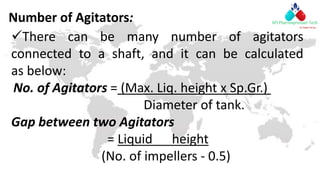

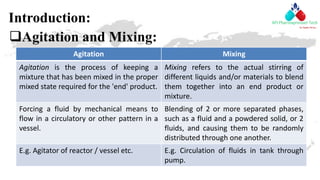

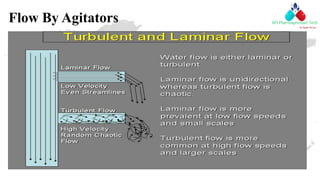

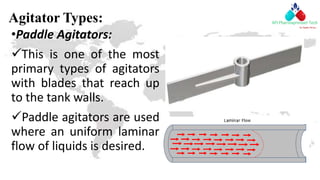

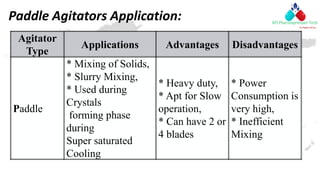

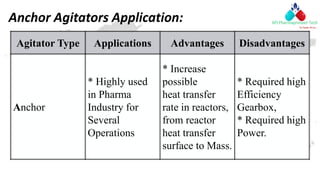

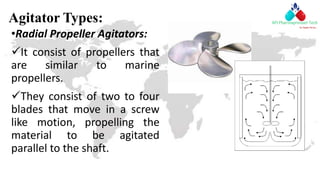

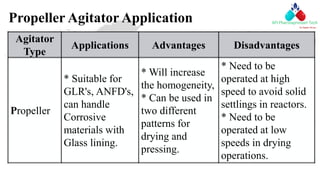

The document discusses various types of agitators used for mixing liquids in various applications, including their functions, advantages, and disadvantages. It contrasts agitation with mixing, explains the difference between laminar and turbulent flow, and outlines multiple specific types of agitators such as paddle, anchor, radial propeller, and helical agitators. Additionally, it covers the calculation for the number of agitators required in a system based on specific parameters.

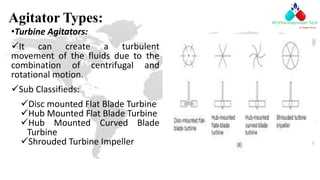

![Turbine Agitator Application:

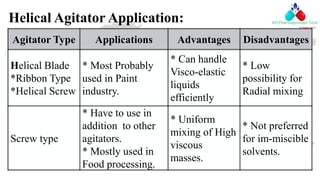

Agitator Type Applications Advantages Disadvantages

Turbine

*Straight Blade

*Pitched Blade

*Curved Blade

*Disk Blade

* Liquids and

Gas reactions,

* Highly used

during Reaction

and Extraction

Operations.

* Generates

high Radial

Flow,

* Highly used

for dispersion

operations

* Not preferred

for solvents

with

high viscosity[

NMT 20 cP]](https://image.slidesharecdn.com/agitatorandtypes-220313061123/85/Agitator-types-application-function-No-of-agitator-calculation-16-320.jpg)