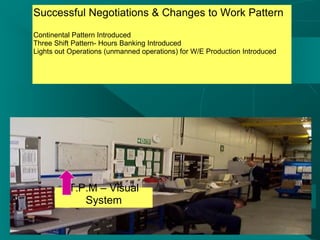

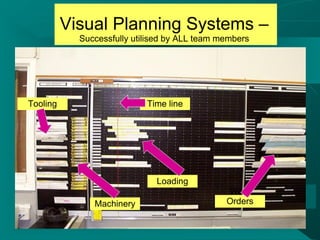

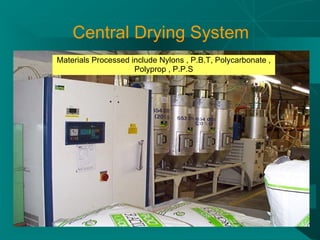

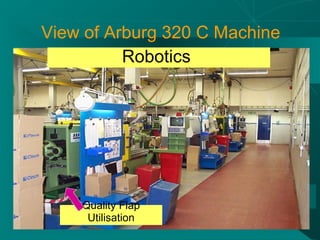

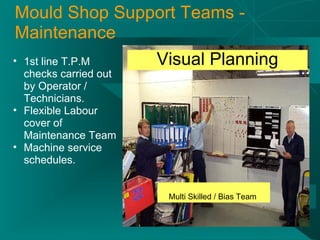

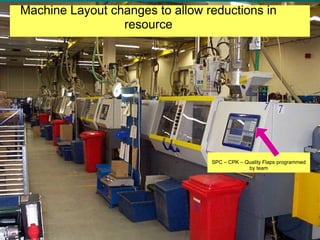

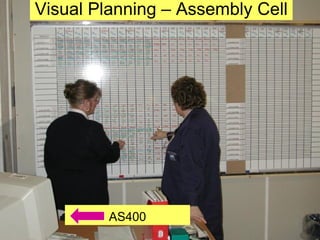

This document provides an overview of Cinch Connectors' mould shop operations. It discusses the workshop's achievement of awarding body centre approval status and introduces key performance indicators. It also summarizes recent successful negotiations that introduced changes to work patterns and hours banking. The rest of the document outlines various systems, machines, teams, and processes that support mould production and quality assurance at the workshop.