The document presents a detailed overview of aramid fibers, including their history, types, fabrication processes, properties, and applications. It highlights key figures in their development, such as Stephanie Kwolek and Wilfred Sweeny, and identifies para-aramid and meta-aramid as the primary varieties. Additionally, the document discusses the manufacturing process, physical and thermal properties, and various applications of aramid fibers in industries like construction and protective textiles.

![Introduction

ARAMID FIBERS 4

Amide

Carbonyl and amino group condensate to generate amide monomer.

There are basically two types of polyamides:

Nylon Aramids

Less than 85% amide linkages. Atleast 85% amide linkages.

Have [(CH2)n] chains b/w amide linkages. Have (aromatic ring) b/w amide linkages.](https://image.slidesharecdn.com/ppt-200112152513/85/Aramid-Fiber-as-reinforcement-4-320.jpg)

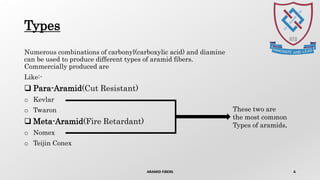

![ARAMID FIBERS 7

Worldwide production of Aramid Fibers

Fiber Name Basic Polymer Producer Estimated Capacity

(Ton/Yr)

M-Aramid Fiber

Nomex Poly(m-phenylene isopthalamide) DuPont Co. 10,000

Teijin Conex Poly(m-phenylene isopthalamide) Teijin Ltd. 5000

Fenilin Poly(m-phenylene isopthalamide) Russia 1000

P-Aramid Fiber

Kevlar Poly(m-phenylene isopthalamide) Du Pont Co. 20,000

Twaron Poly(m-phenylene isopthalamide) Akzo Nobel 10,000

Aramid Co-Polymer Fibers

Technora Copoly(l,4-phenylene/3,4′- diphenylether

terephthalamide)

Teijin Ltd. 1000

Armos Copoly[p-phenylene/5-amino-2- (p

aminophenyl)benzimidazole terephthalamide]

Russia Unknown

Trevar Aramid Copolymer Hoechst AG Unknown](https://image.slidesharecdn.com/ppt-200112152513/85/Aramid-Fiber-as-reinforcement-7-320.jpg)