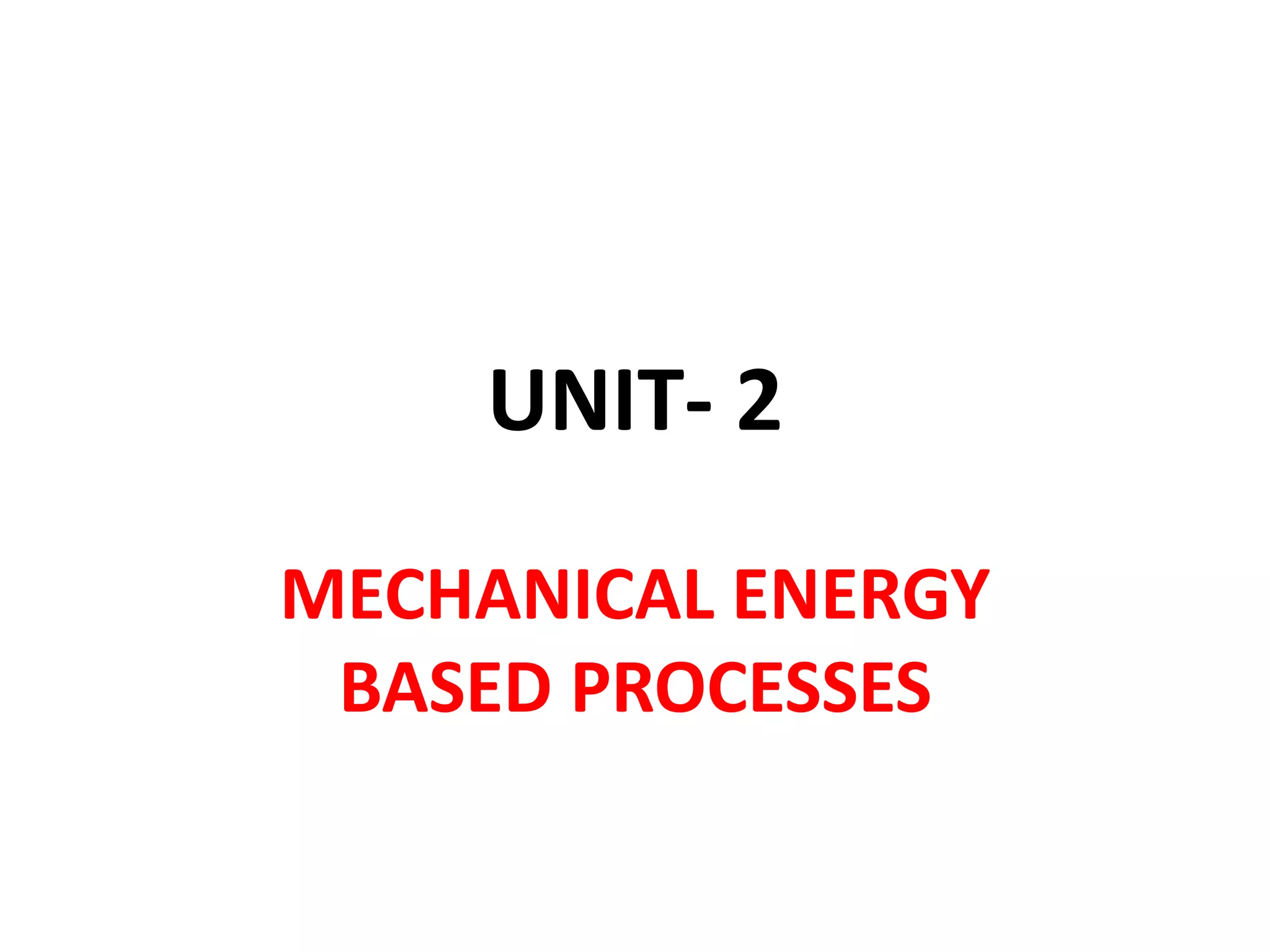

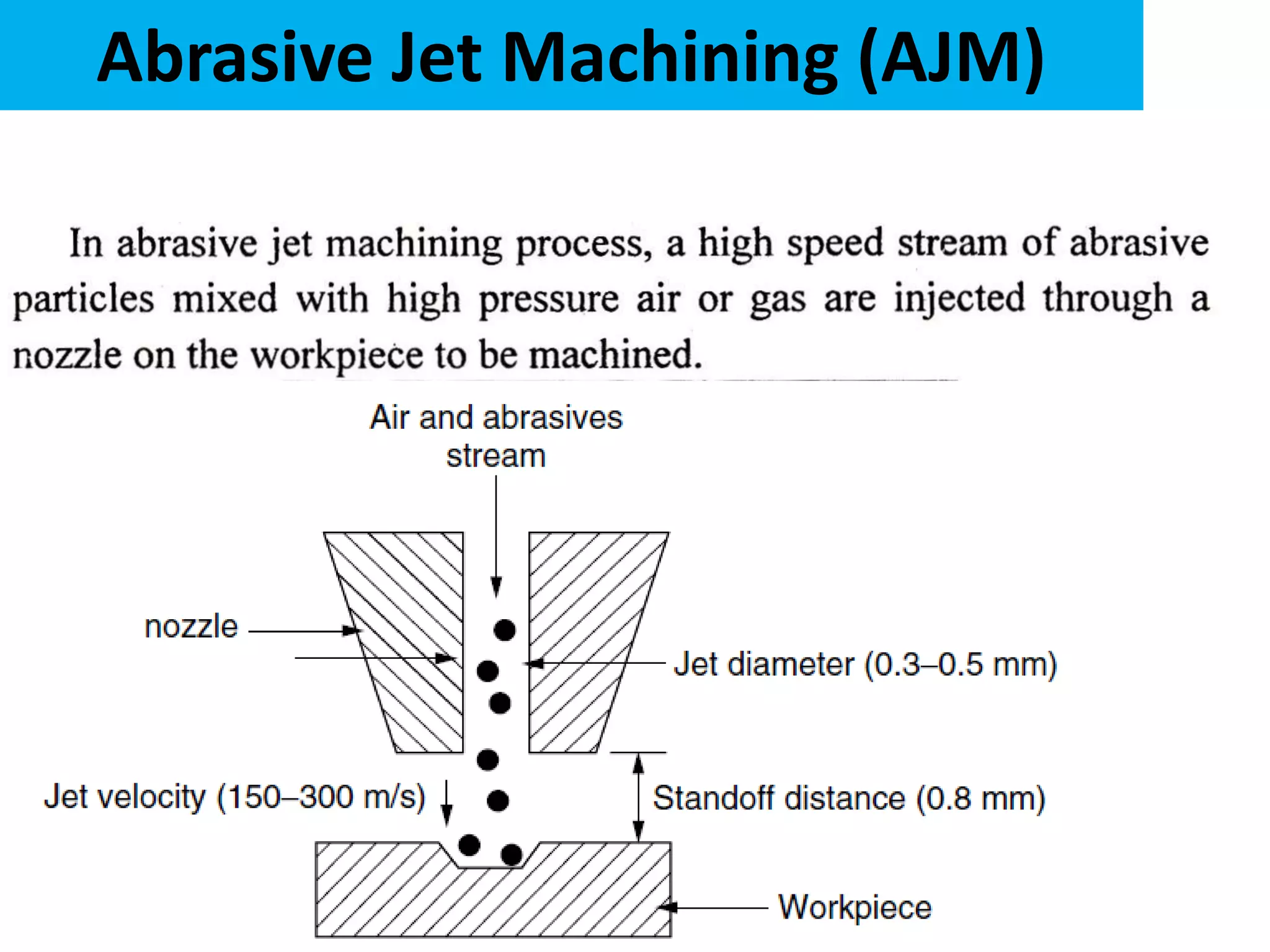

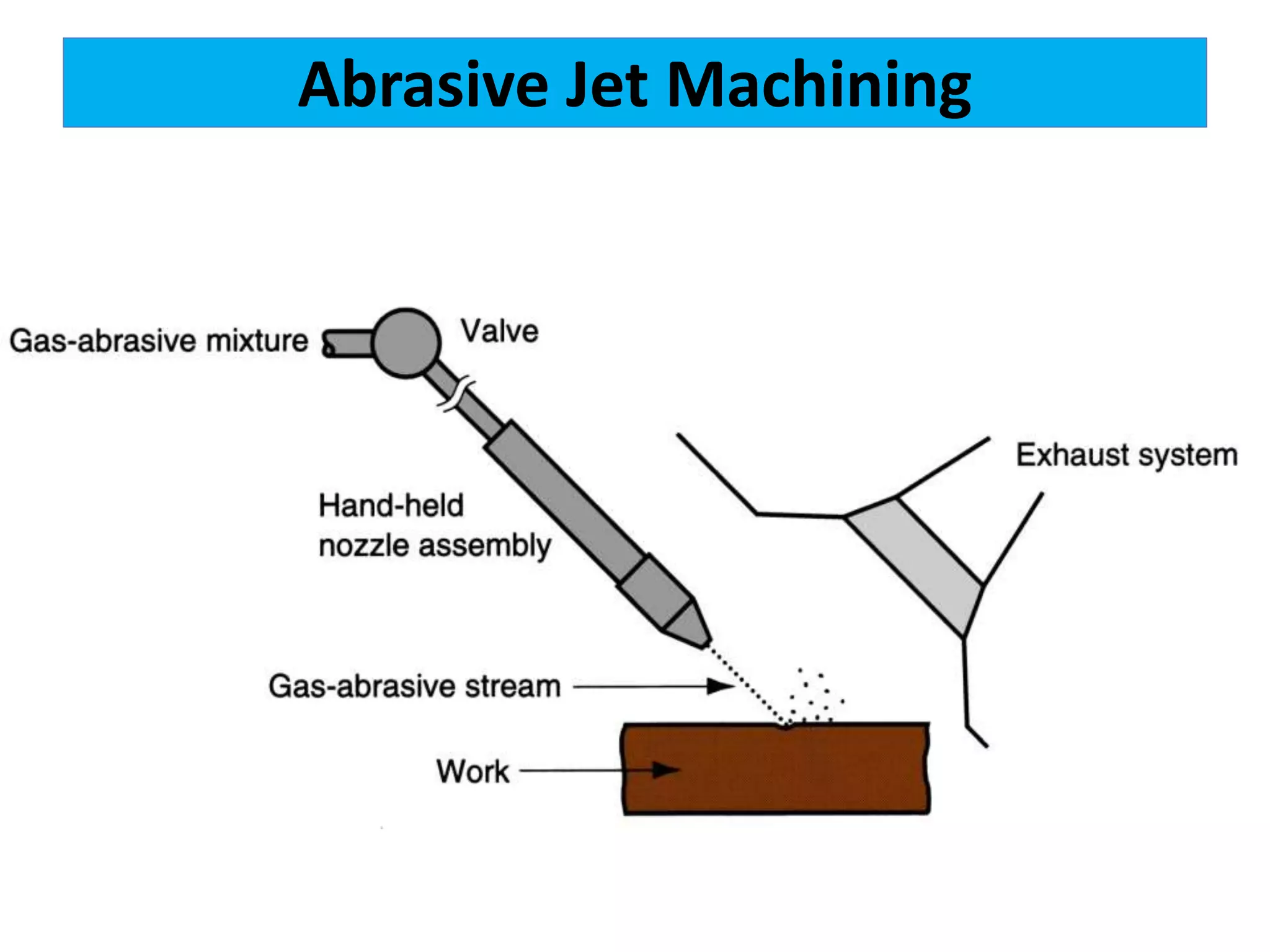

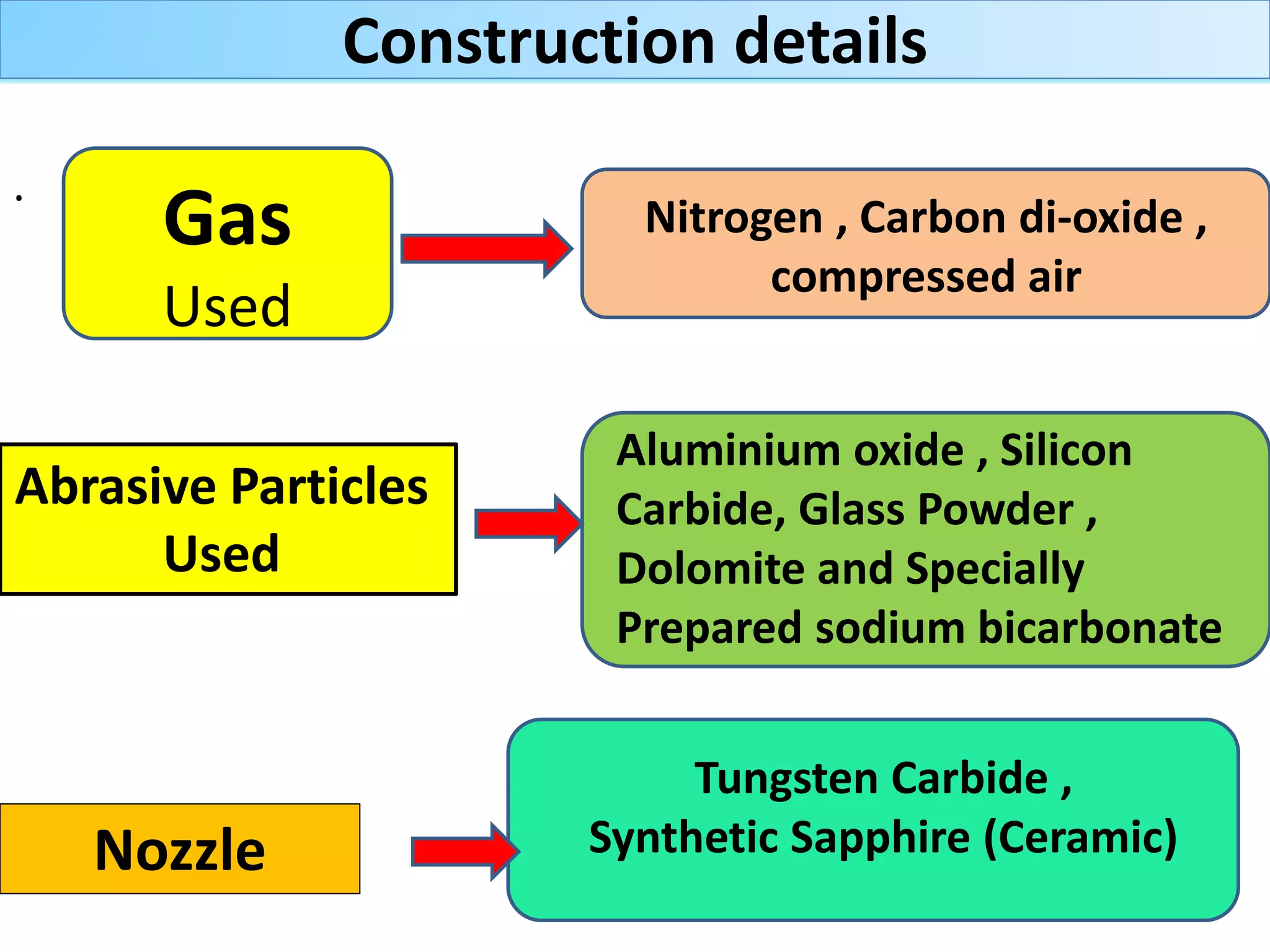

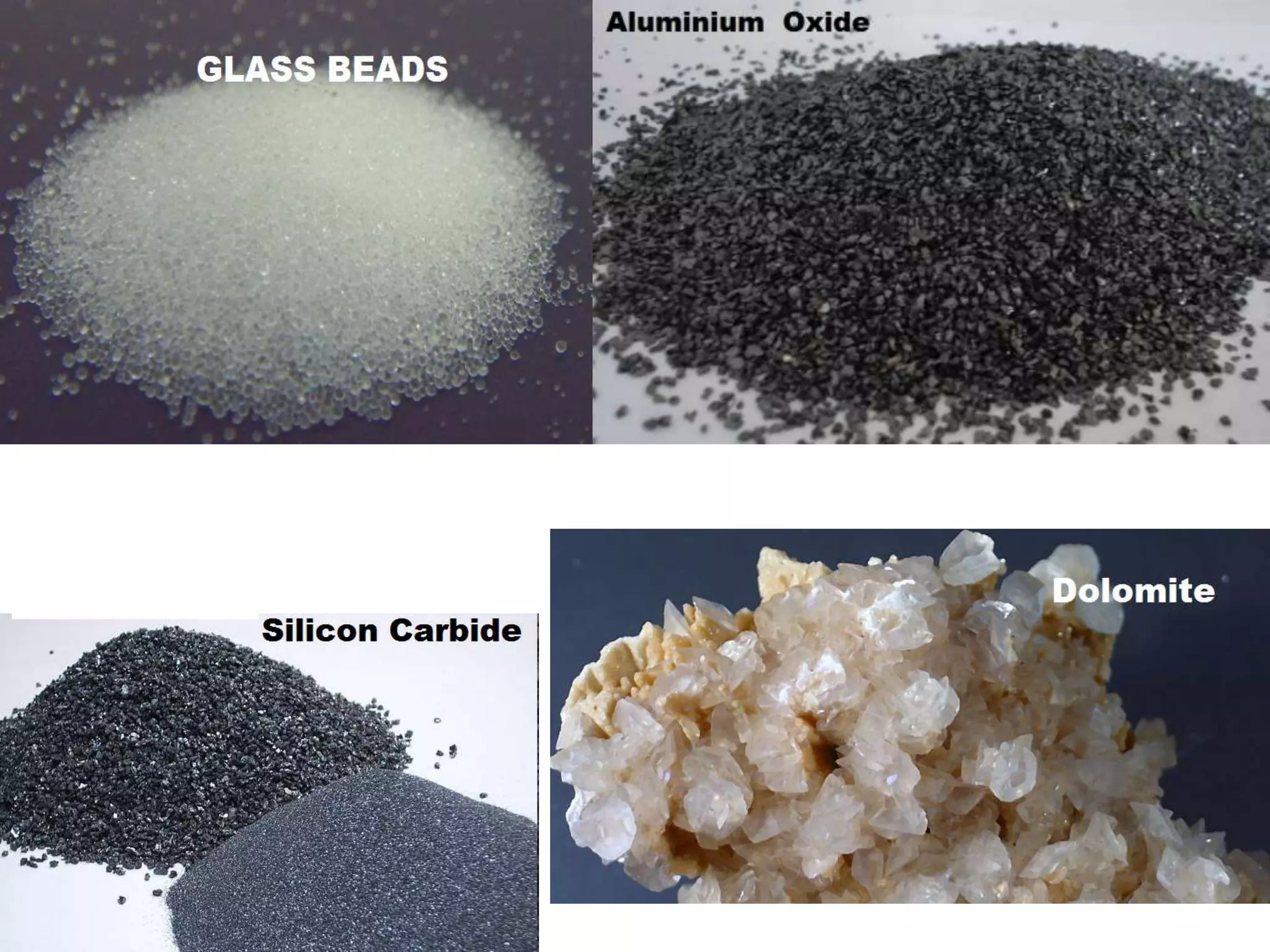

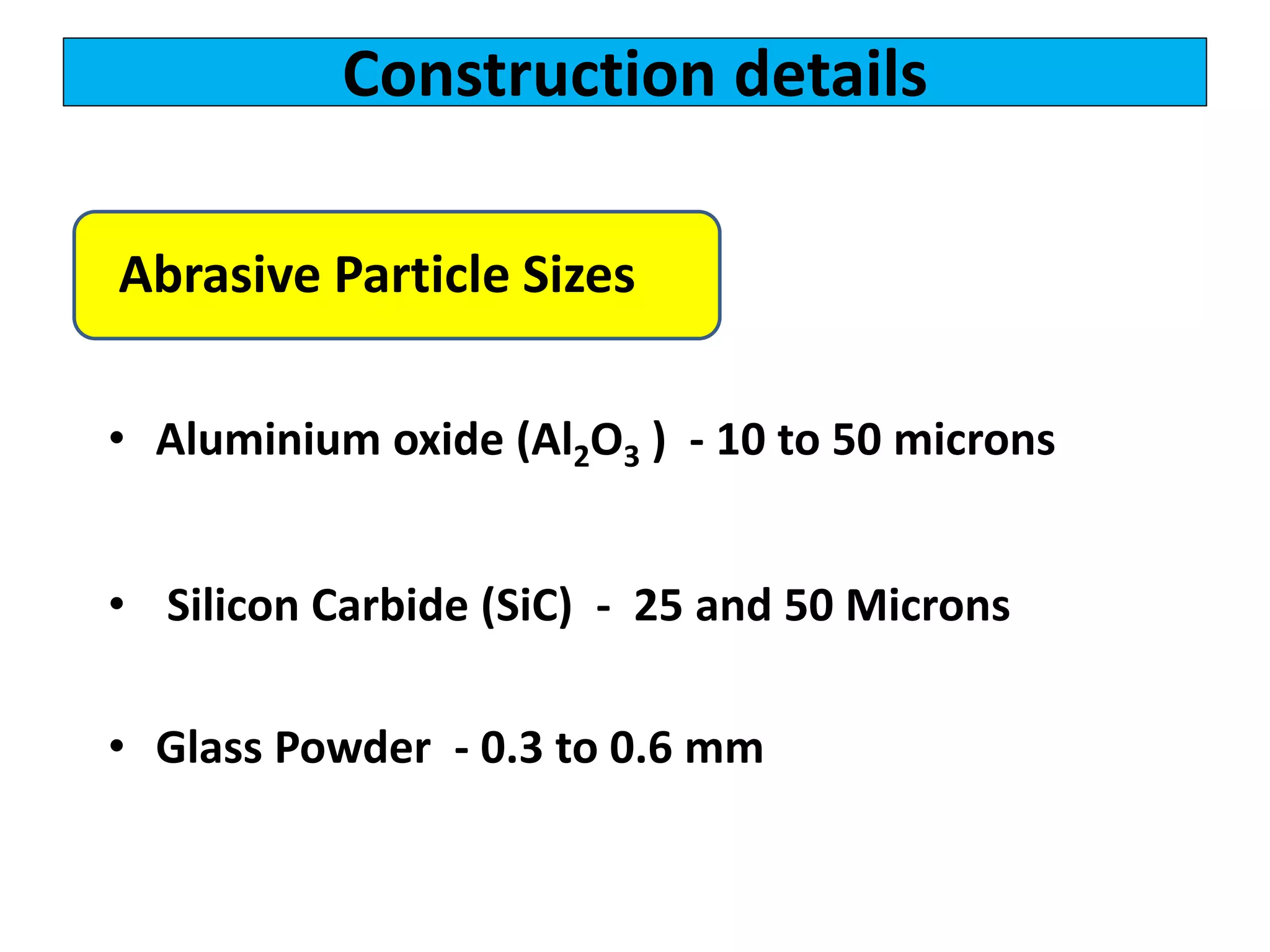

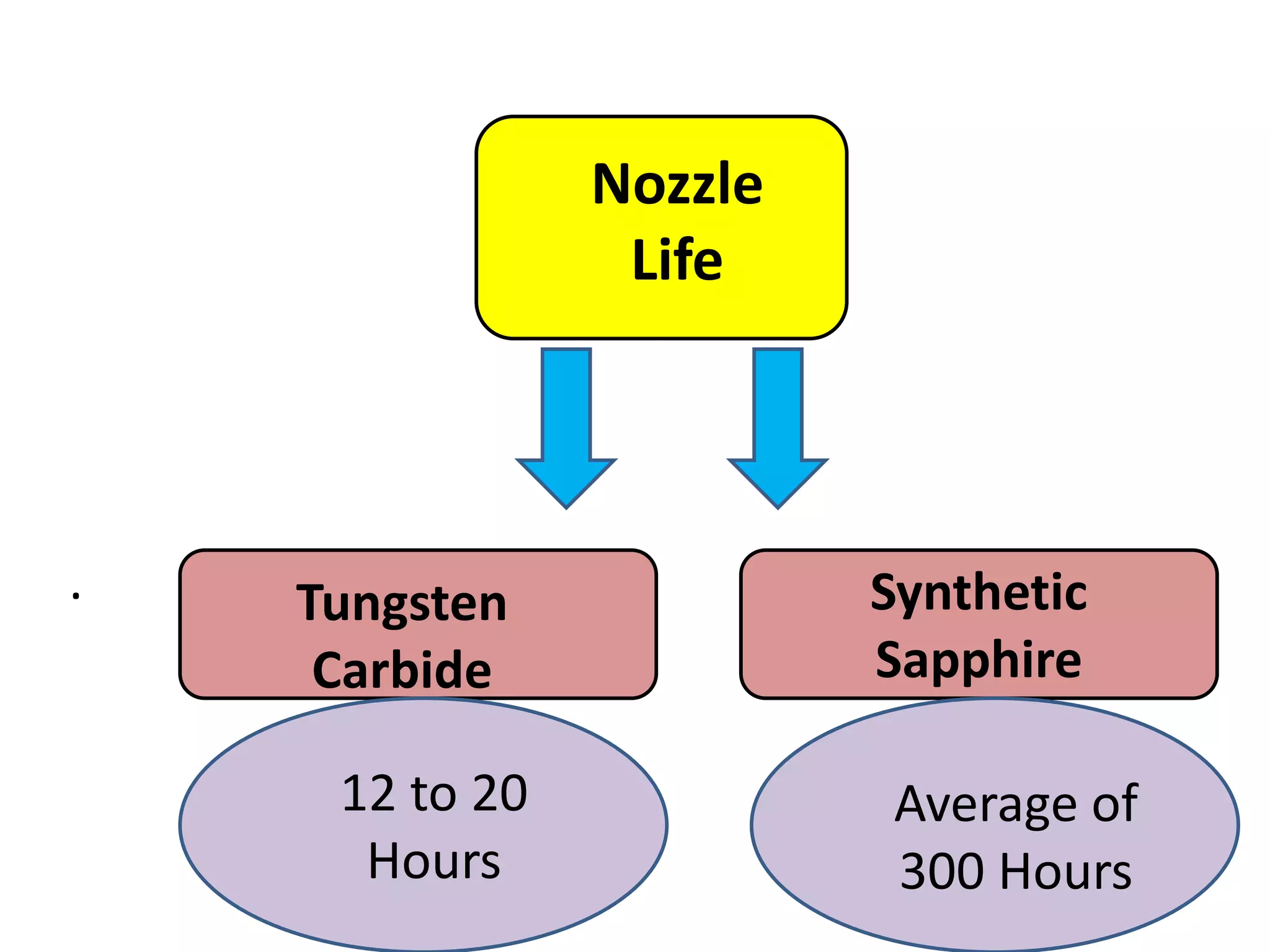

