- Strukturas is a company founded in 1991 that specializes in turnkey bridge projects worldwide. They have experience dating back to the 1960s.

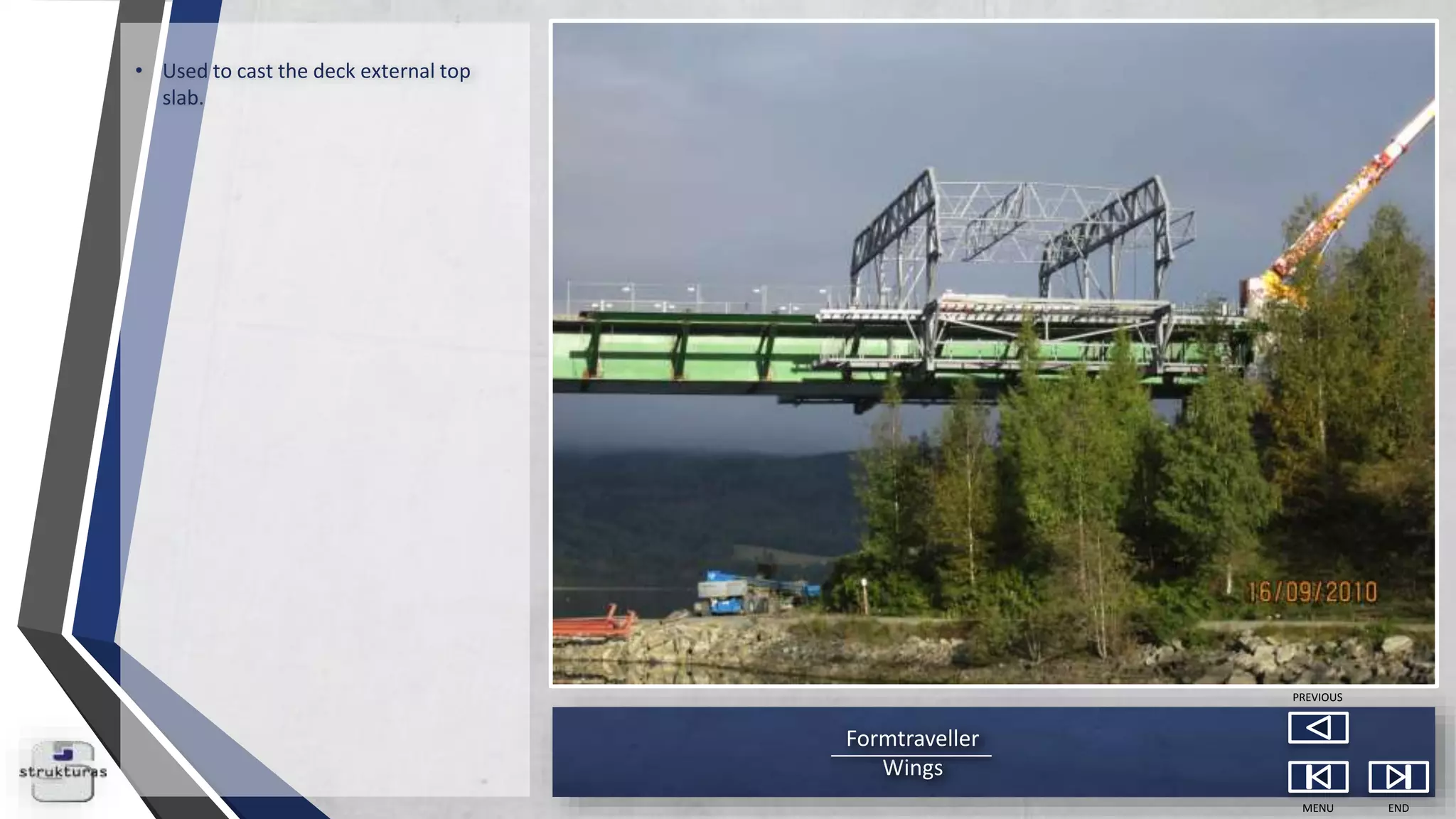

