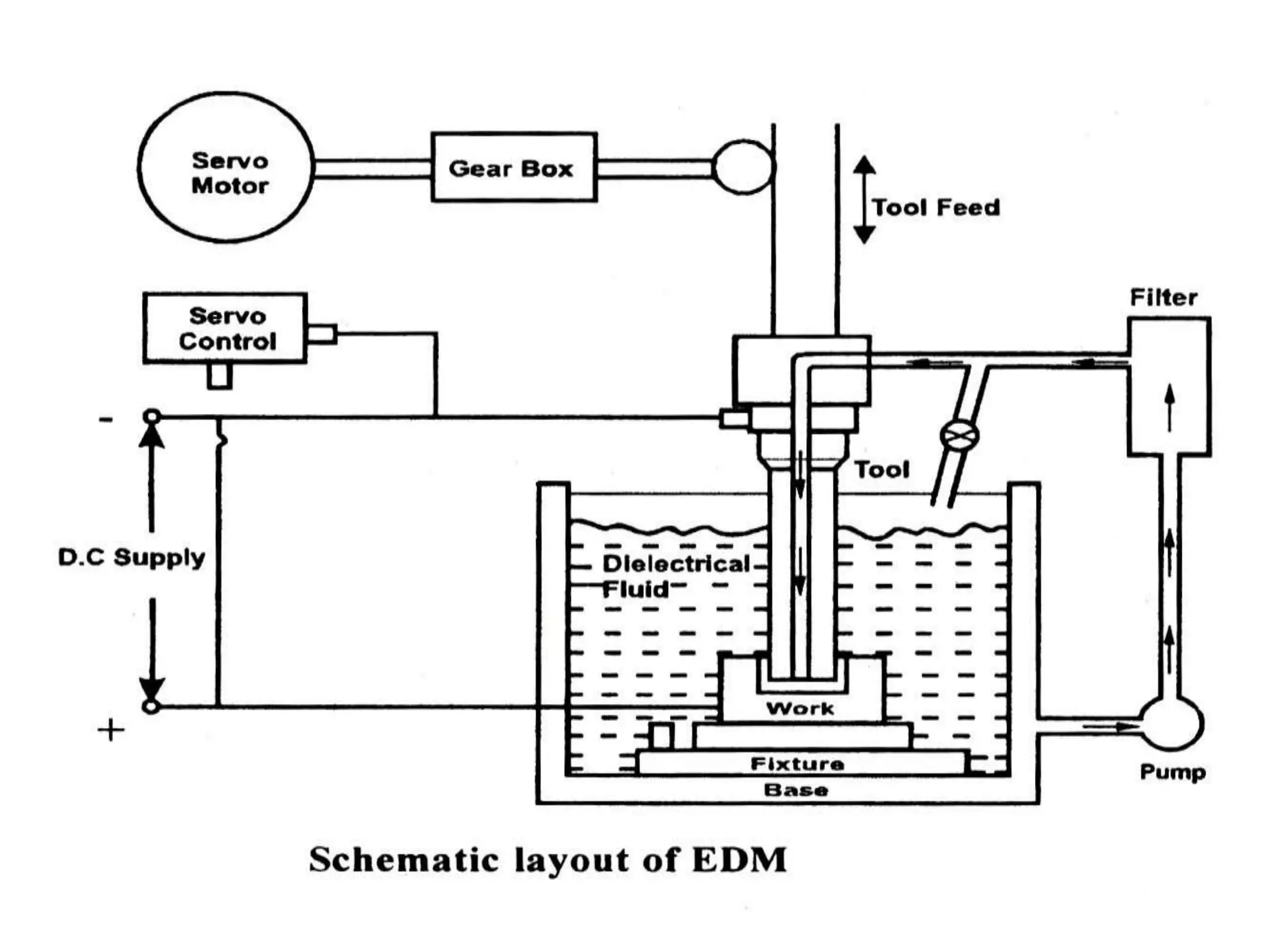

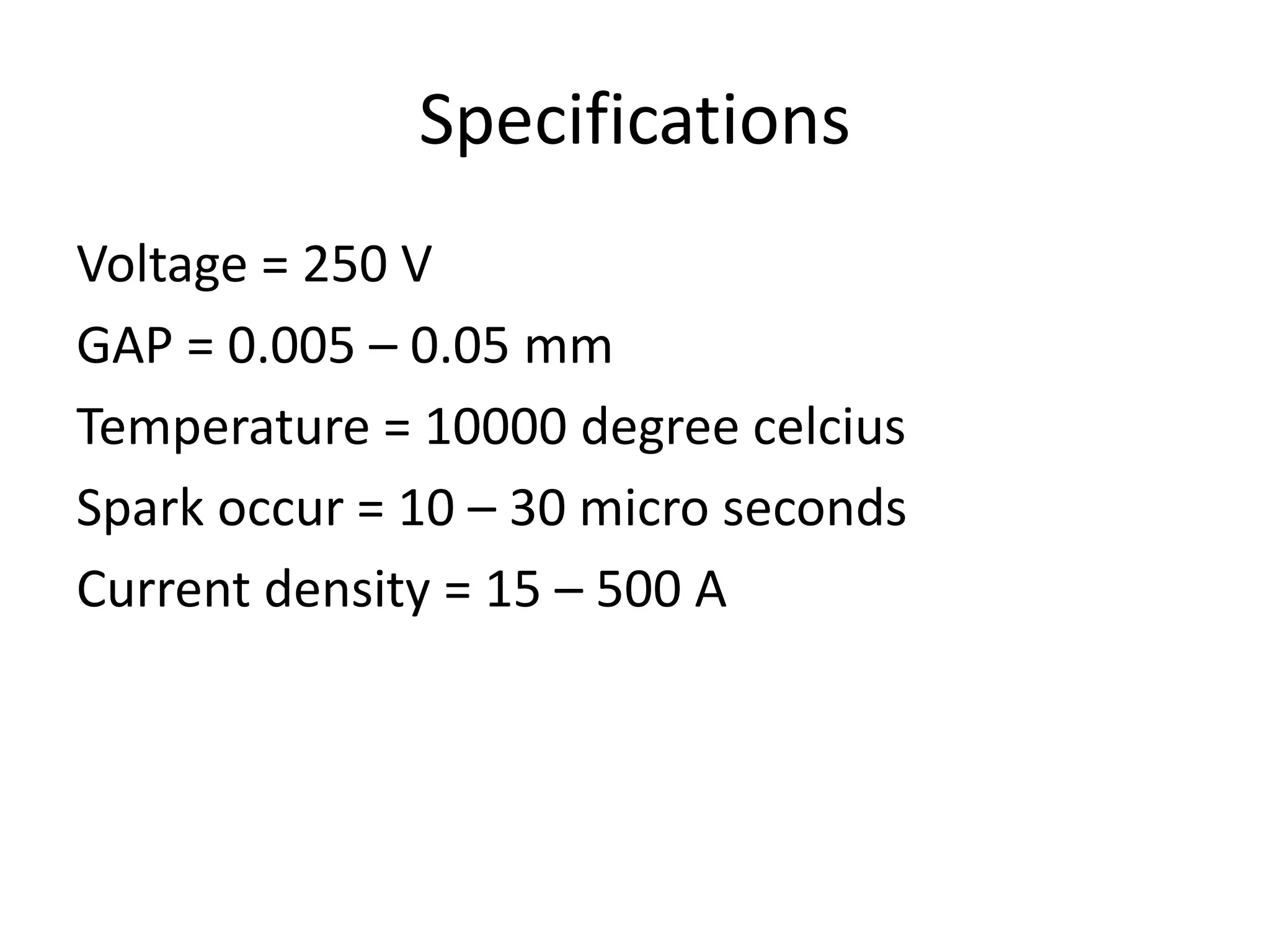

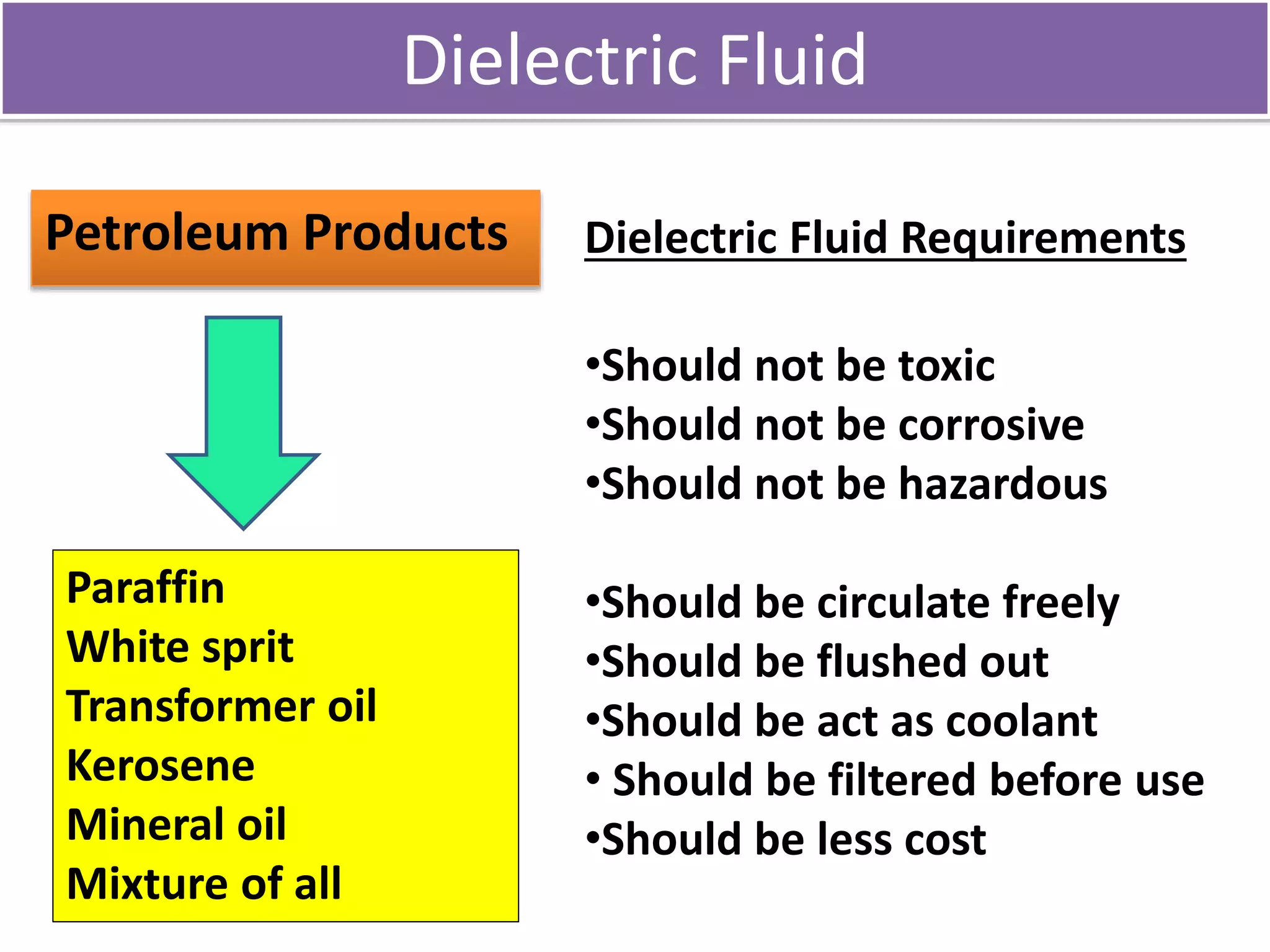

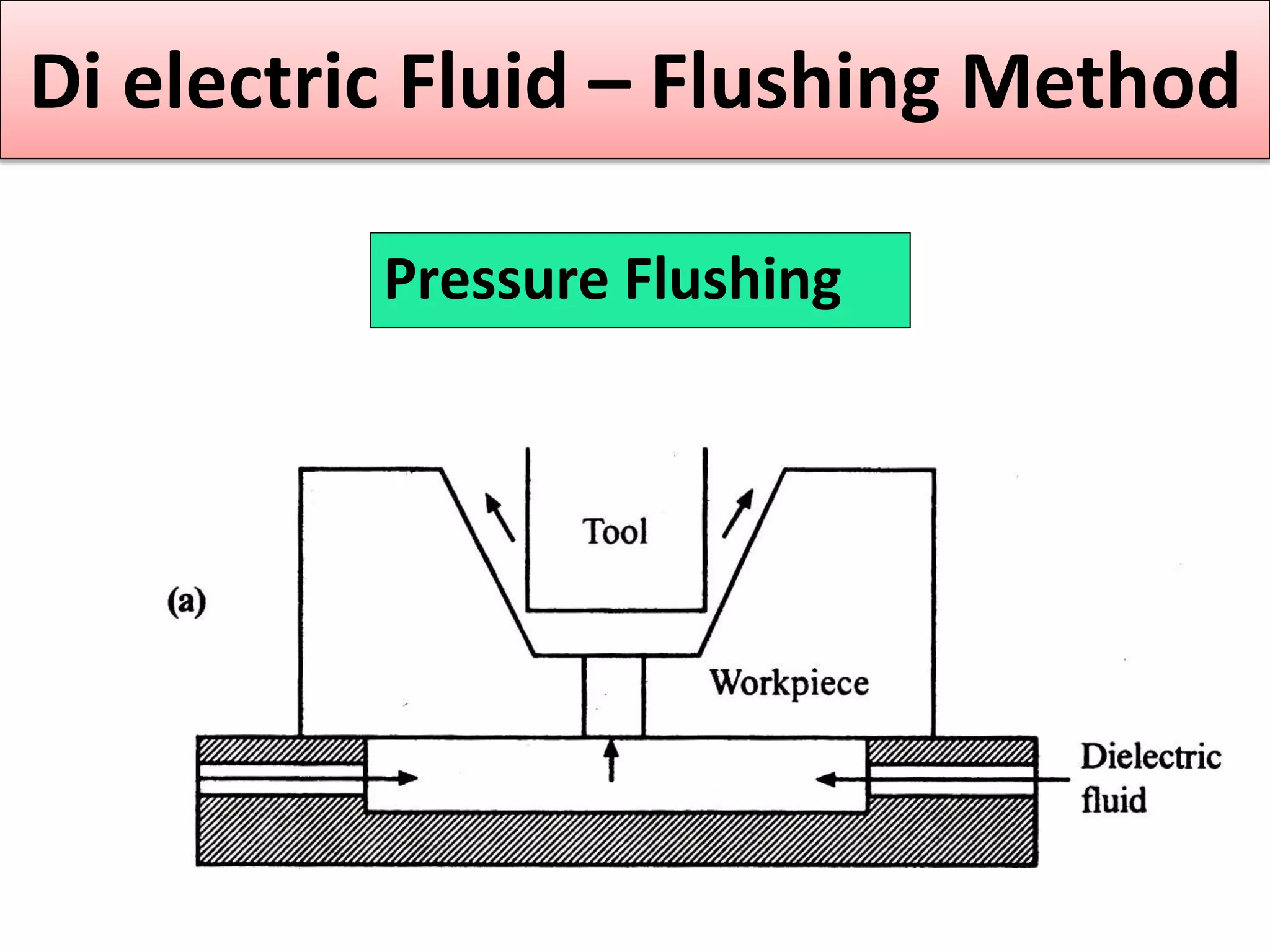

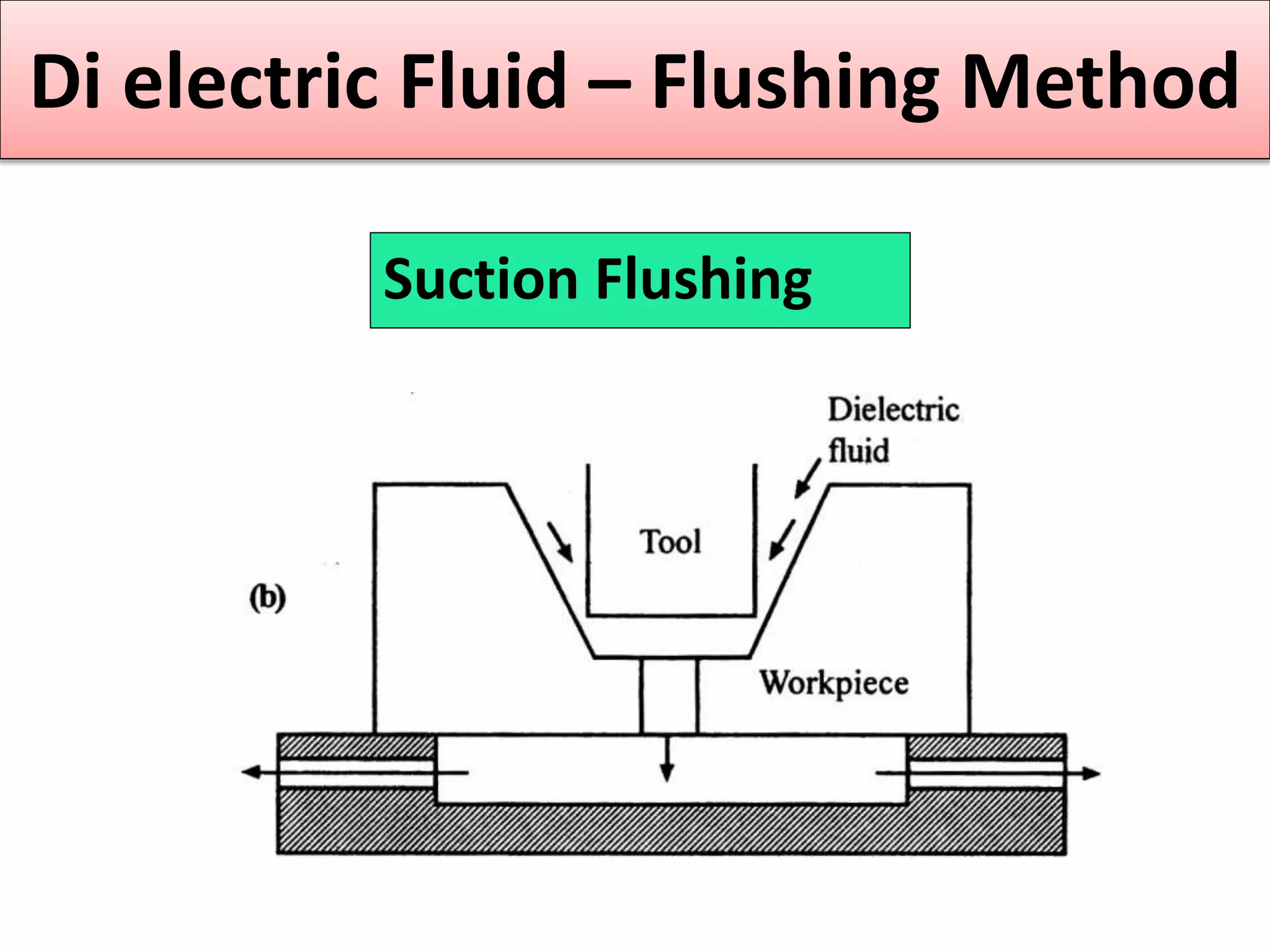

