This document provides information on various mechanical tests conducted to evaluate properties of materials, including:

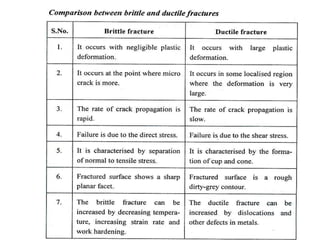

- Plastic deformation testing which evaluates a material's ability to deform permanently under load.

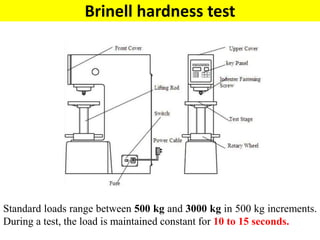

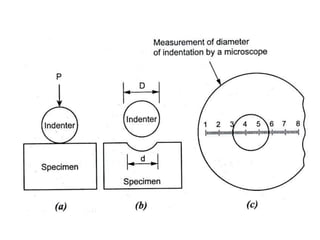

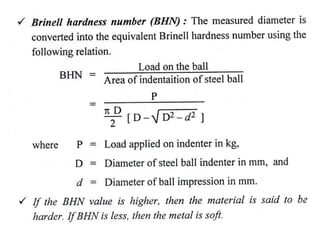

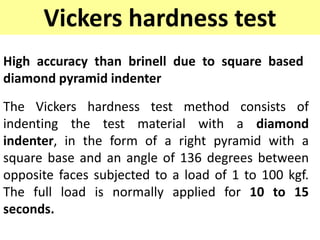

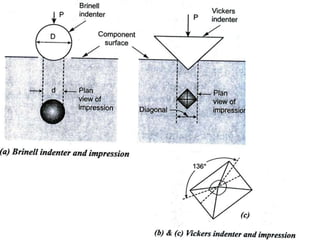

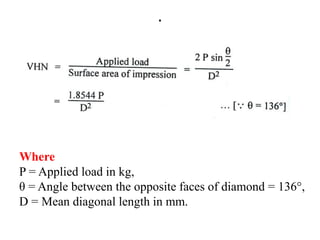

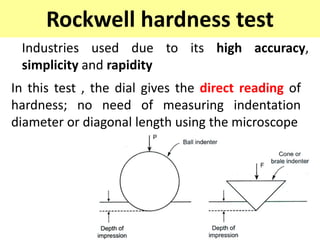

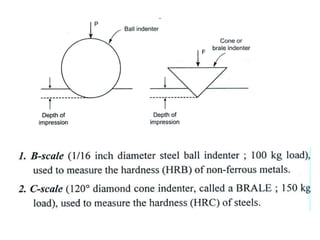

- Hardness testing methods like Brinell, Vickers, and Rockwell which indent materials with an indenter to assess hardness.

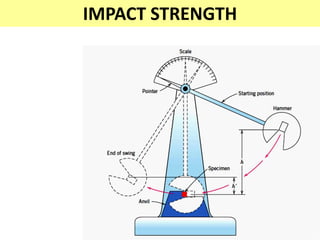

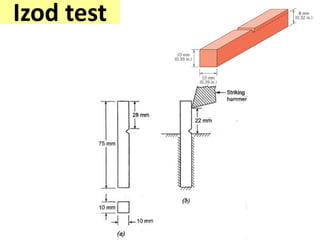

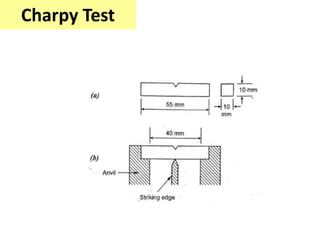

- Impact testing like Izod and Charpy tests which determine a material's resistance to sudden load by measuring how much energy is absorbed during fracture.

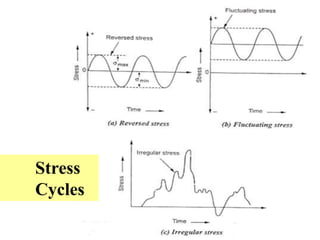

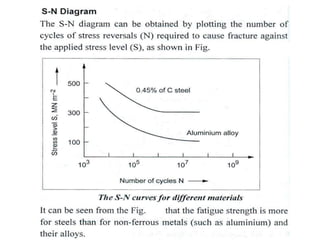

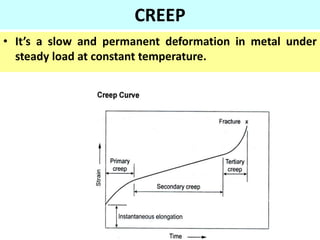

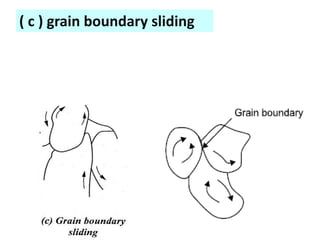

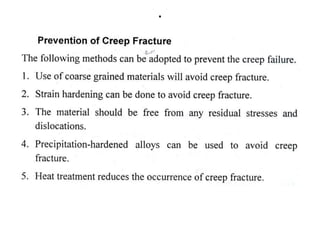

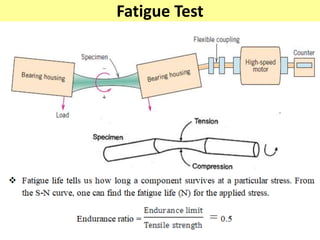

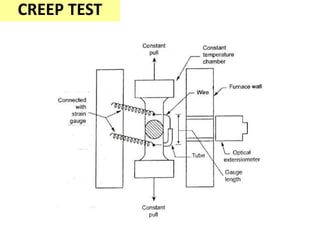

- Fatigue and creep testing which apply repeated or sustained loads to examine how materials withstand cyclic stresses or deformation over time.

A variety of destructive and non-destructive tests are described that are used industrially and for research to