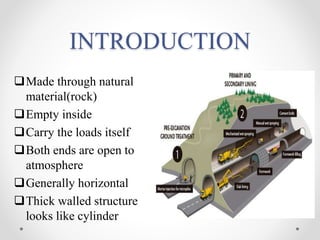

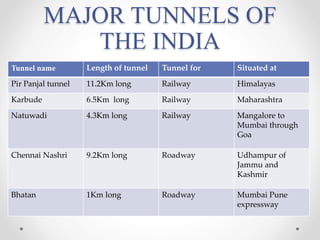

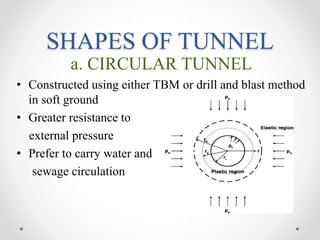

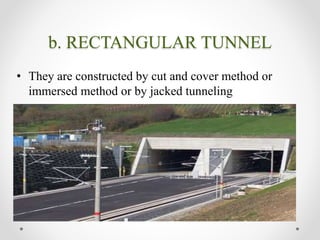

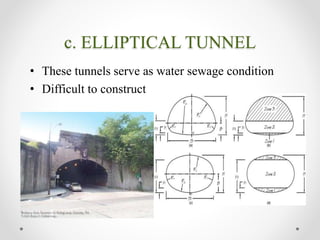

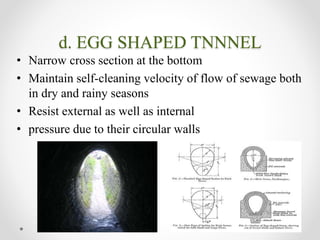

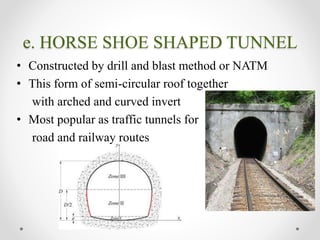

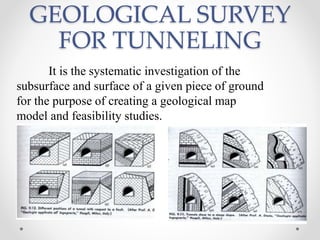

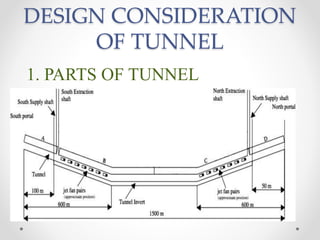

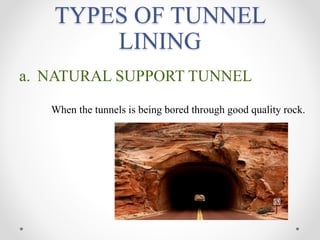

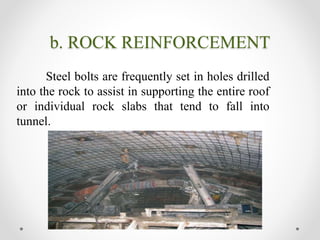

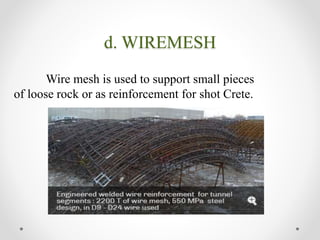

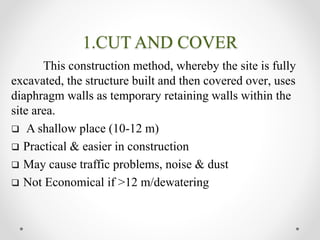

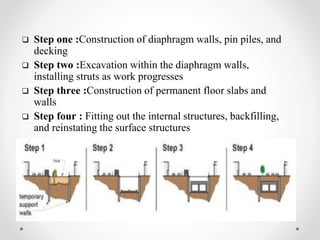

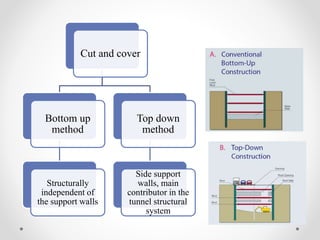

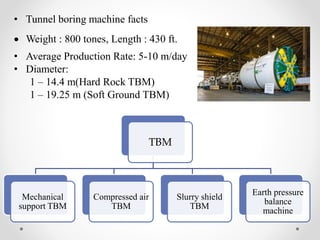

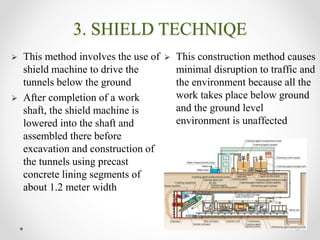

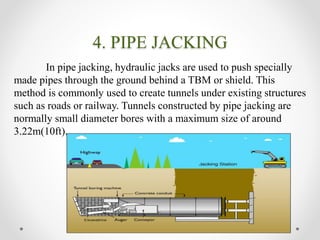

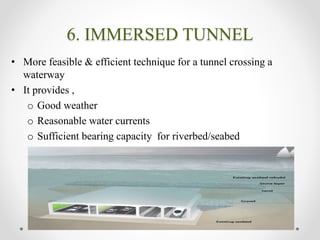

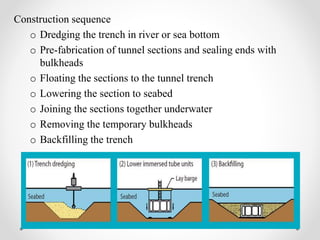

This document discusses various aspects of tunnel construction including definitions, purposes, factors affecting construction, major tunnels in India, shapes of tunnels, geological surveys, design considerations, construction methods, and conclusions. It defines a tunnel as an underground passageway dug through surrounding soil or rock and enclosed except at entrances and exits. Common construction methods described are cut-and-cover, tunnel boring machine (TBM), shield technique, pipe jacking, and sprayed concrete. Design considerations include alignment, tunnel lining, groundwater control, ventilation, and investigation.