This document provides an overview of plastics, including:

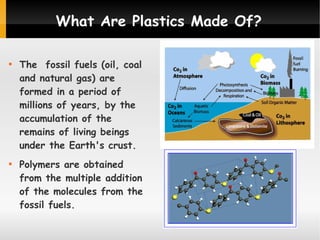

1. Plastics are synthetic polymers derived from fossil fuels that are generally flexible, resistant, light, and insulating materials.

2. Plastics are classified into three main groups: thermoplastics, which can be reshaped and recycled; thermosettings, which are harder but not recyclable; and elastomers, which are elastic but cannot withstand high temperatures.

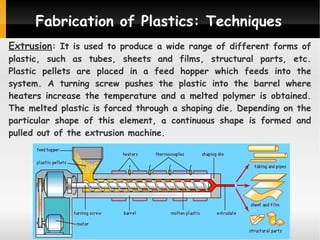

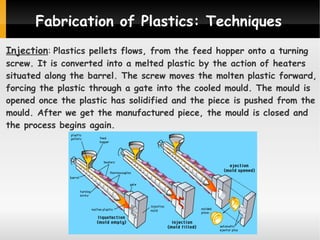

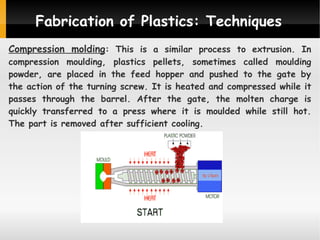

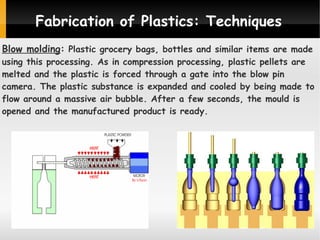

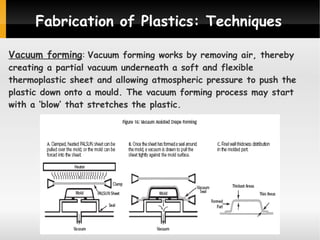

3. Plastics are fabricated using techniques like extrusion, injection molding, compression molding, and blow molding to process plastic pellets or powders into a variety of forms.