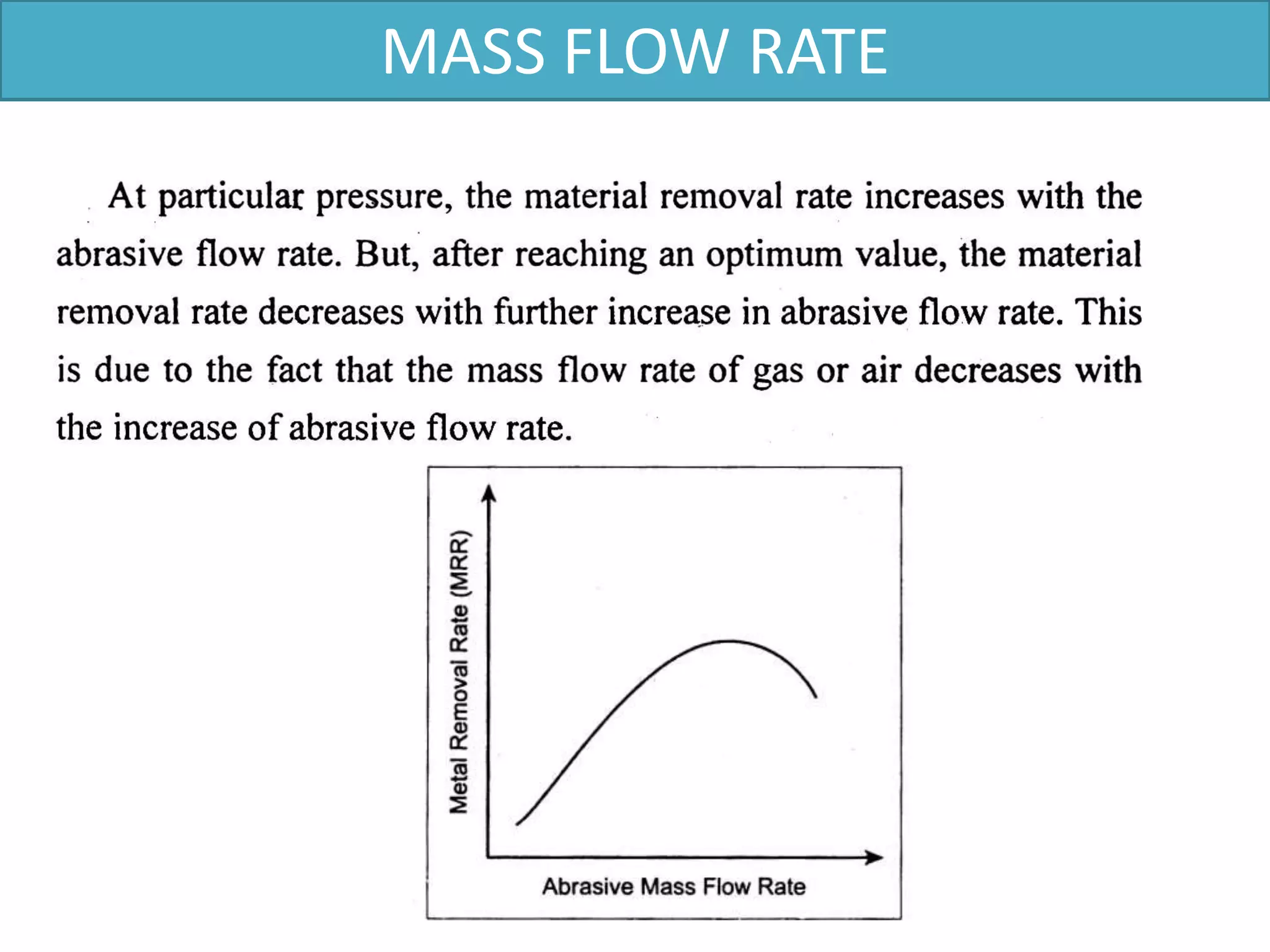

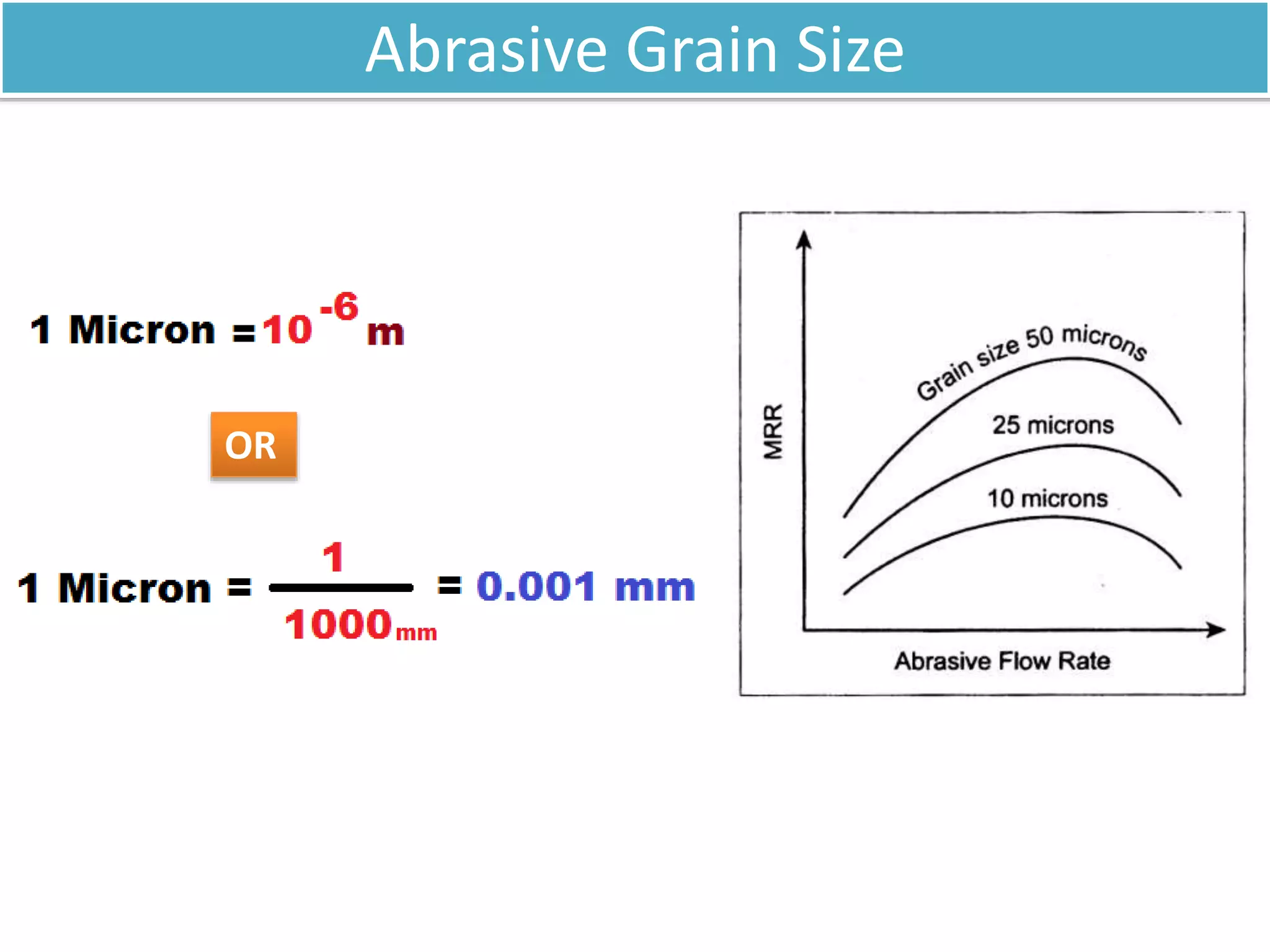

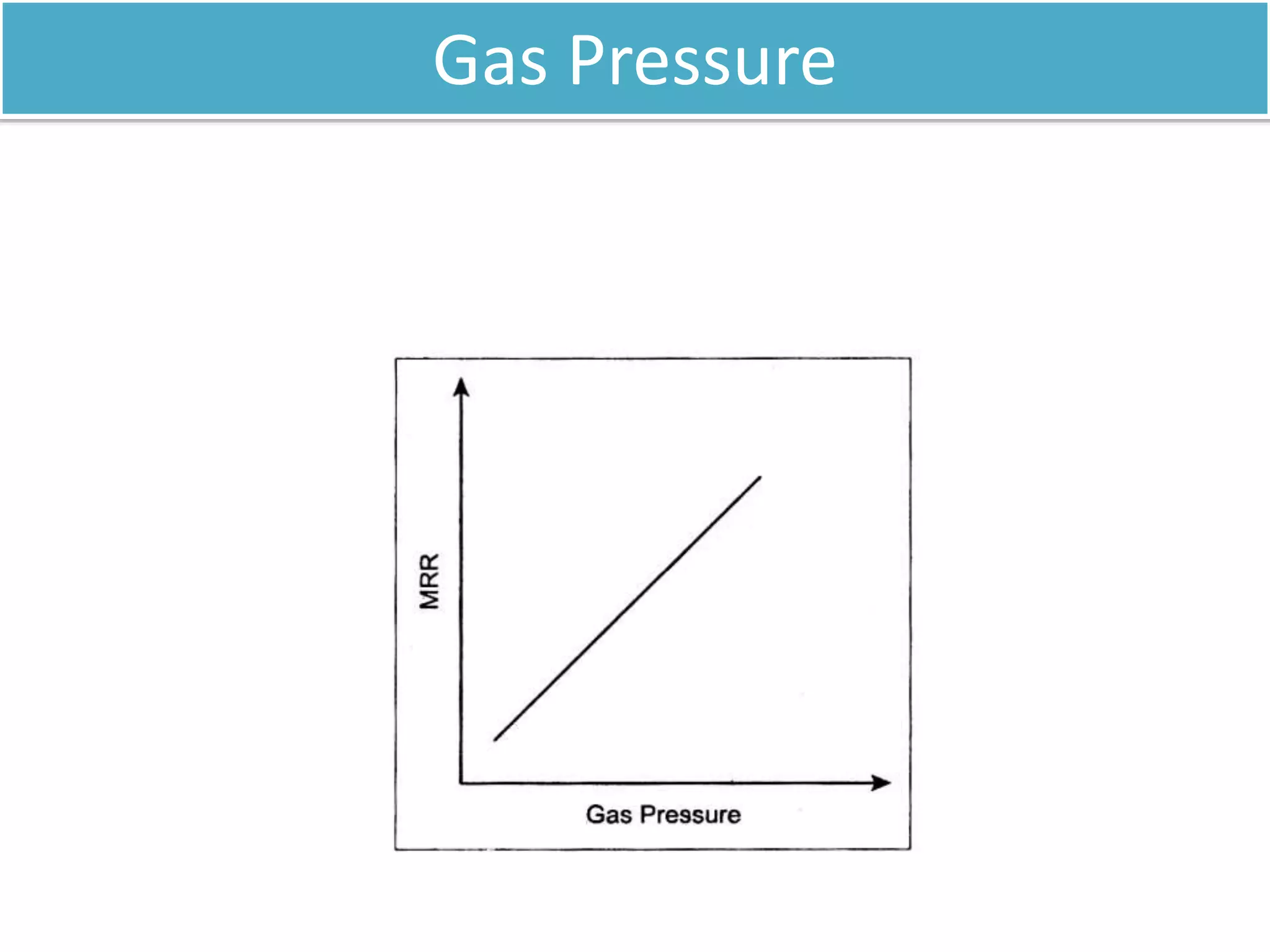

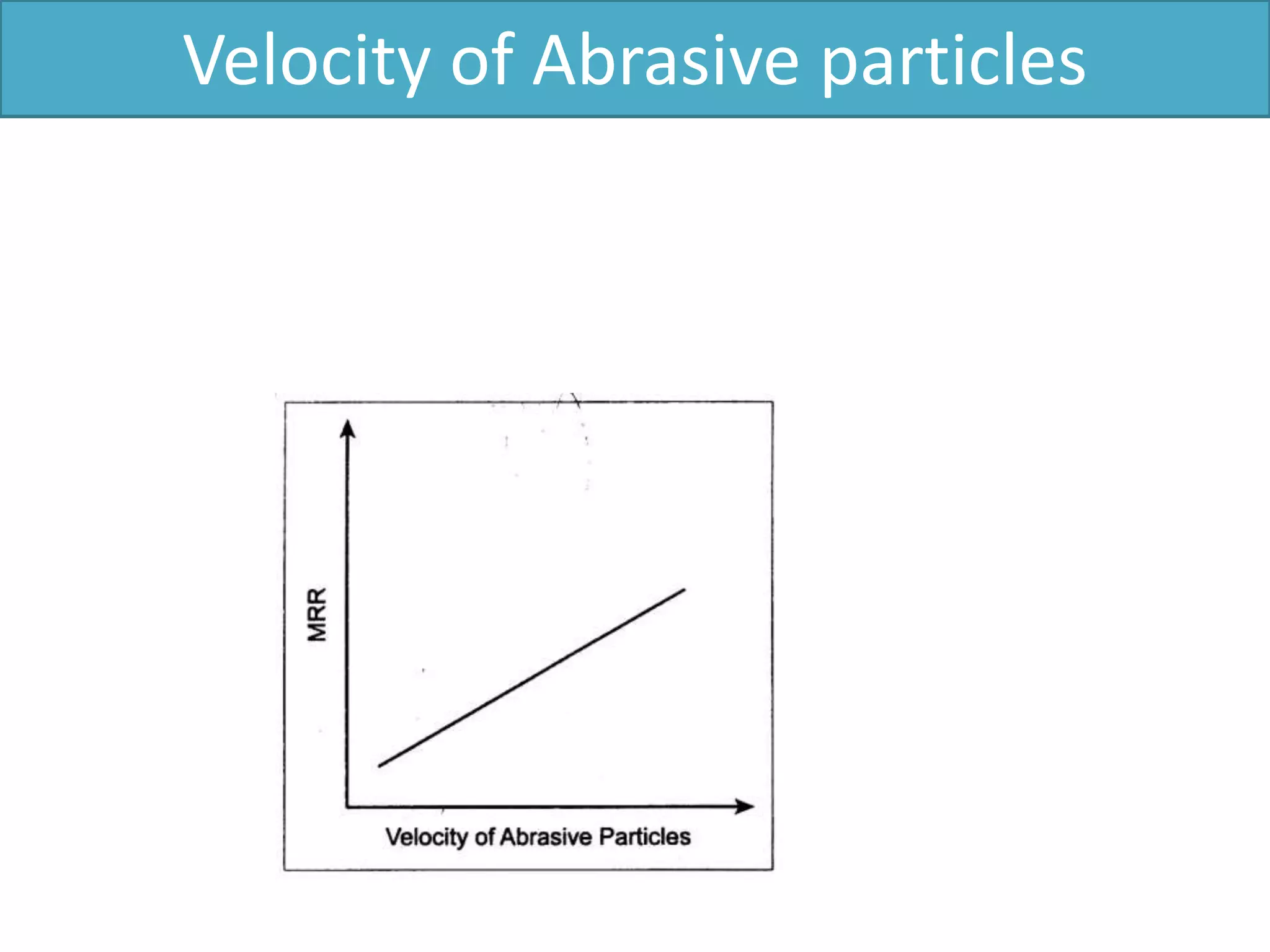

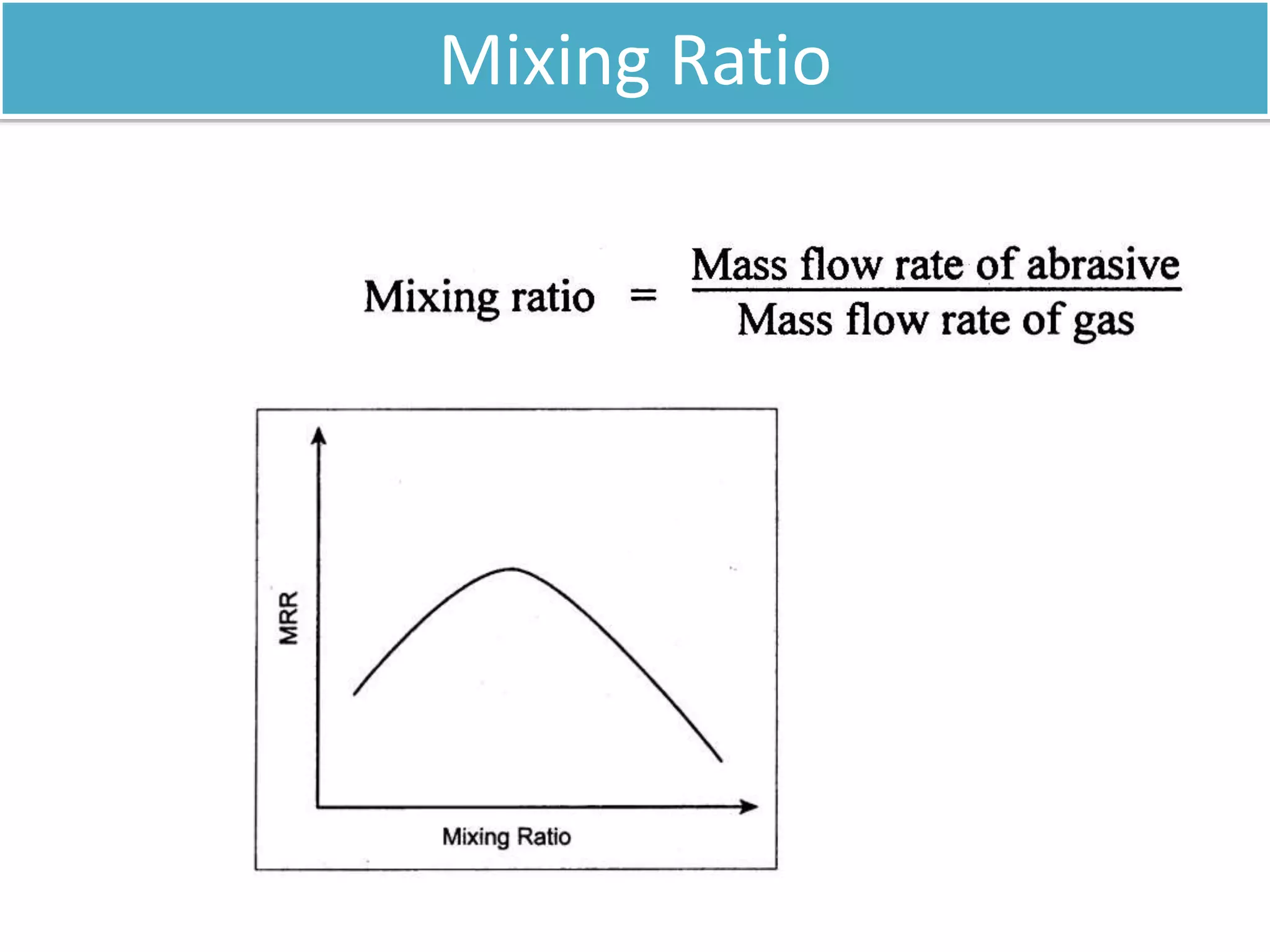

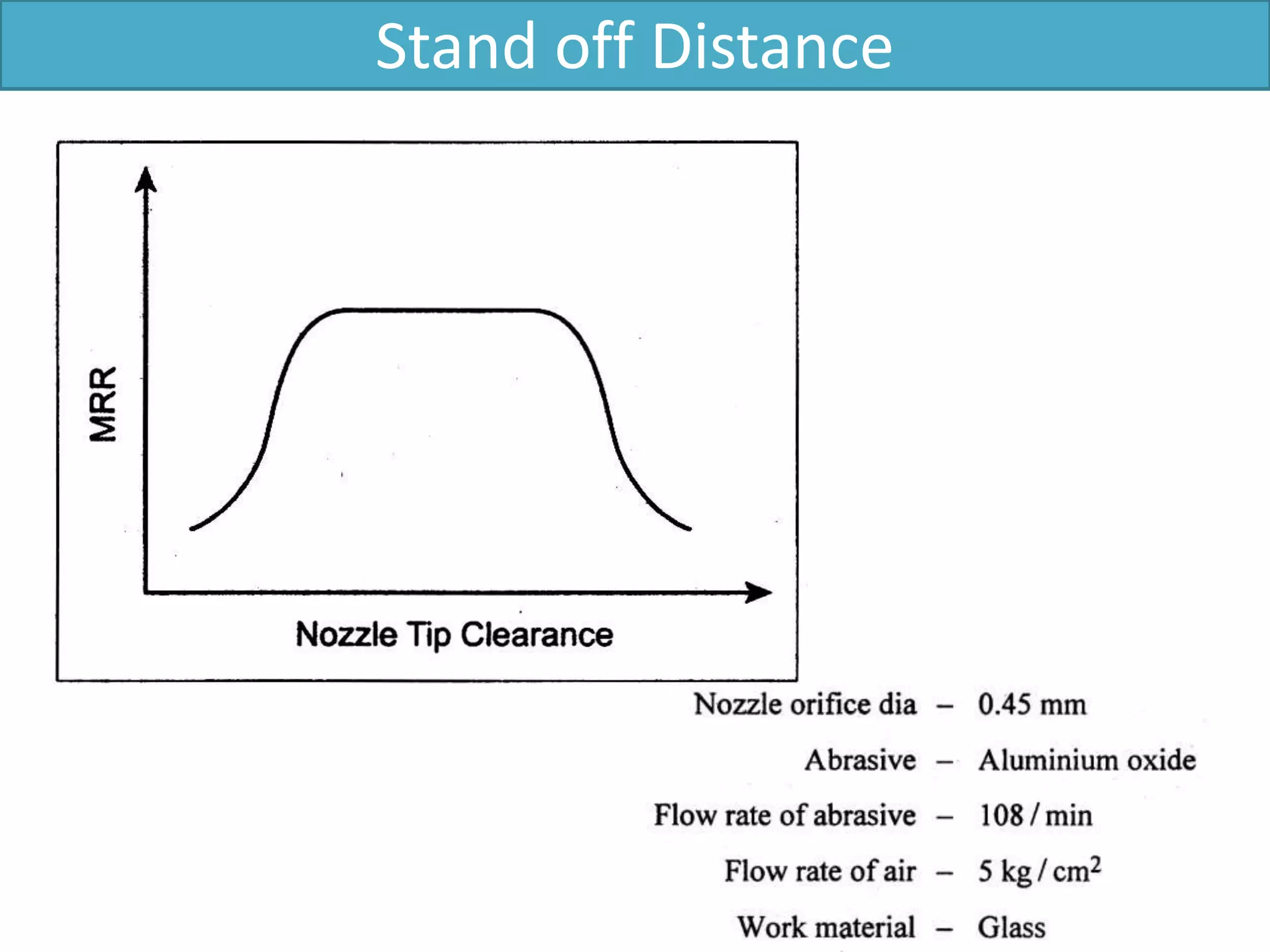

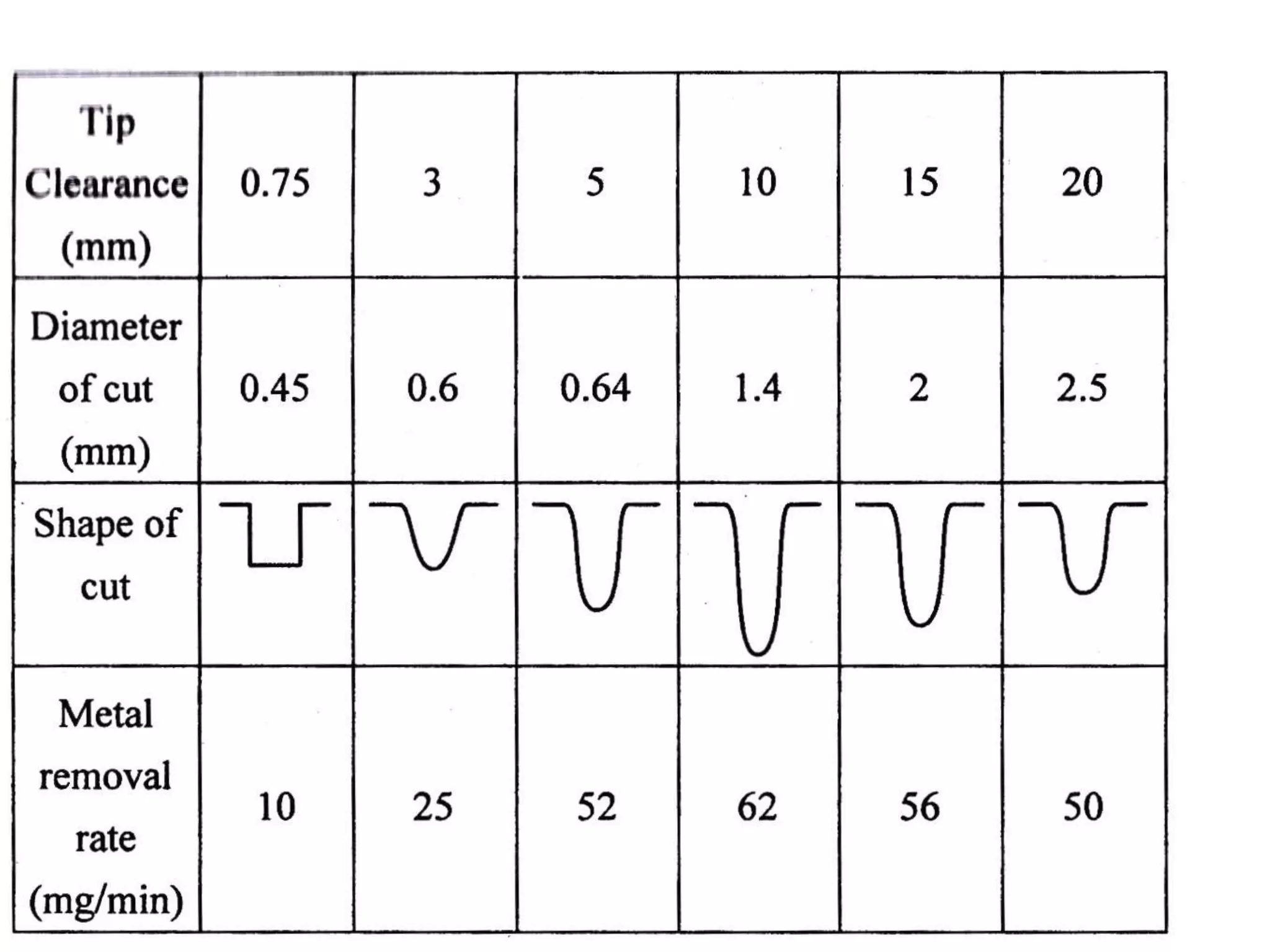

