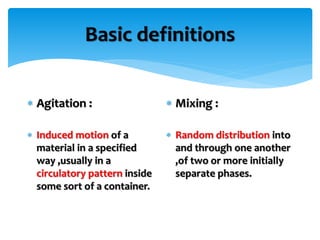

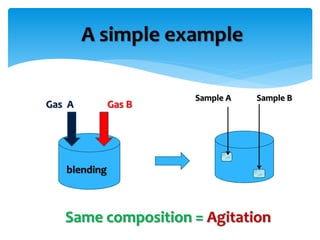

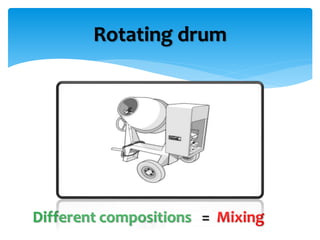

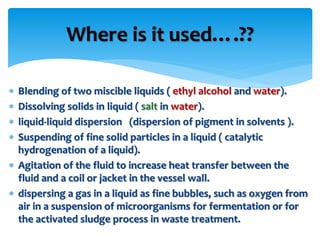

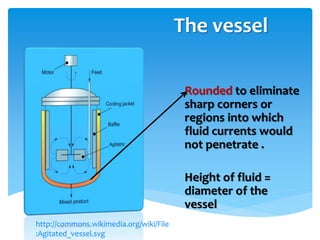

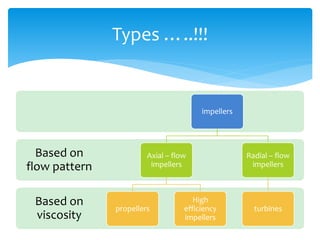

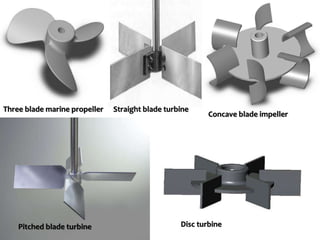

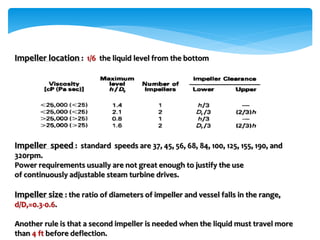

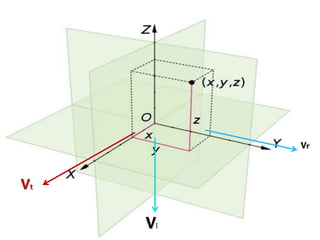

This document discusses the basic design of agitated vessels. It defines agitation as induced circulatory motion inside a container, while mixing is the random distribution of separate phases. Agitated vessel design considers factors like vessel shape, impeller type/size/placement, flow patterns, baffles, and power requirements. Common impeller types include axial-flow and radial-flow varieties. Baffles are used to prevent vortexes and direct flow. Power correlations can determine agitator power needs based on parameters like pumping number and Reynolds number.