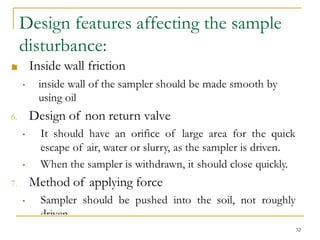

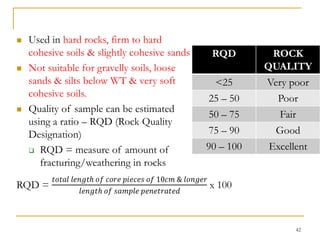

This document provides an overview of subsurface exploration, which involves site investigation and soil exploration to assess soil conditions for engineering projects. It discusses the objectives, phases and methods of subsurface exploration. The main methods covered are open excavation techniques like test pits and trenches, as well as boring techniques like auger, wash, percussion and rotary boring. It also describes different sampling techniques for obtaining disturbed and undisturbed soil samples, and different types of in-situ tests like standard penetration tests and cone penetration tests.