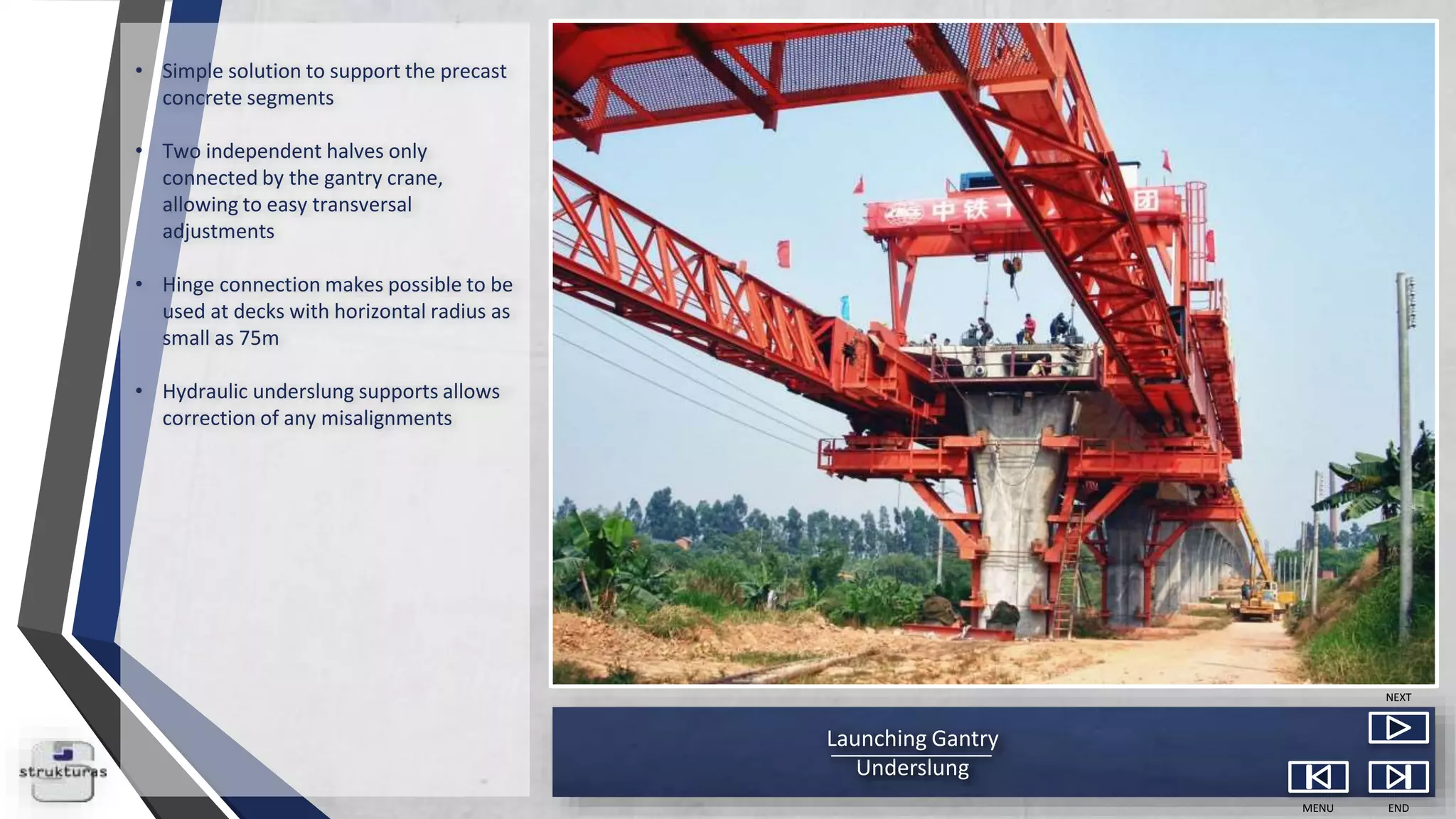

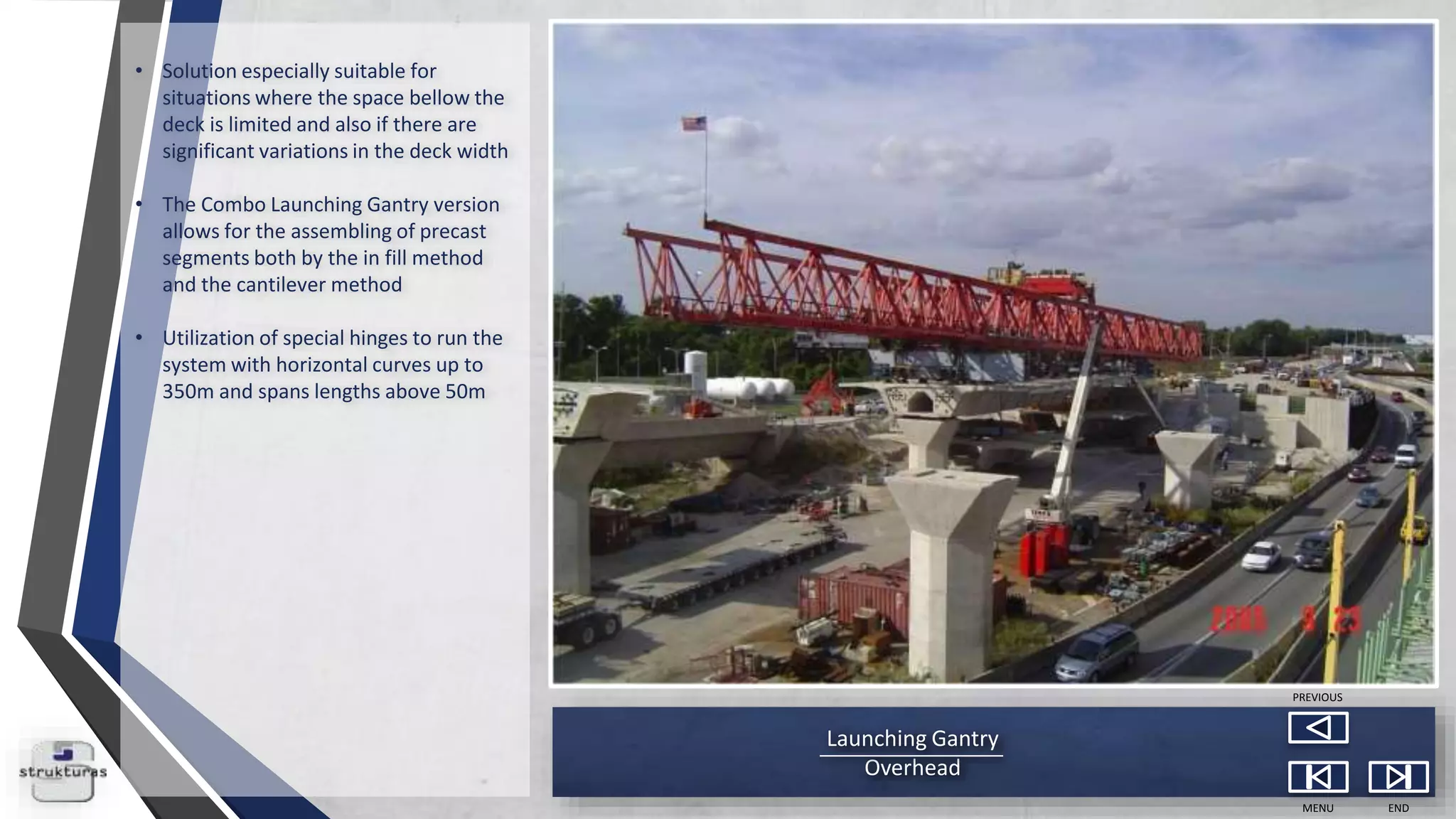

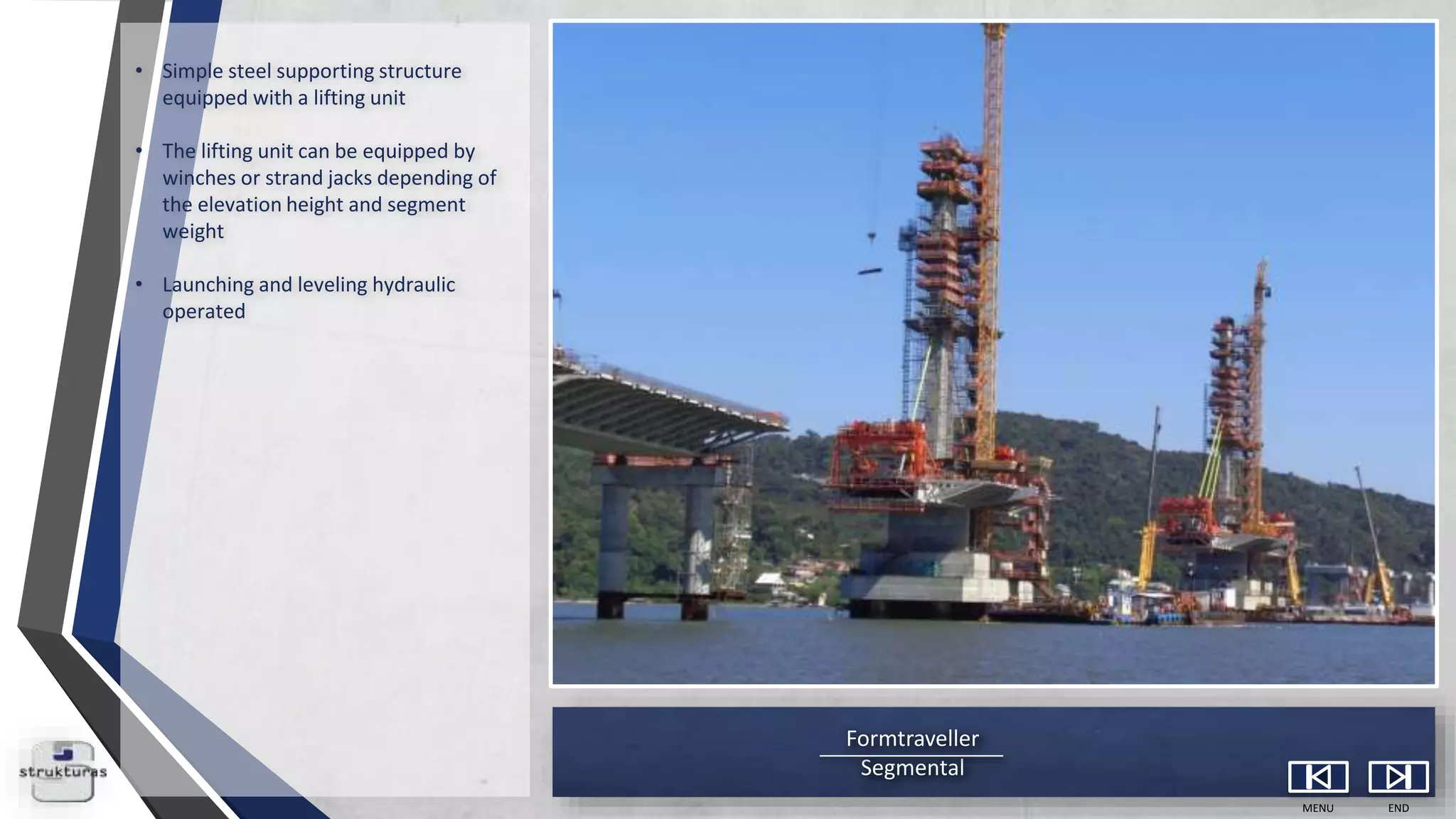

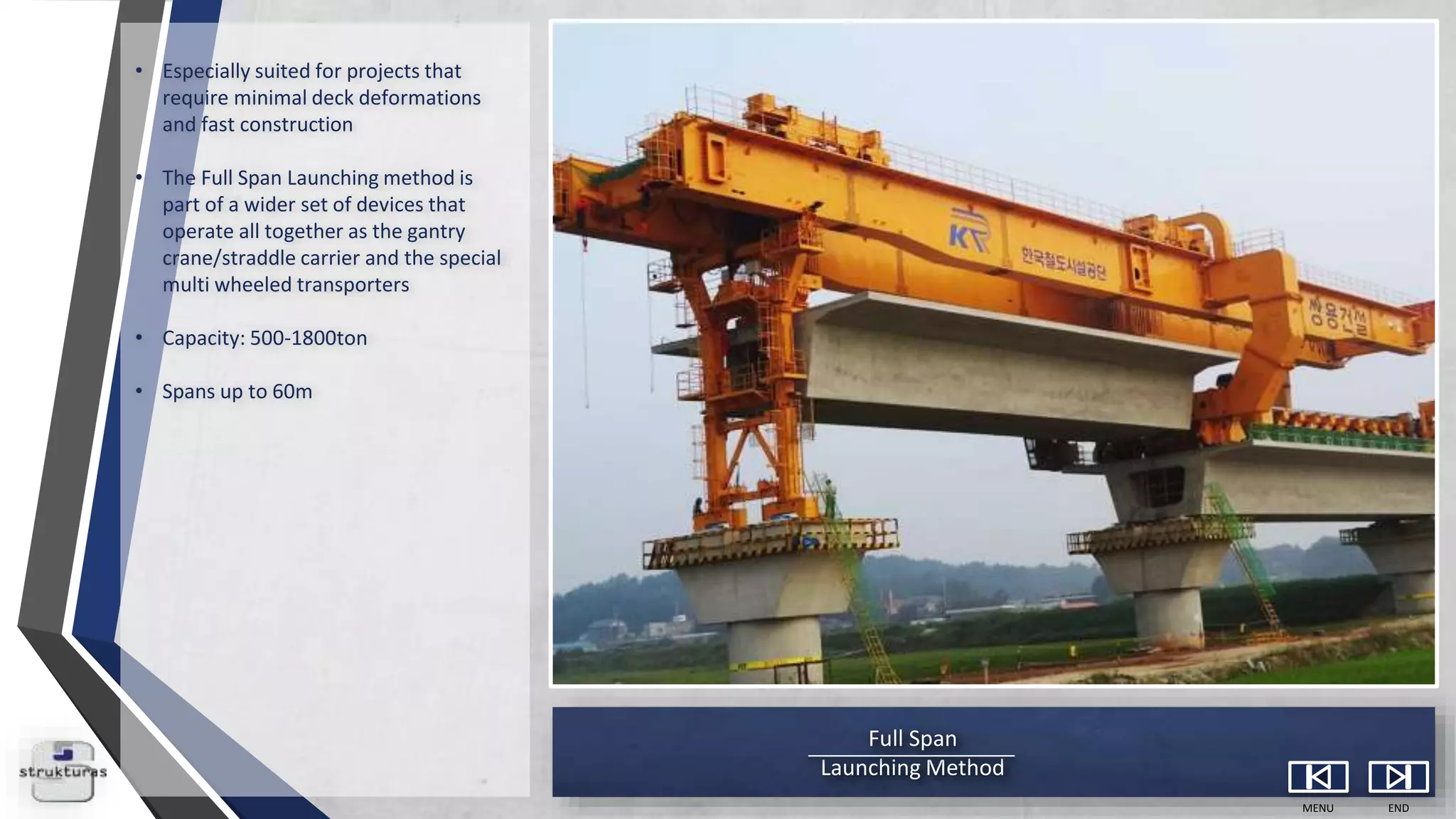

- They design, engineer, fabricate, and provide quality control for various types of bridge building equipment for cast in situ and precast concrete bridges.

