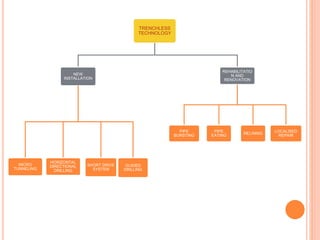

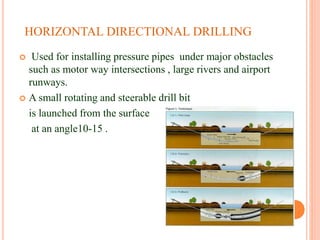

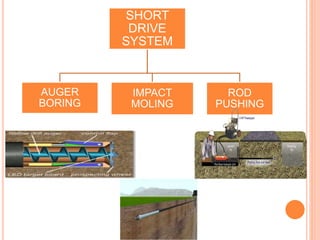

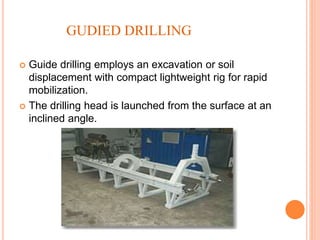

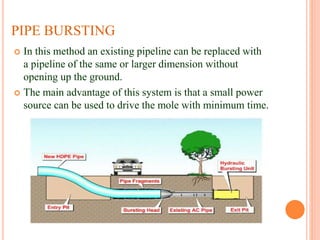

This document discusses trenchless technology, which involves installing underground pipes and cables without disrupting the surface. It notes the disadvantages of conventional trenching that led to trenchless methods. Various trenchless techniques are described, including microtunneling, horizontal directional drilling, pipe bursting, pipe eating, and relining. The advantages of trenchless methods are that they minimize surface damage, accidents, environmental impacts, and disruption to daily life above ground. Trenchless technology allows for installation, repair, and rehabilitation of underground infrastructure with minimal disturbance.