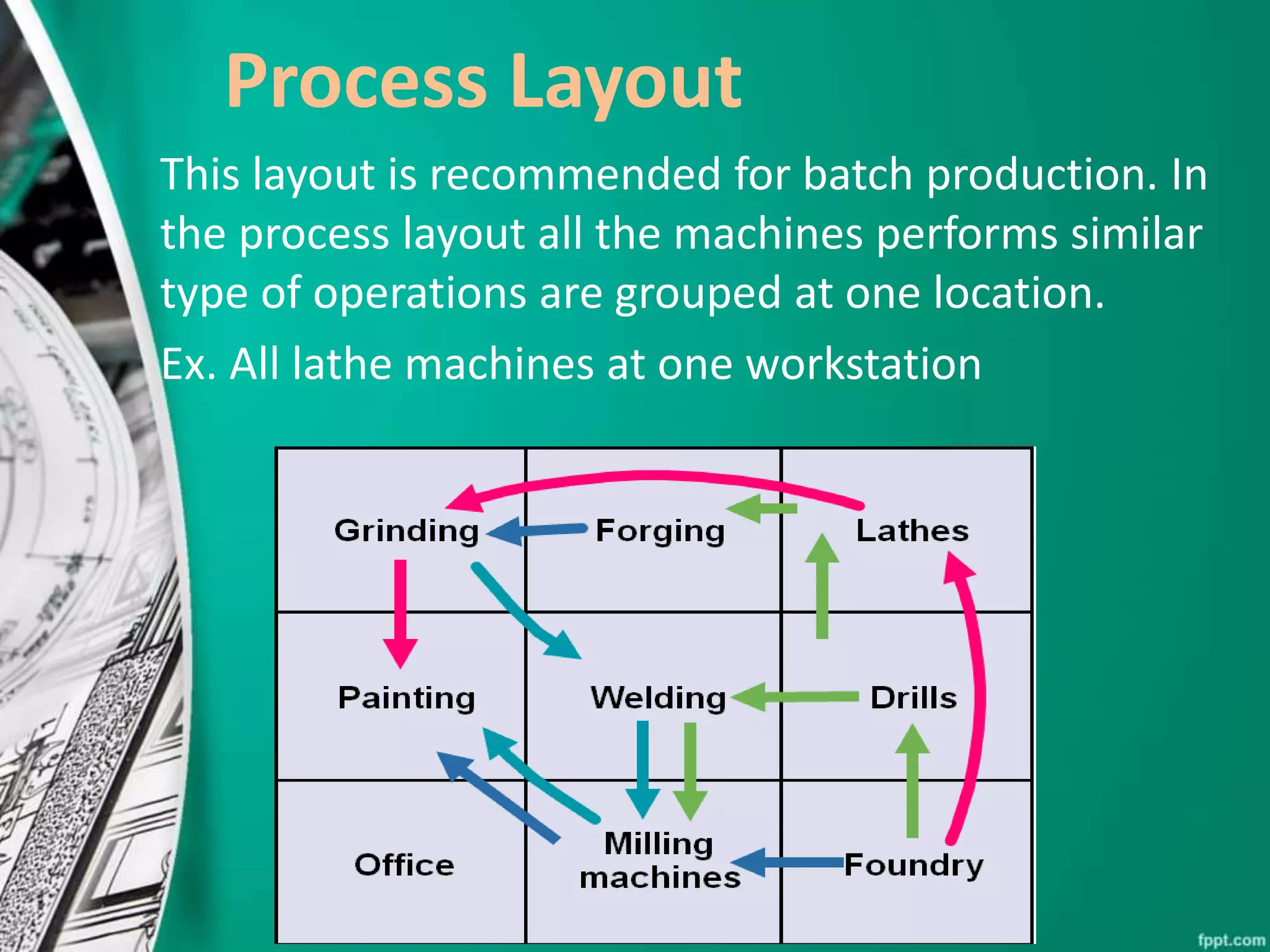

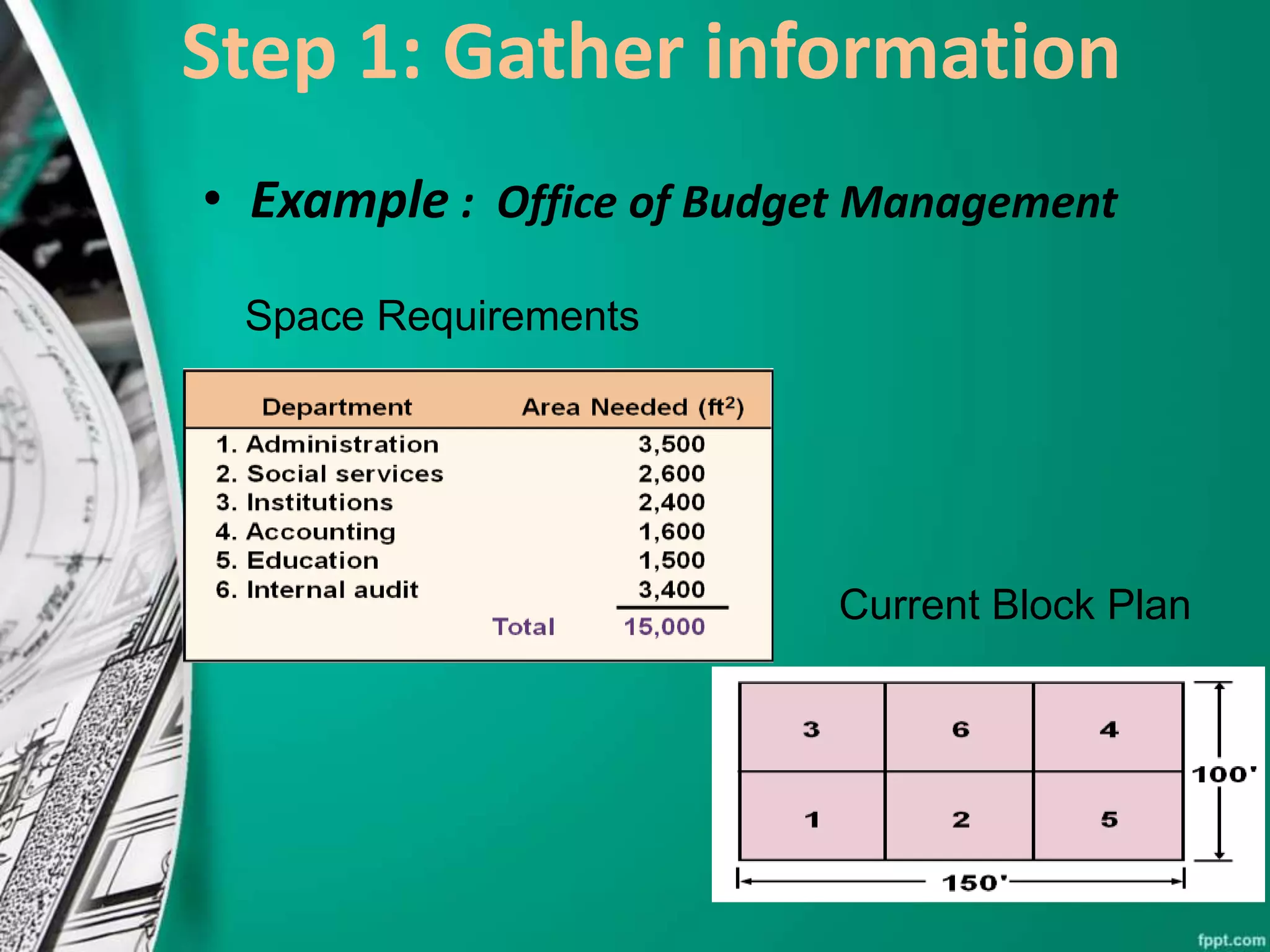

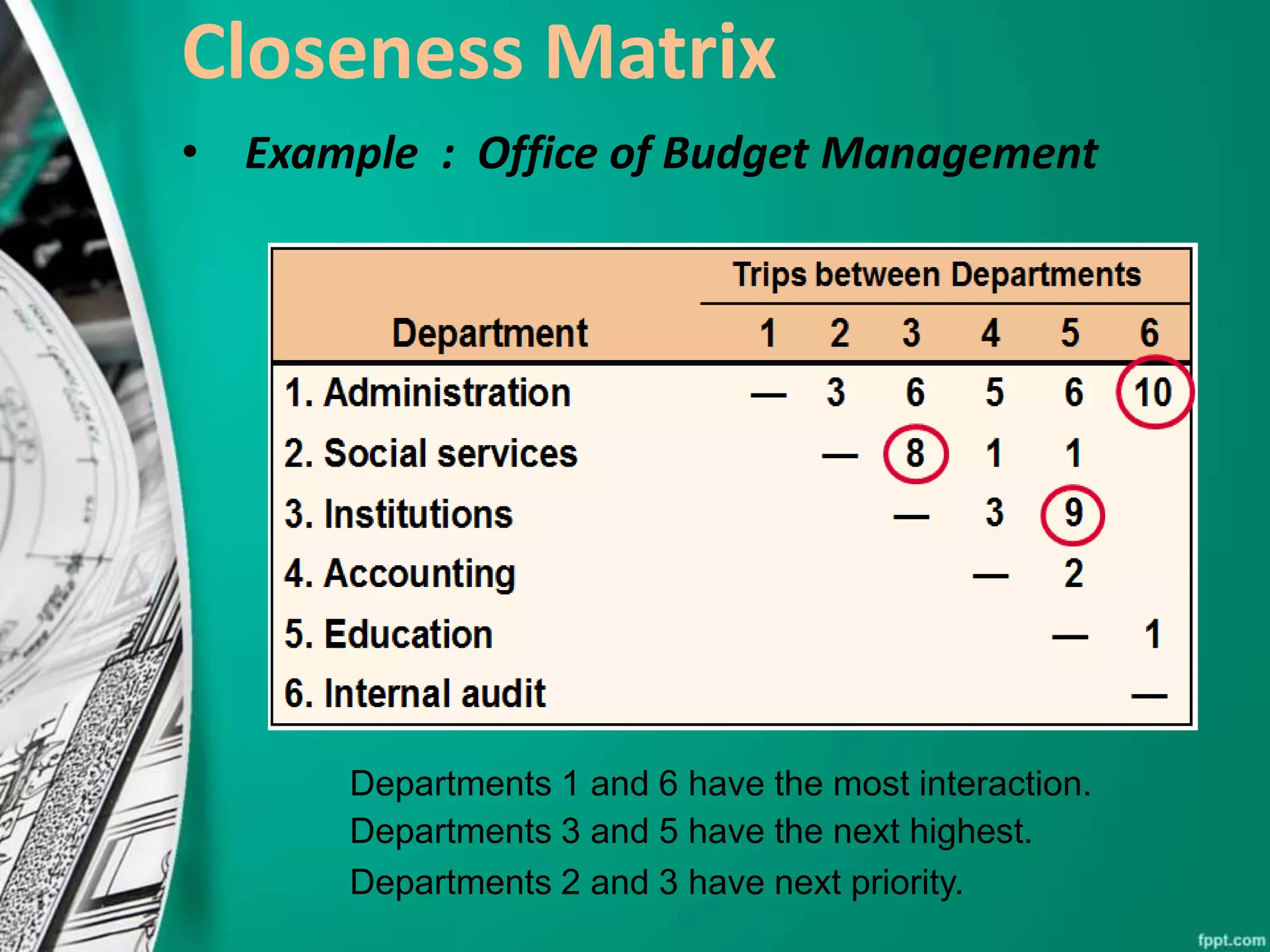