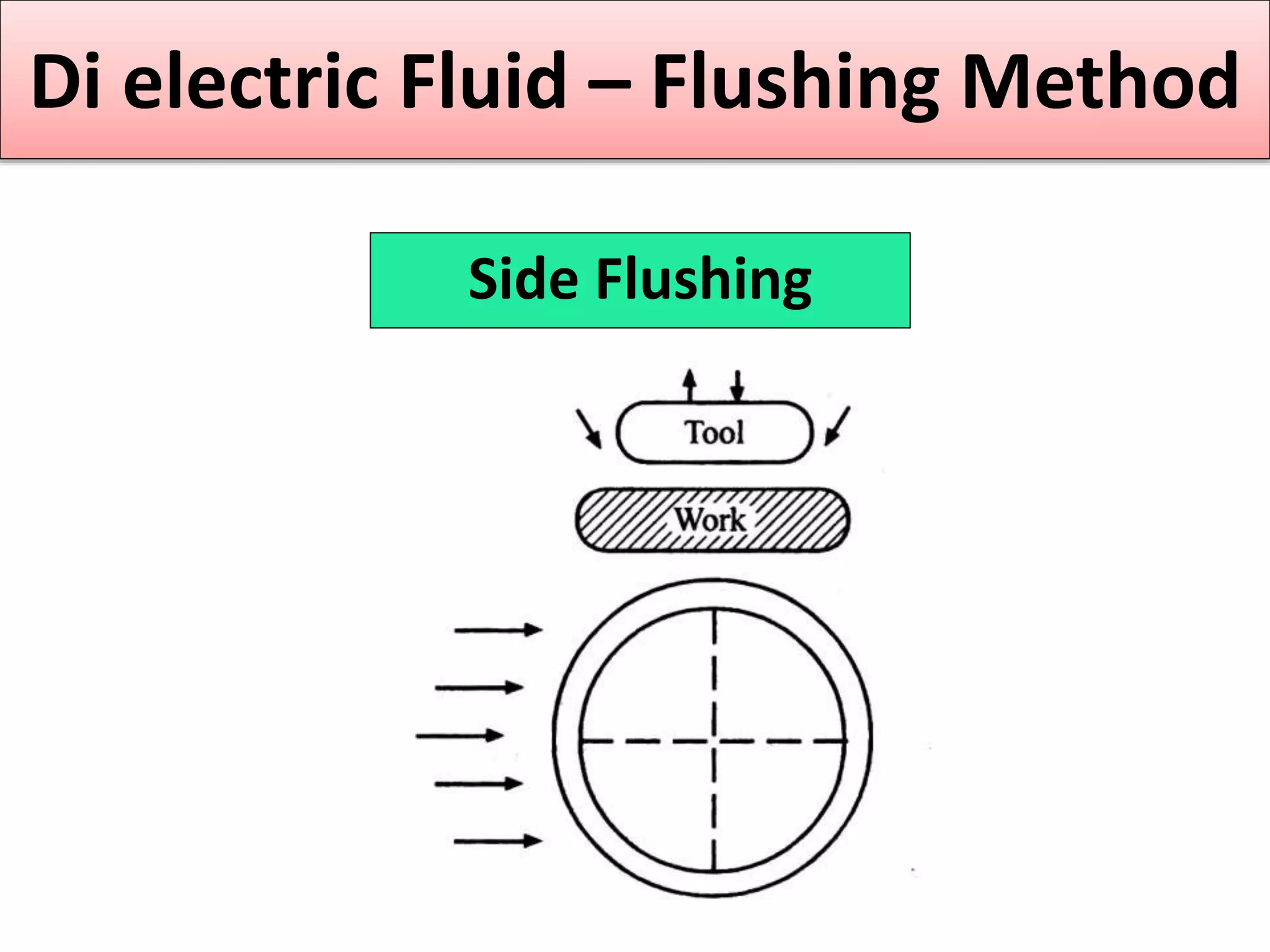

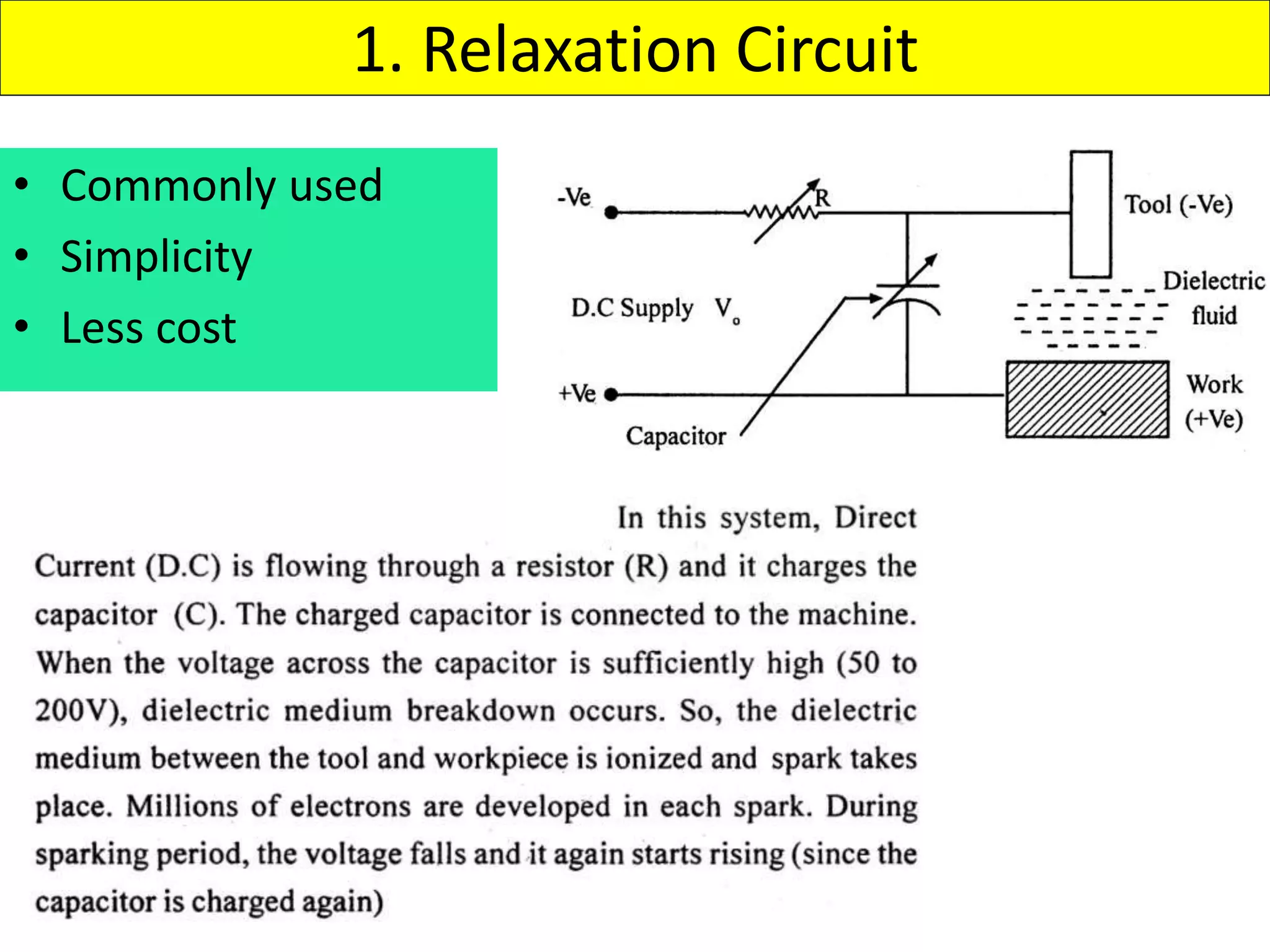

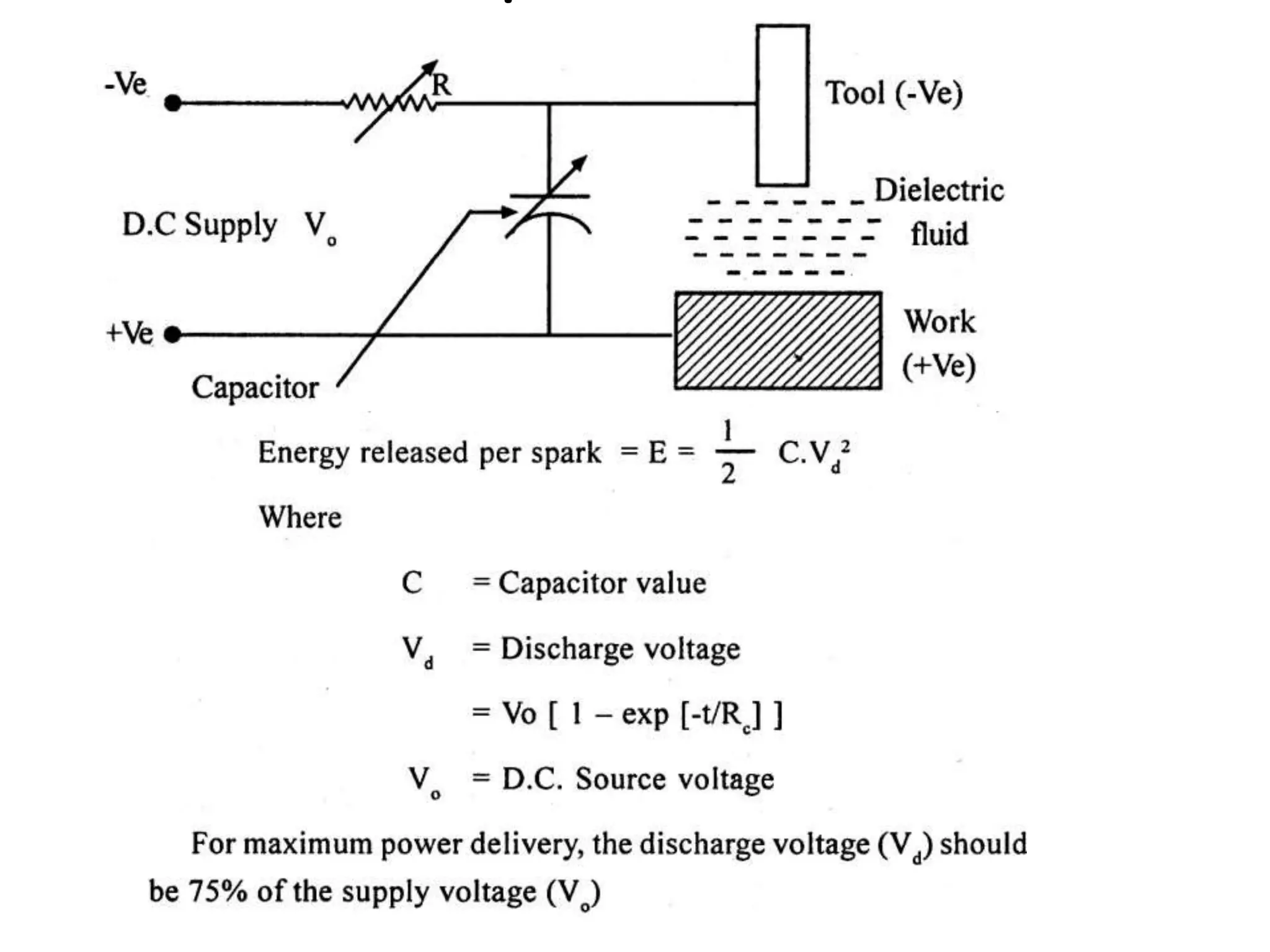

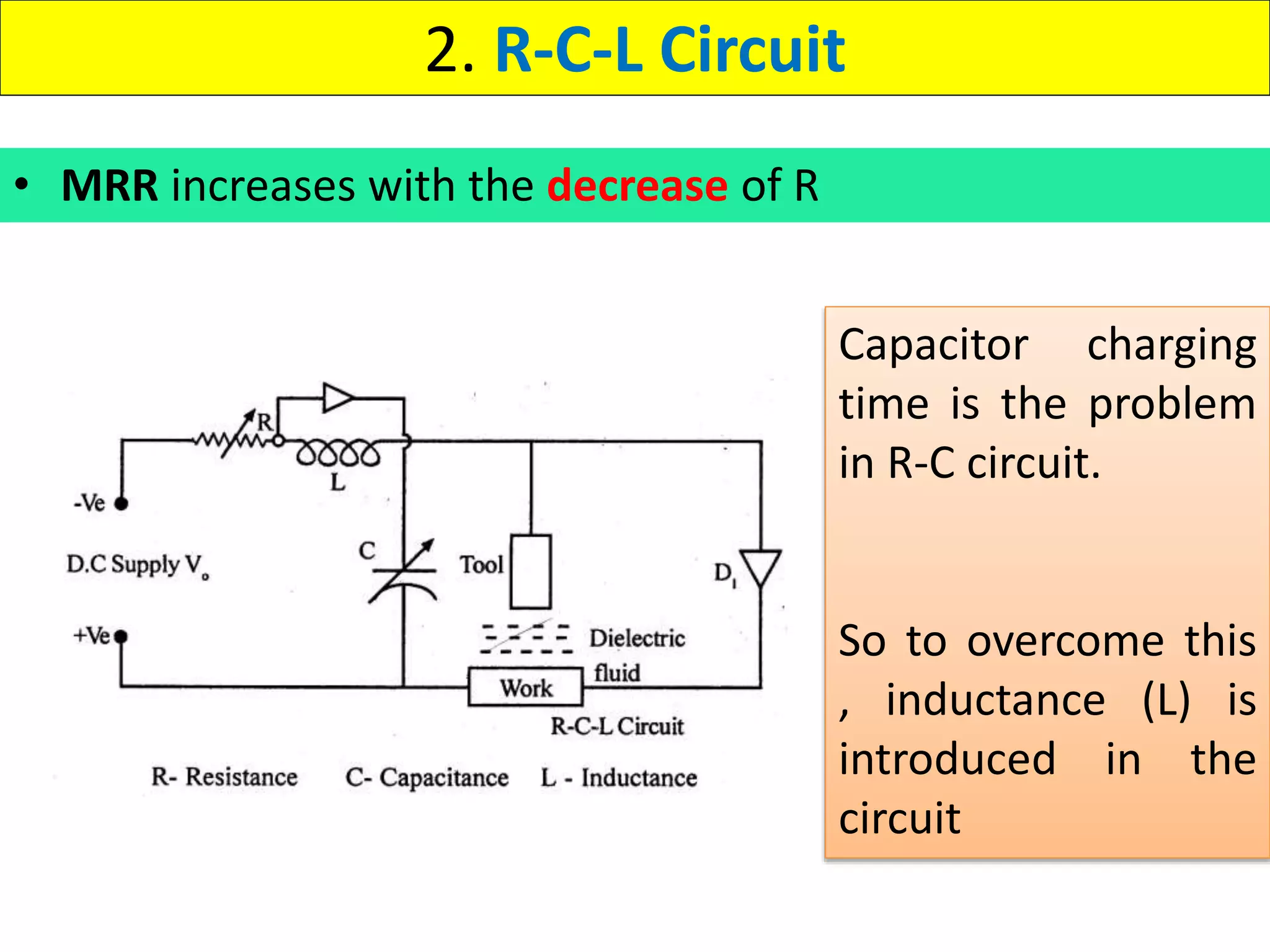

