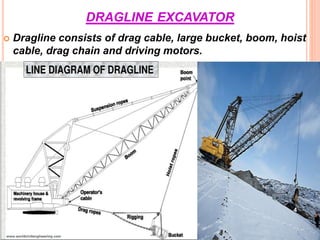

The document provides an overview of dragline excavators used in civil engineering and surface mining, detailing their working mechanism, applications, and factors affecting performance. It outlines the types of draglines, including crawler, wheel, and truck mounted, as well as their advantages, such as efficient operation on natural ground, and disadvantages like lower digging force compared to power shovels. Overall, the document serves as a comprehensive guide to understanding dragline equipment.