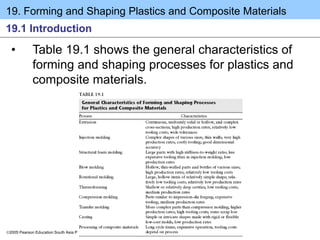

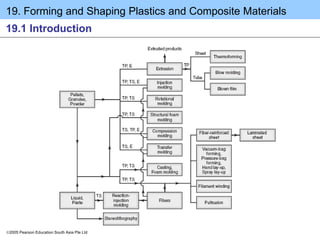

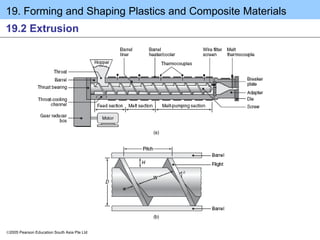

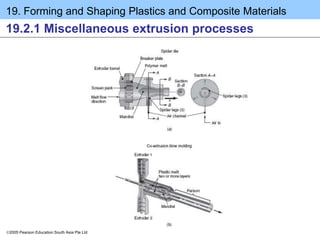

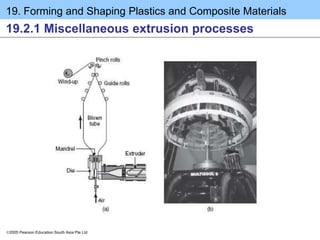

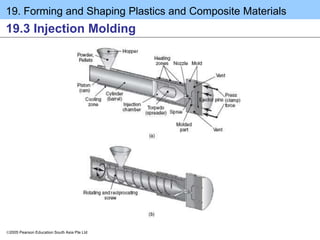

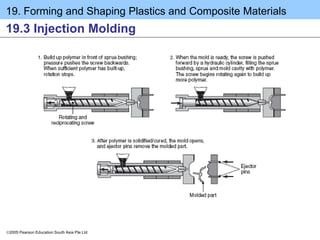

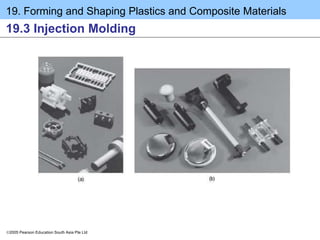

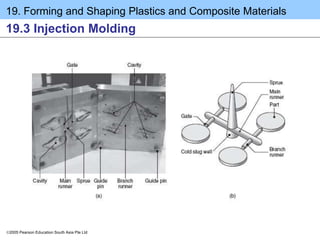

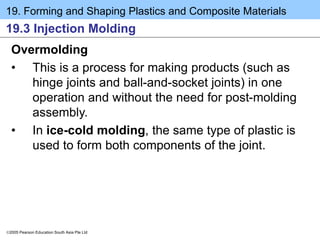

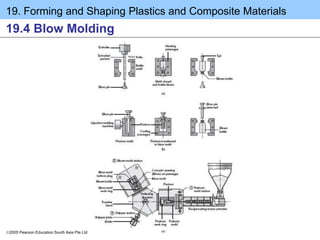

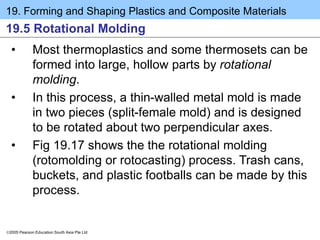

The document discusses various plastic forming processes including extrusion, injection molding, and blow molding. Extrusion is used to produce plastic rods, tubes, sheets and films through the use of a screw extruder. In injection molding, plastic pellets are melted and injected into a mold under high pressure to form complex parts. Blow molding uses extruded tubes that are expanded using air pressure to form hollow shapes like bottles.