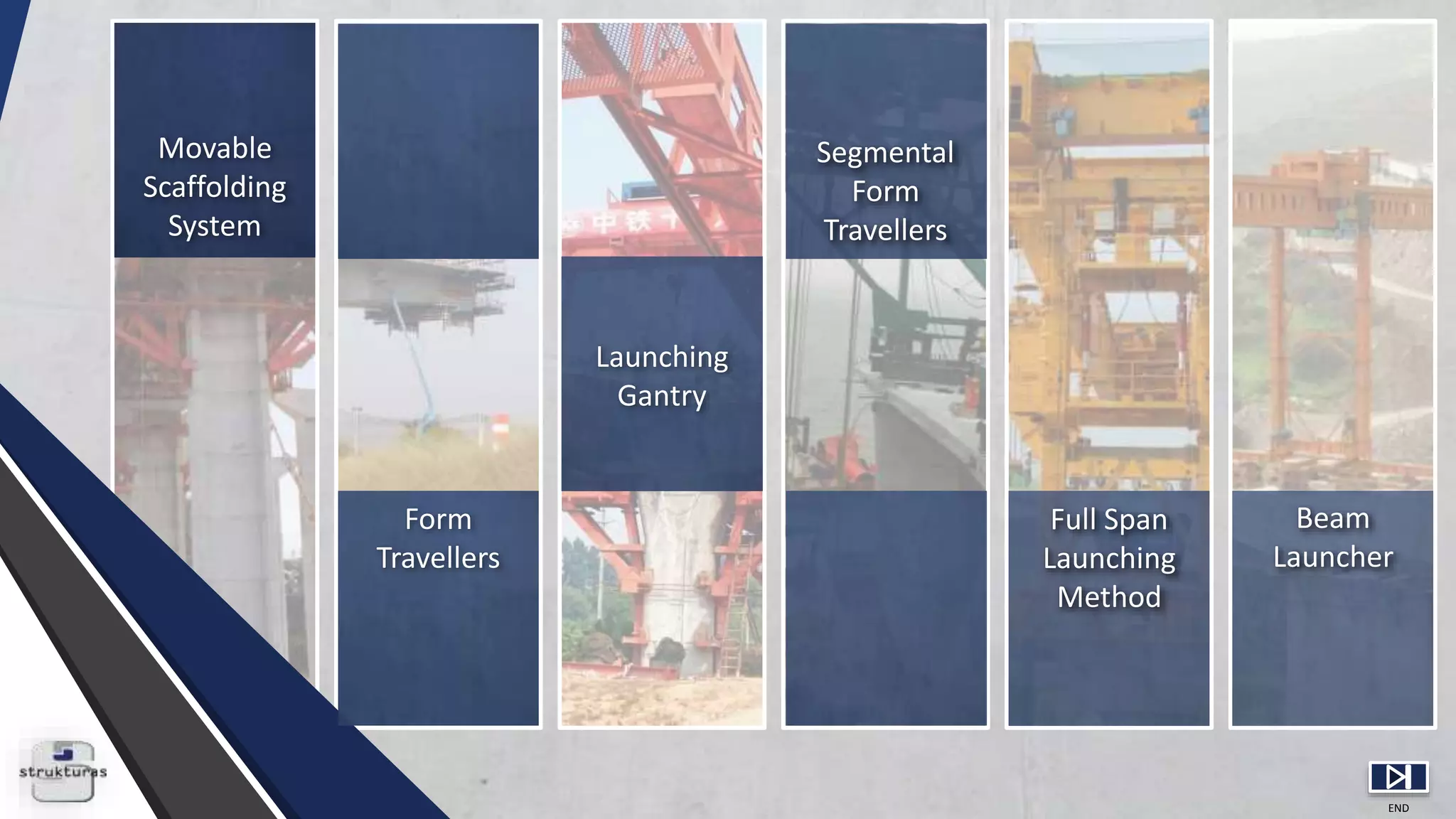

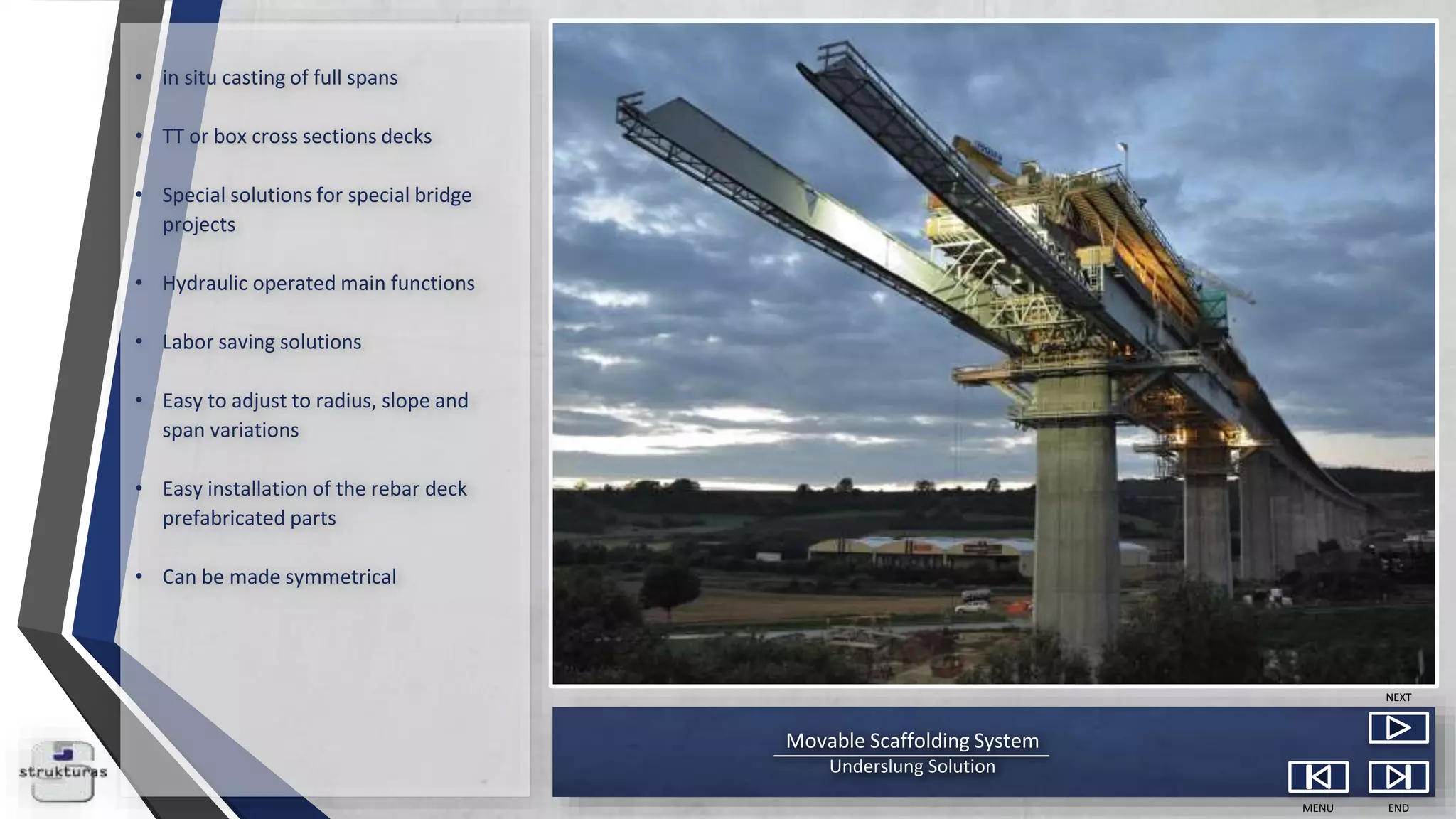

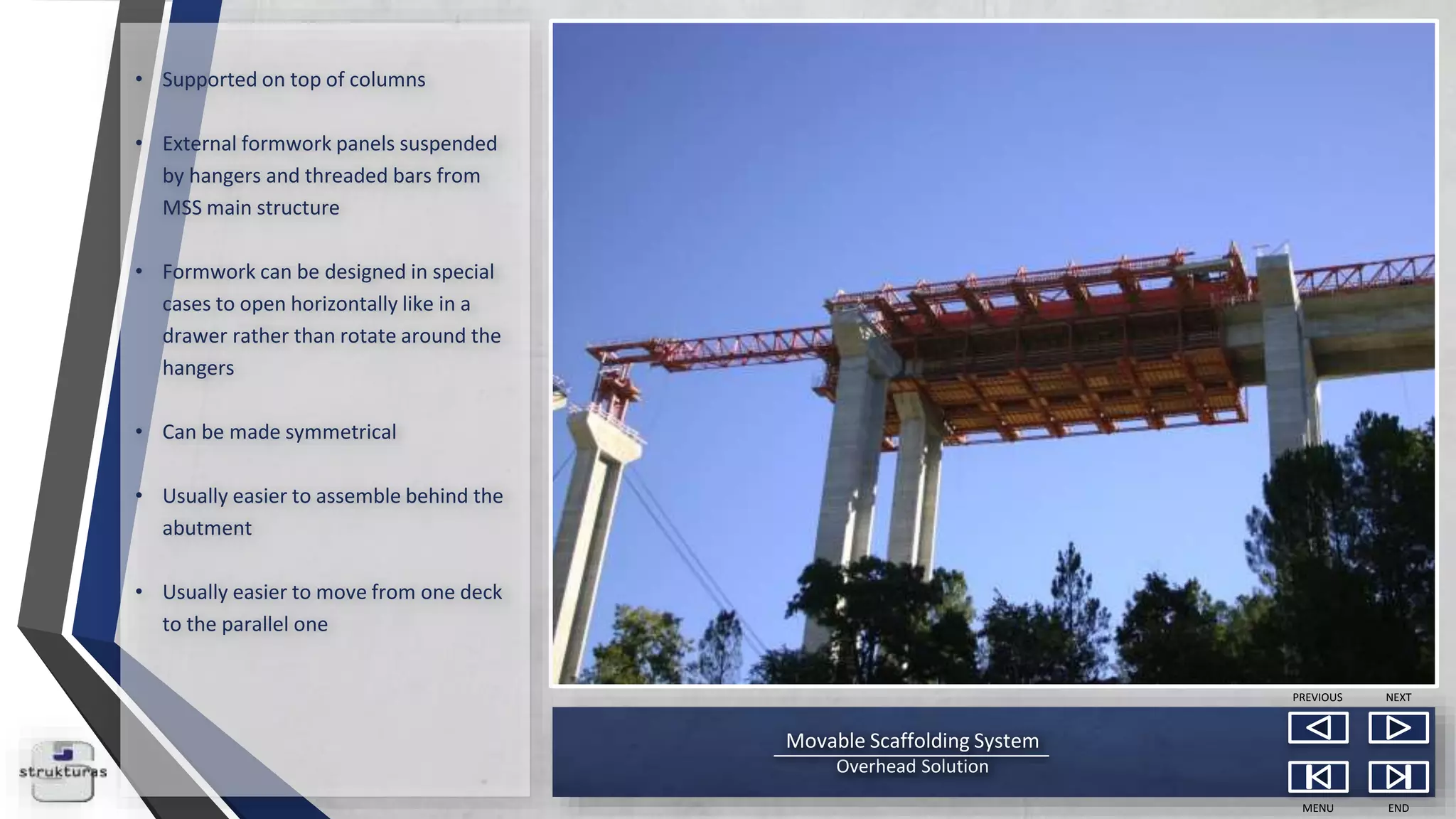