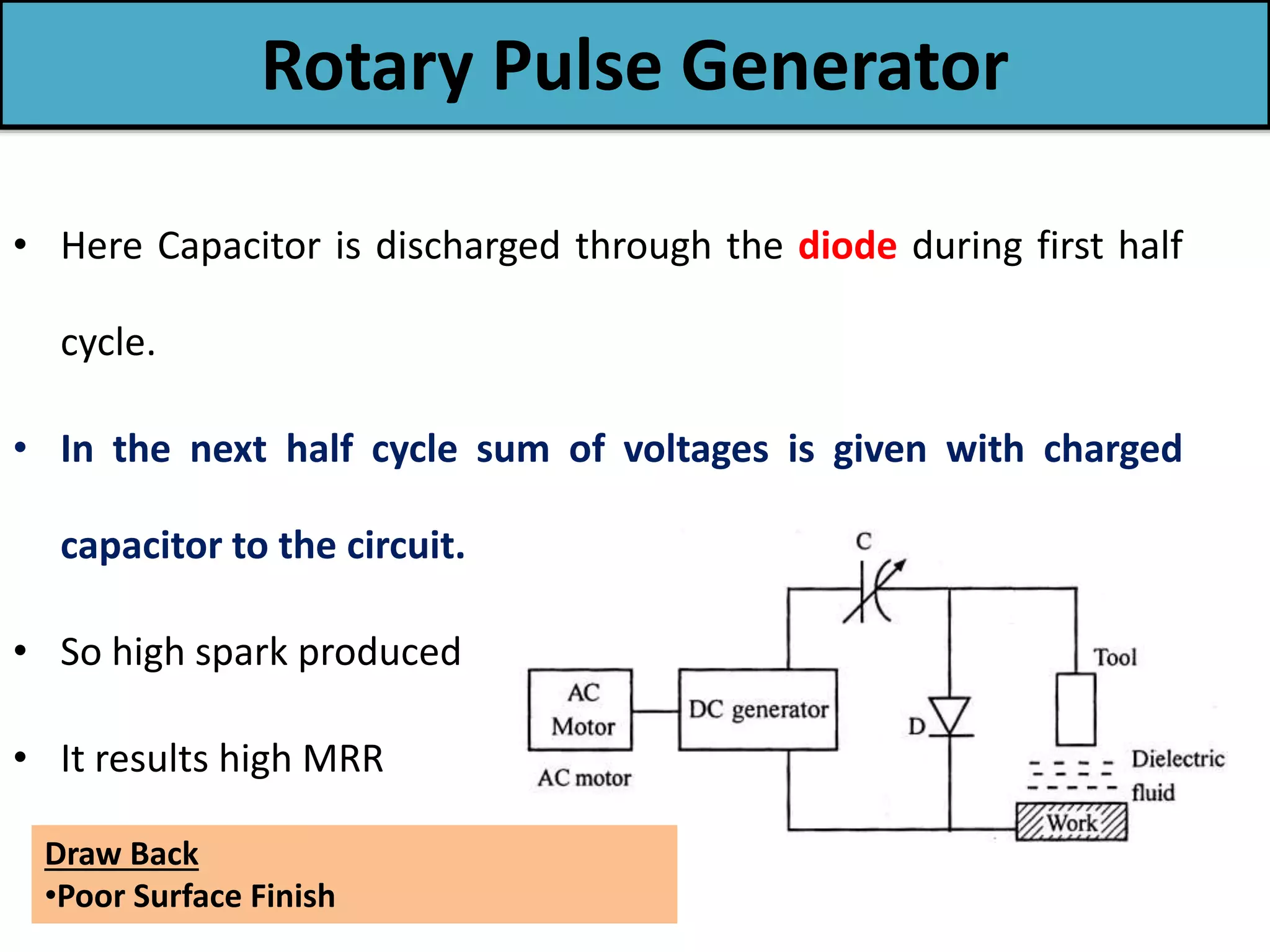

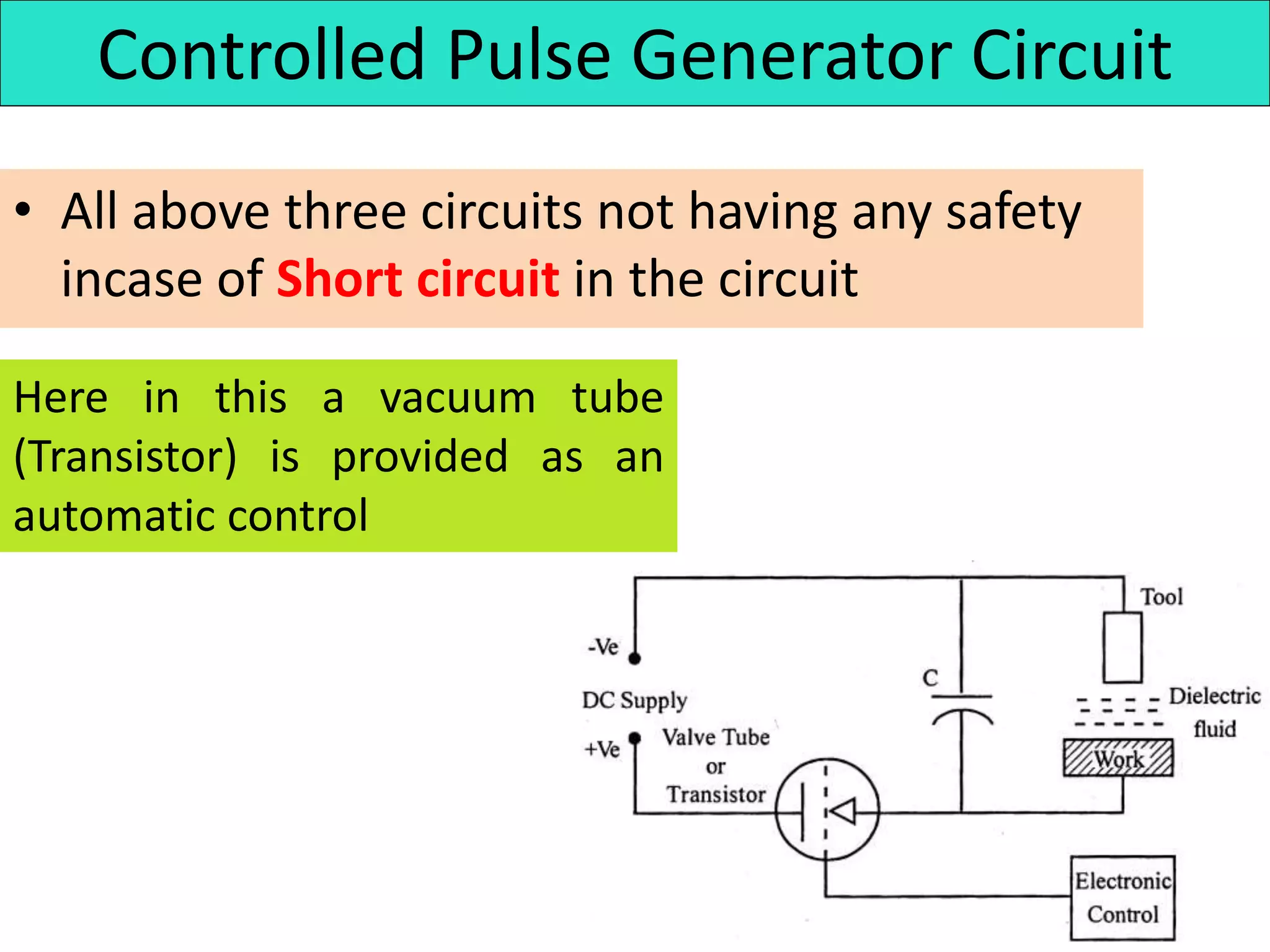

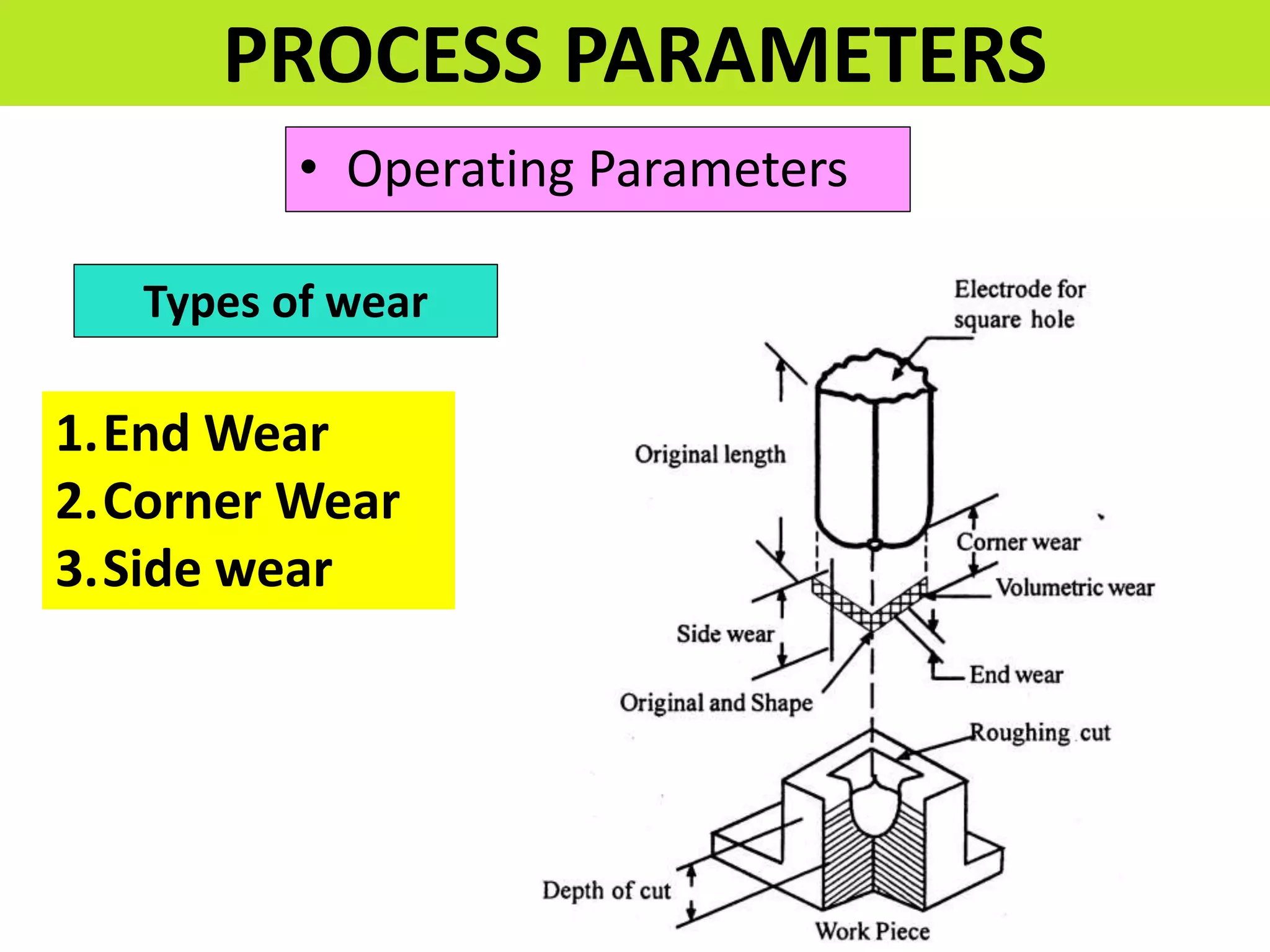

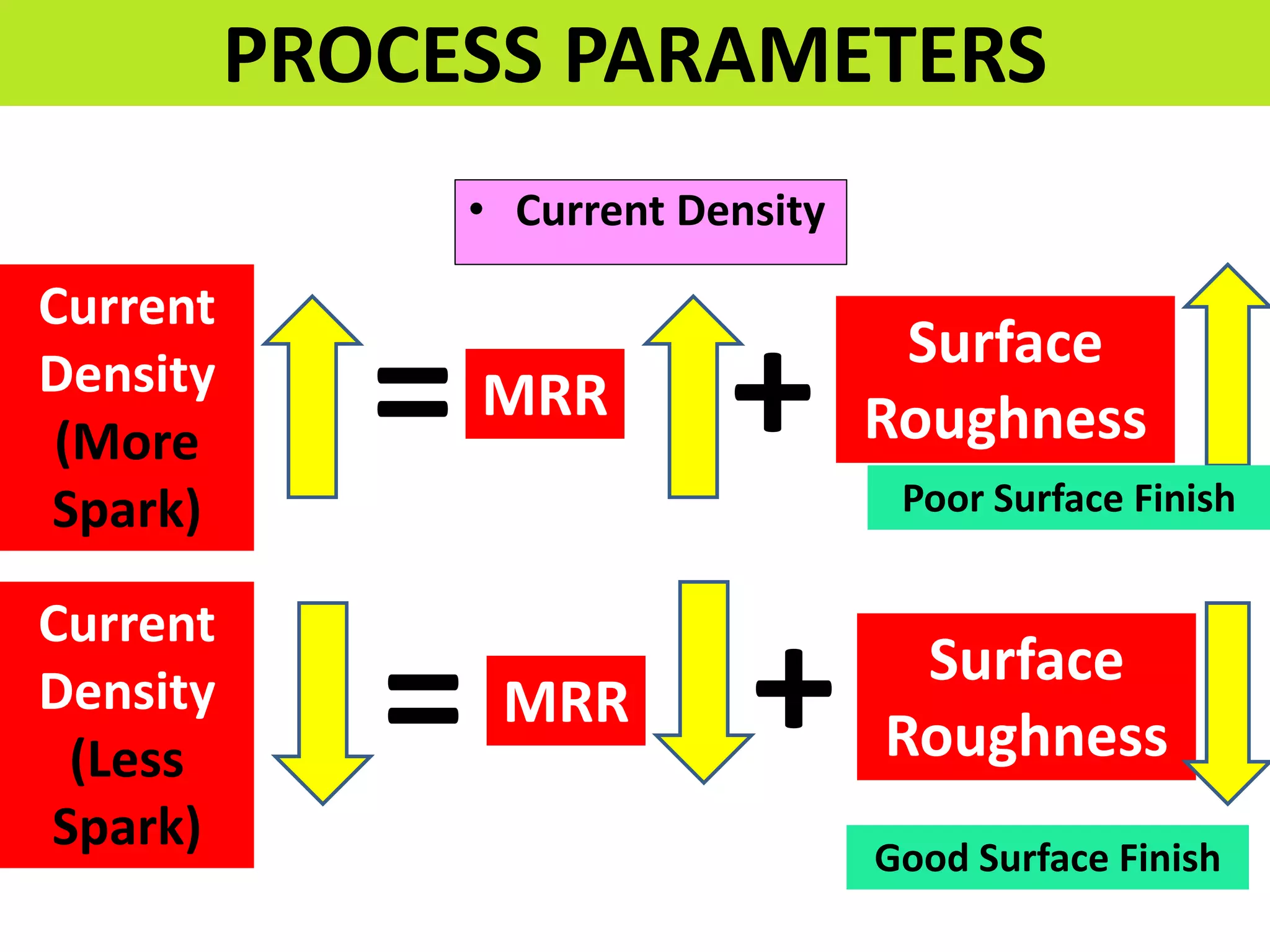

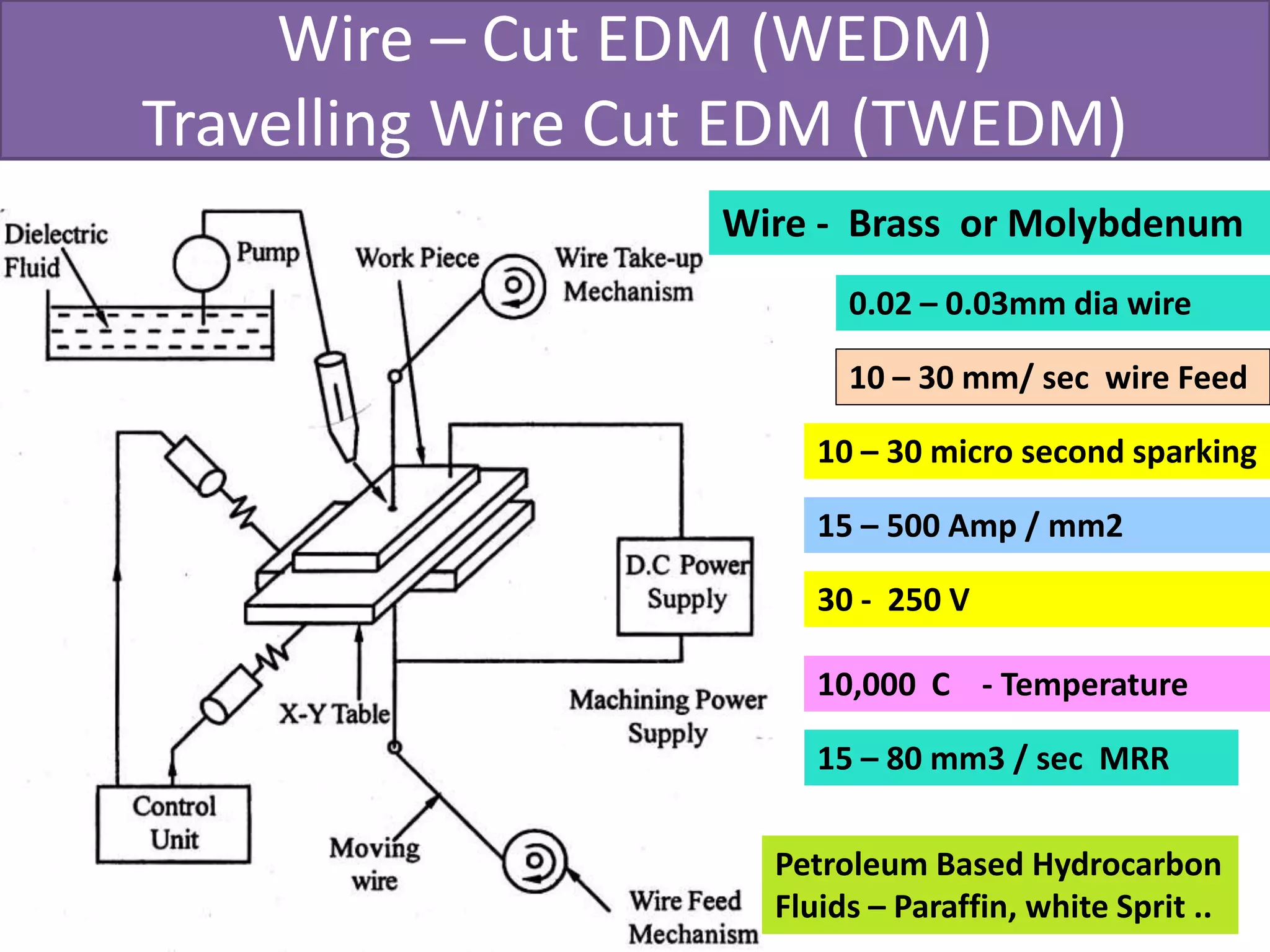