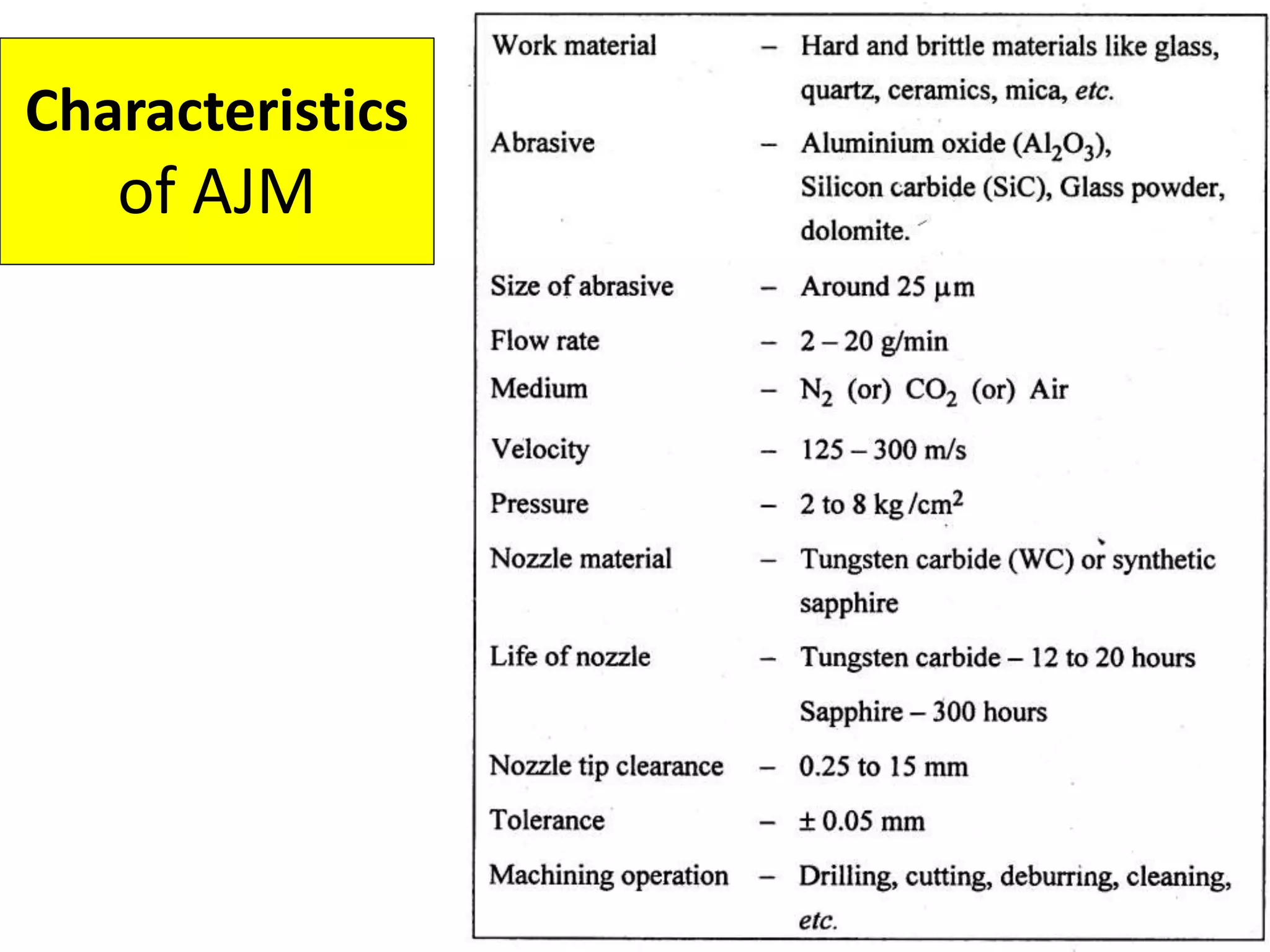

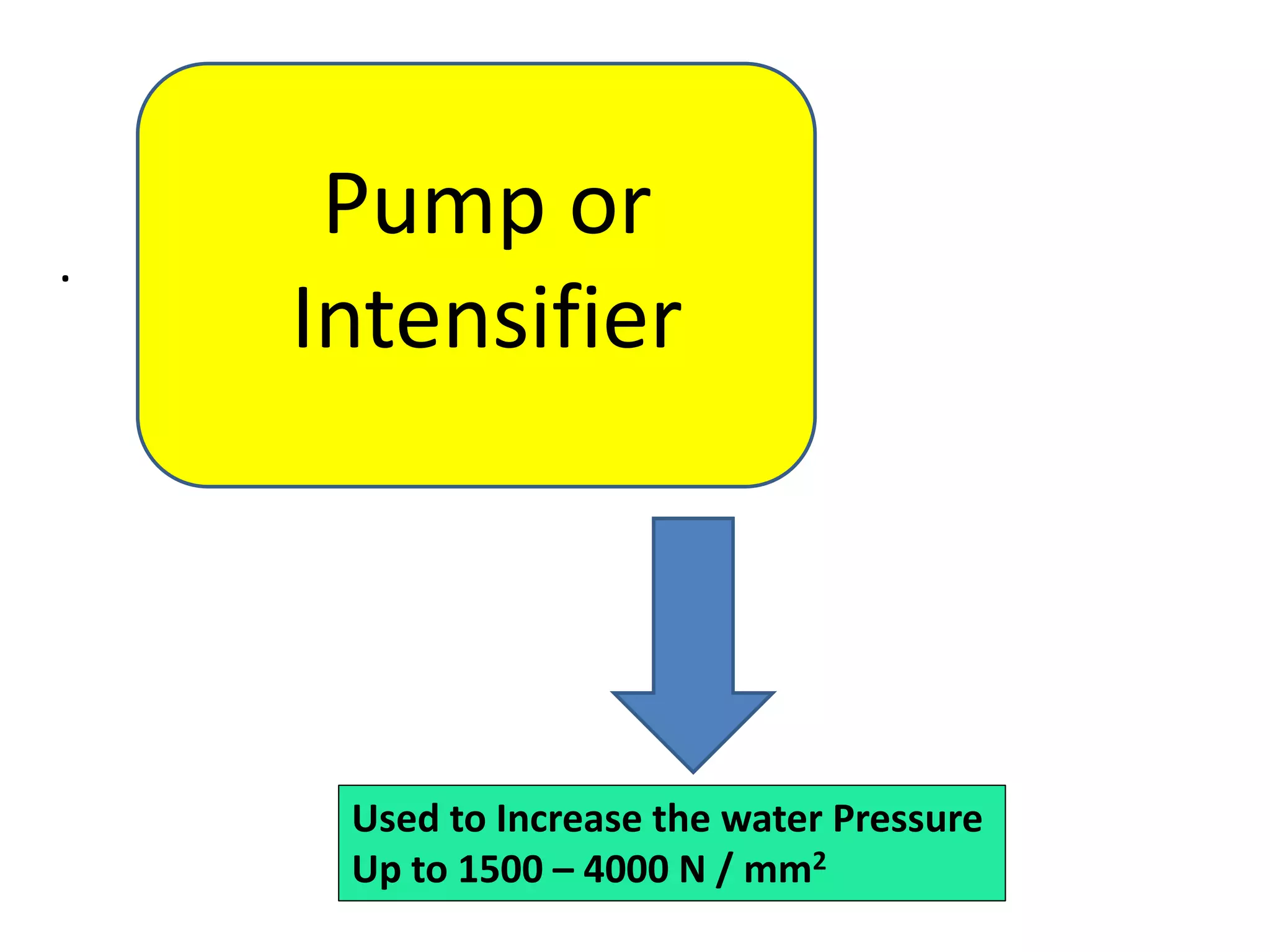

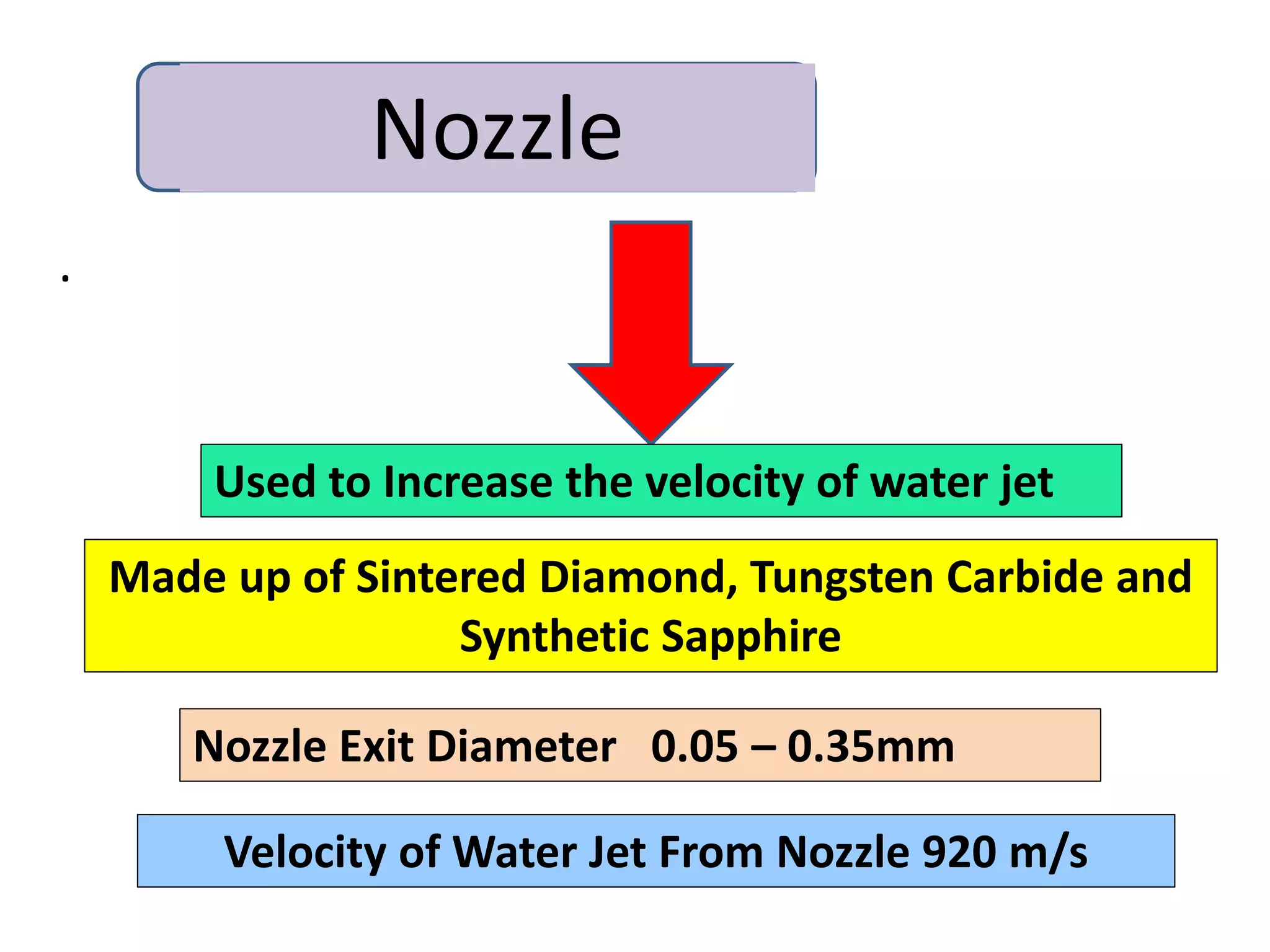

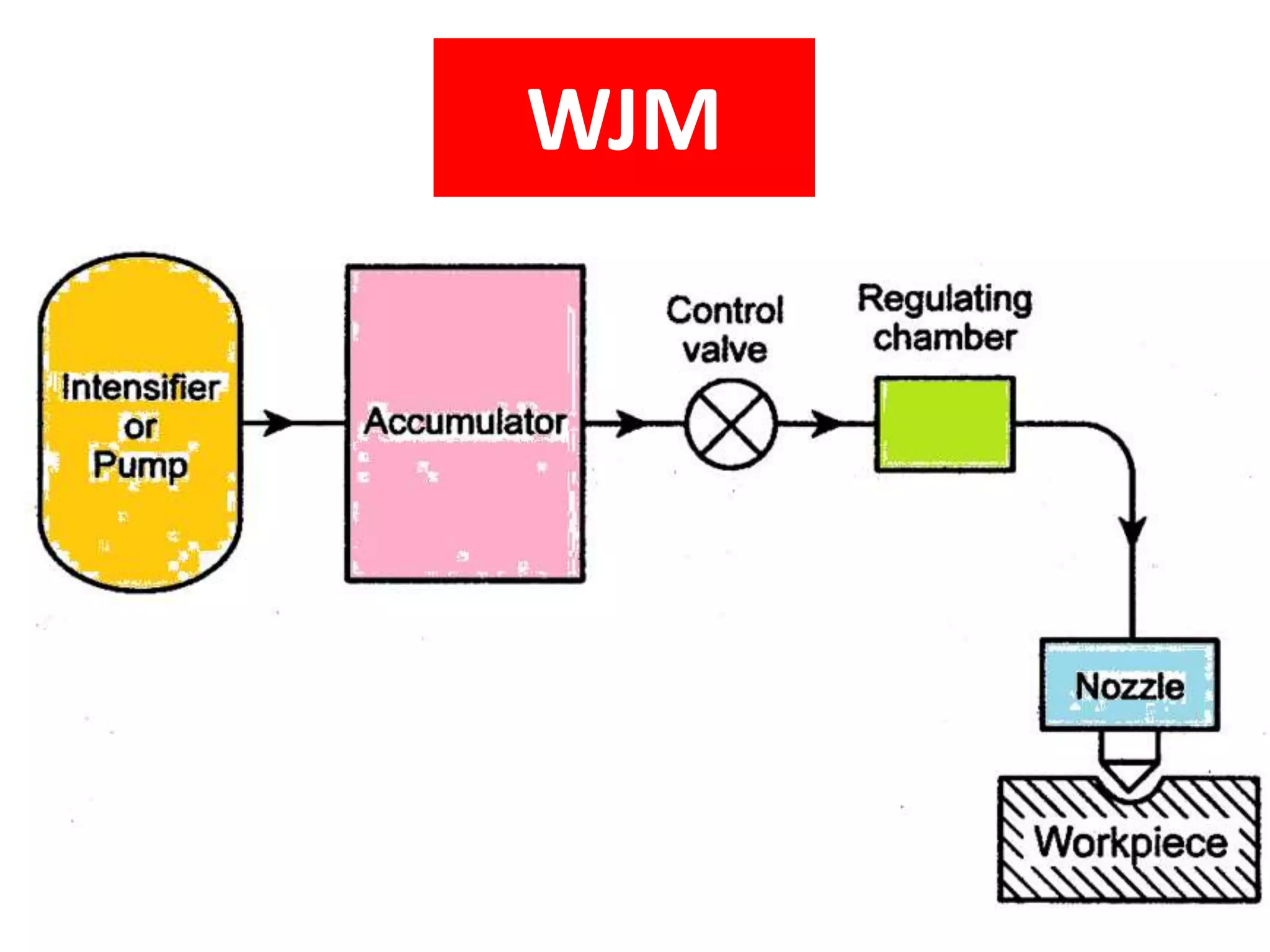

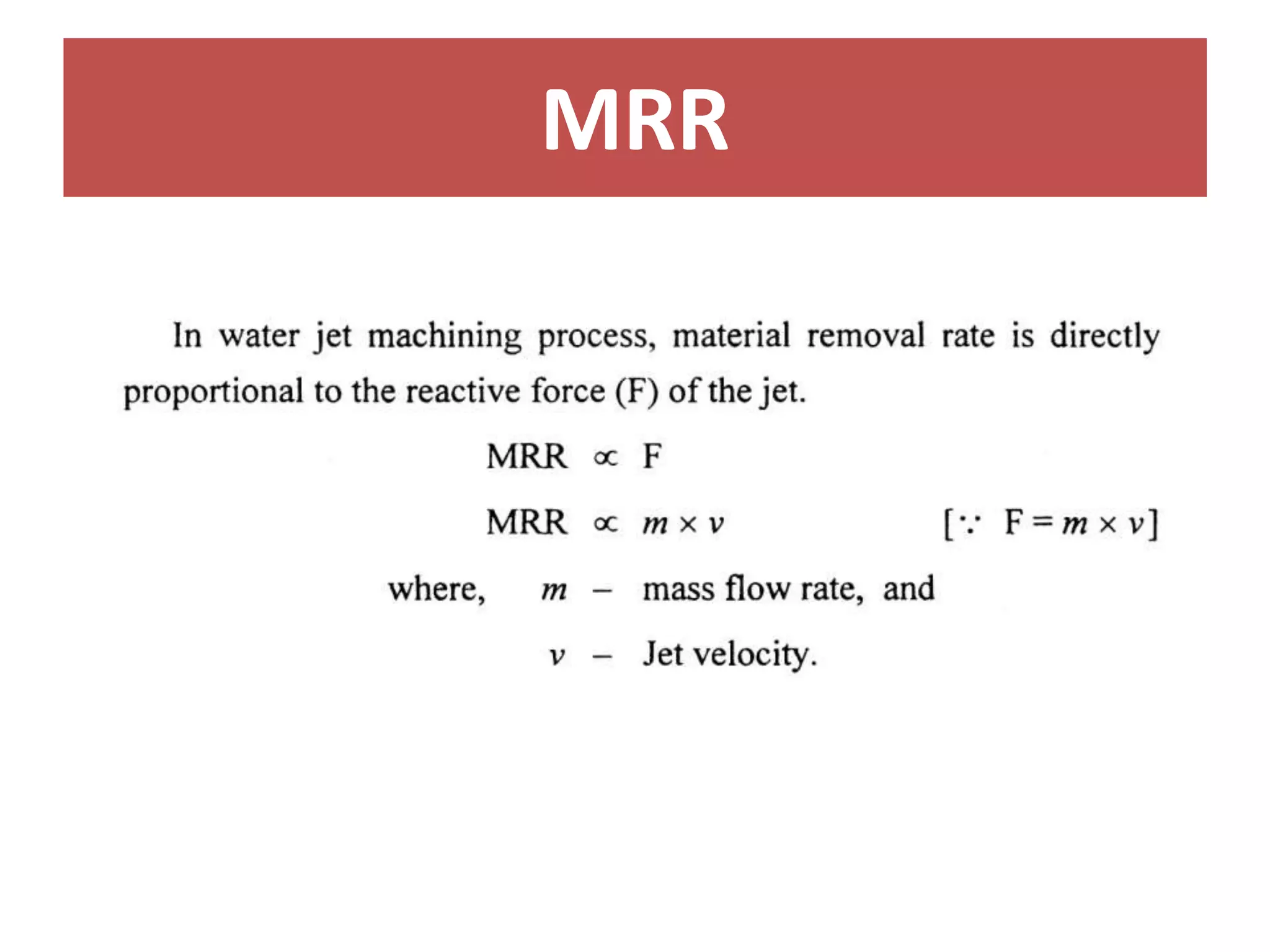

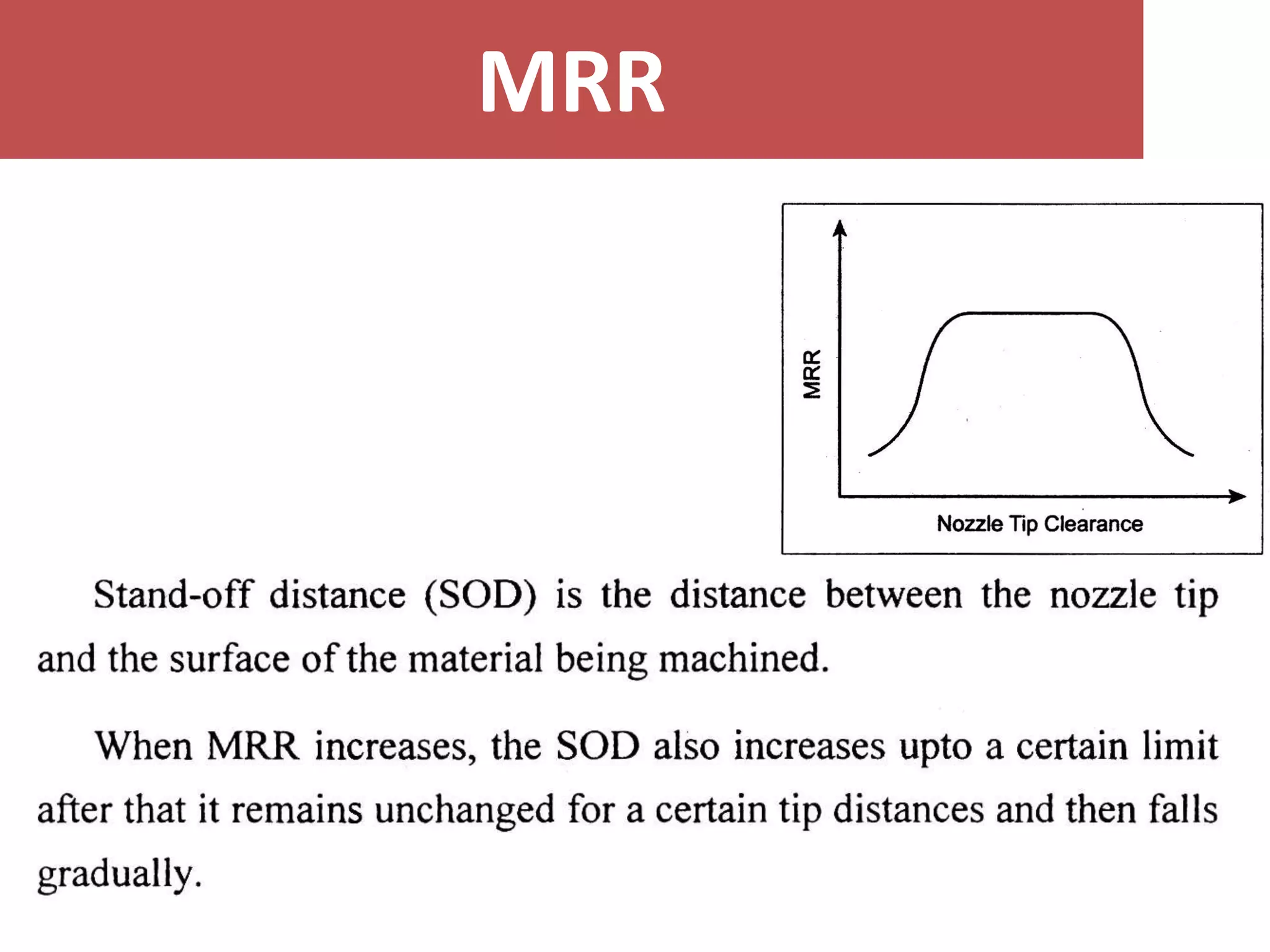

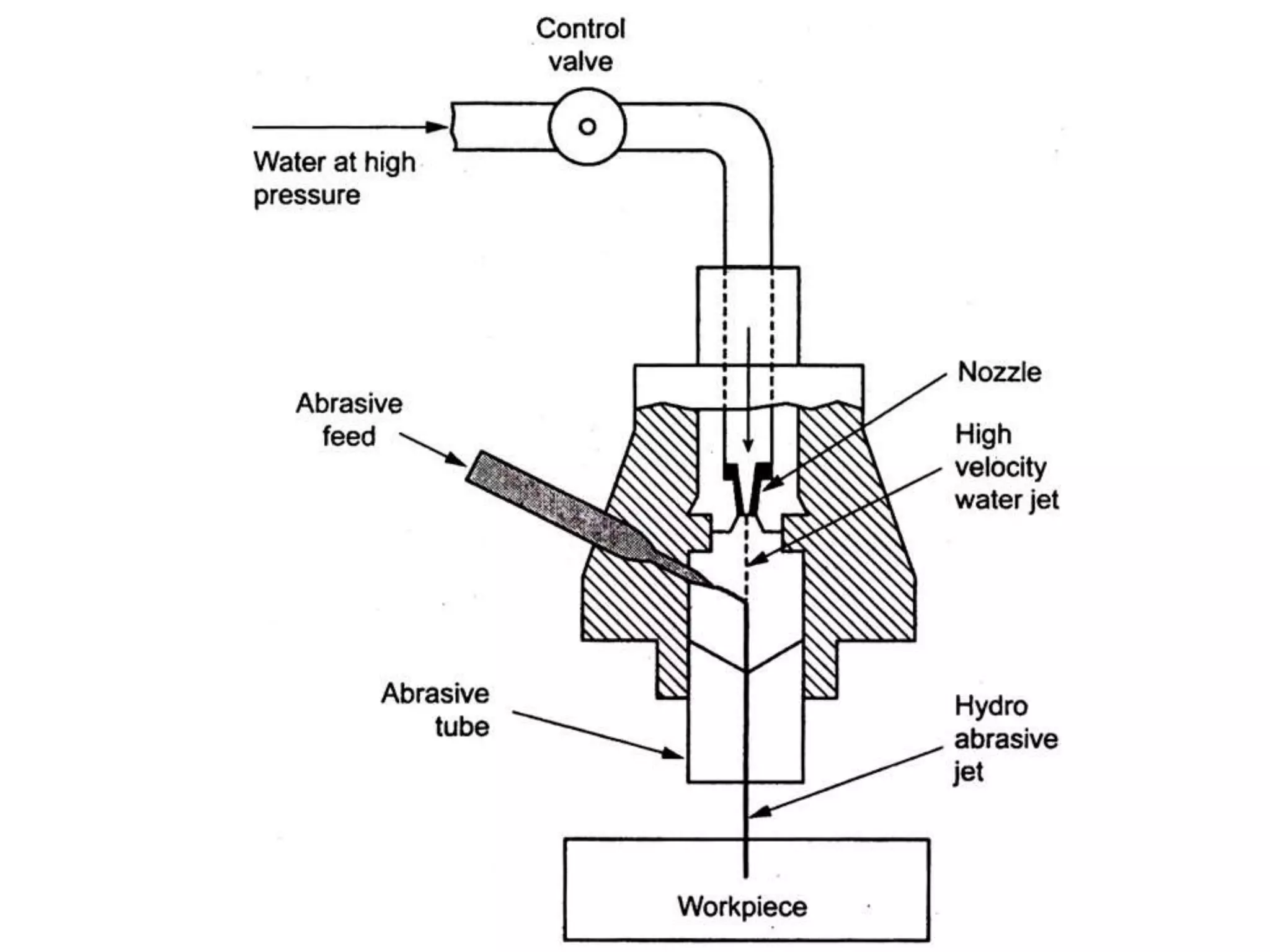