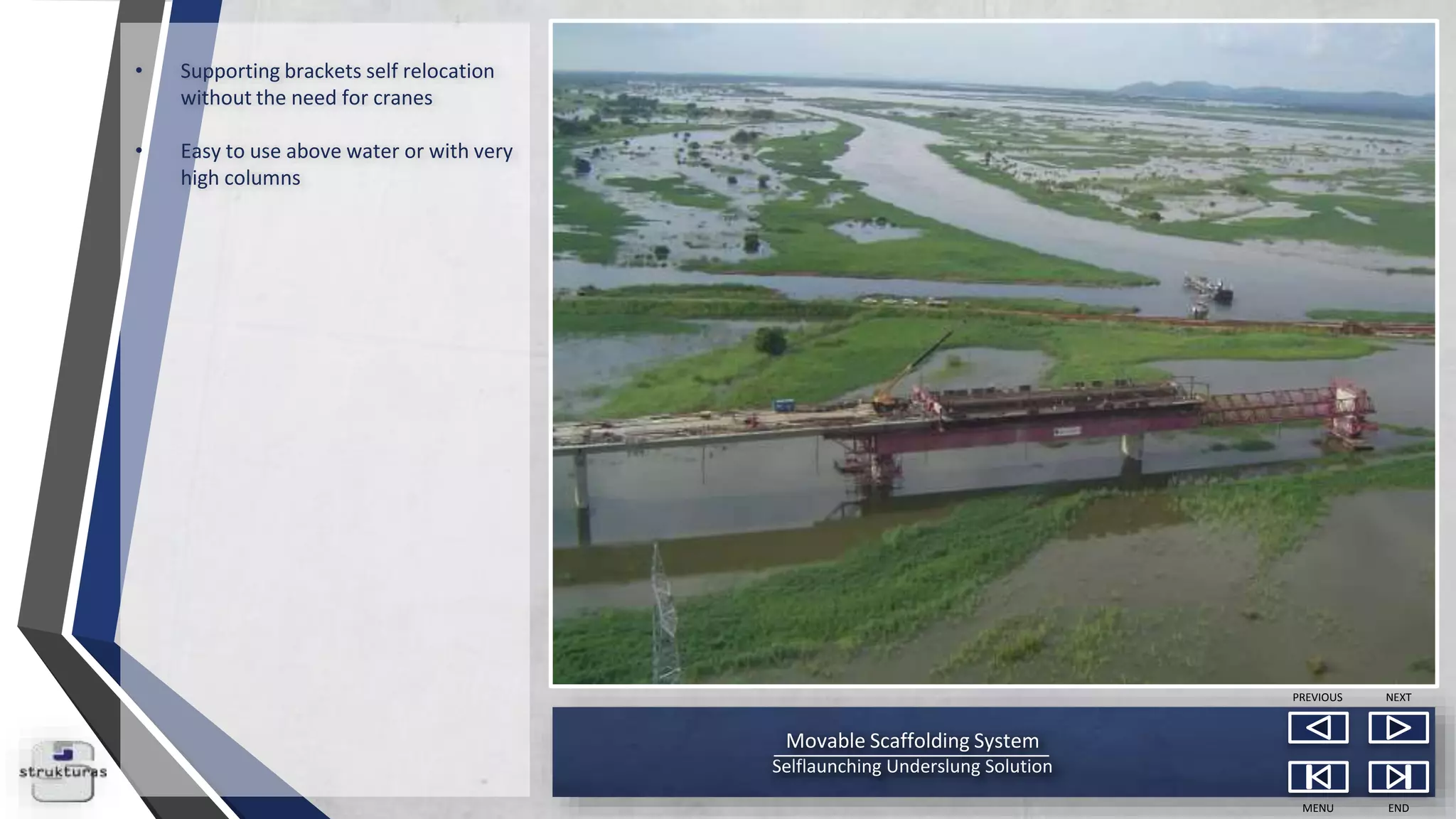

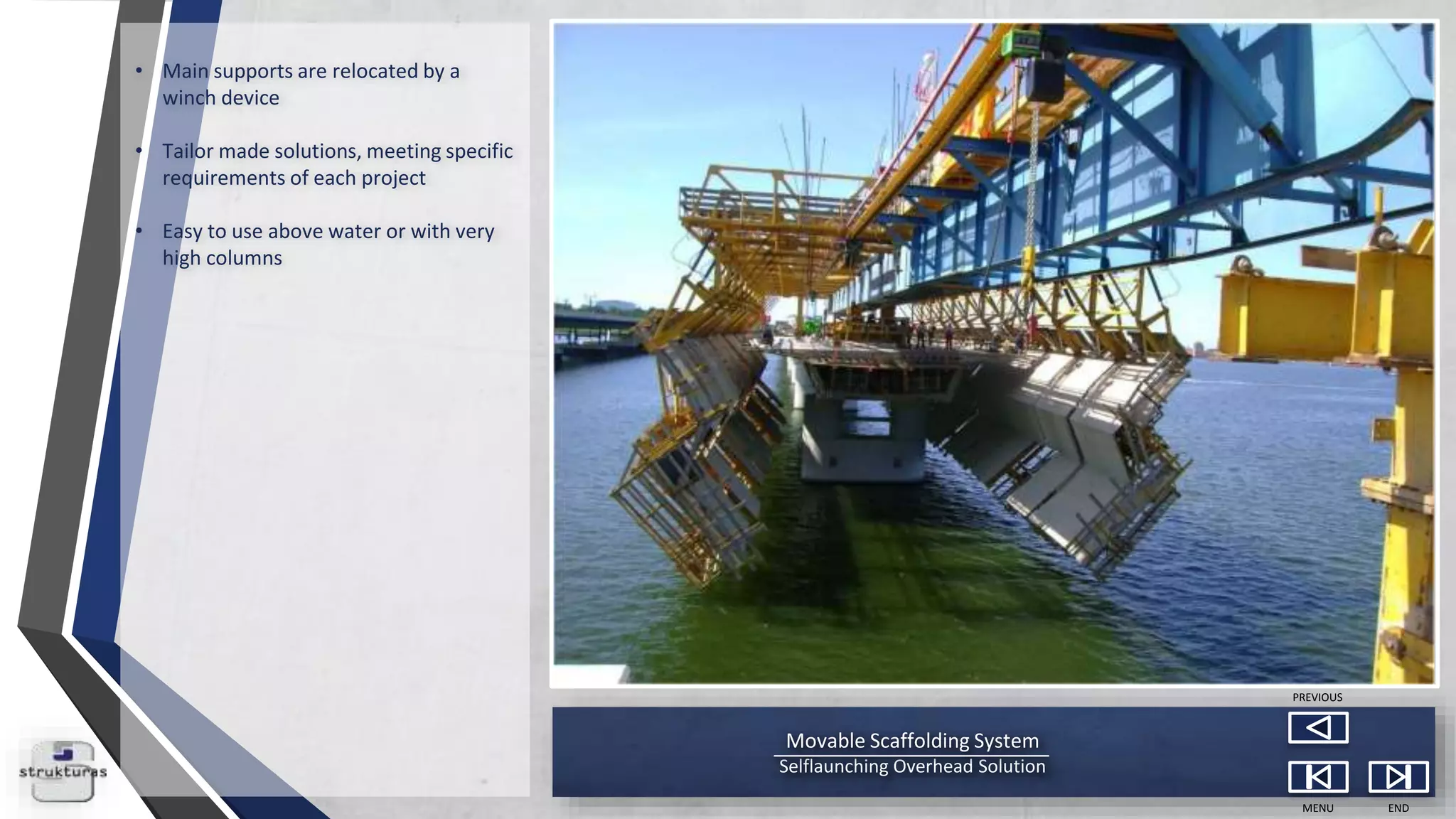

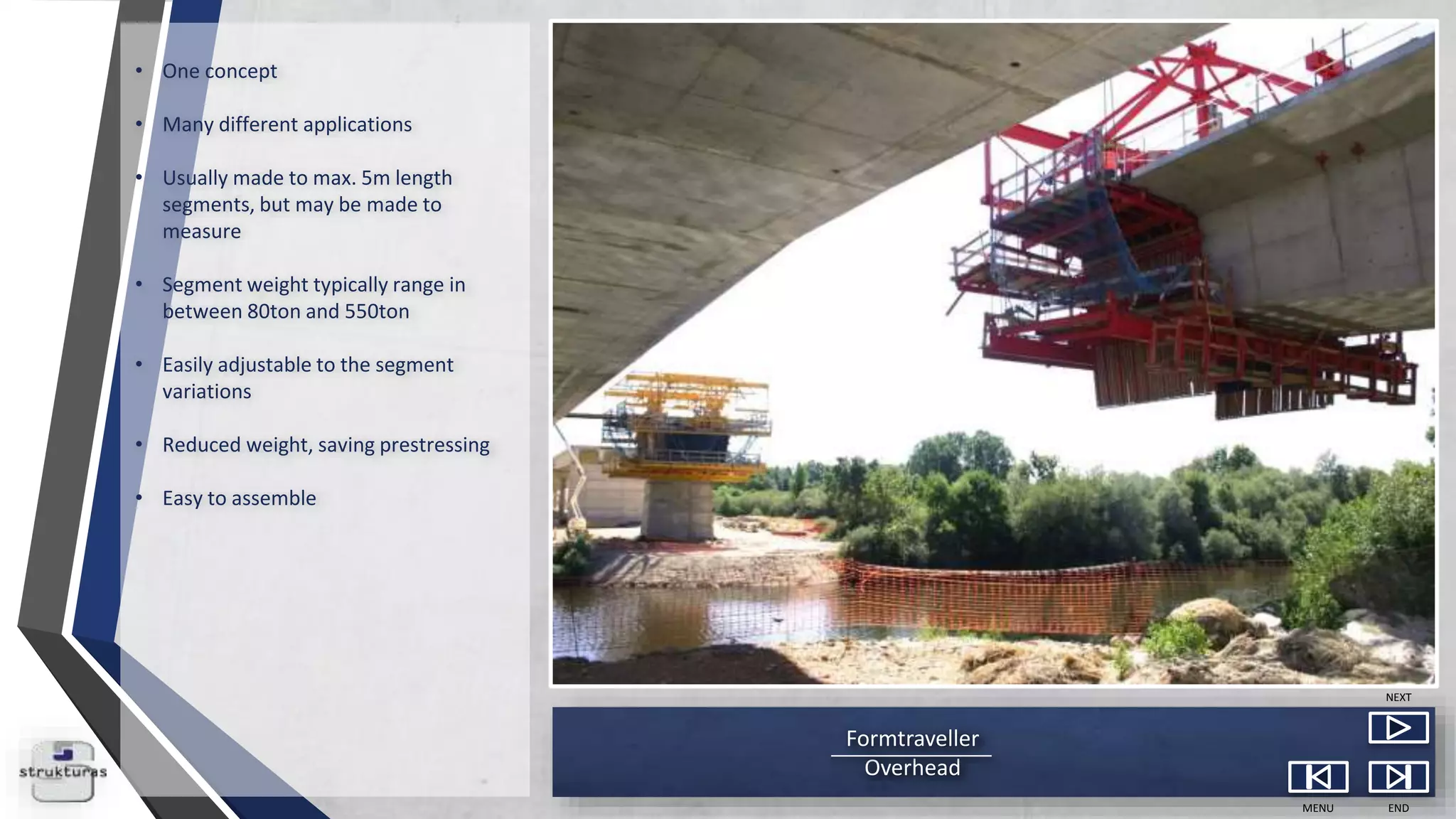