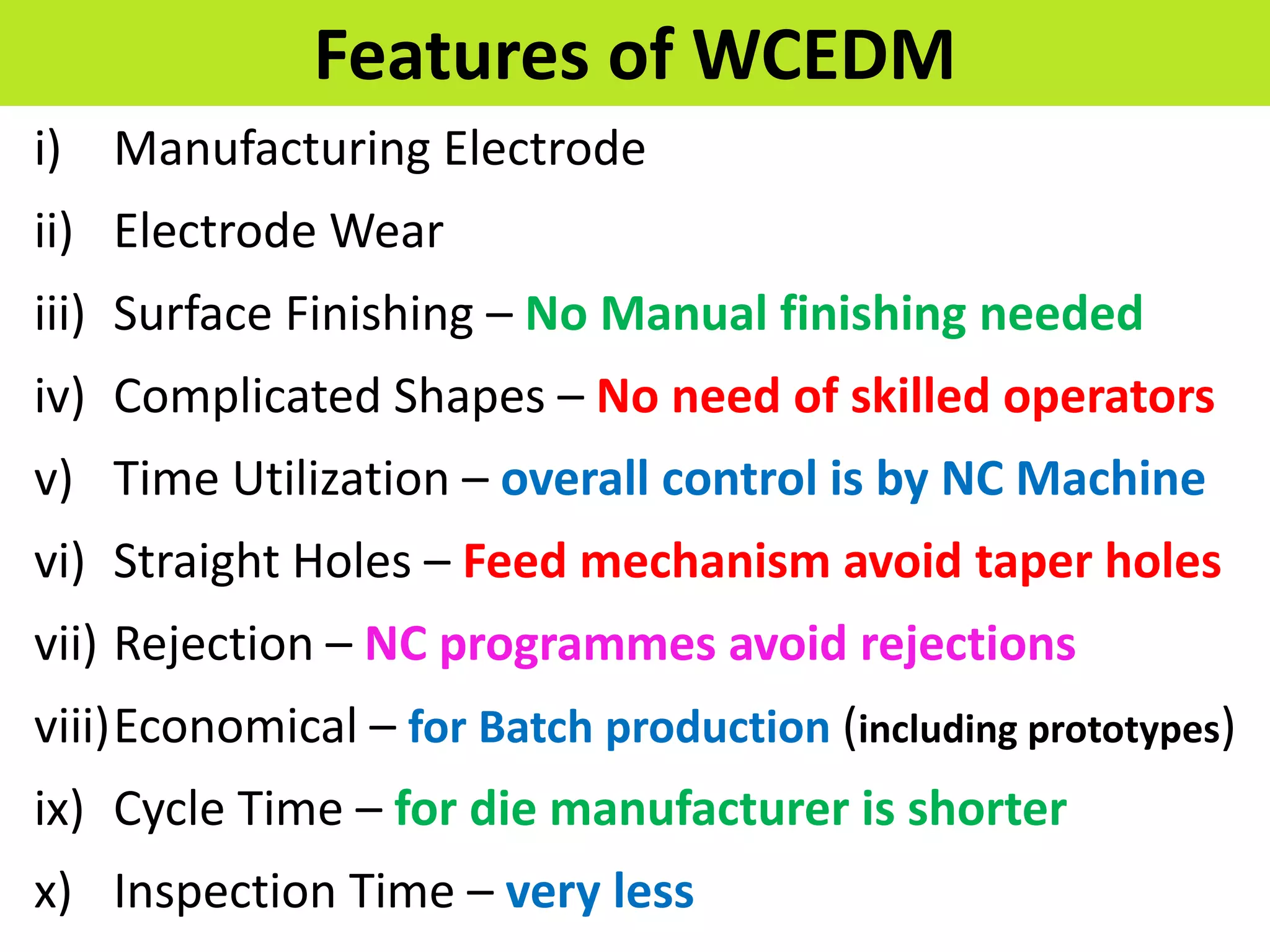

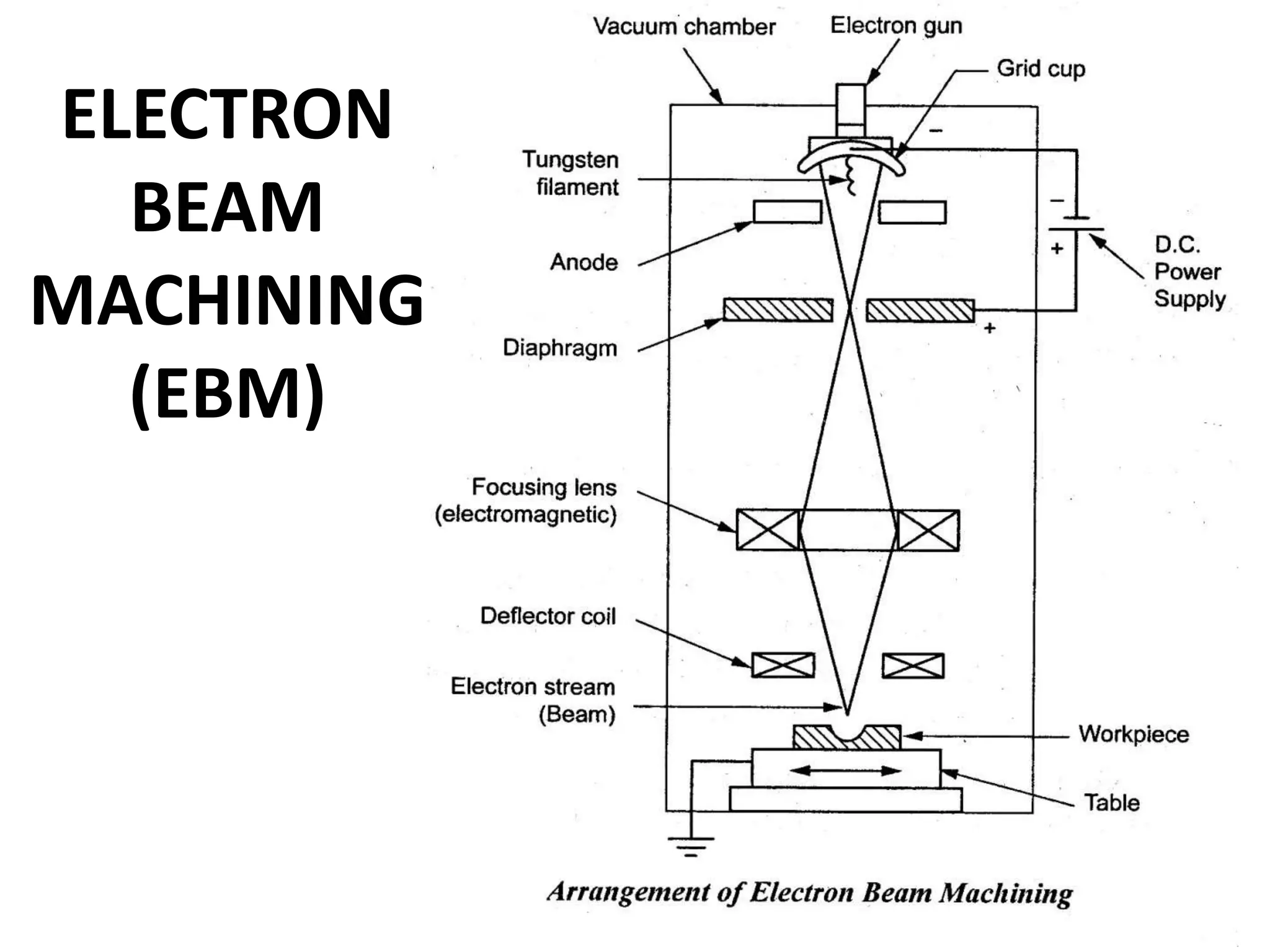

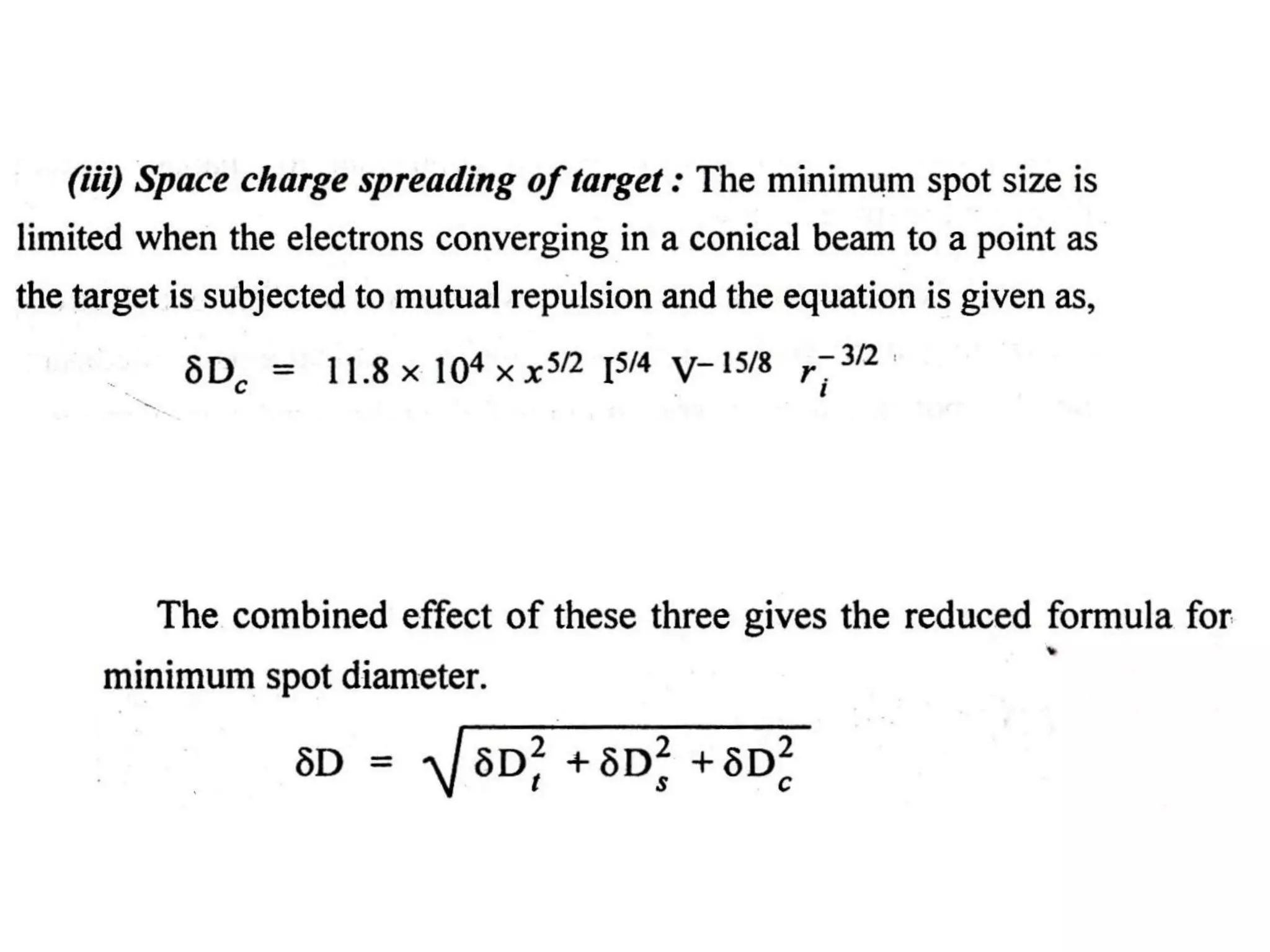

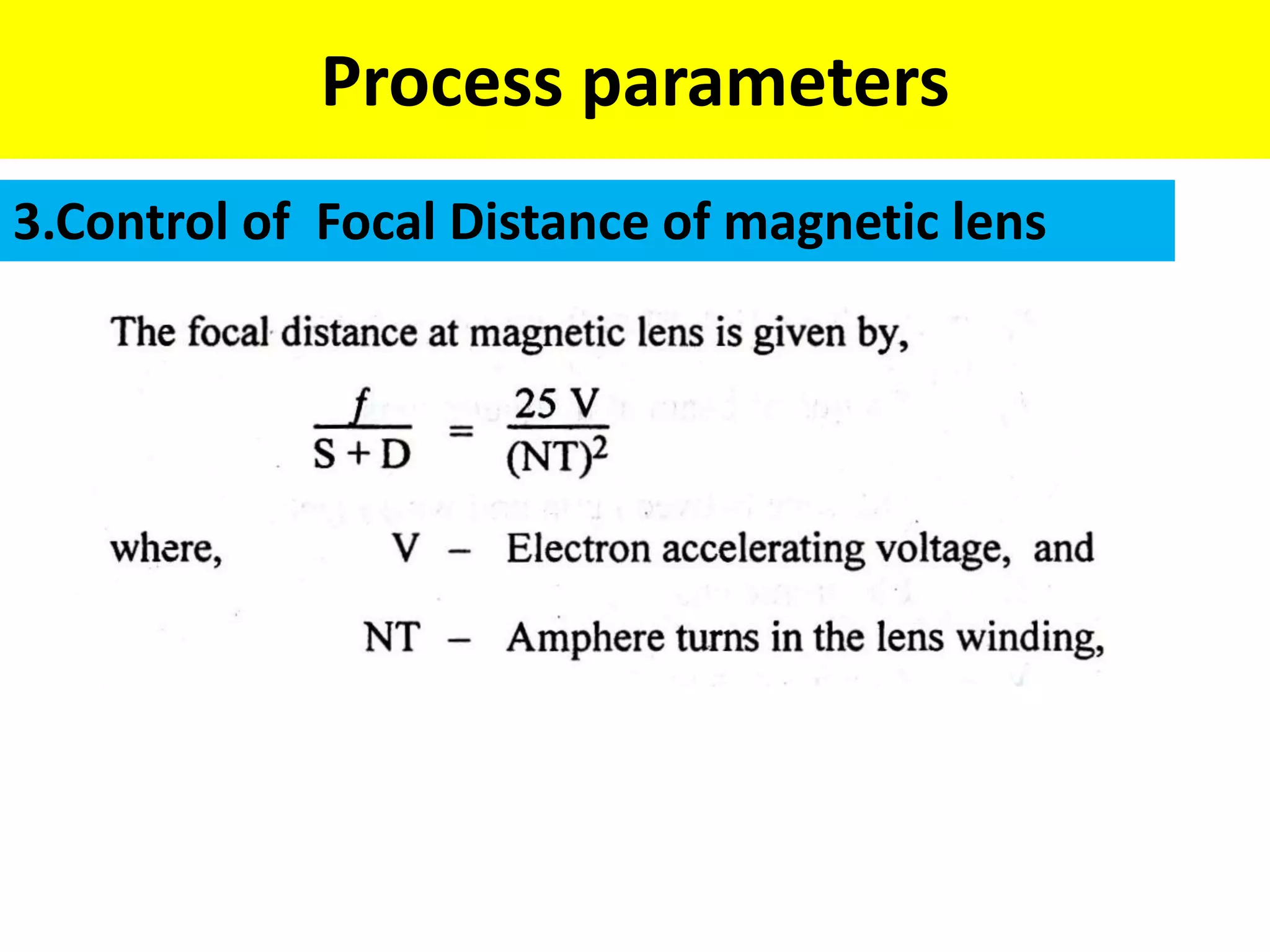

