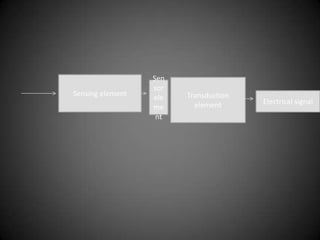

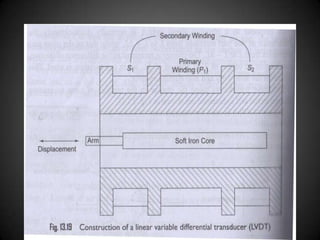

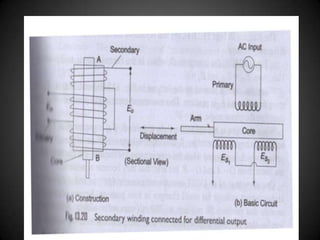

A transducer is a device that converts energy from one form to another. There are two main types - electrical and mechanical. An electrical transducer converts a non-electrical signal to an electrical signal. Examples include strain gauges, thermistors, and LVDTs. These transducers contain a sensing element and a transduction element. Parameters like linearity, dynamic range, accuracy, and size are important in transducer selection and performance.