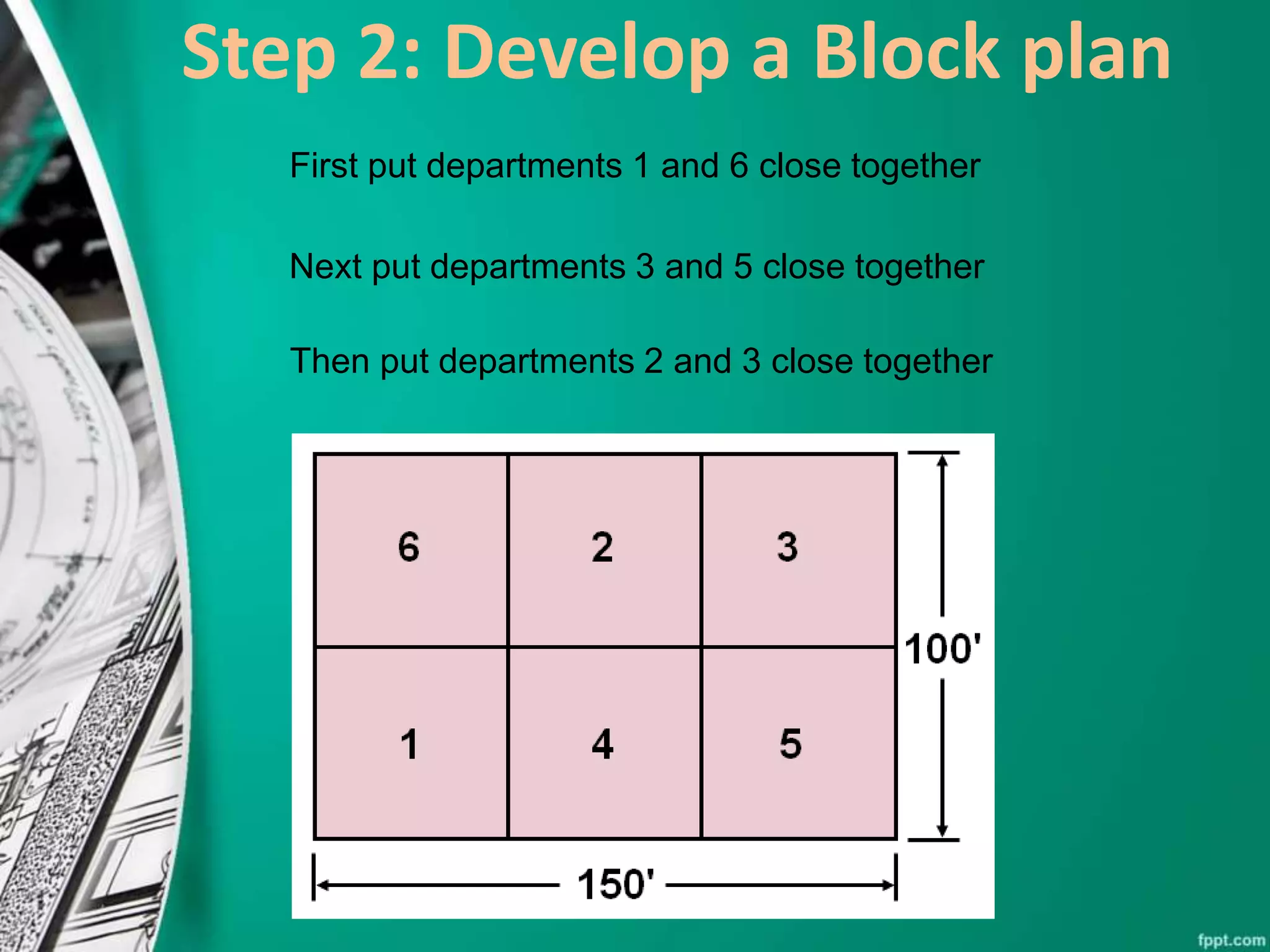

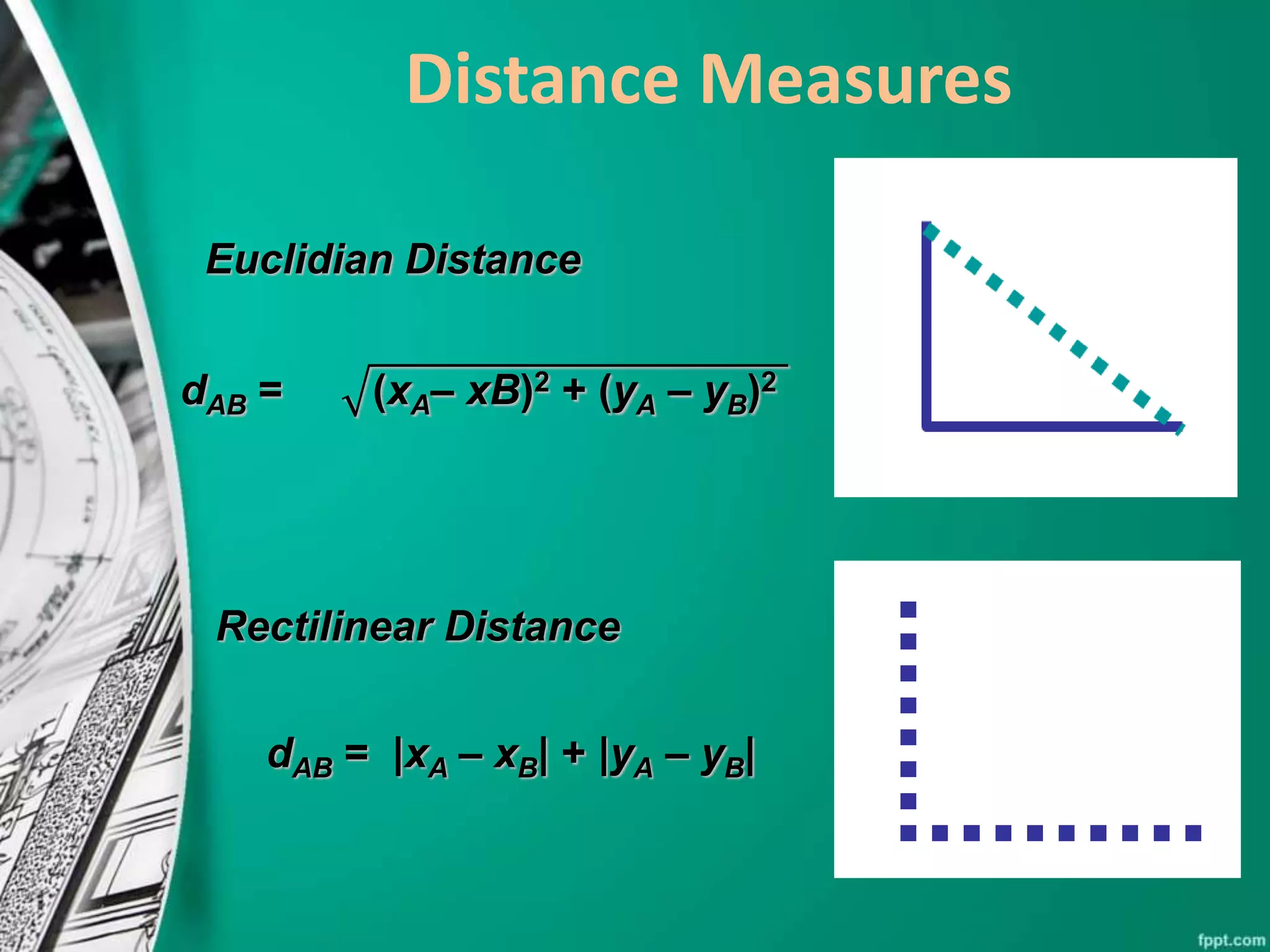

