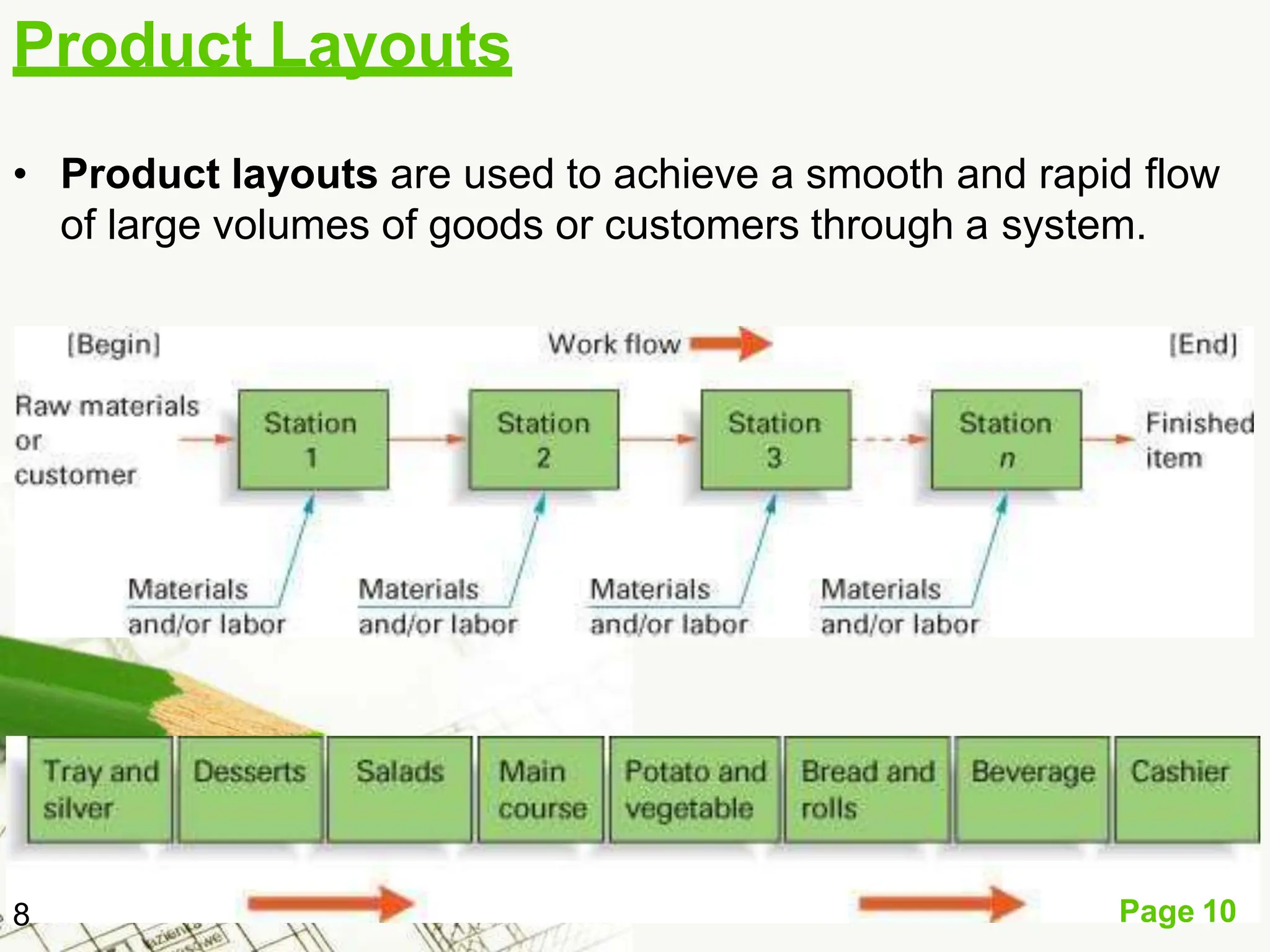

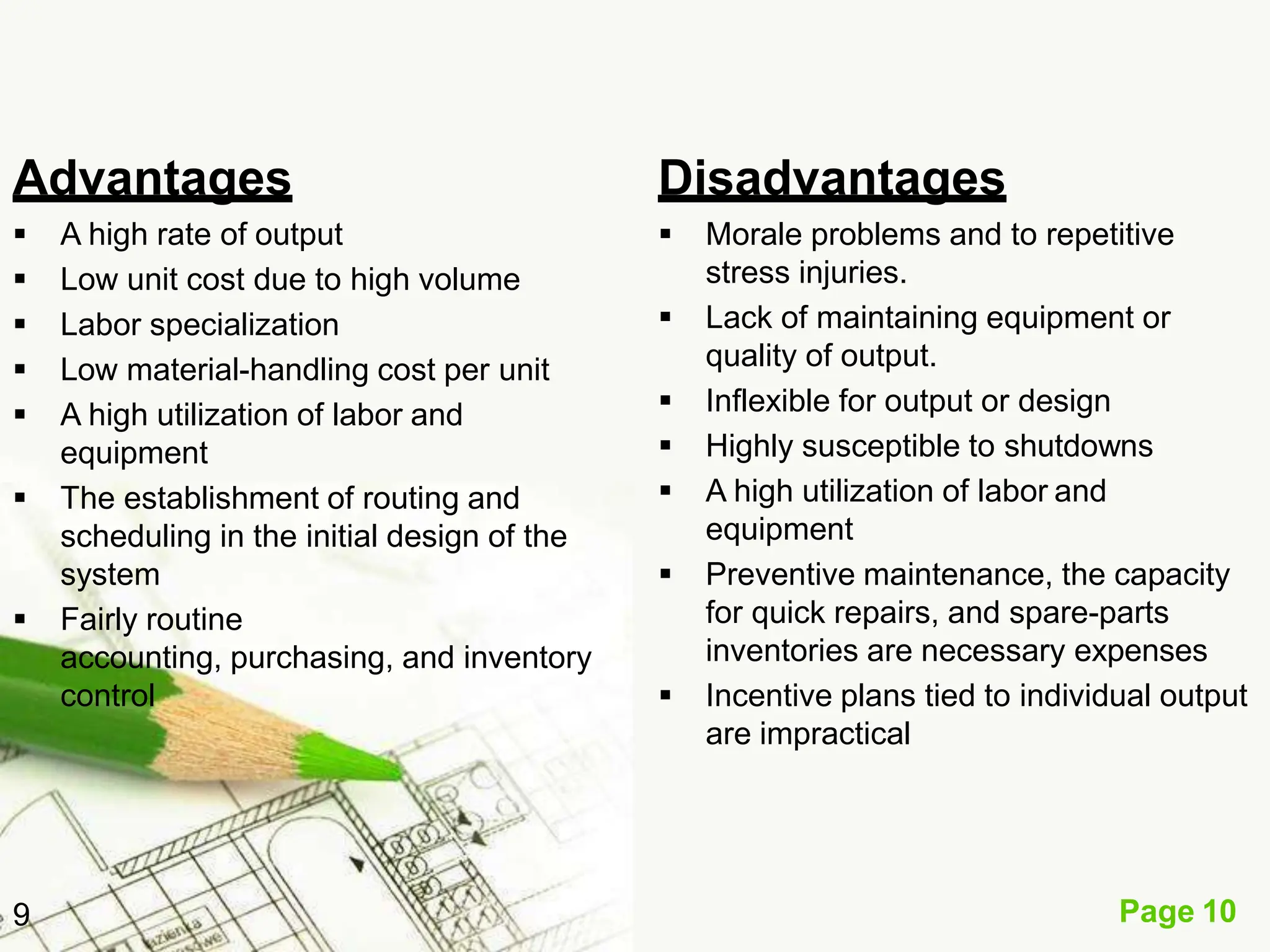

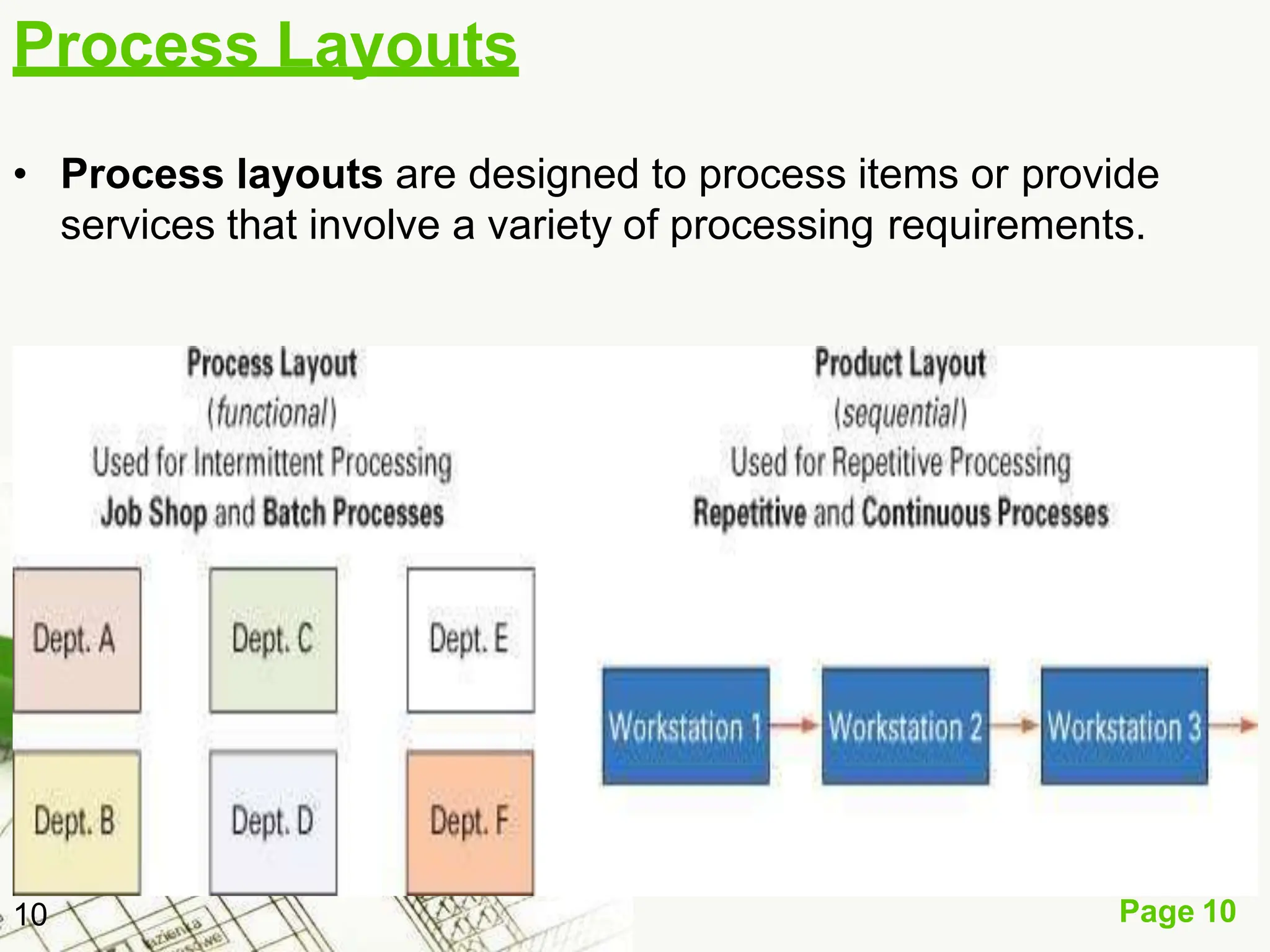

The document discusses various types of plant layouts, including fixed position, product oriented, process oriented, and combined layouts, each with advantages and disadvantages related to efficiency and workflow. It highlights the importance of layout design in improving production efficiency, reducing costs, and facilitating smooth movement of materials and information. Supporting objectives for layout design include maximizing worker and space utilization, ensuring product quality, and minimizing bottlenecks and unnecessary movements.