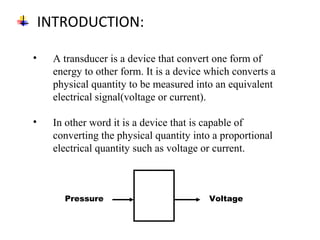

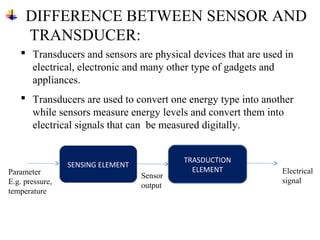

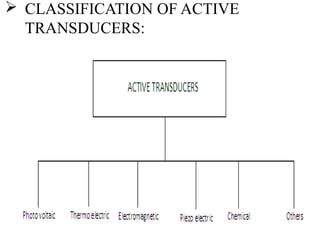

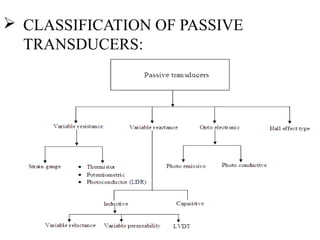

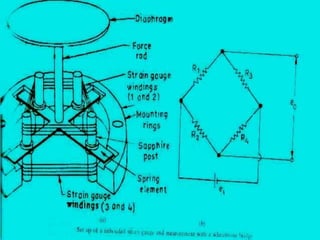

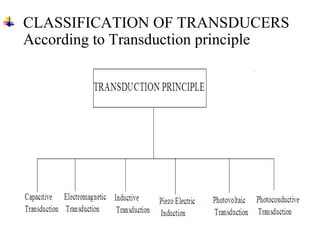

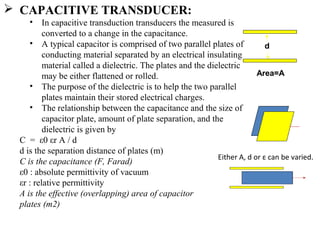

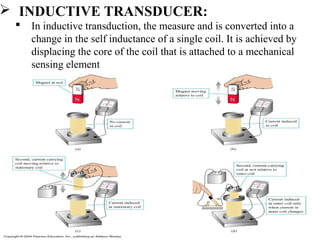

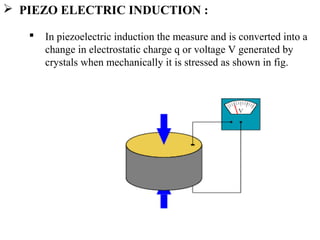

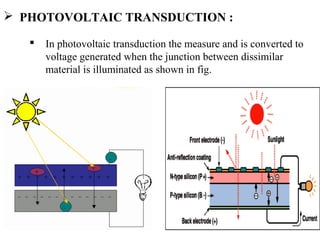

This document discusses transducers, which convert one form of energy to another. It defines transducers as devices that convert a physical quantity into an equivalent electrical signal. It then describes different types of transducers, such as resistive, capacitive, electromagnetic, and piezoelectric transducers. The document also distinguishes between sensors and transducers, and discusses factors to consider when selecting transducers, such as operating principle, sensitivity, accuracy, and environmental compatibility. It concludes by classifying transducers as active/passive, analog/digital, and primary/secondary transducers.