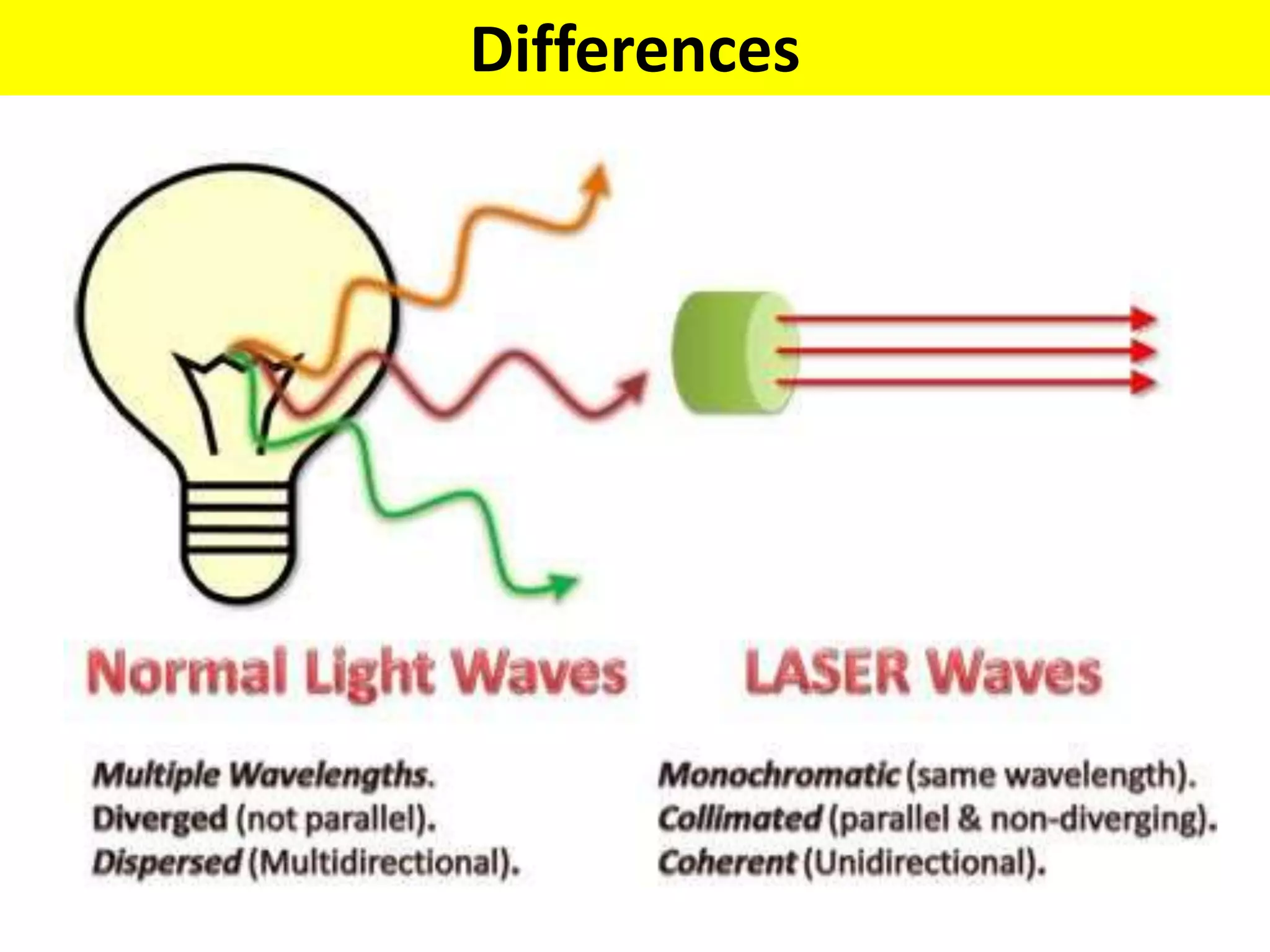

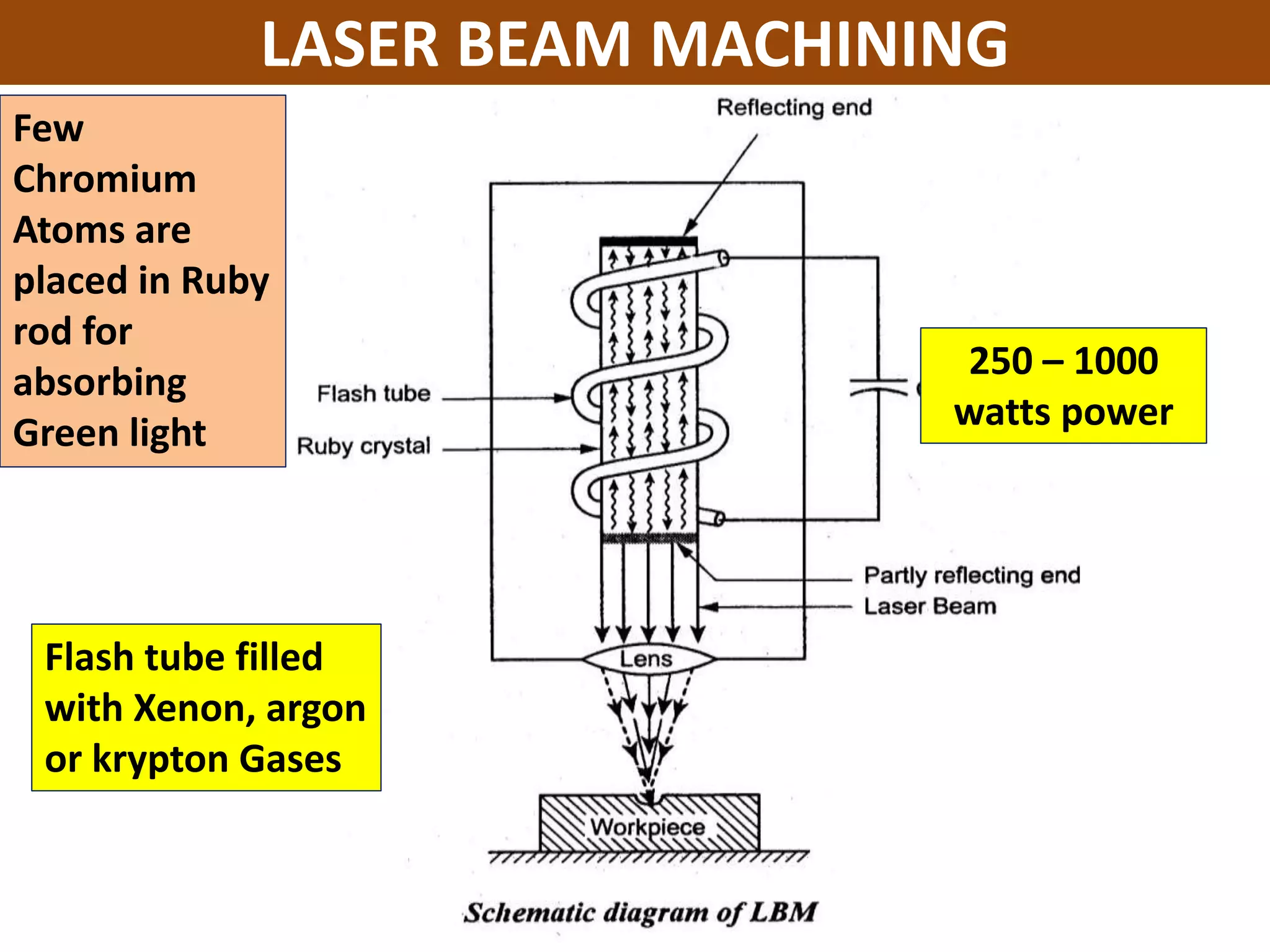

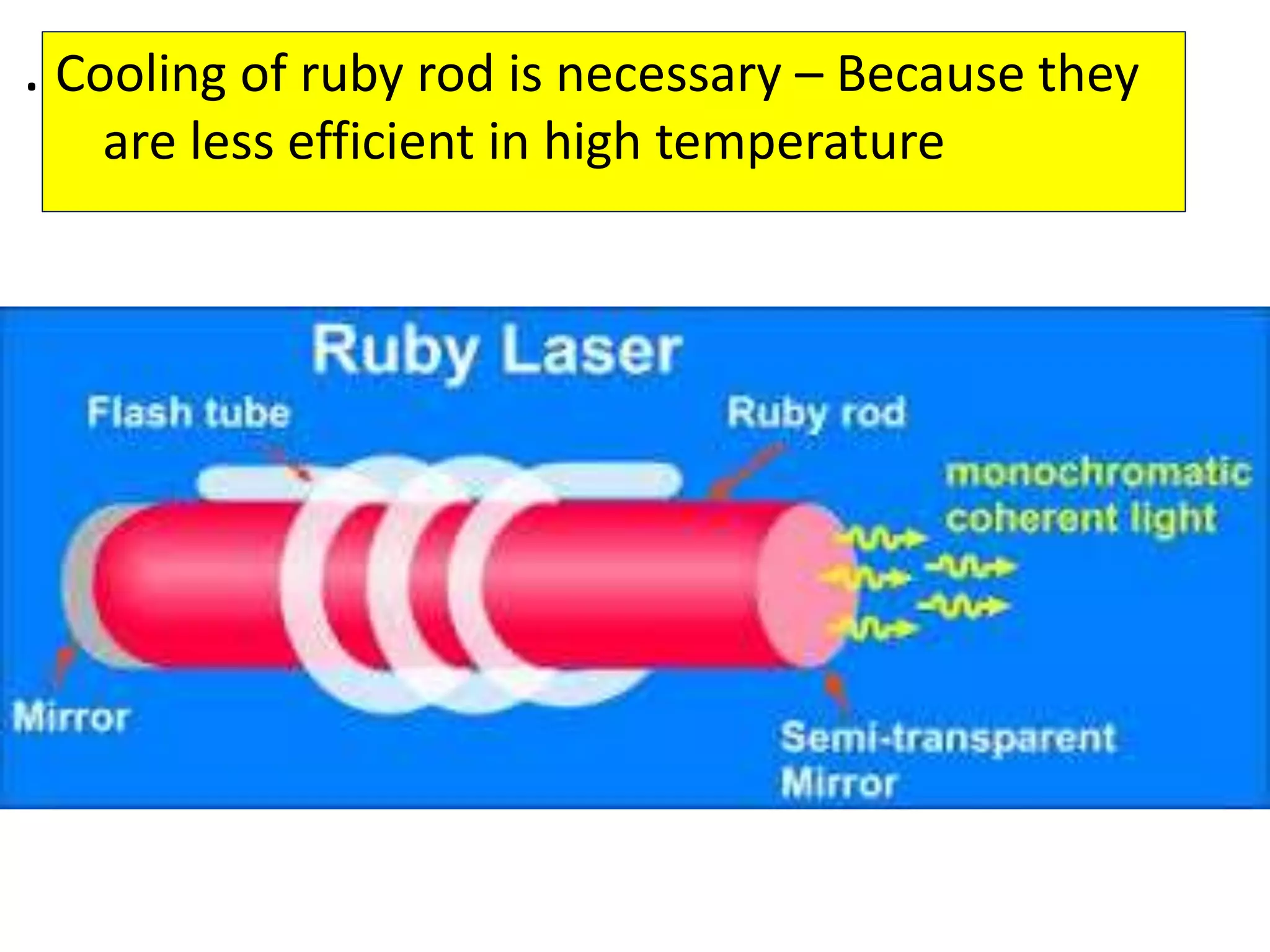

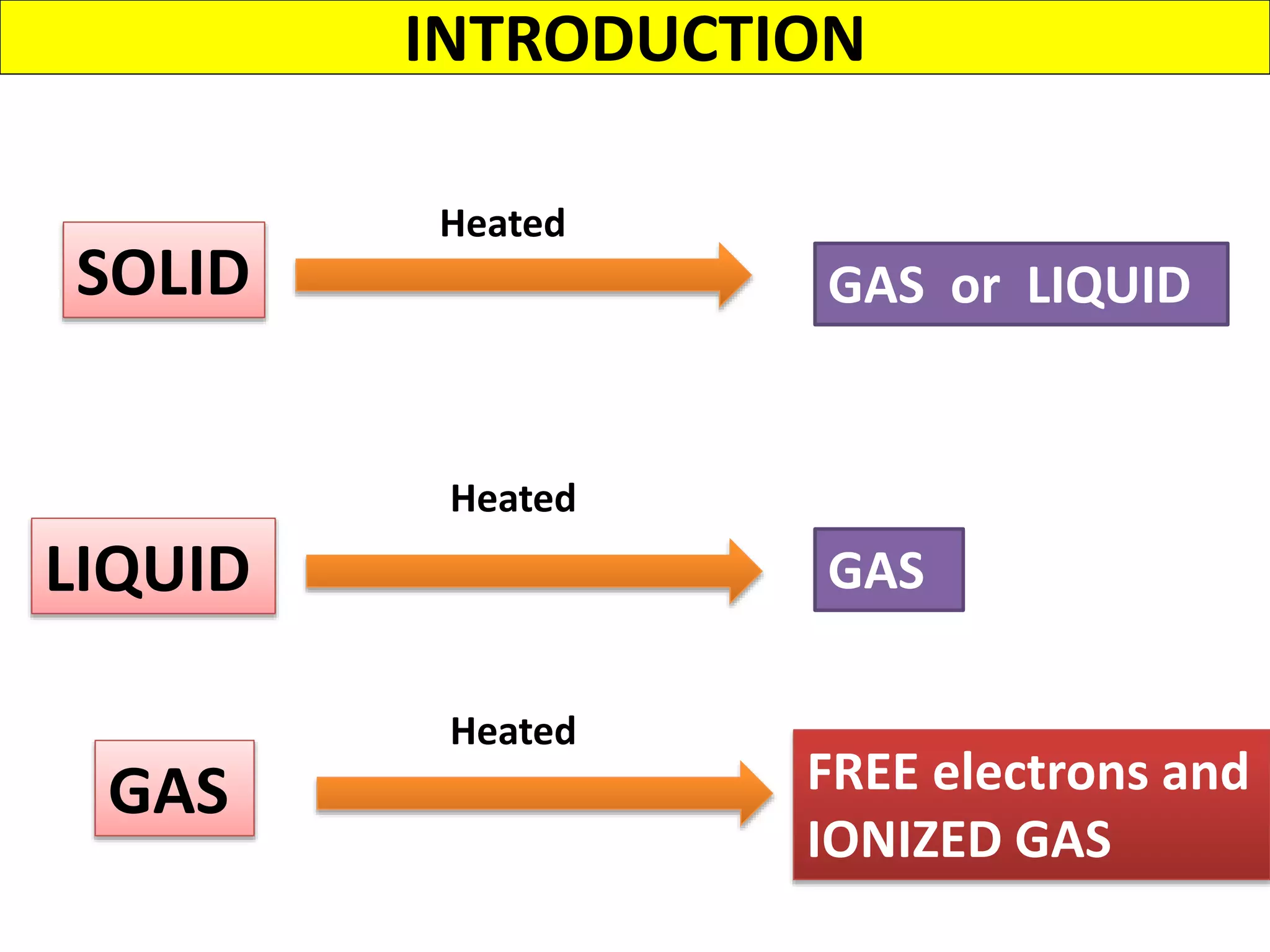

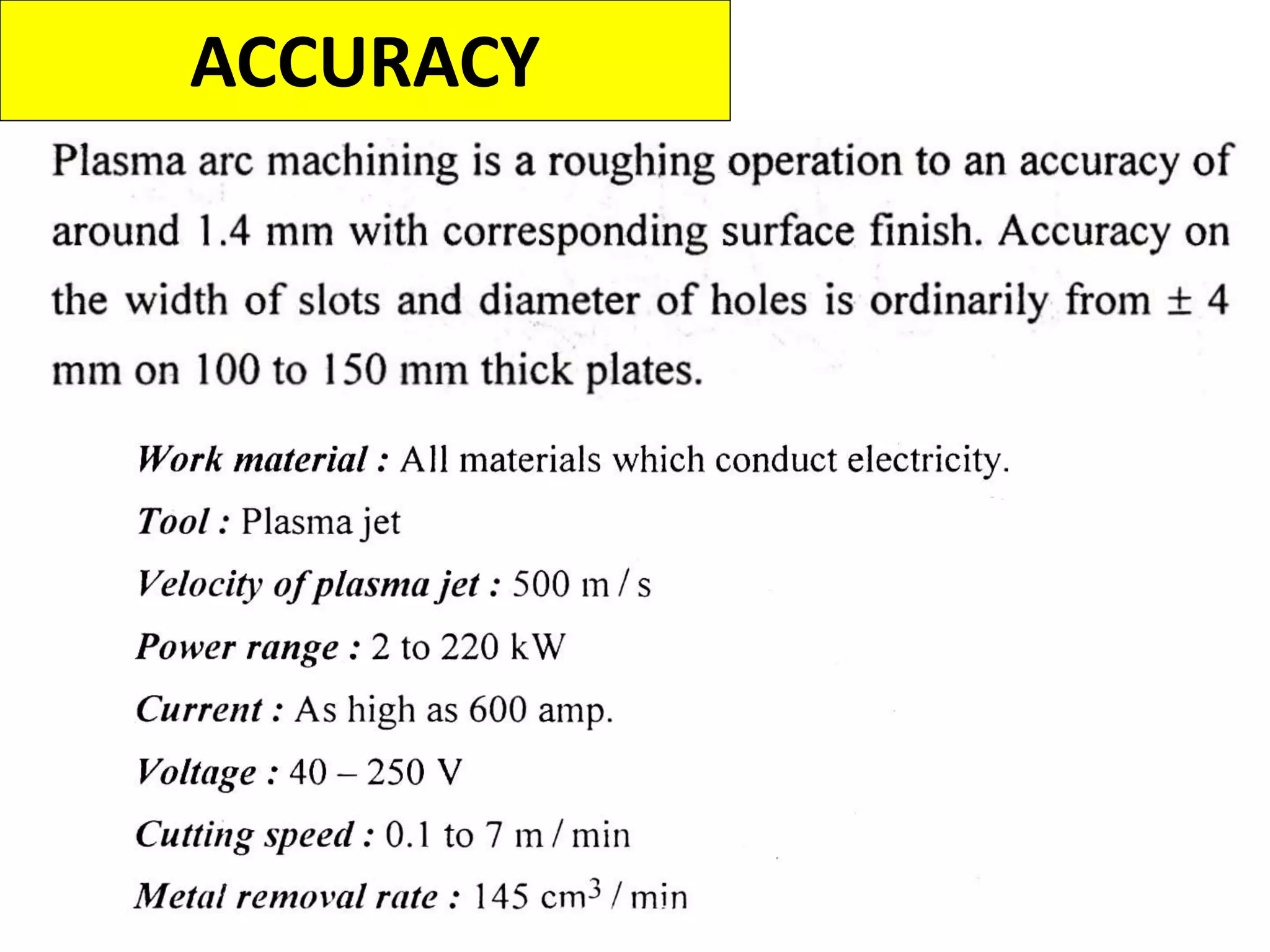

