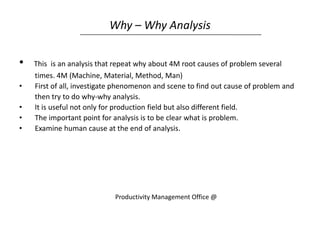

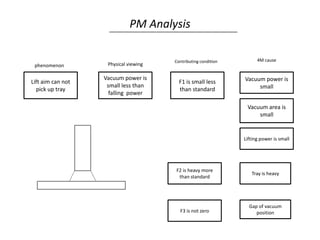

- The document discusses analyzing problems using a "why-why" analysis to find the root 4M (machine, material, method, man) causes by repeatedly asking why. It provides an example PM analysis of a lifting problem.

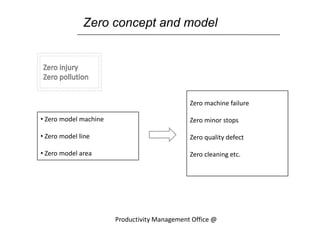

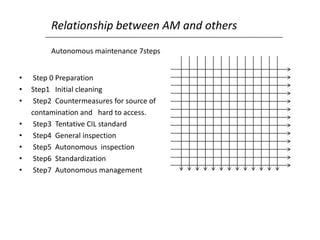

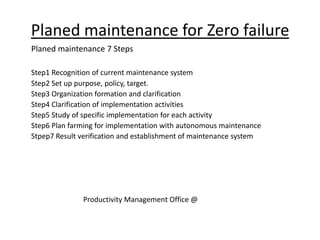

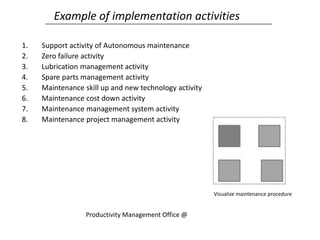

- It discusses key aspects of autonomous maintenance (AM) and planned maintenance for achieving zero failures. Specific implementation activities are outlined.

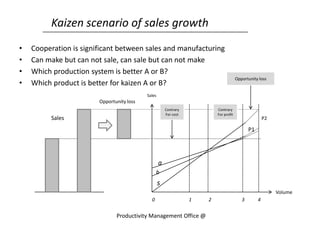

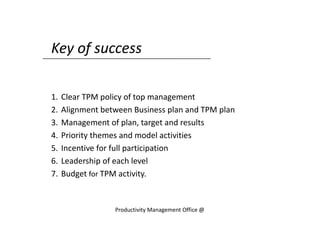

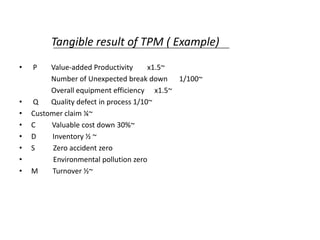

- TPM program success relies on clear top management policy alignment, target management, priority themes, participation incentives, and leadership at all levels. Programs have achieved tangible results like 50% reduced costs and inventory.