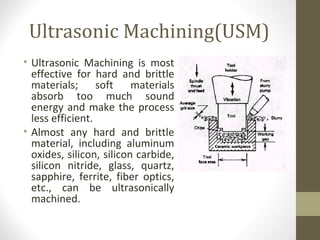

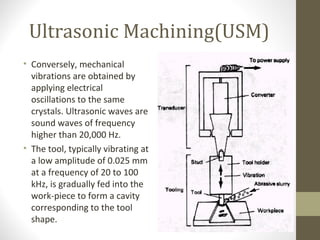

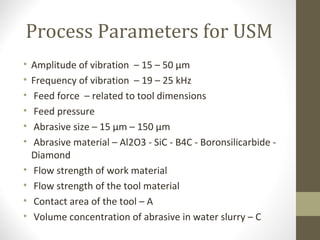

Ultrasonic machining is a non-traditional machining process that uses high-frequency vibrations delivered to an abrasive tool tip to accurately machine hard and brittle materials without inducing stresses. The tool vibrates at 20-100 kHz with an amplitude of 0.025 mm while submerged in an abrasive slurry, and material is removed through micro-chipping as the abrasive particles are driven between the tool and workpiece. Ultrasonic machining works well for materials like aluminum oxides, silicon, glass, and ceramics that are difficult to machine through traditional methods.