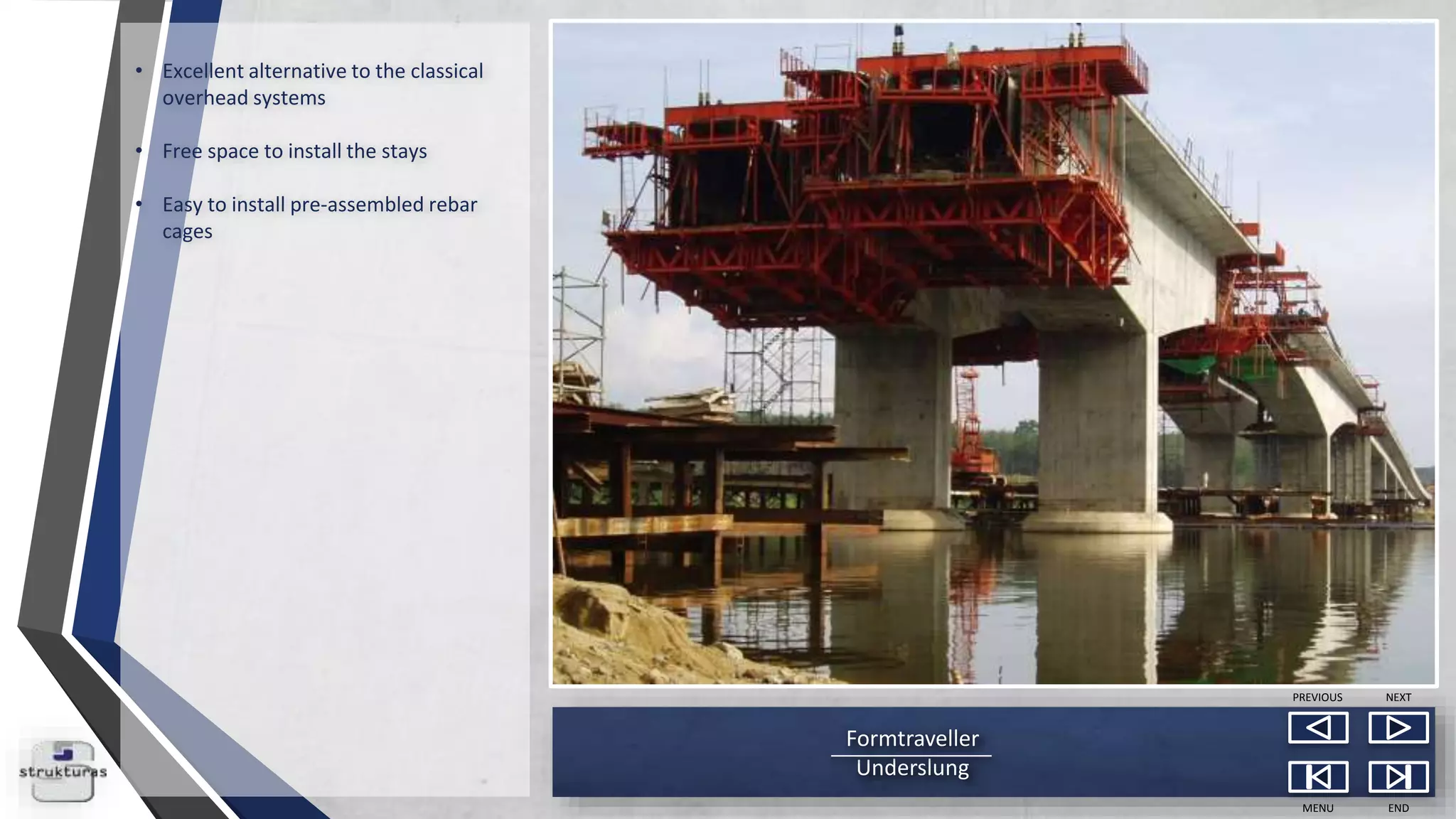

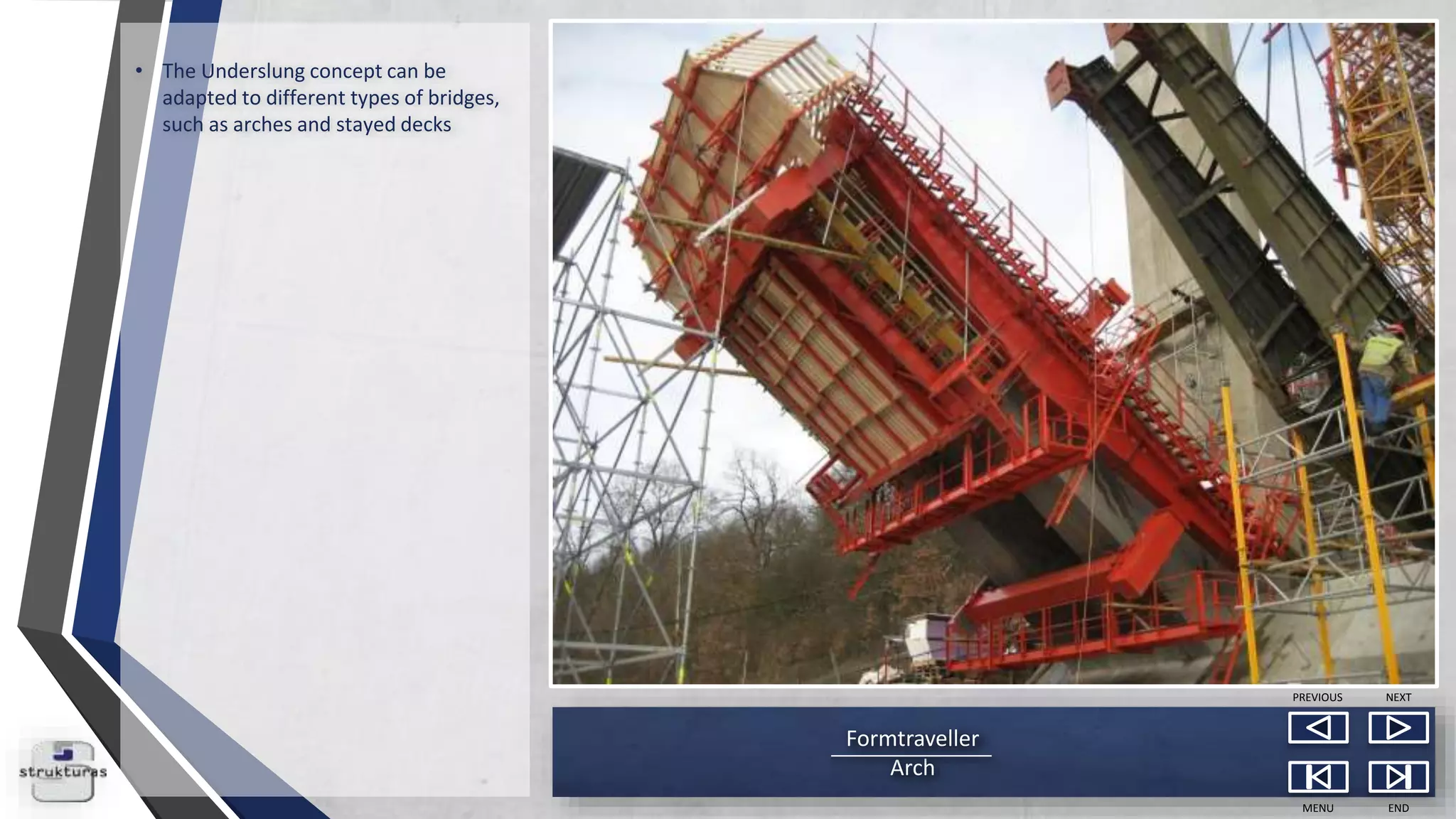

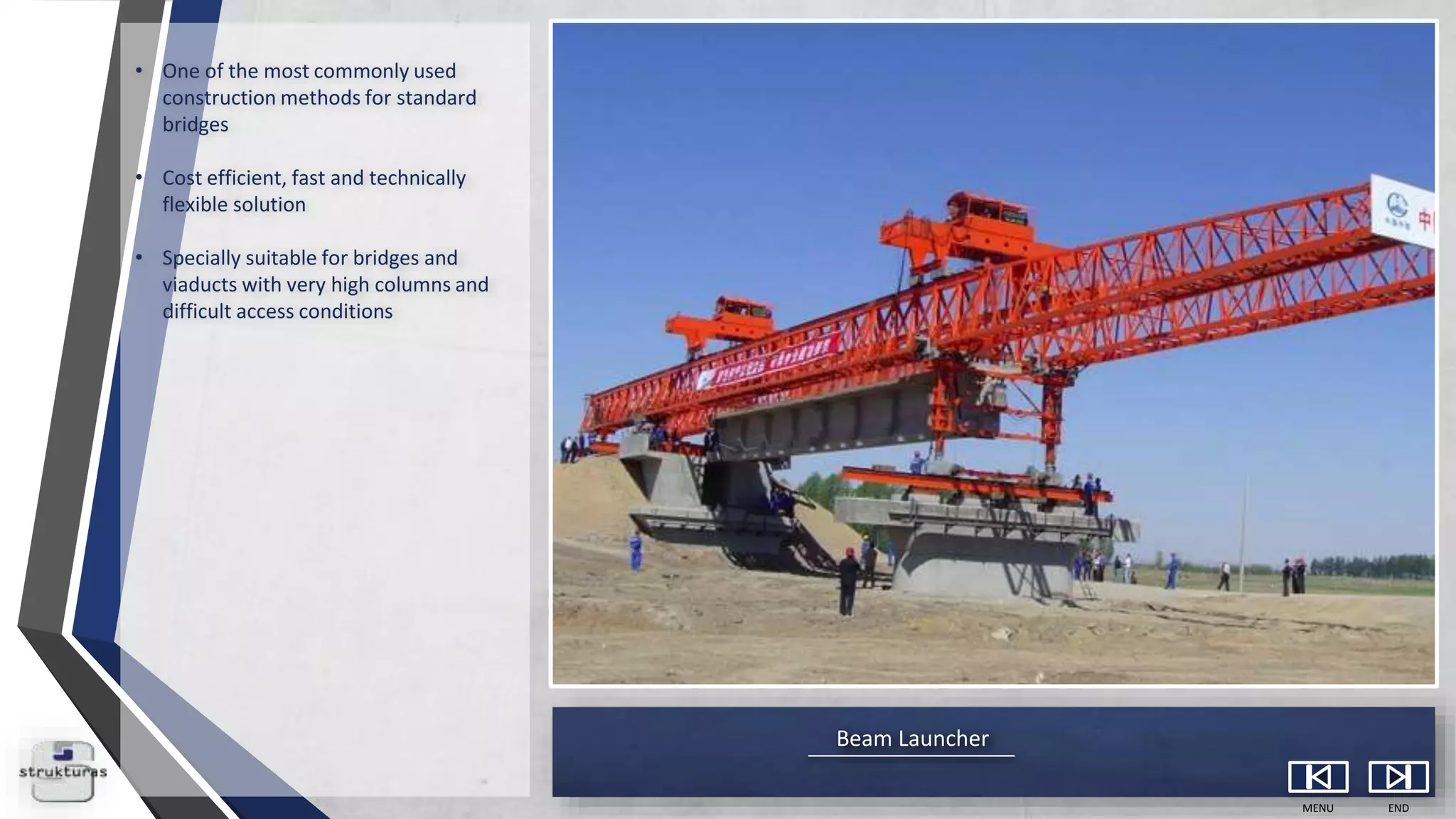

- The document describes and provides images of different types of movable scaffolding systems, form travellers, launching gantries, segmental form travellers, full span launching methods, and beam launchers that Strukturas provides for efficient bridge construction.