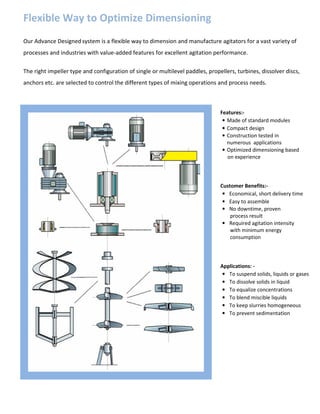

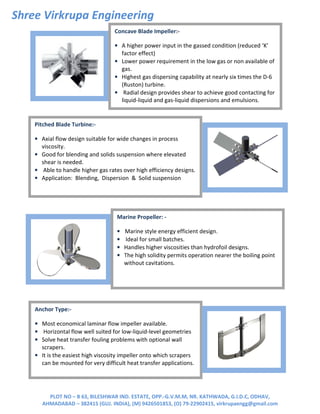

This document discusses agitators and impellers for mixing applications from Shree Virkrupa Engineering. It describes several models of agitators that can be used for various industries and processes. The models include top-entering agitators, side-entering agitators, and portable mixers. It also outlines different types of impellers available, such as straight blade turbines, high efficiency impellers, axial flow impellers, and more that are suitable for different mixing needs.