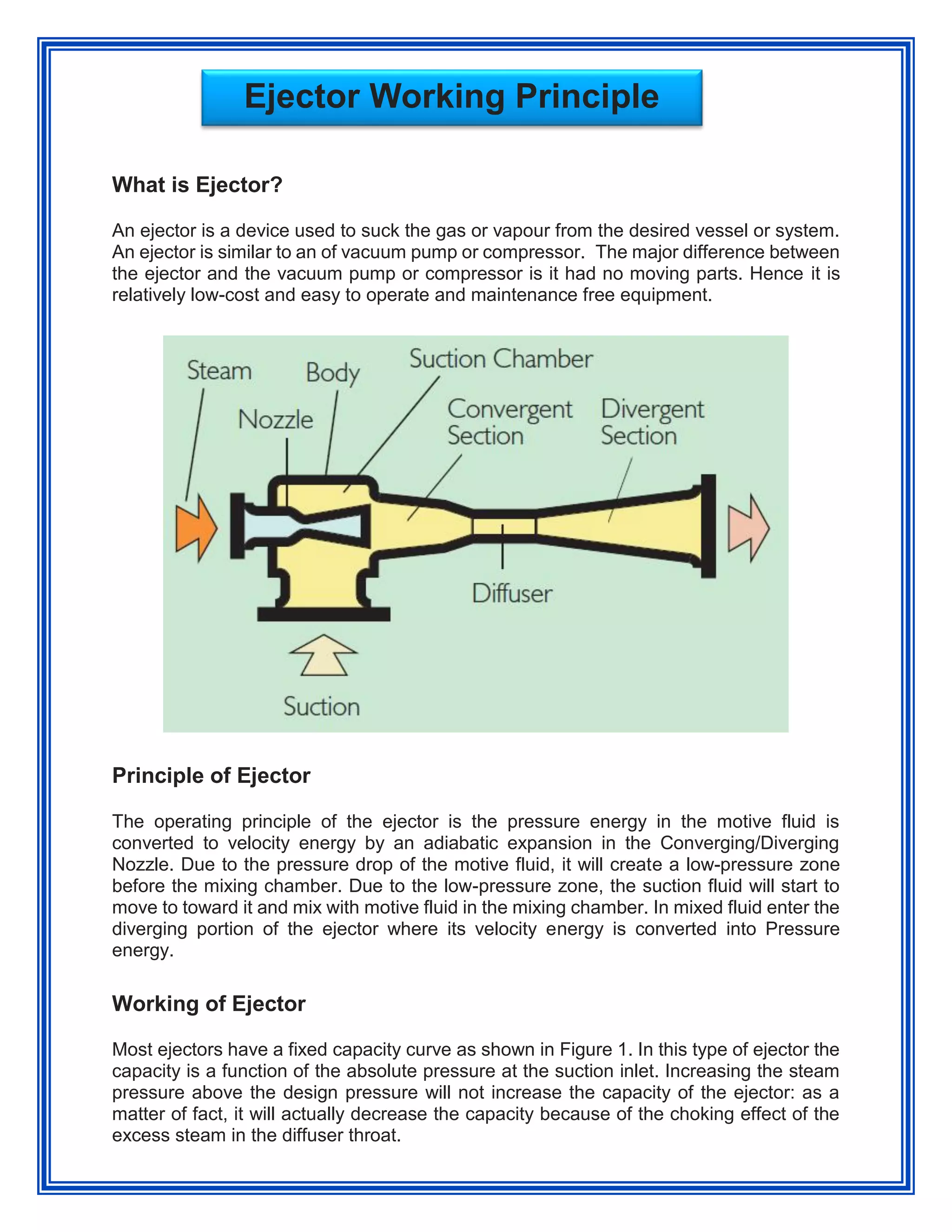

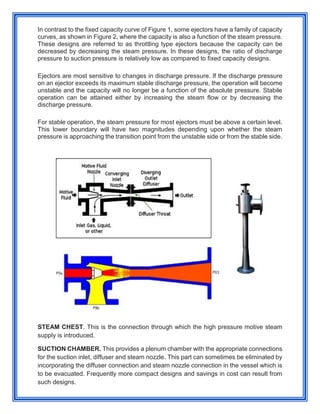

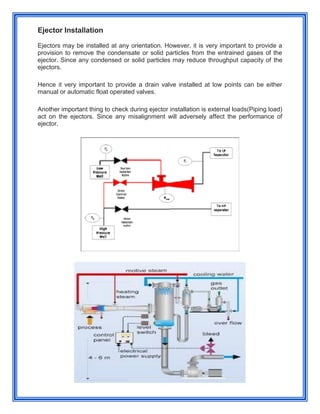

An ejector is a non-mechanical device that utilizes pressure energy from a motive fluid to create a vacuum by converting velocity energy in a nozzle, capable of handling various fluids with minimal maintenance. Ejectors can operate under different conditions and designs, including single-point and multipoint systems, with specific operating curves indicating their efficiency at varying pressures. They are versatile, cost-effective, and applicable in numerous industries for applications like vacuum pumping, mixing, and compressing fluids.