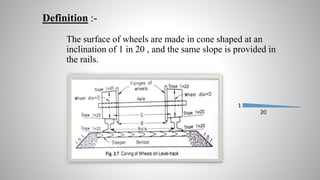

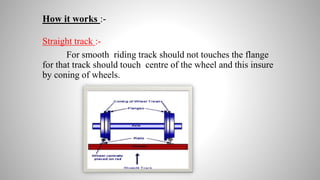

The wheels of trains are shaped conically, sloping at an angle of 1 in 20 to match the conical slope of the rails. This coning prevents lateral movement between the wheels and rails that could cause uneven load distribution. On straight tracks, coning ensures the wheels roll along the center of the rails without touching the flanges. On curved tracks, the increased diameter on the outer wheels and decreased diameter on inner wheels compensates for the greater distance the outer wheels must travel due to centrifugal force. Coning reduces lateral movement and contact between flanges and rails to allow for smooth train movement.