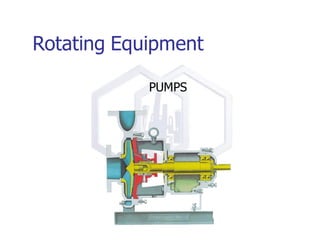

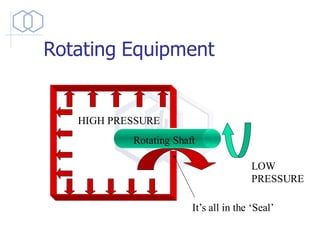

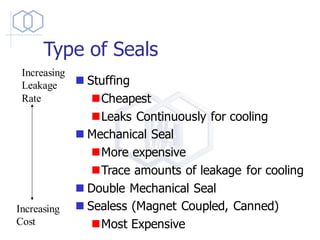

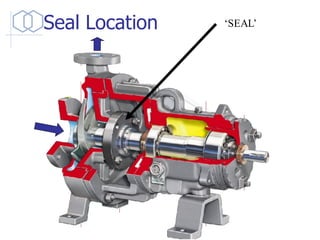

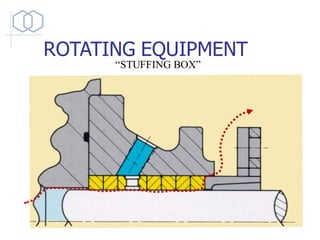

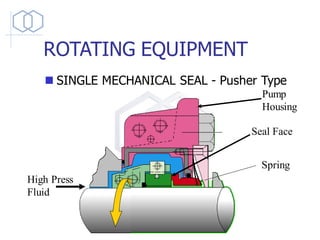

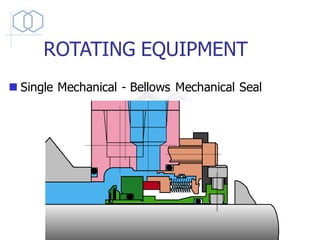

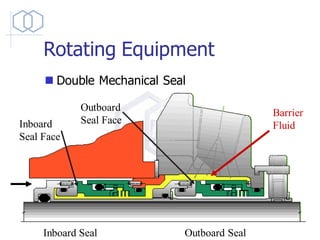

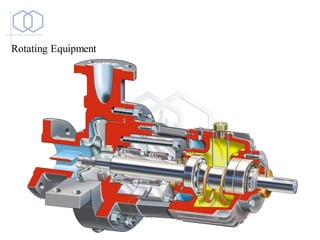

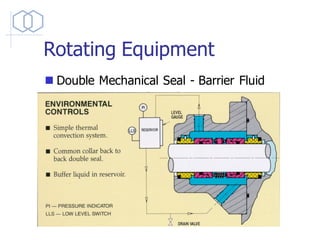

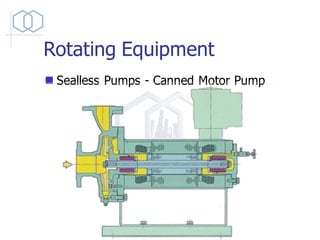

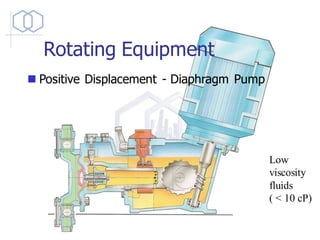

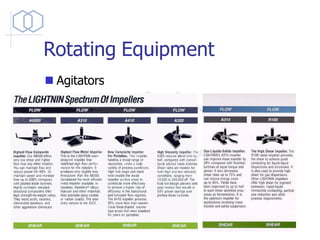

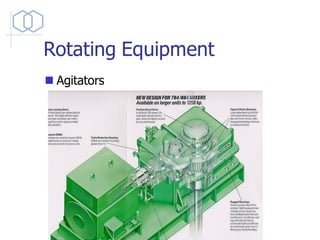

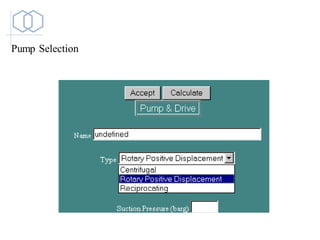

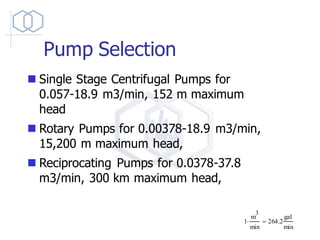

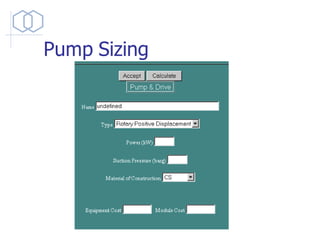

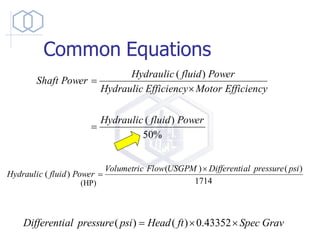

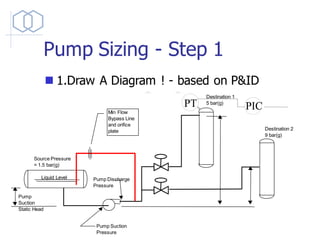

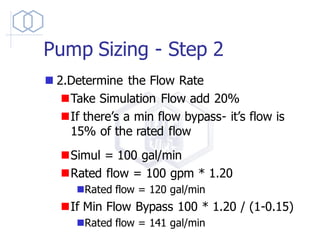