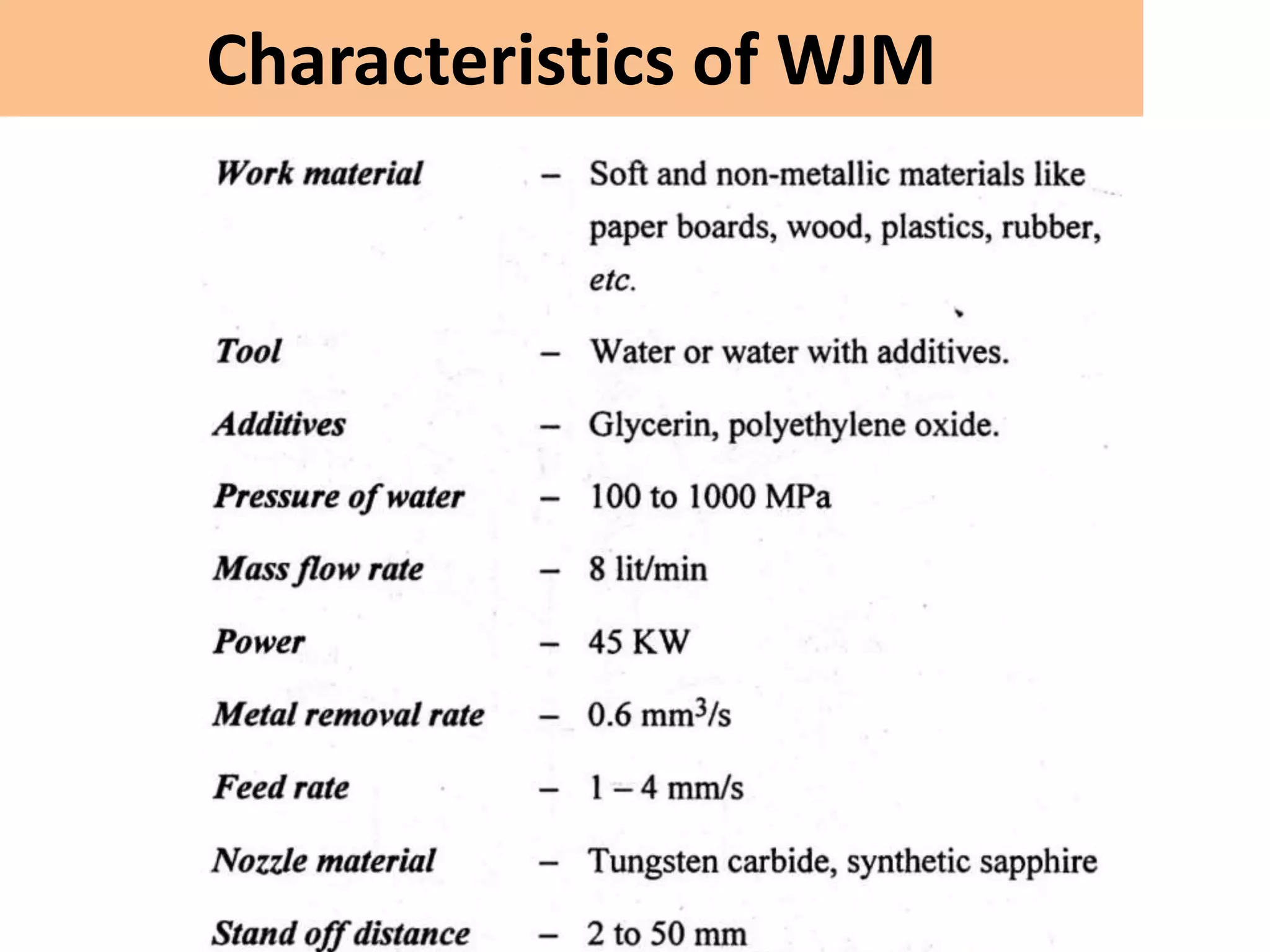

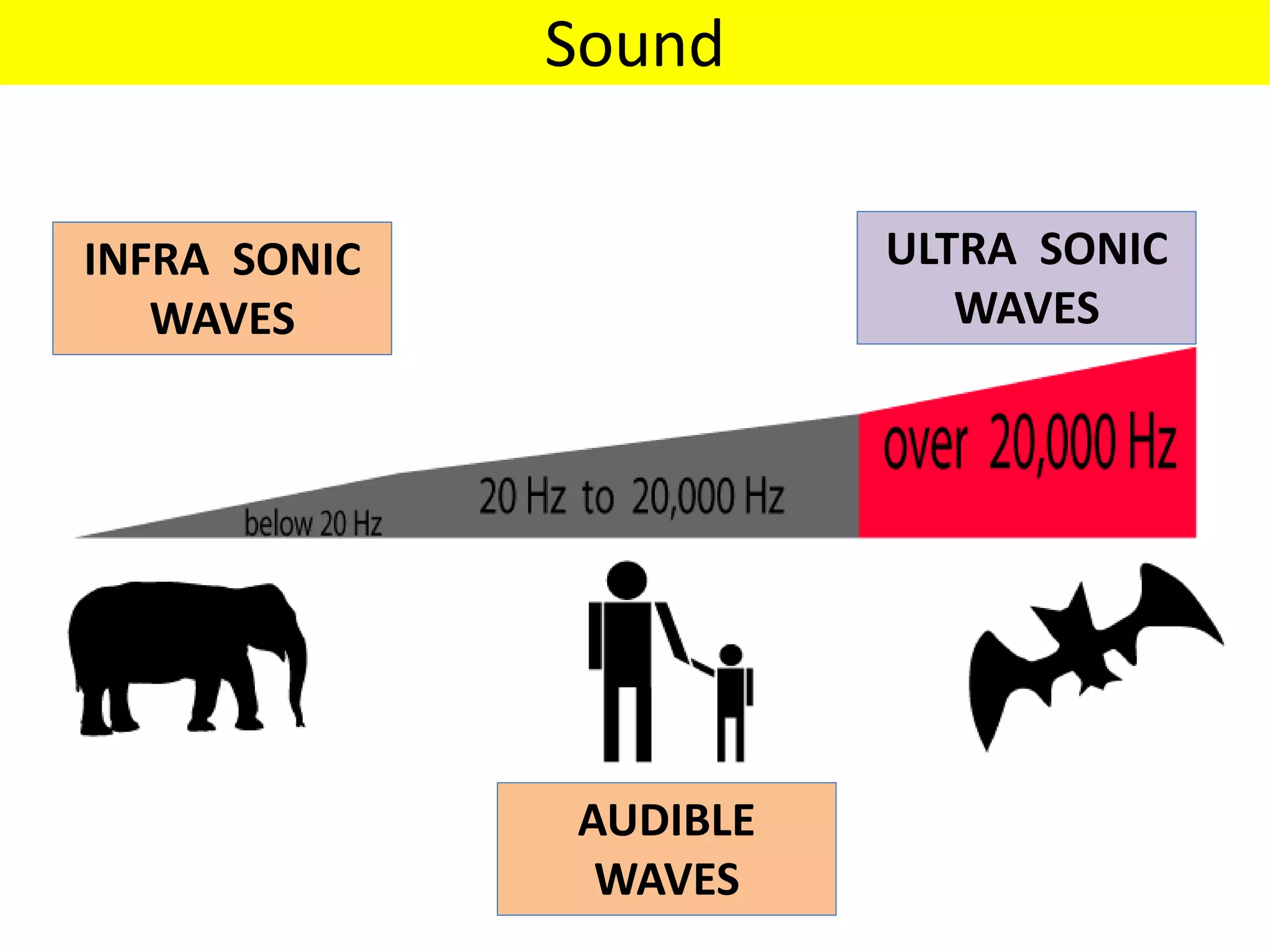

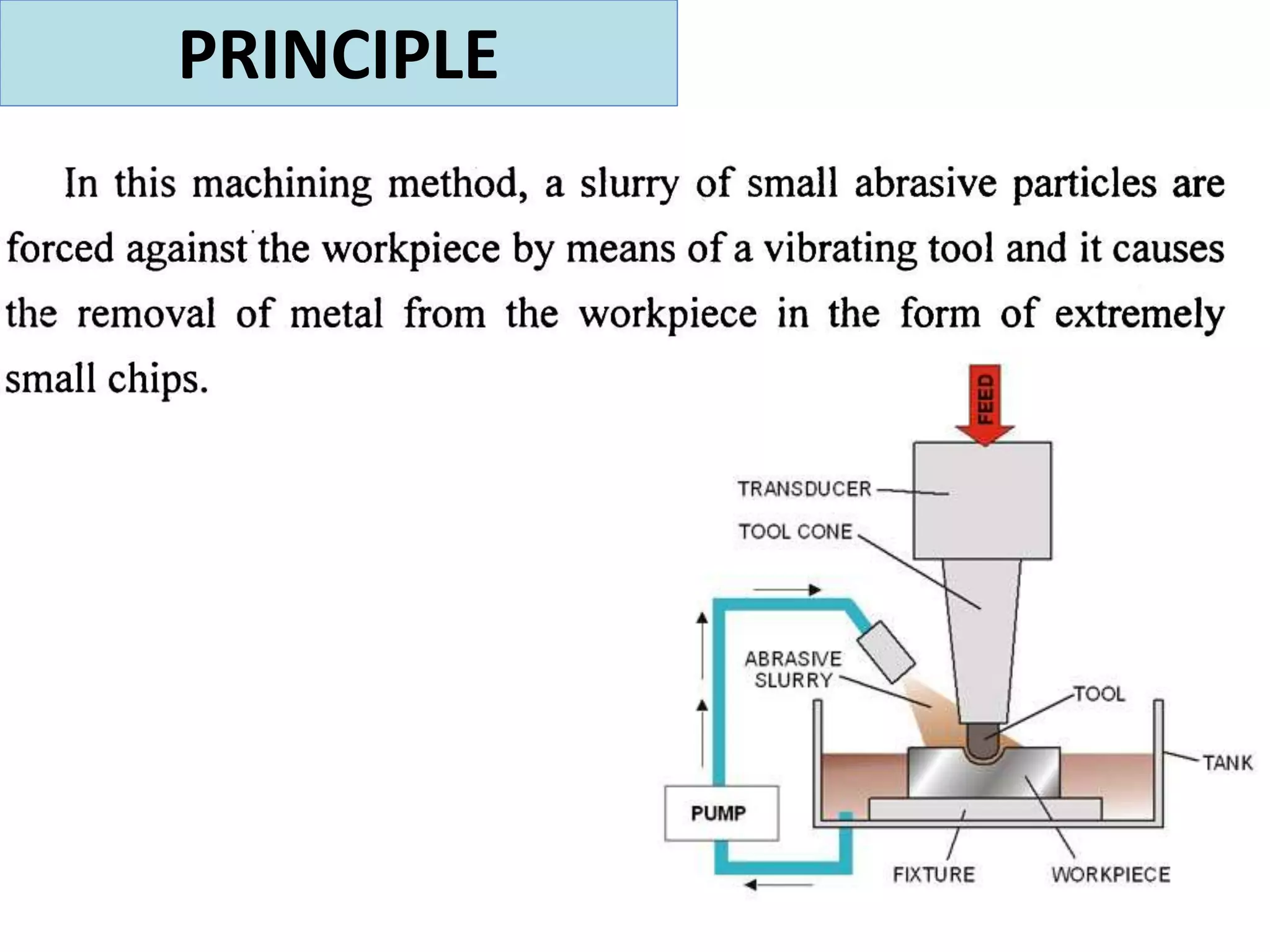

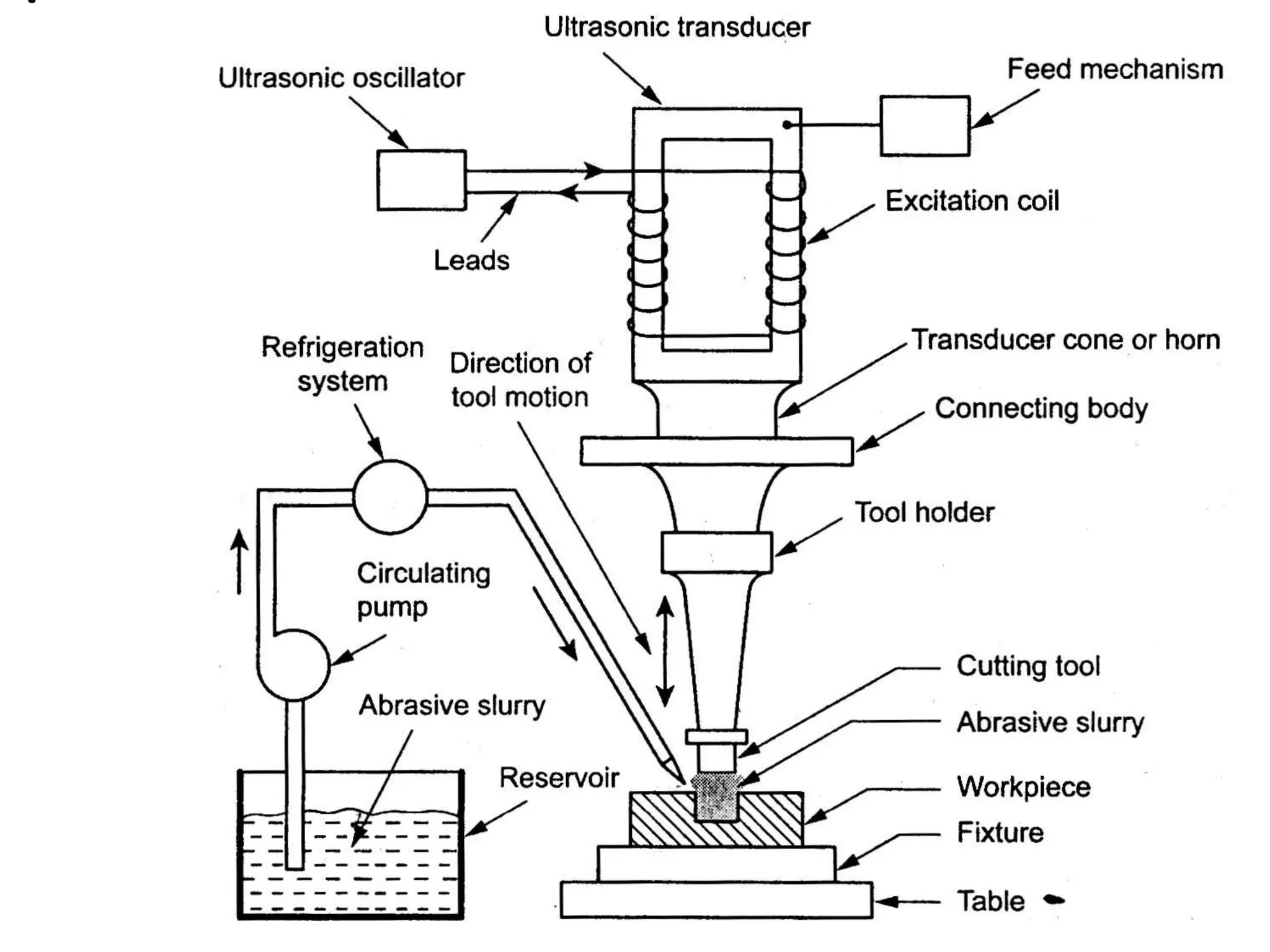

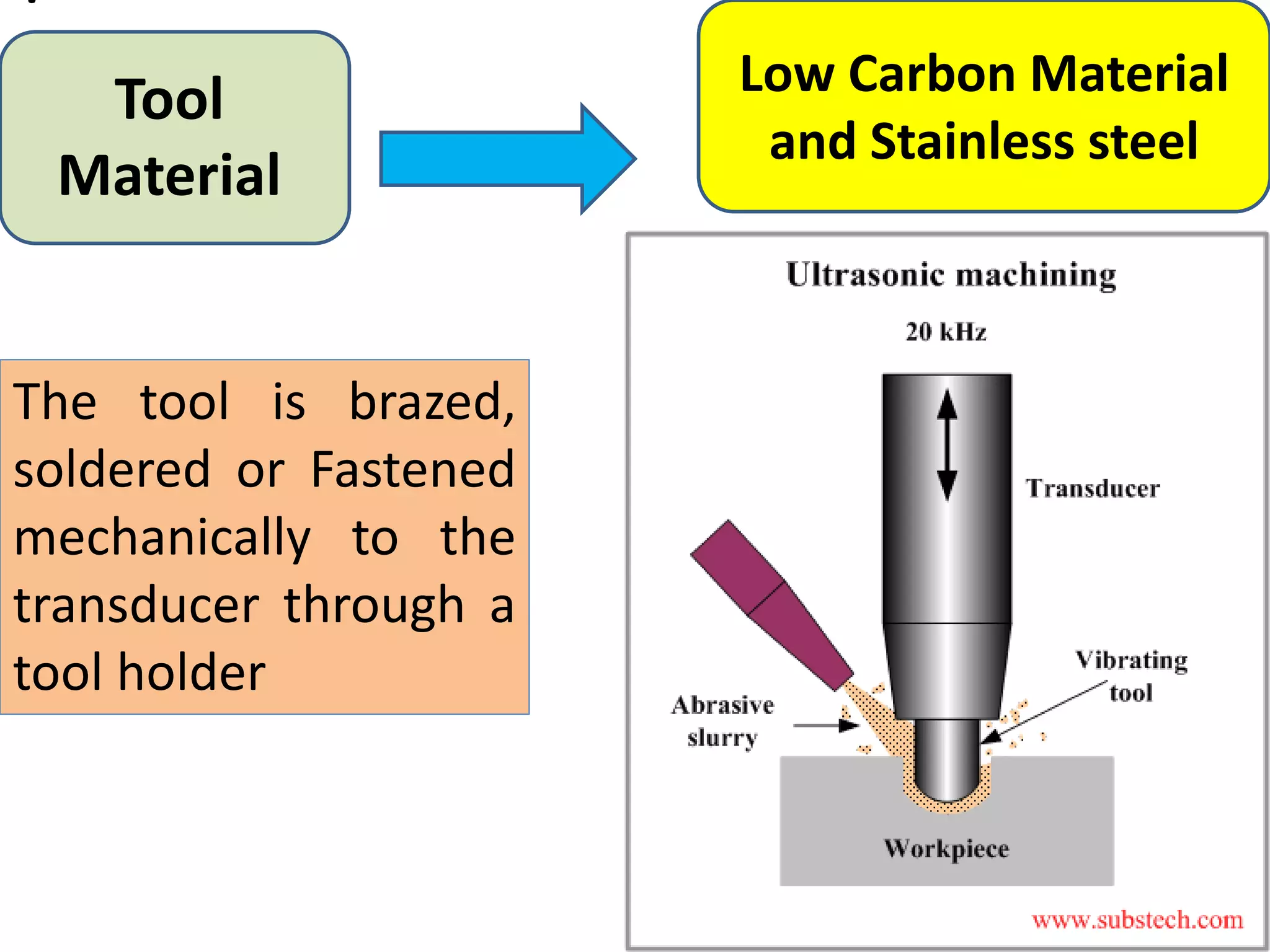

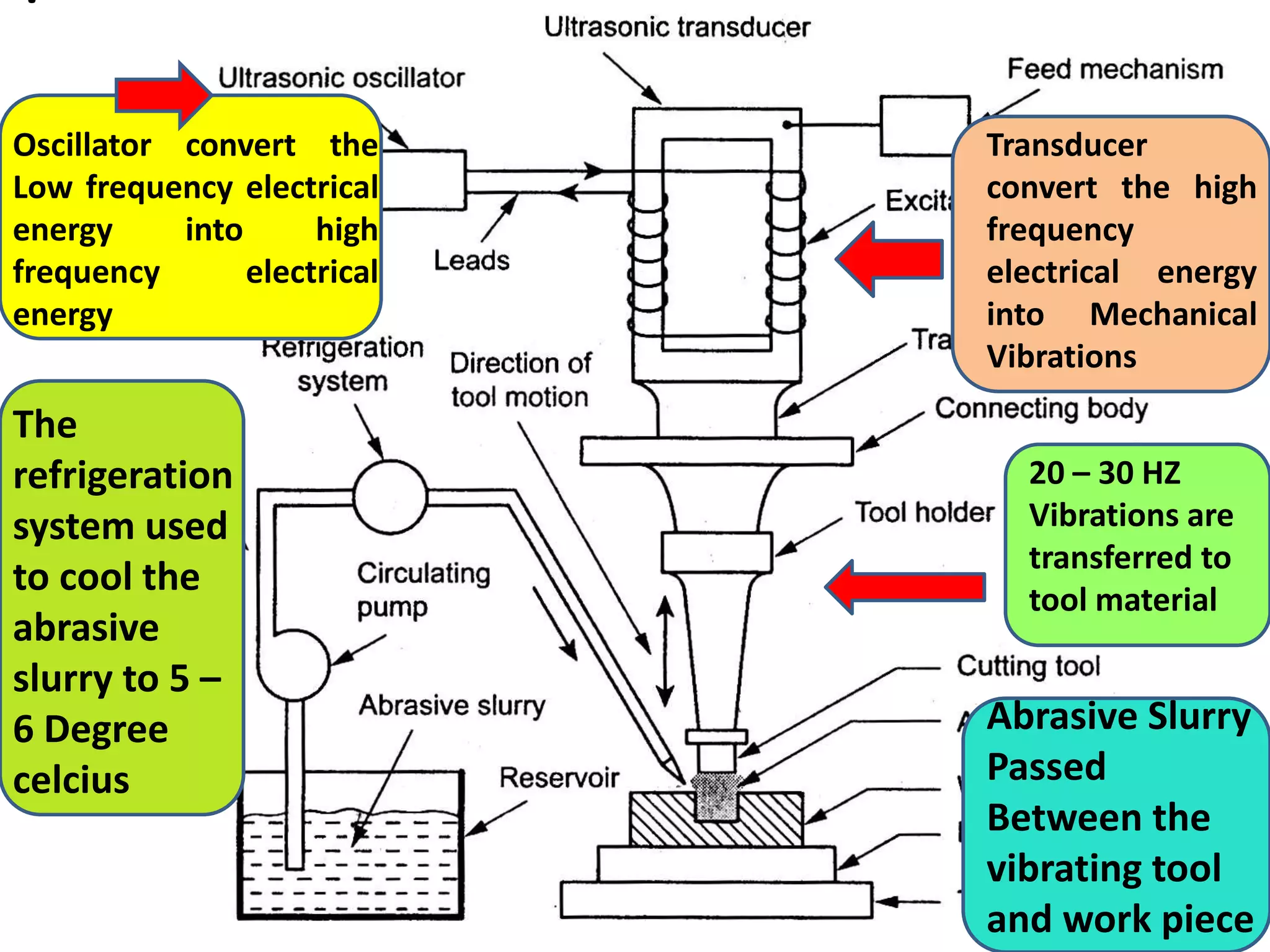

