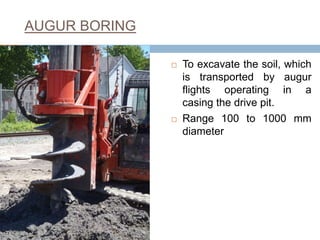

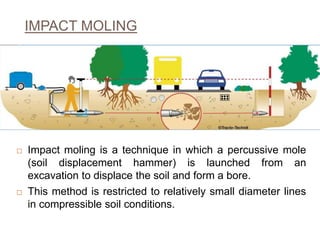

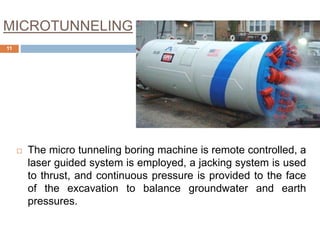

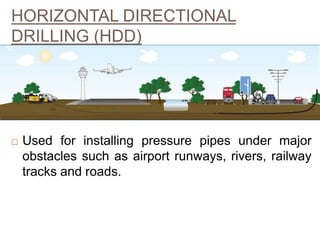

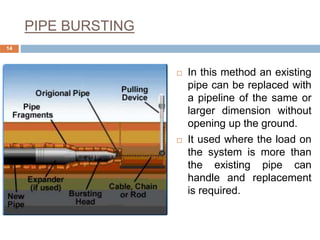

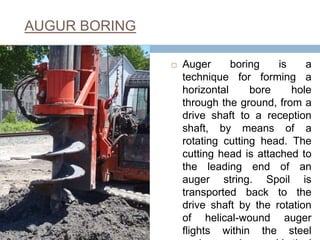

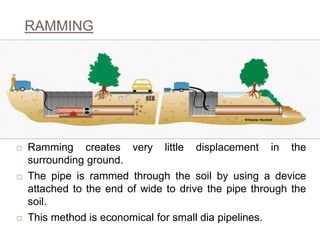

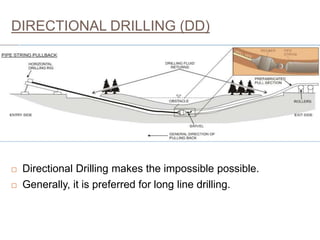

Trenchless technology involves the installation or rehabilitation of underground infrastructure with minimal surface disruption. Some common trenchless methods include auger boring, impact moling, microtunneling, pipe bursting, pipe eating, and horizontal directional drilling. Trenchless technology provides advantages over traditional trenching such as reduced traffic and business disruptions, improved safety, and less environmental damage. While trenchless methods require specialized equipment and skills, they allow for construction with fewer impacts and hazards compared to traditional trench excavation.

![TRENCHLESS TECHNOLOGY

Prepared By:

PATEL HEMISHKUMAR ANILBHAI

ENROLLMENT NO: 130080714008

FIRST SEMESTER

BIRLA

VISHVAKARMA

MAHAVIDHYALAYA

GUJARAT

TECHNOLOGICAL

UNIVERSITY

M.E. [ CONSTRUCTION

ENGINEERING &

MANAGEMENT ]CONSTRUCTION TECHNIQUES

(711402)

Guide By:

PROF. JAYESHKUMAR R. PITRODA

ASSISTANT PROFESSOR & RESEARCH

SCHOLAR

CIVIL ENGINEERING DEPARTMENT

B.V.M ENGINEERING COLLEGE](https://image.slidesharecdn.com/tt-copy-140511014403-phpapp01/85/trenchless-technology-1-320.jpg)