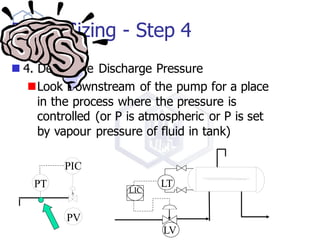

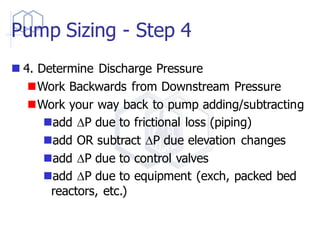

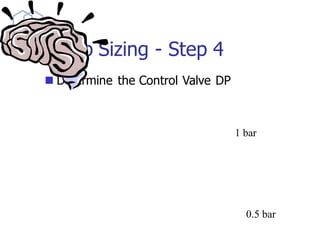

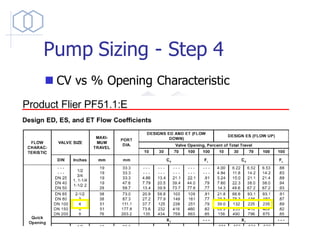

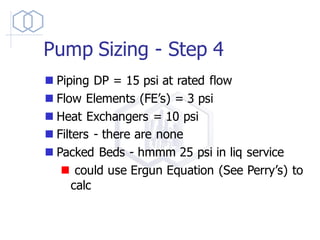

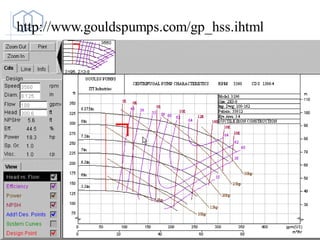

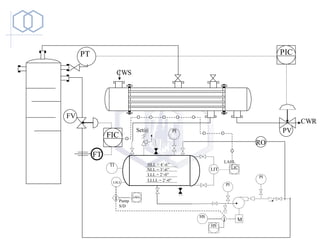

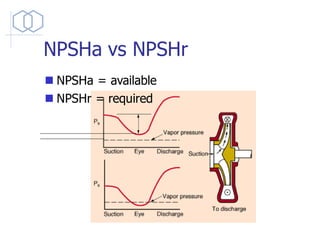

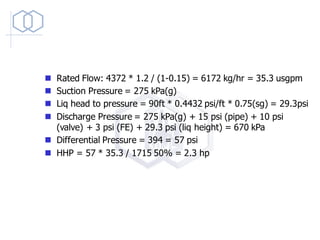

The document discusses various types of rotating equipment such as pumps, compressors, and seals, emphasizing the importance of seals in managing fluid leakage. It outlines the process of pump sizing, detailing steps for determining flow rate, inlet and discharge pressures, and necessary calculations for efficiency. Additionally, it covers specific pump types and their applications based on fluid viscosity and operational metrics.