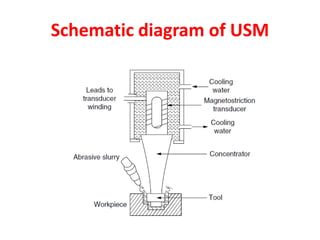

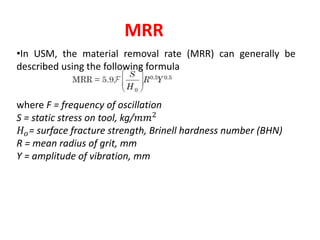

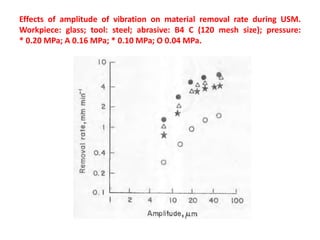

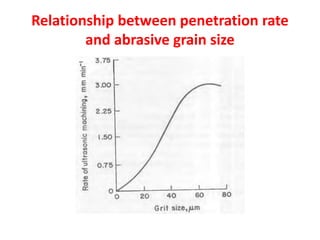

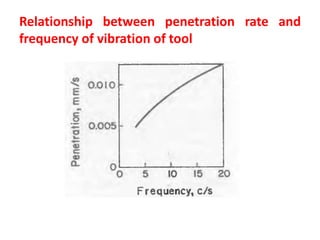

Ultrasonic machining (USM) is a non-traditional machining process that uses a vibrating tool and abrasive slurry to machine hard and brittle materials. In USM, the tool vibrates at ultrasonic frequencies (over 20 kHz) which causes abrasive particles in the slurry to remove small amounts of material from the workpiece. Key factors that influence the material removal rate include the amplitude of vibration, abrasive particle size, tool material, and workpiece hardness. USM can achieve high accuracies between 7-25 μm and is well-suited for machining intricate shapes in hard materials like carbides, ceramics, and glass.