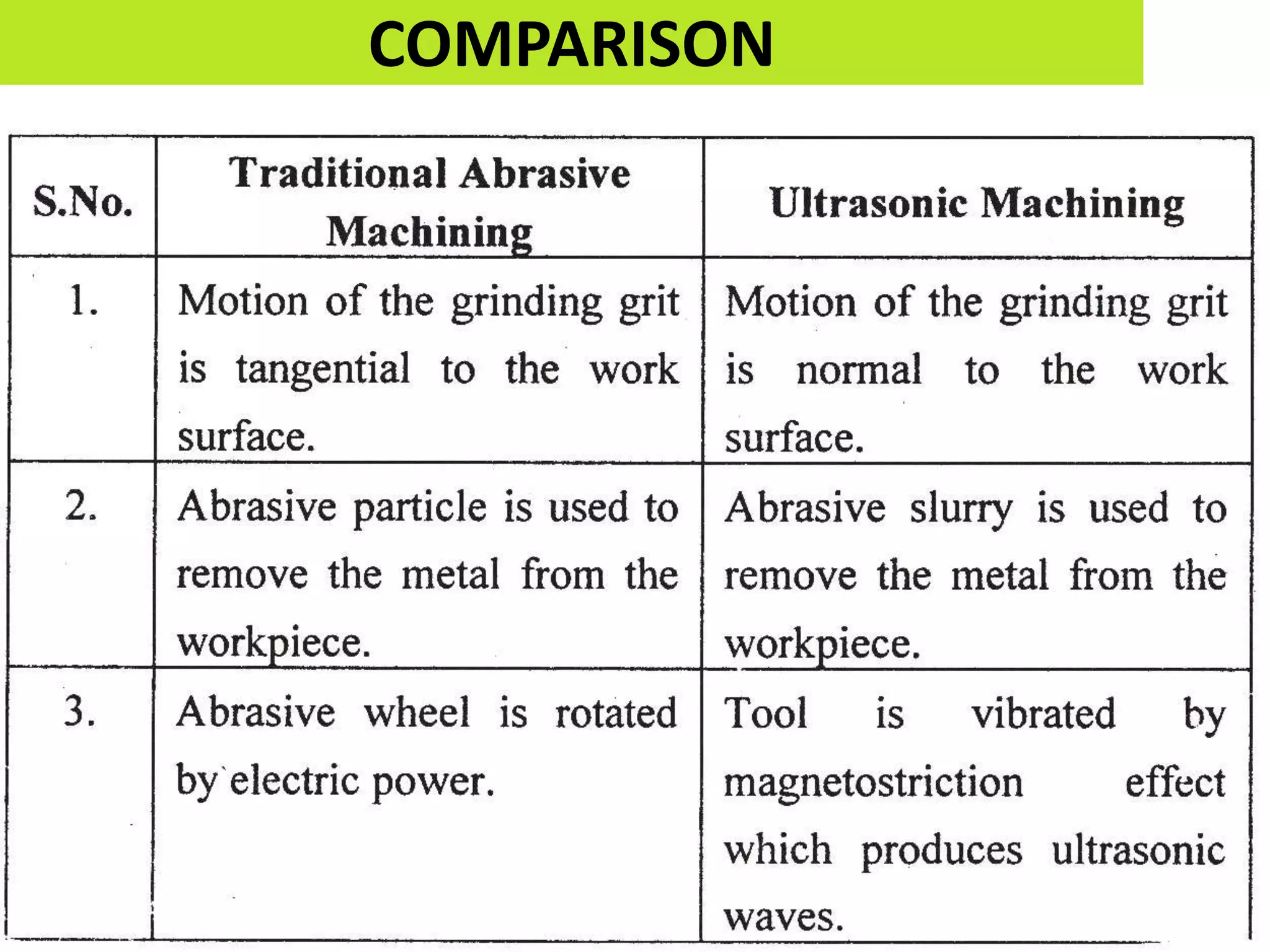

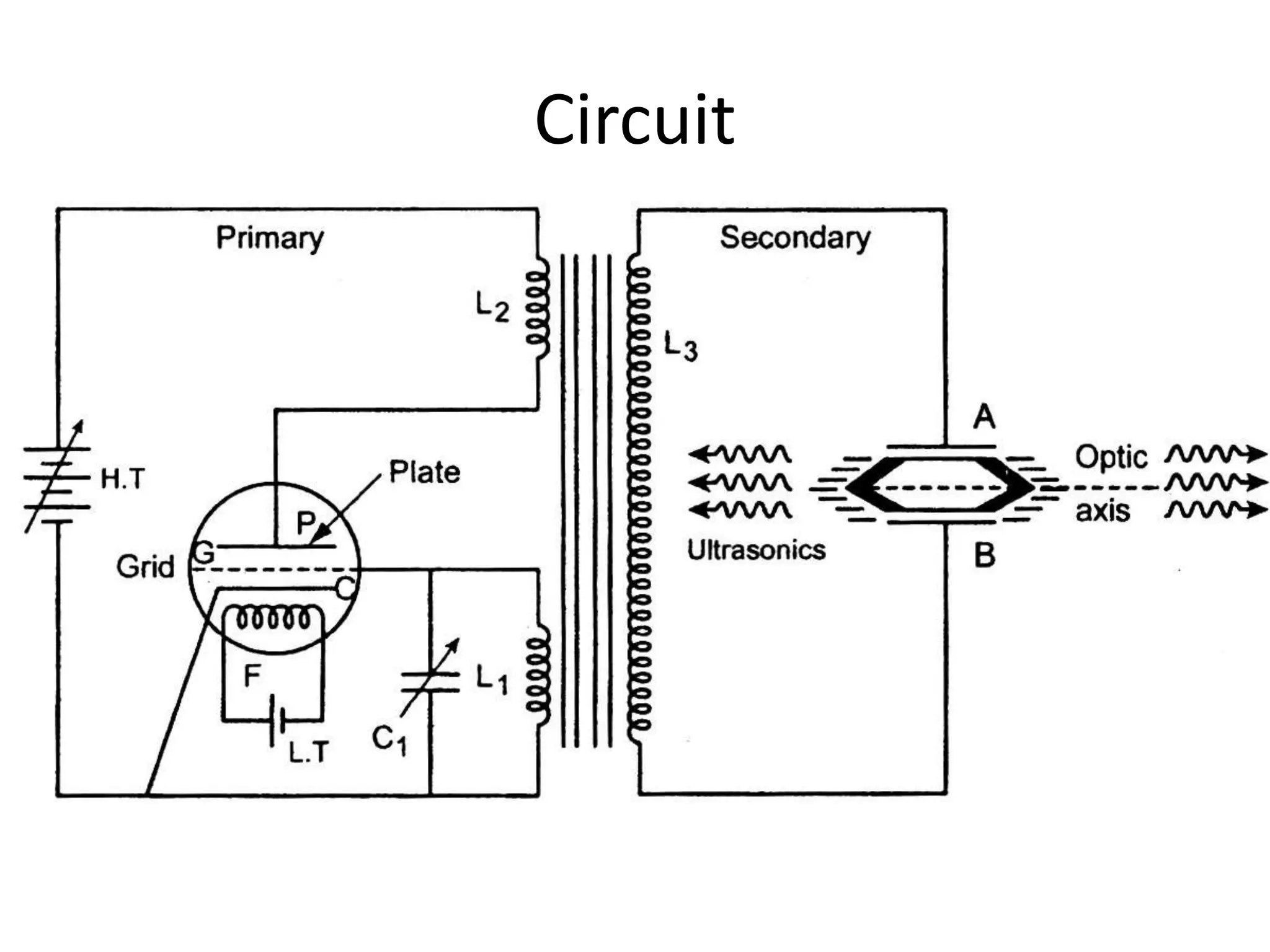

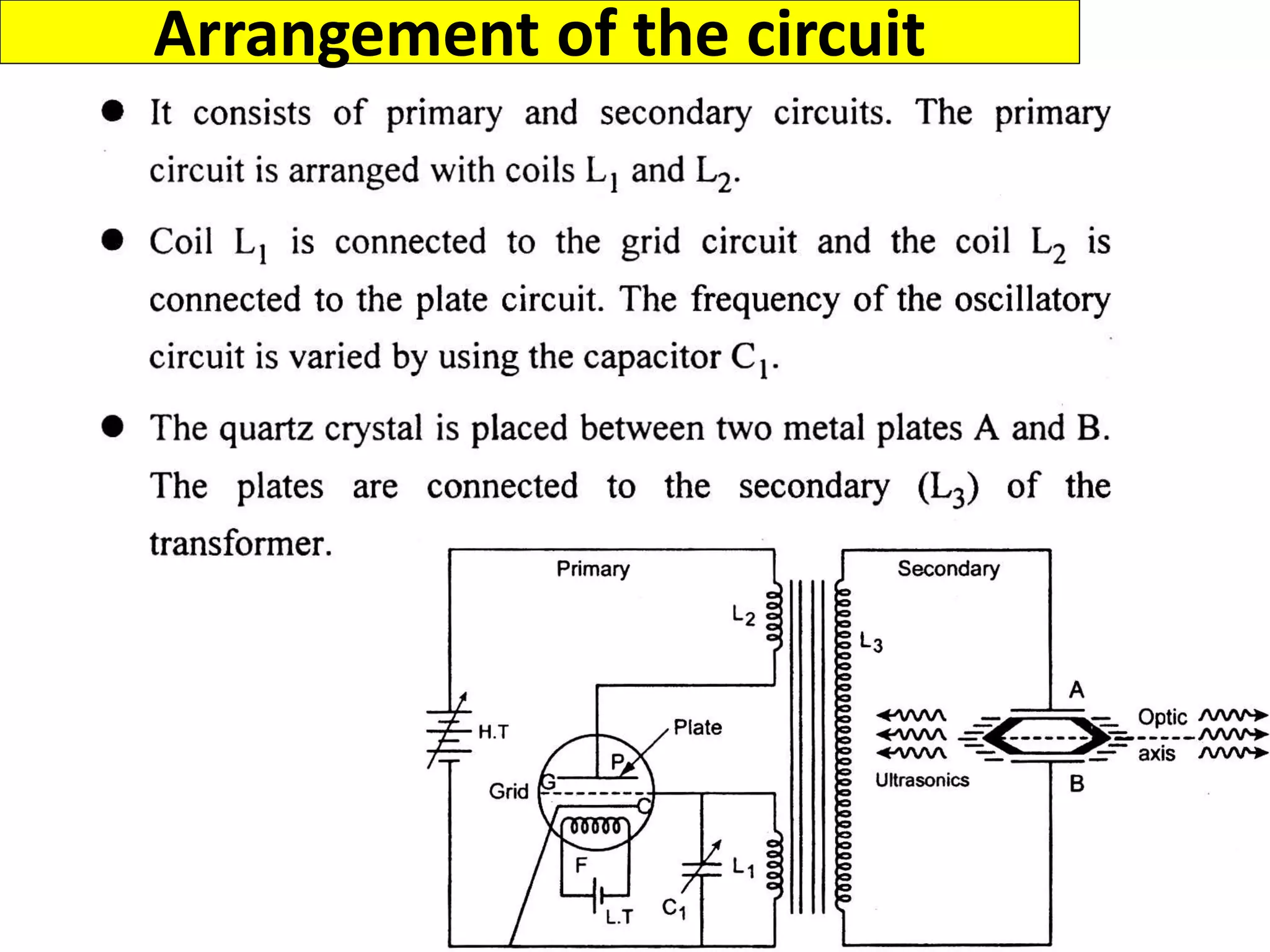

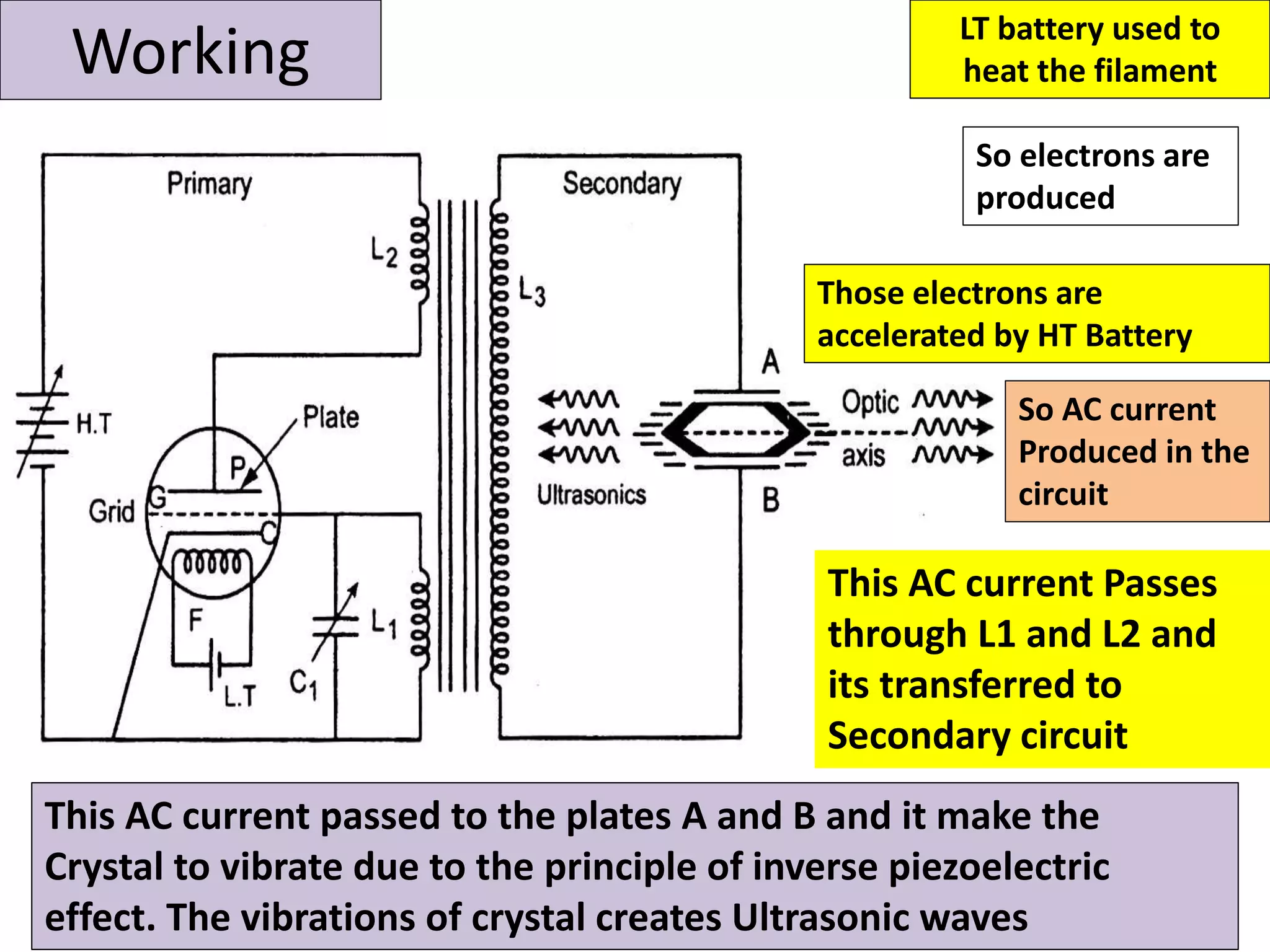

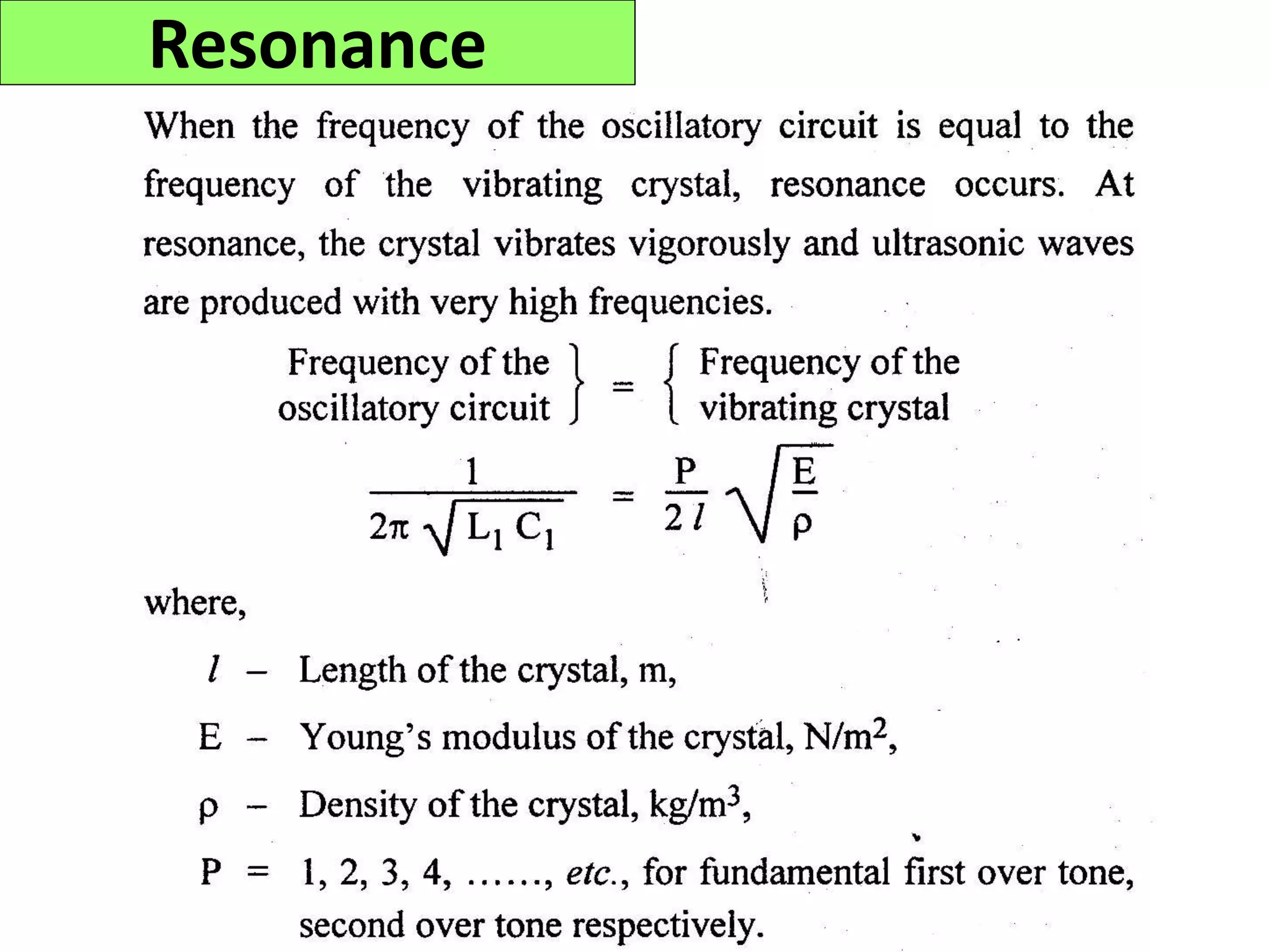

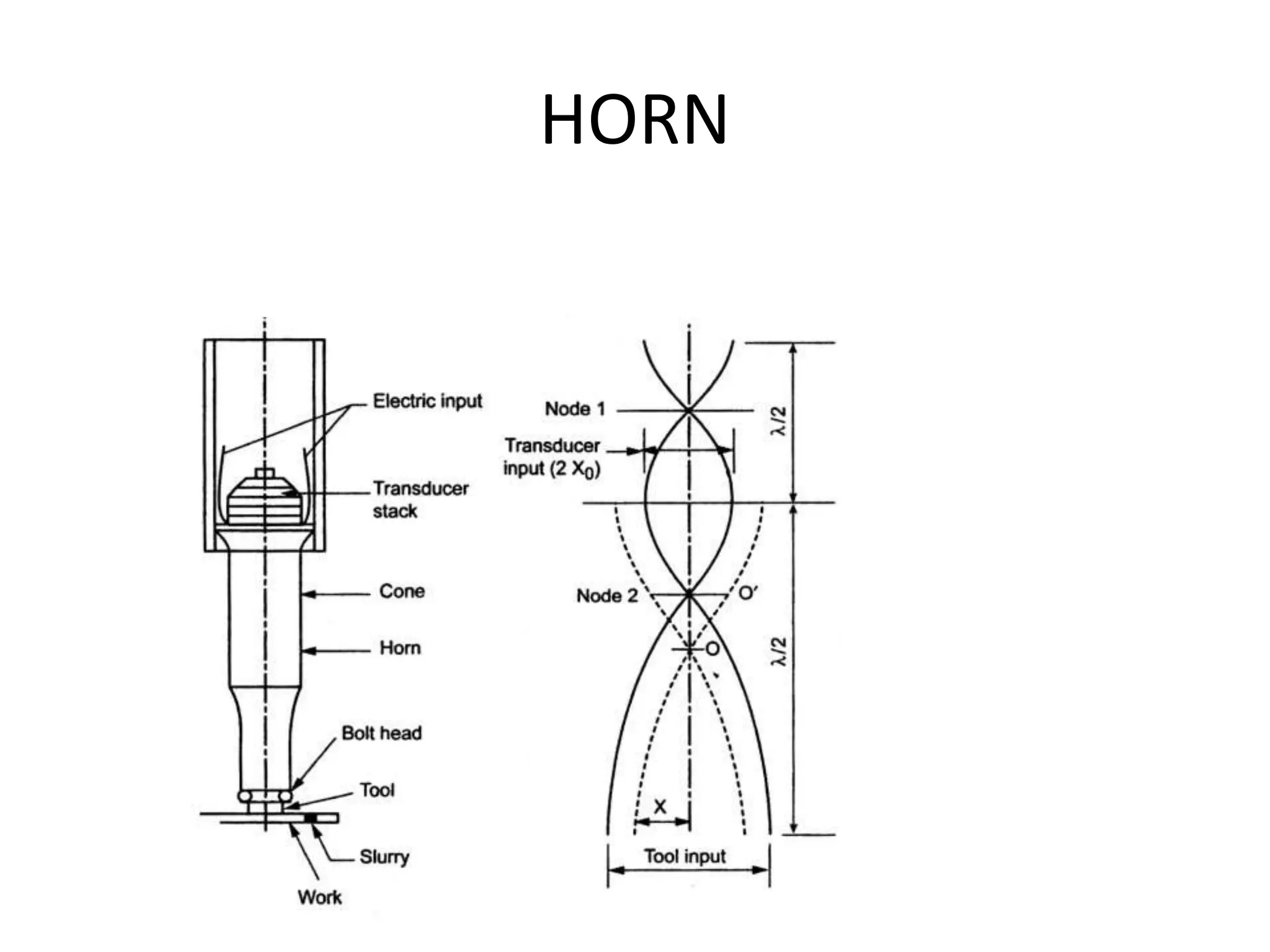

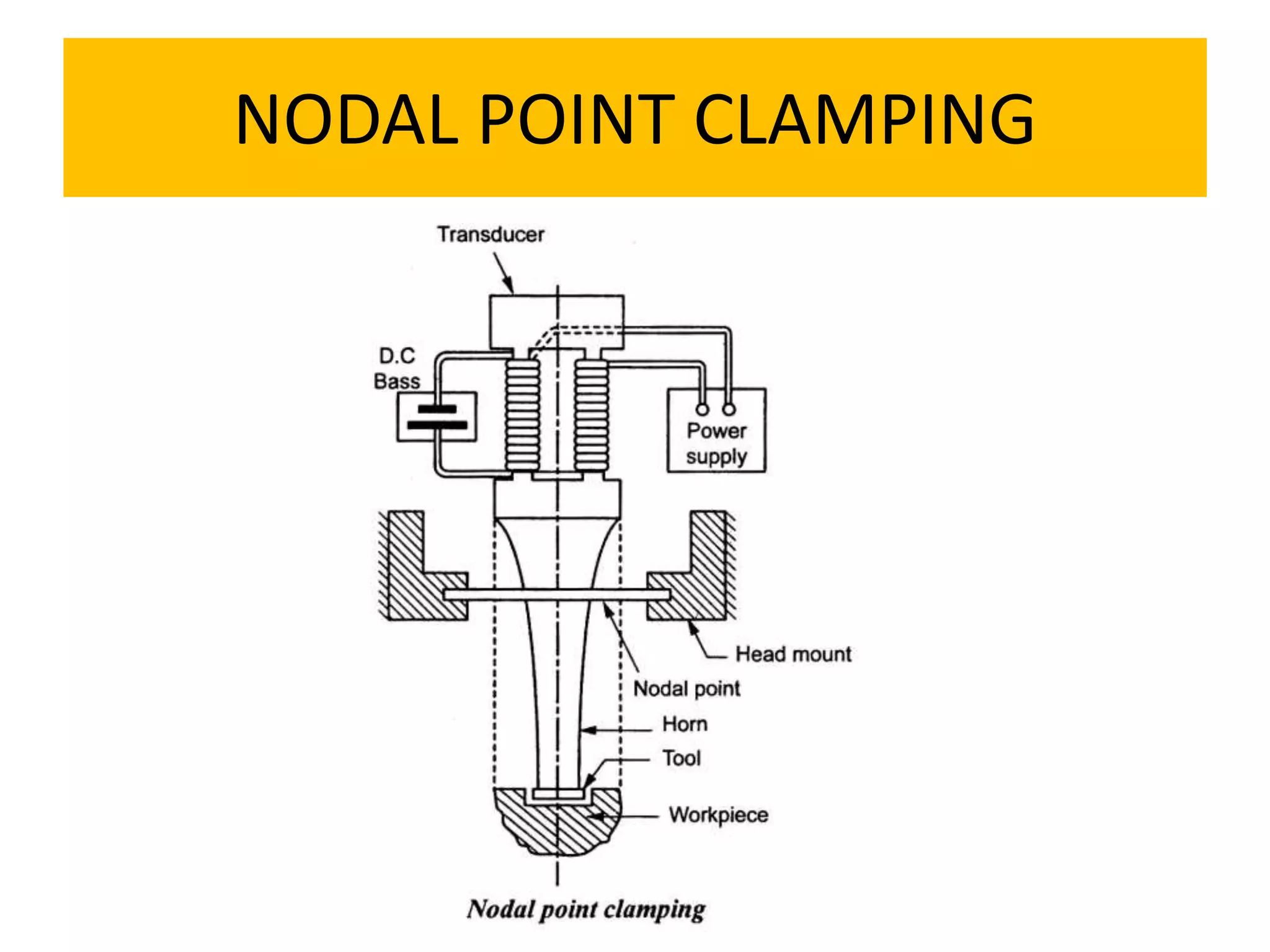