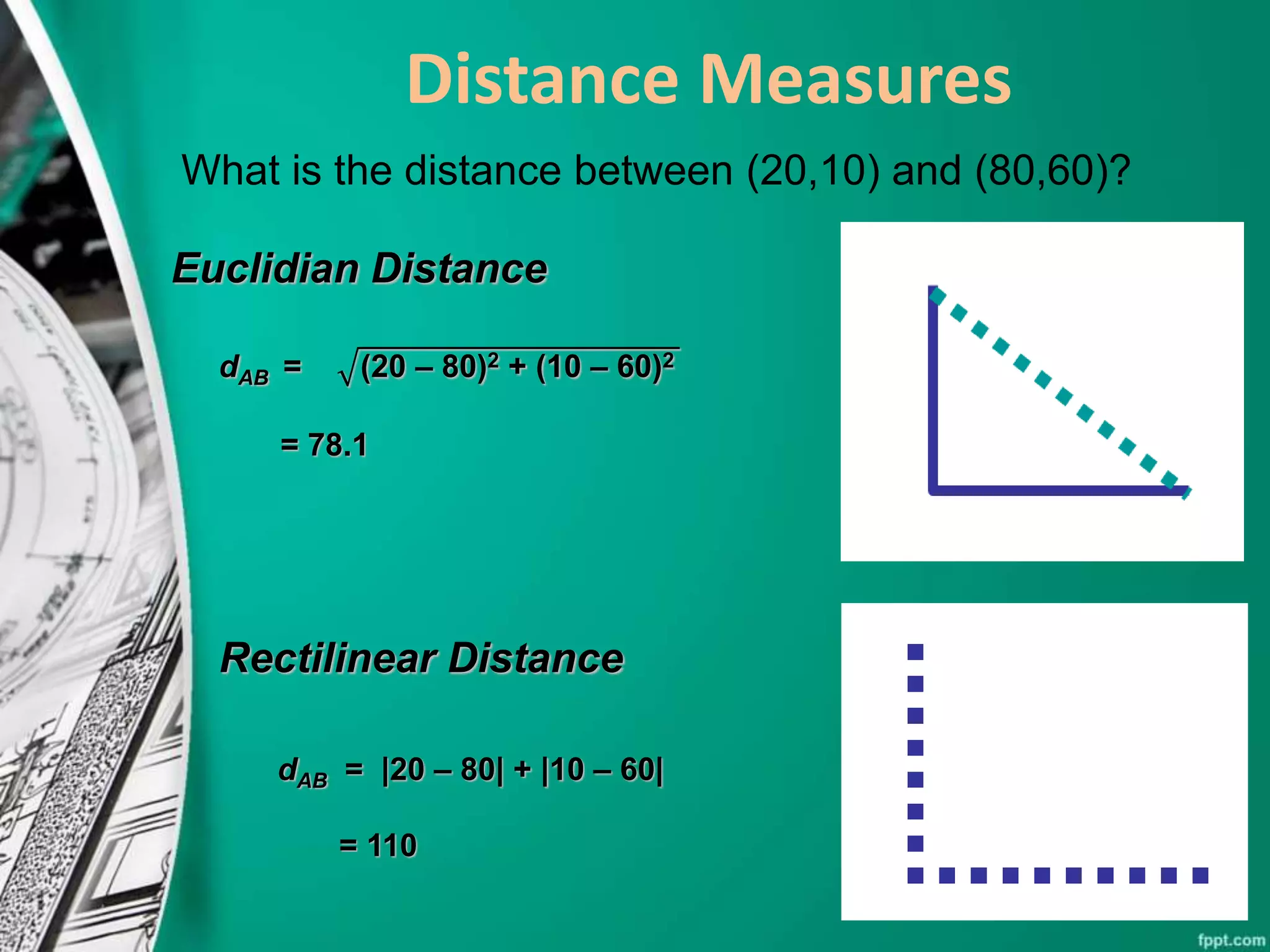

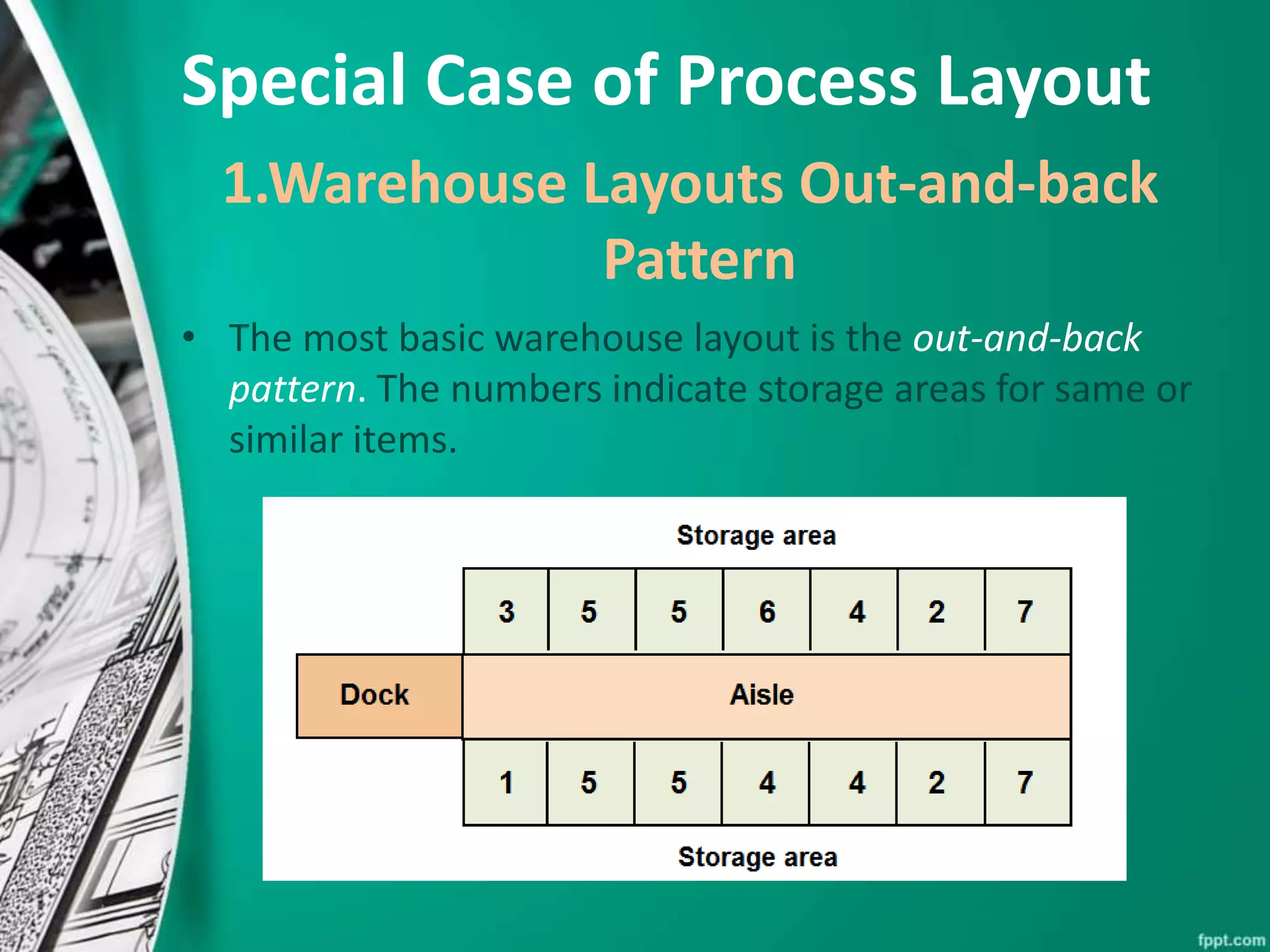

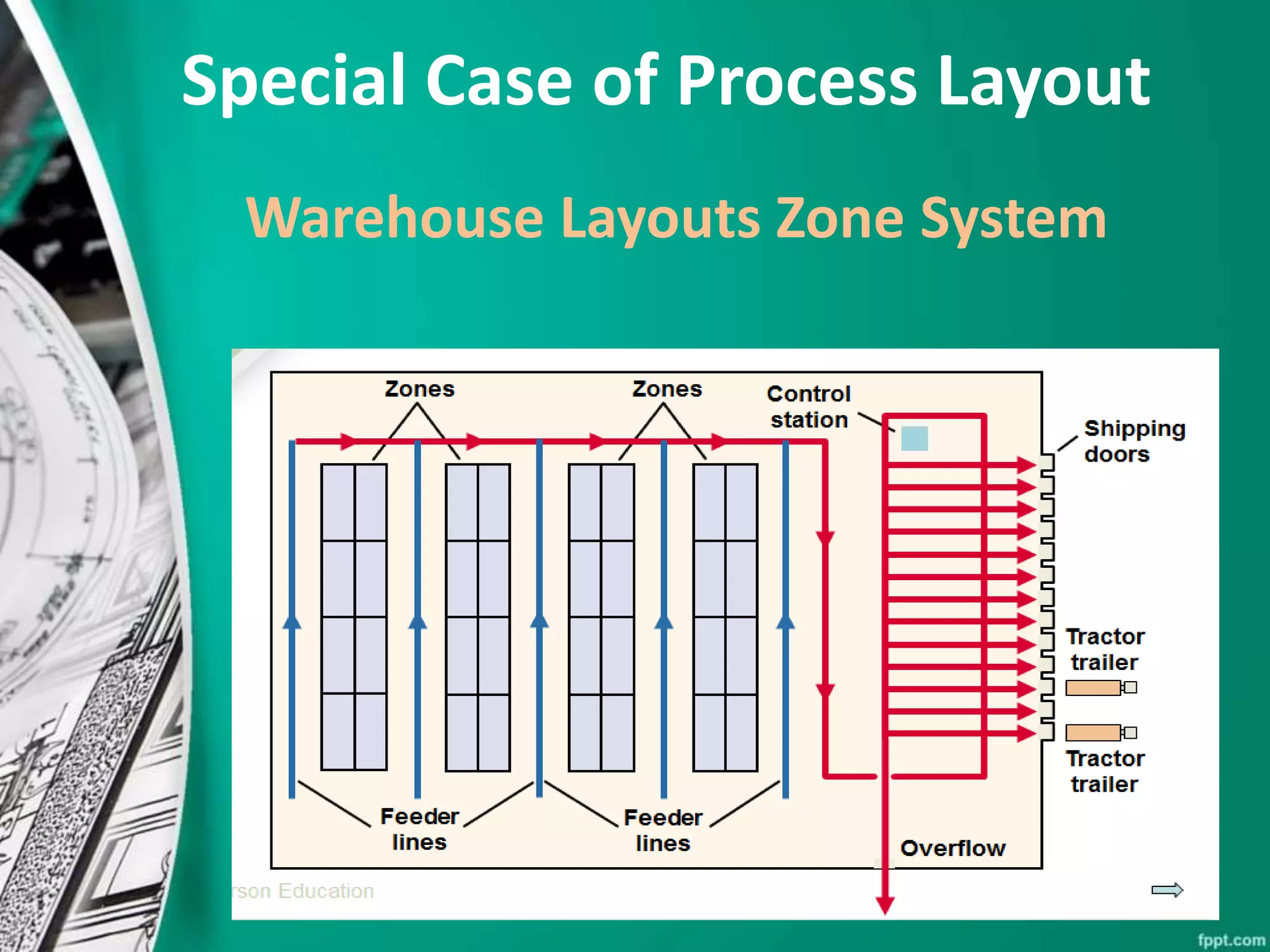

The document outlines various types of process layouts, including process, product, hybrid, and fixed-position layouts, focusing on their organization by function. It details the steps for designing process layouts, emphasizing the importance of space requirements and proximity factors through methods like the closeness matrix and weighted-distance evaluations. Additionally, it discusses advantages such as flexibility and higher utilization of facilities, alongside disadvantages like increased space requirements and lower productivity.