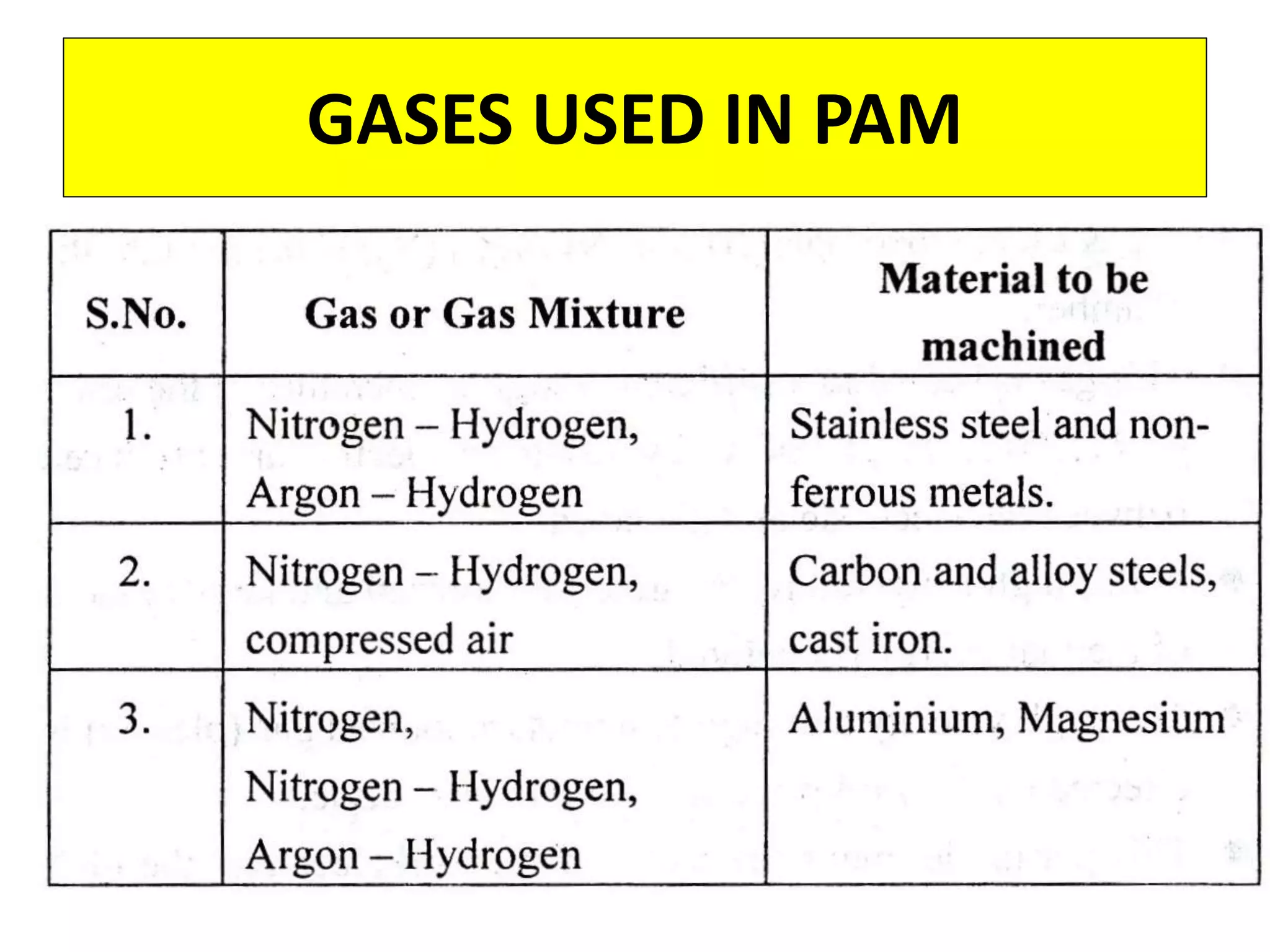

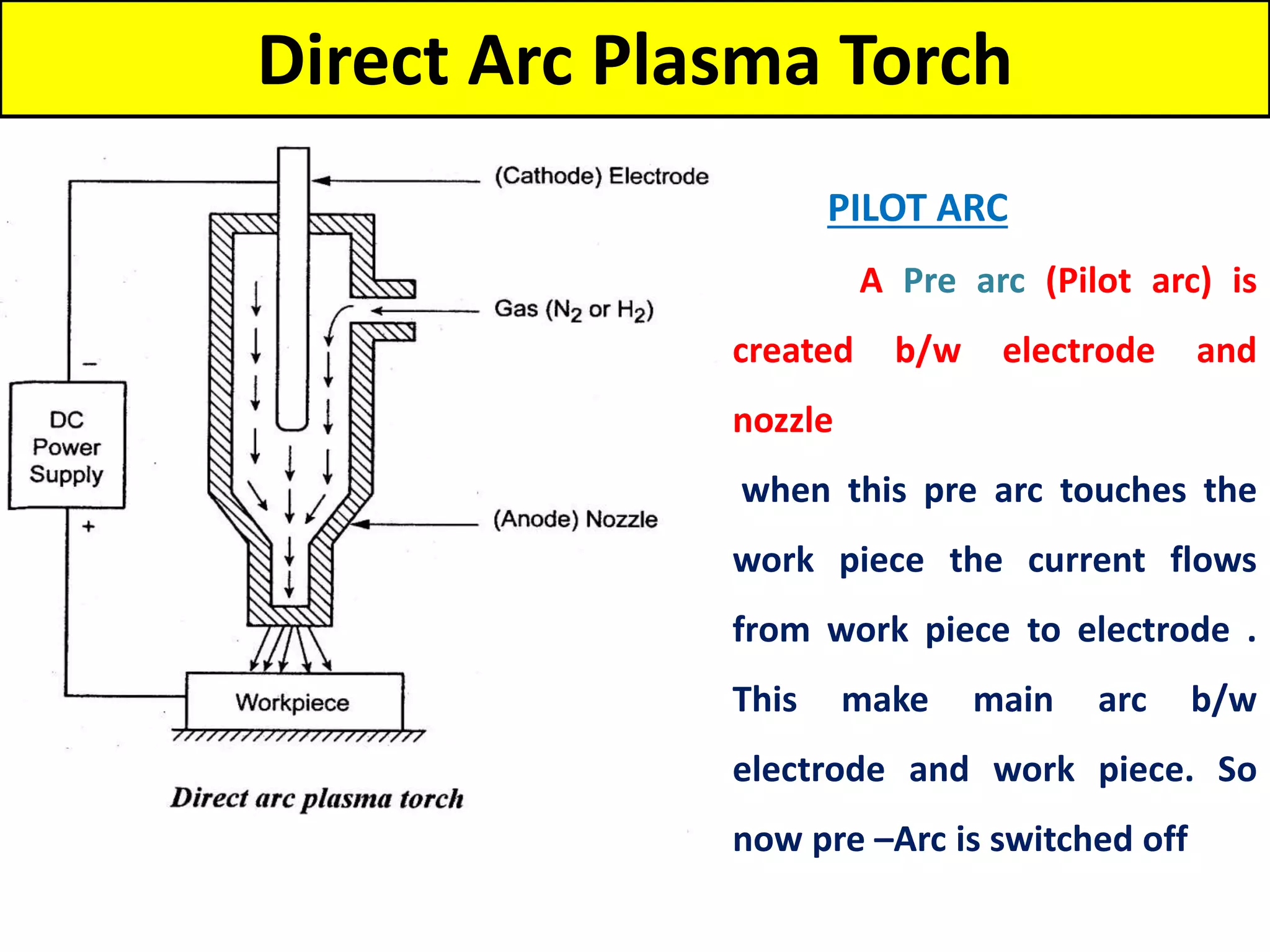

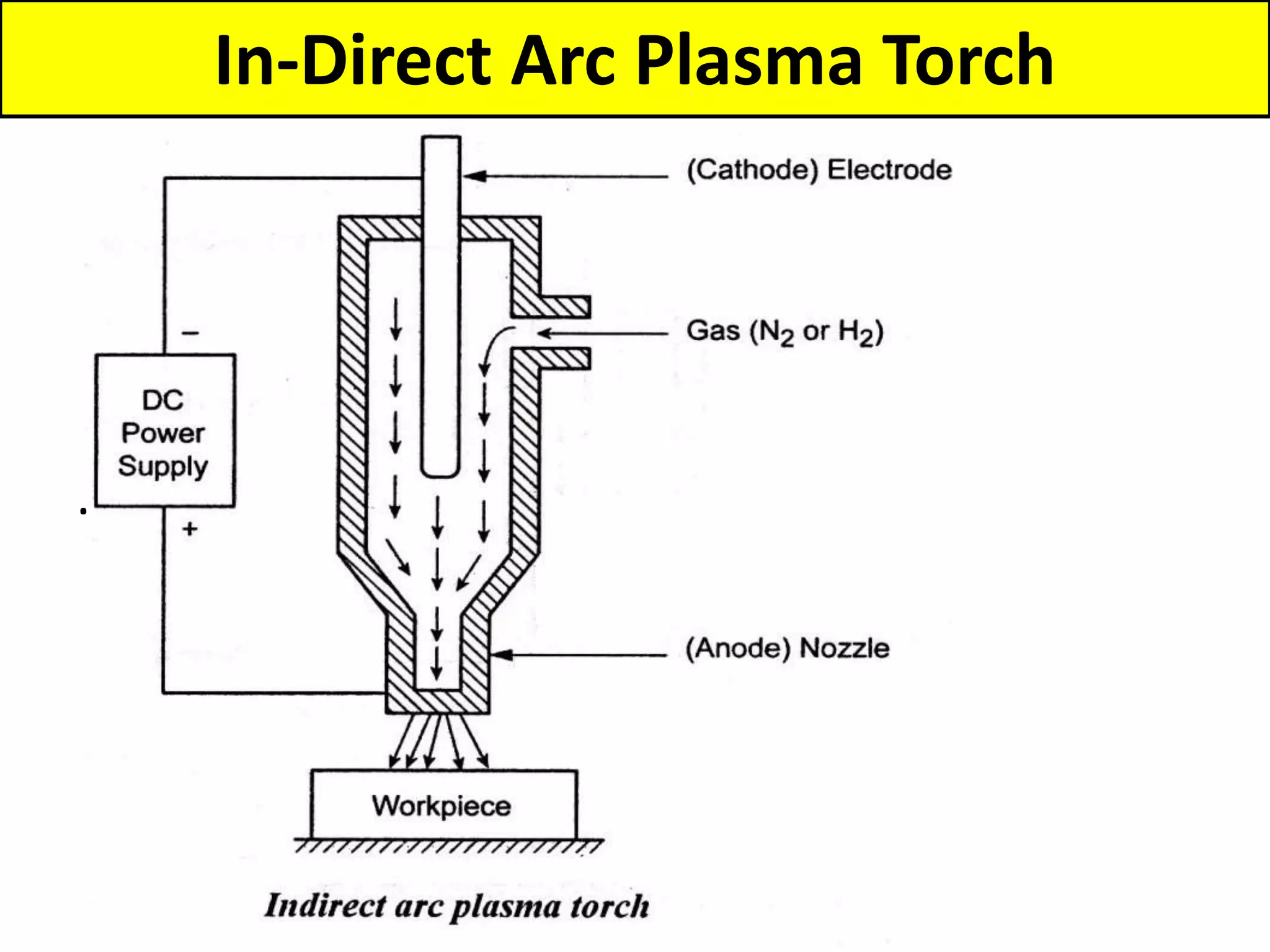

The document discusses various thermal energy based machining processes including EDM, EBM, LBM, and PAM. It provides details on the principles, specifications, and process parameters for EDM such as the use of a wire electrode, dielectric fluids, and circuit types. It also describes the principles of EBM using an electron beam, LBM using lasers, and PAM using ionized plasma gas. Key advantages and applications are highlighted for each process.