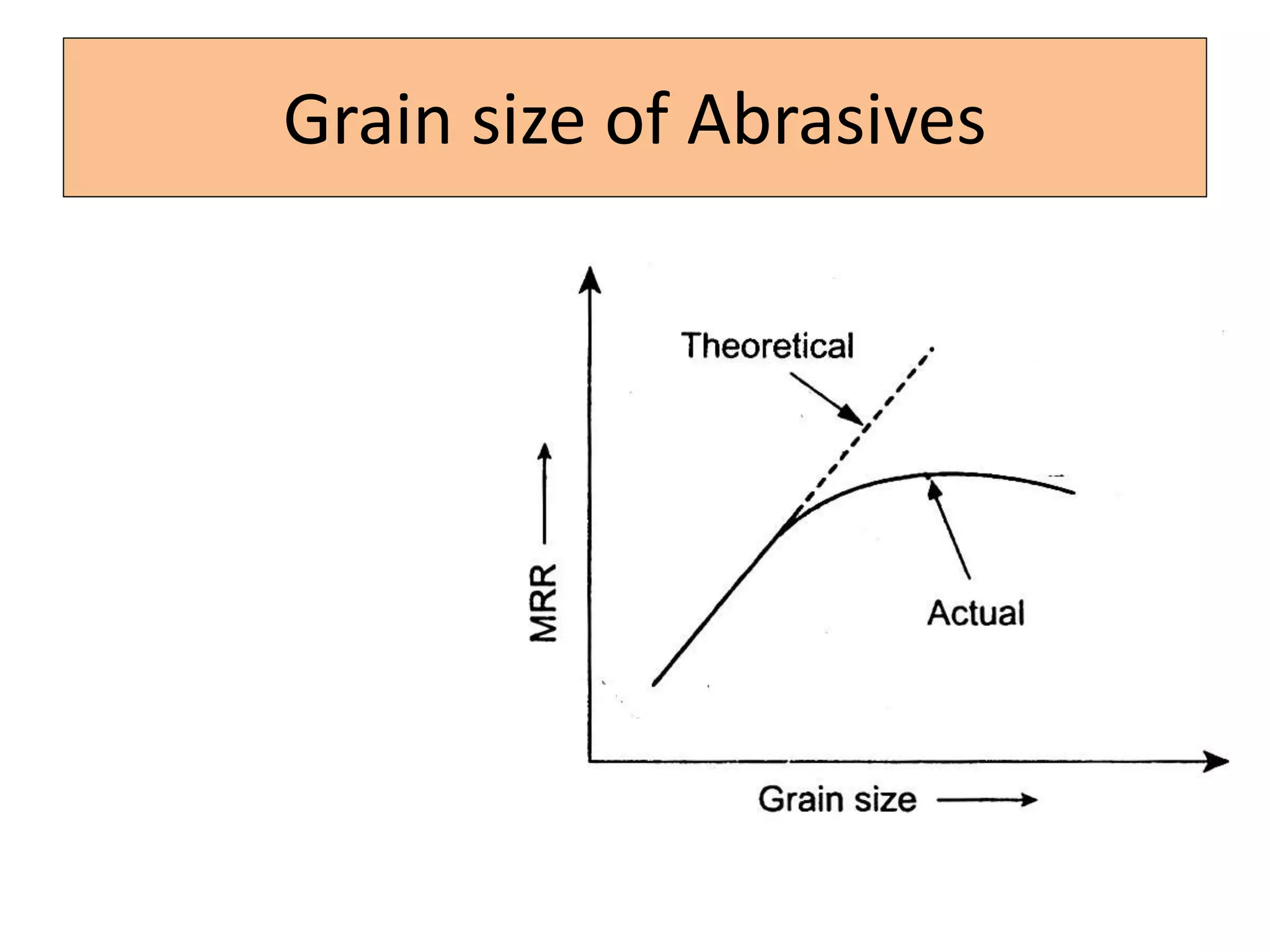

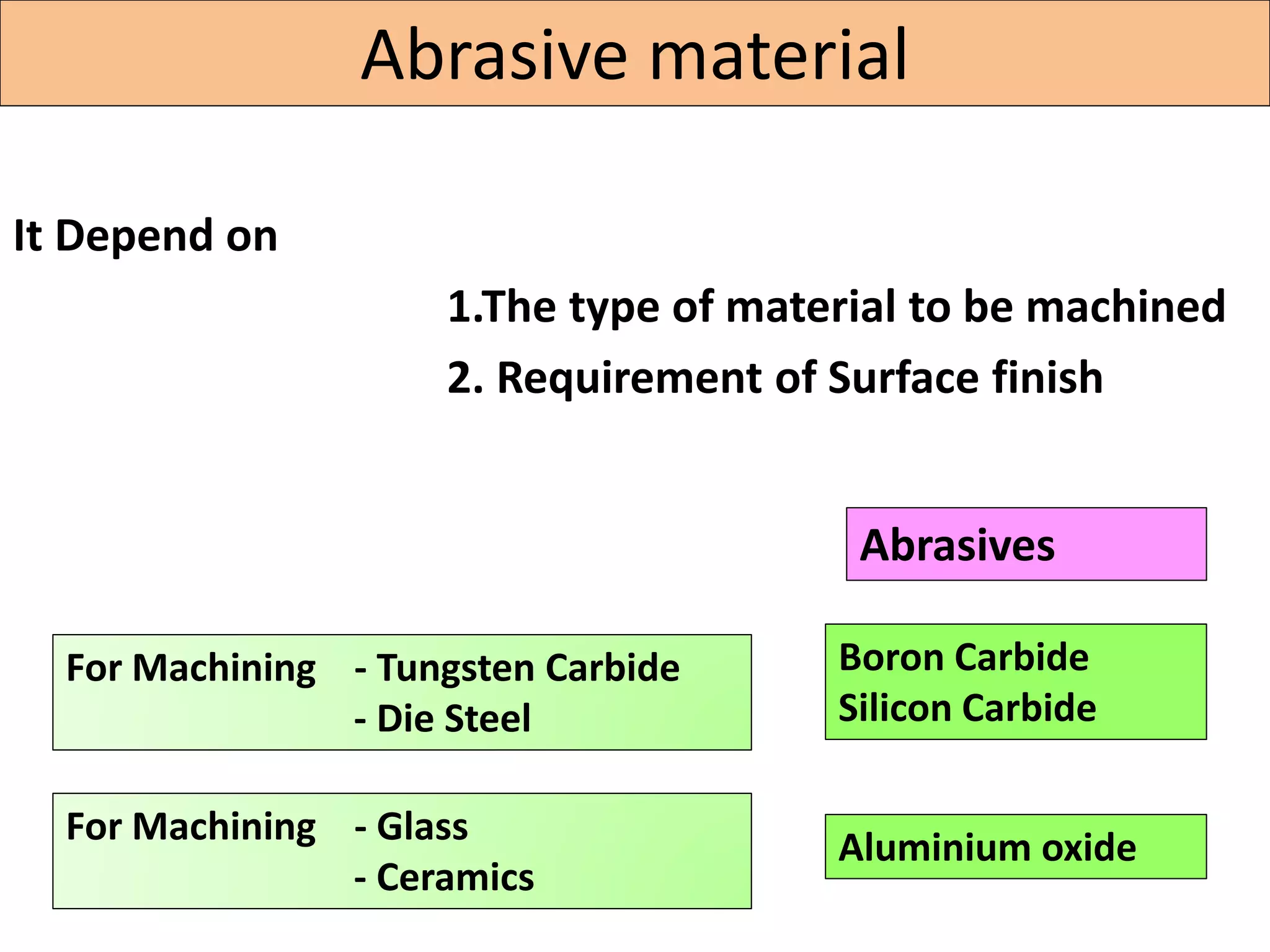

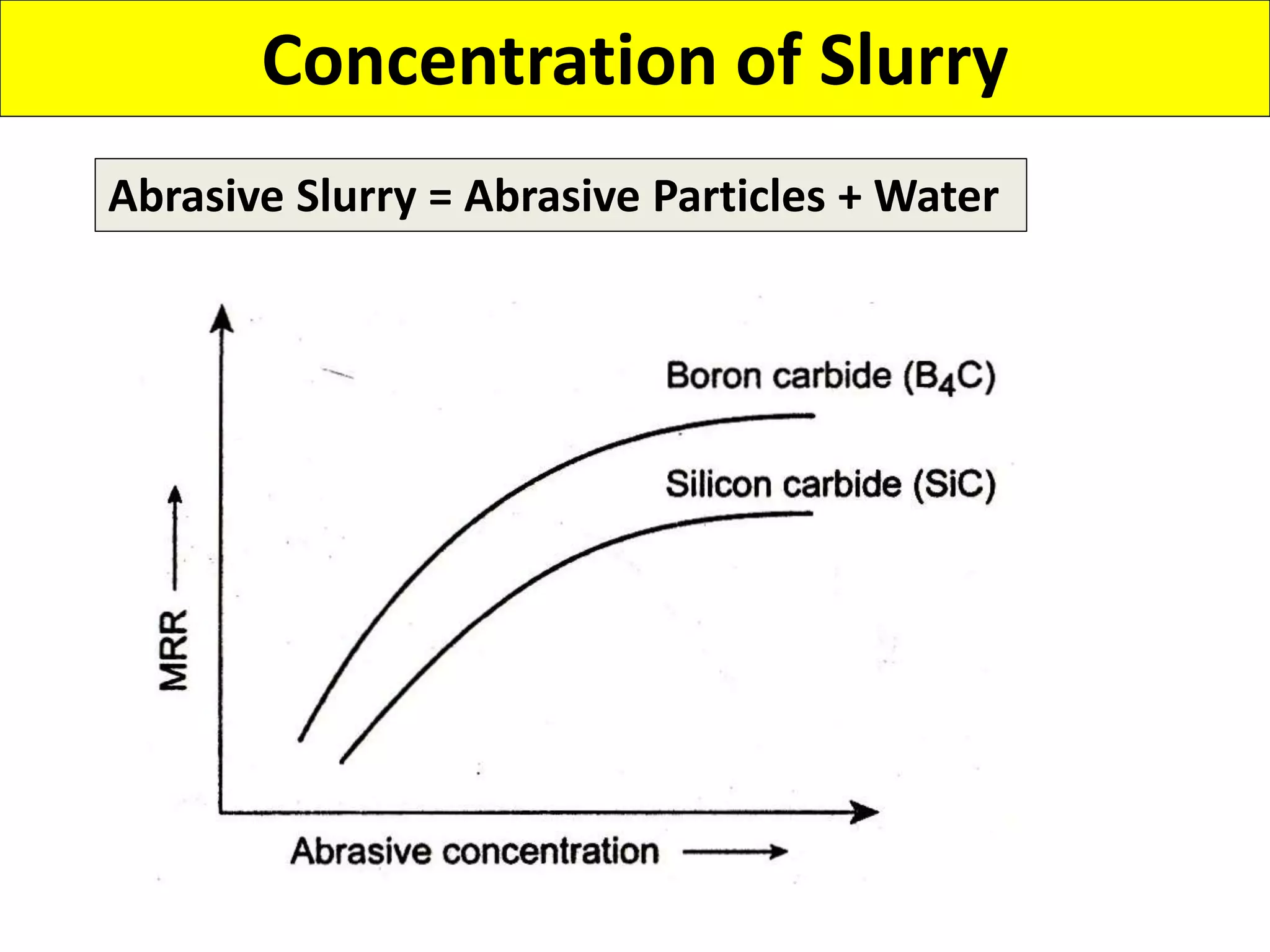

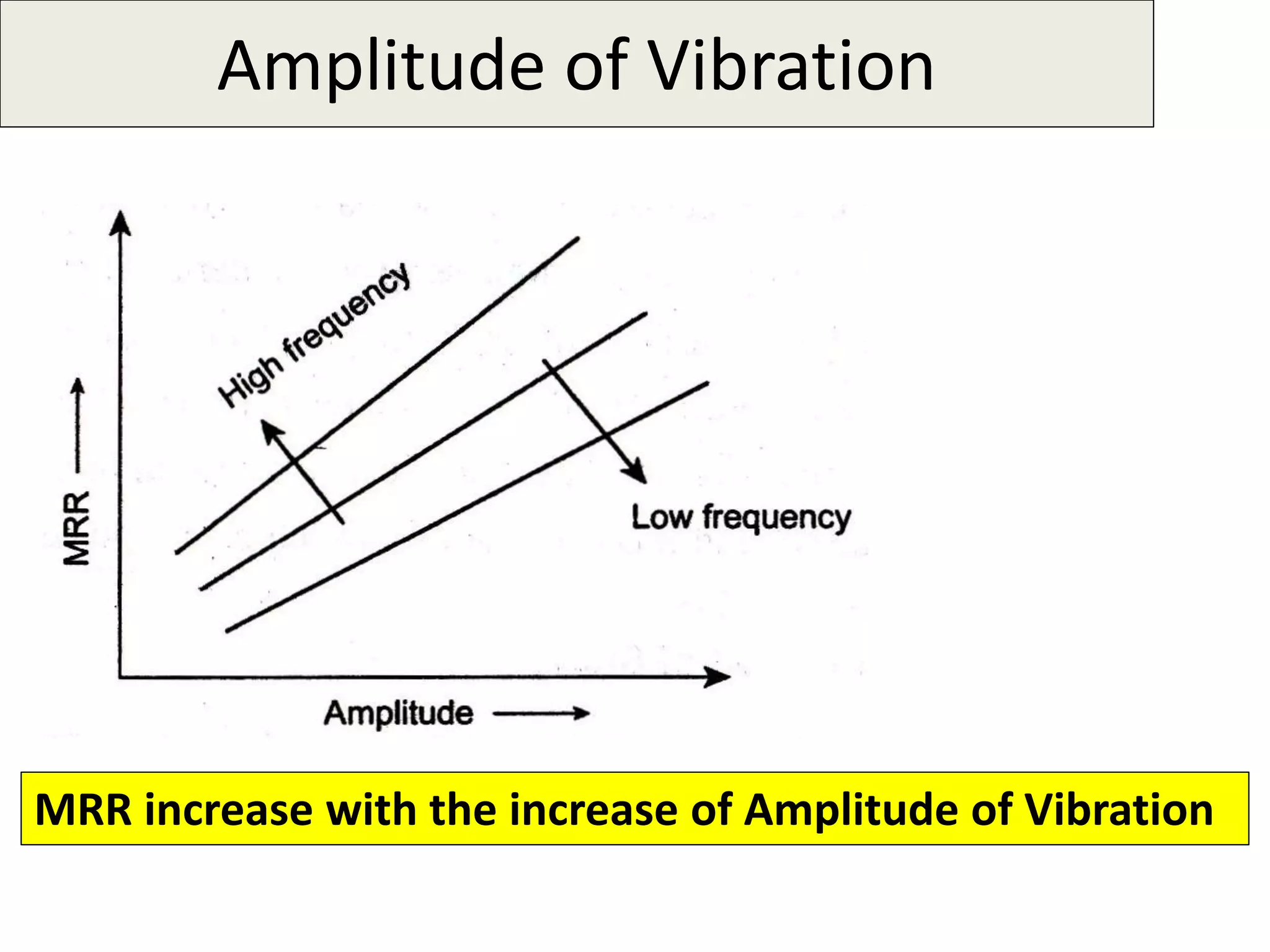

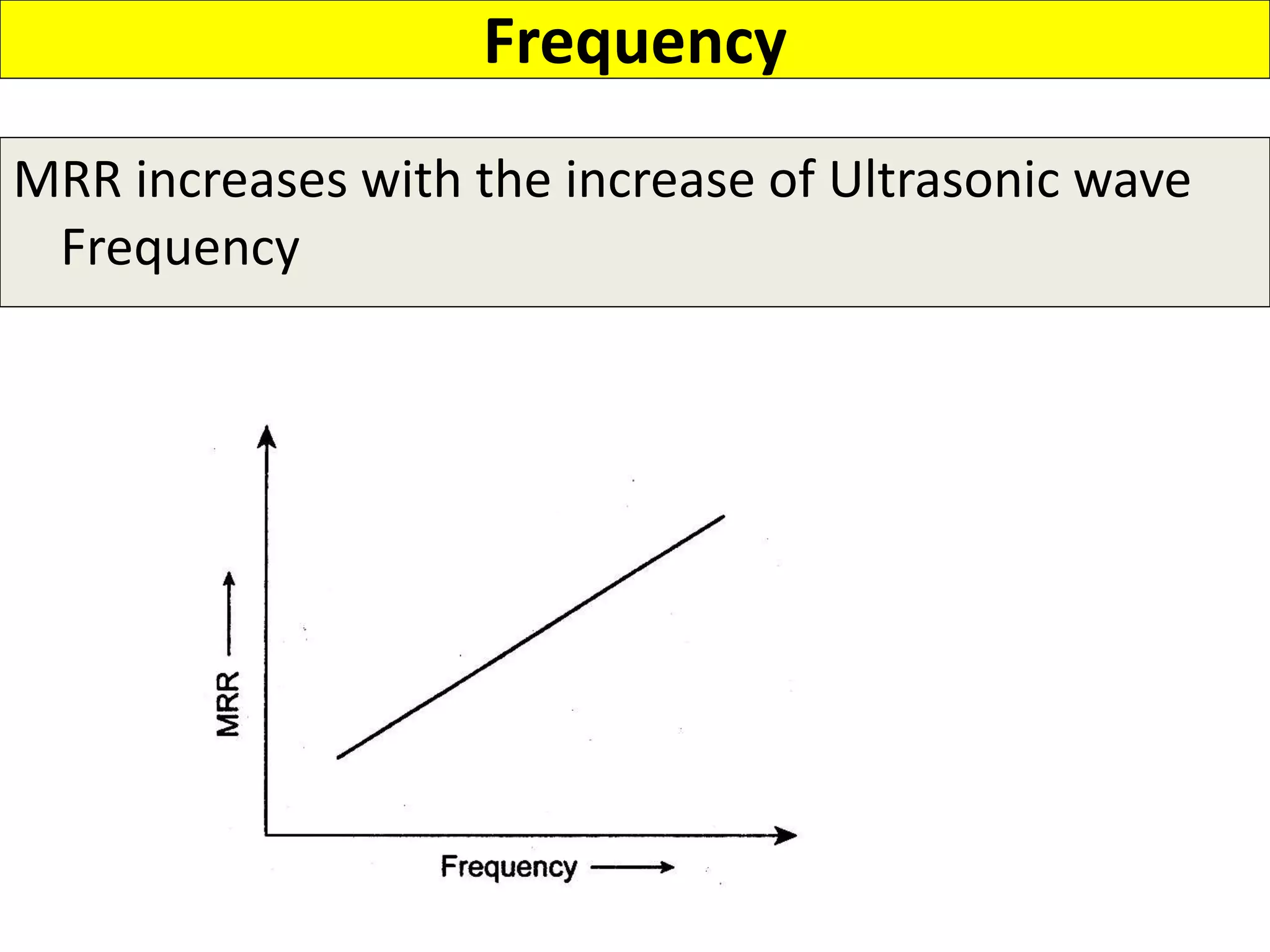

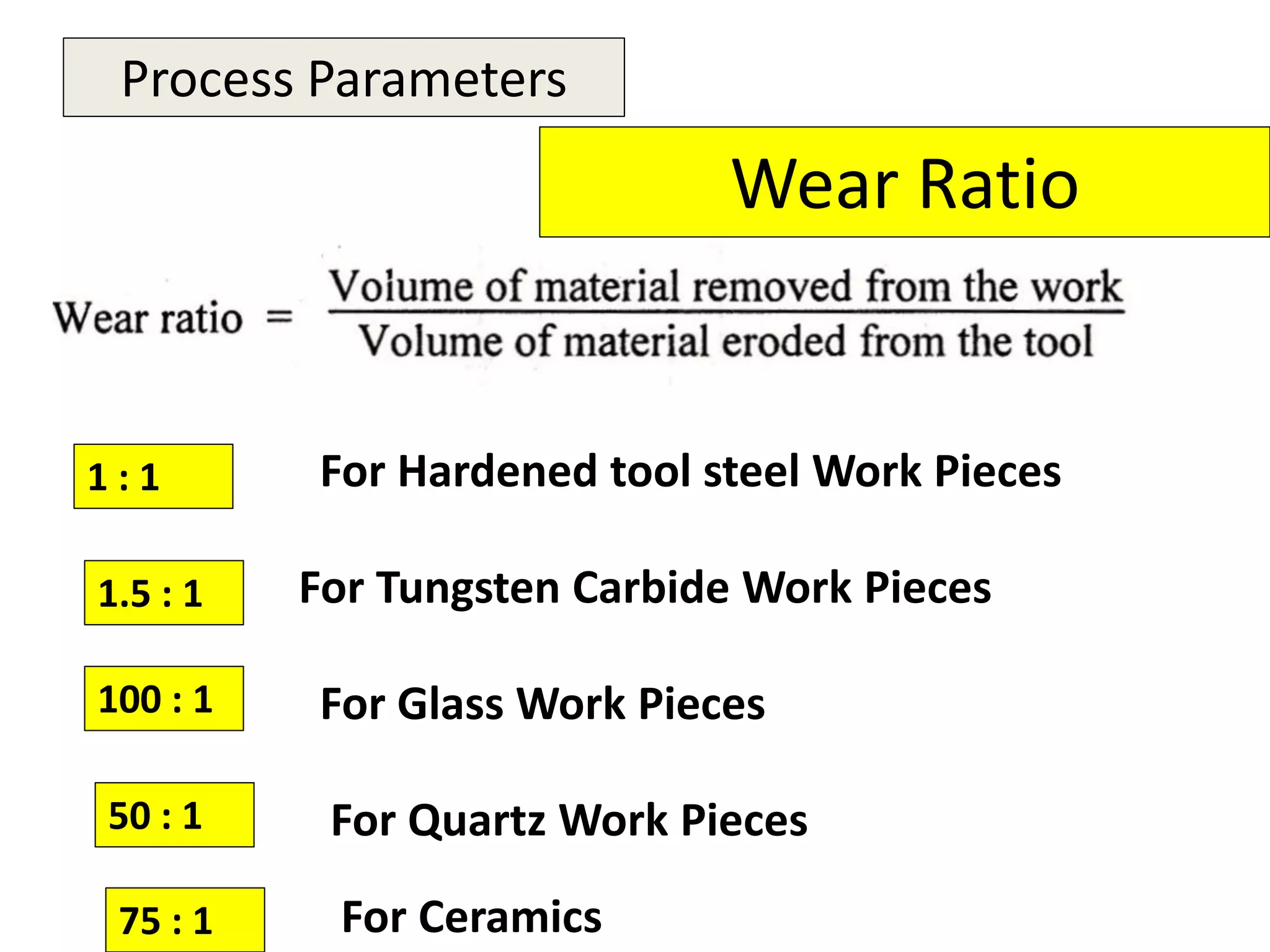

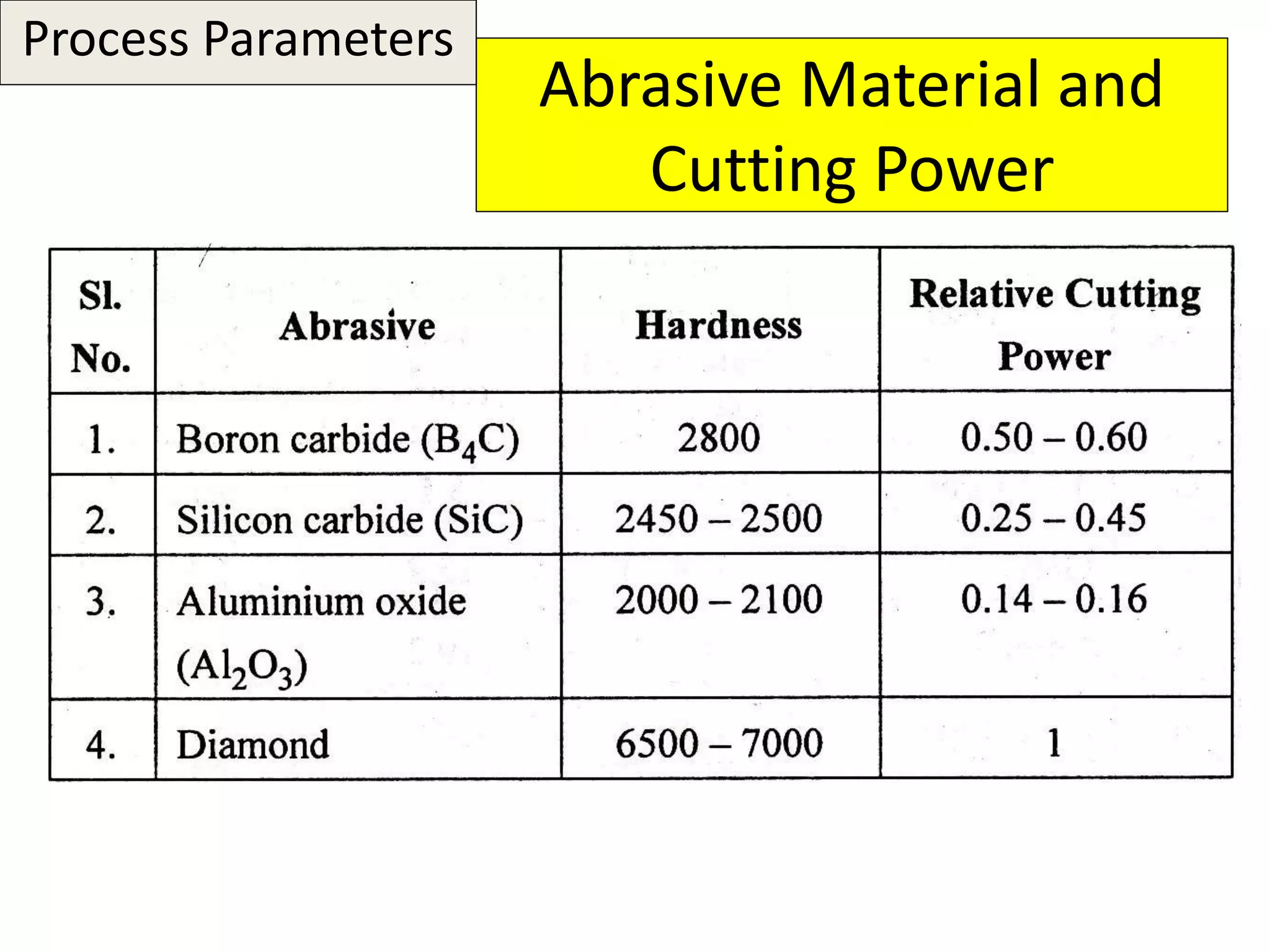

