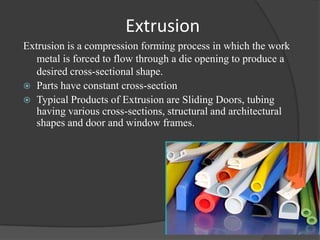

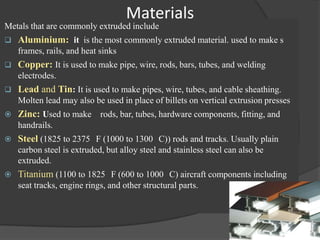

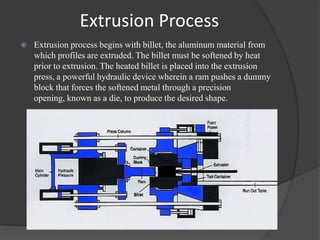

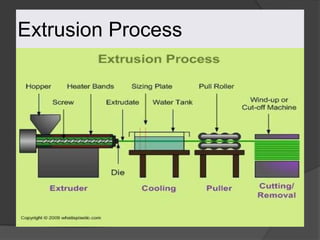

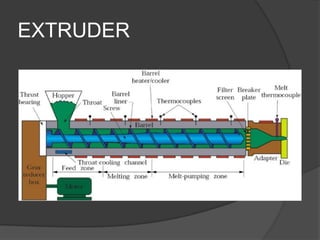

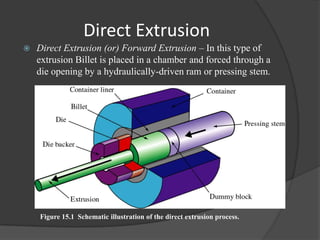

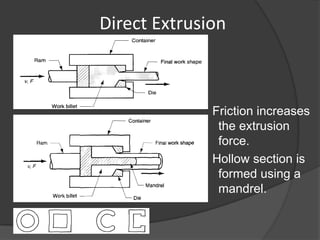

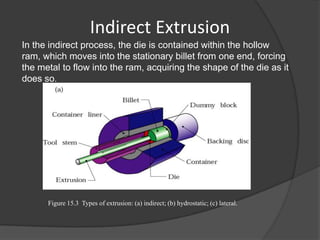

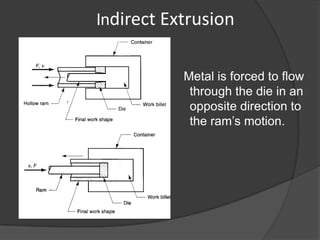

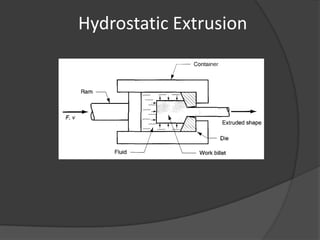

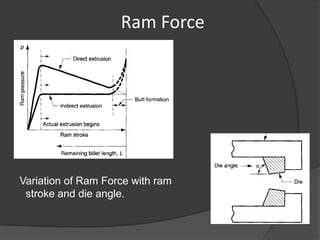

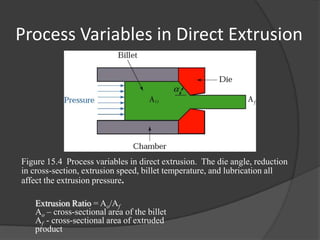

Extrusion is a process where a billet is forced to flow through a die opening under high pressure to produce a part with a constant cross-section. Common materials extruded include metals like aluminum, copper, steel, and plastics. The extrusion process begins by heating the billet and placing it into an extrusion press where a ram pushes it through a die. Direct extrusion uses a stationary die and moving ram, while indirect extrusion has a movable die within a hollow ram. Extrusion can produce complex shapes and is used to manufacture parts like tubing, profiles, and frames.