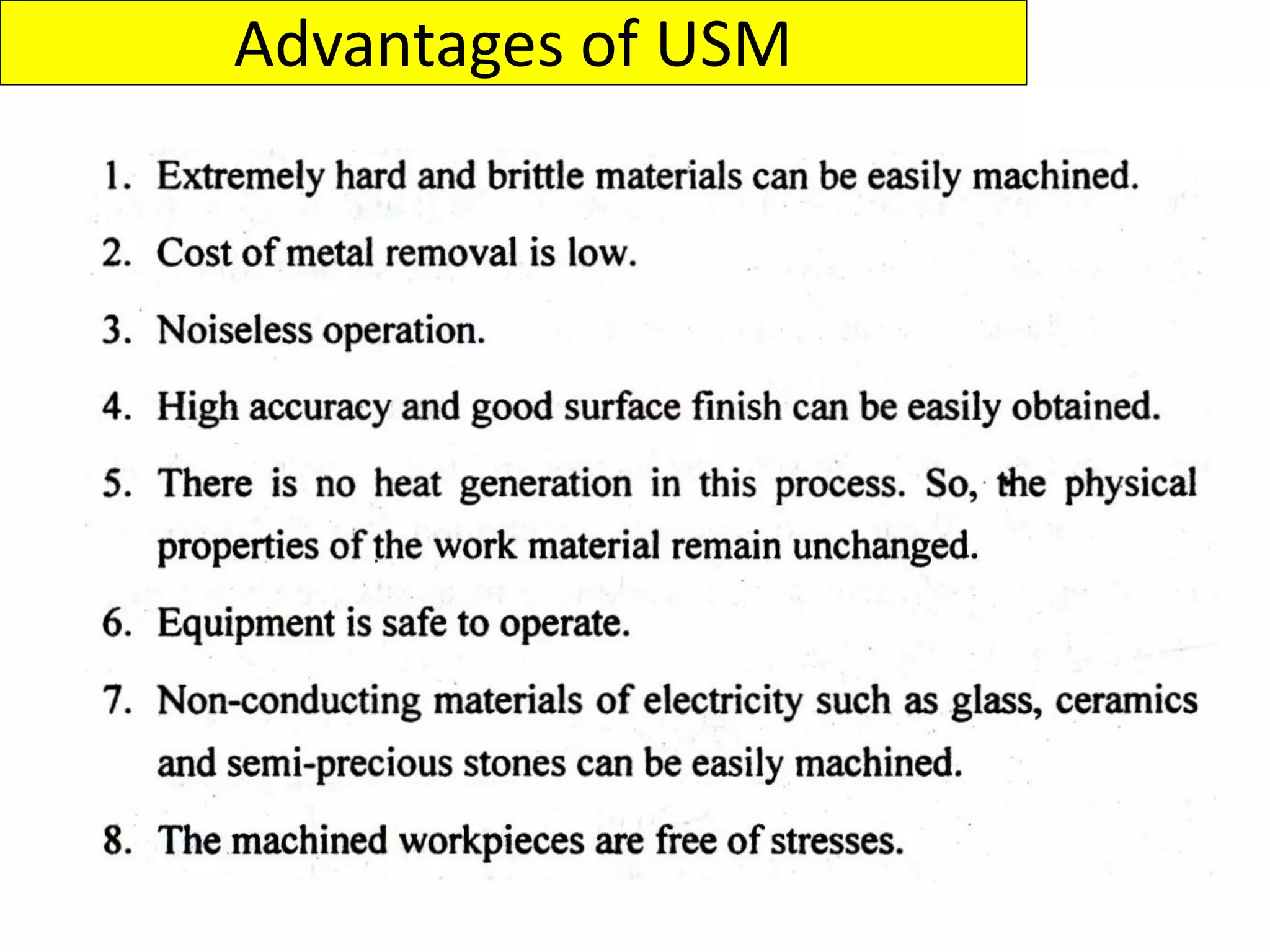

The document provides detailed information about various mechanical energy-based machining processes, including Abrasive Jet Machining (AJM), Water Jet Machining (WJM), and Ultrasonic Machining (USM). It outlines the construction details, parameters, advantages, and disadvantages of these processes, along with the types of materials used for machining and their applications. Each machining method is characterized by specific operational principles, tool materials, and performance factors that influence their efficiency and outcomes.