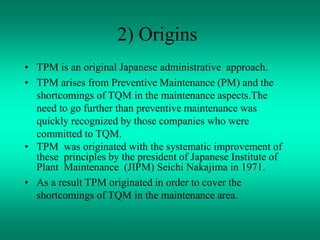

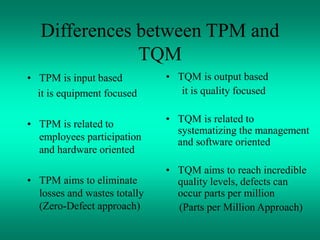

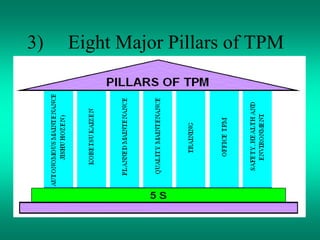

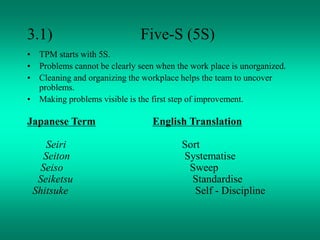

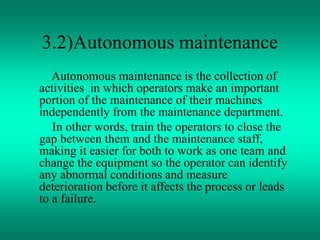

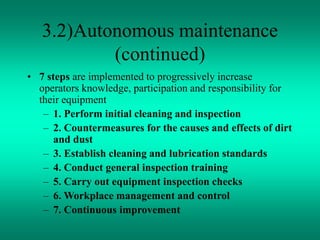

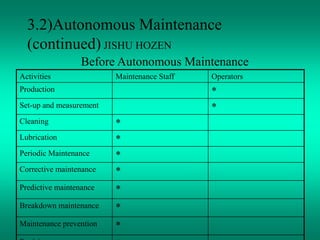

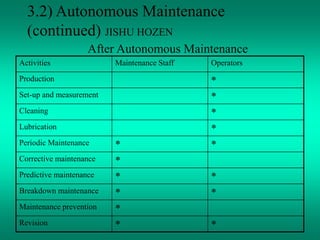

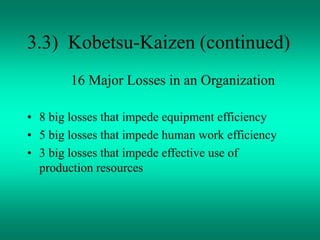

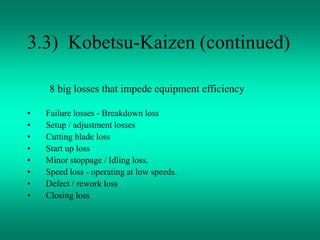

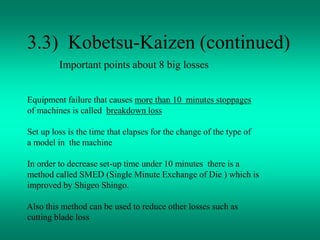

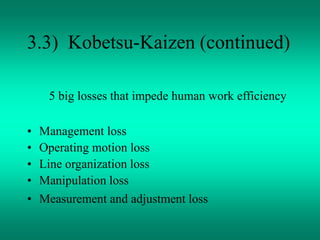

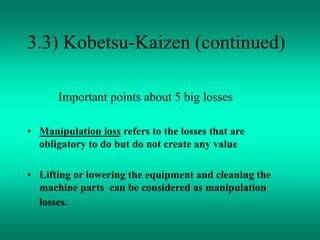

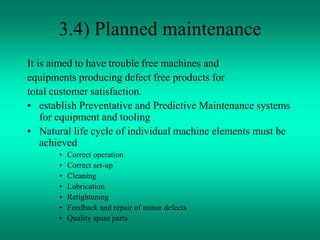

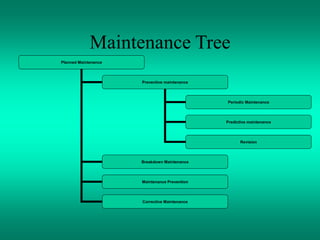

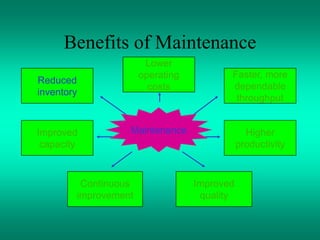

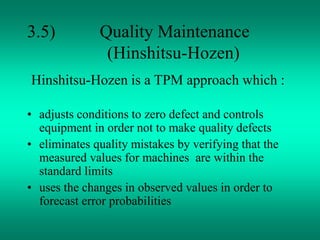

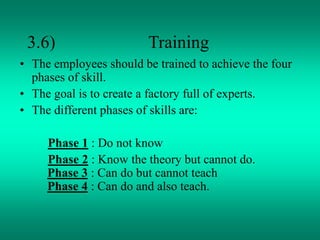

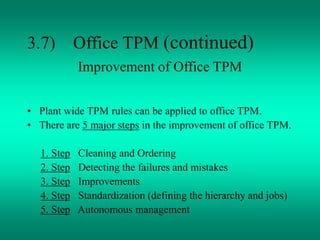

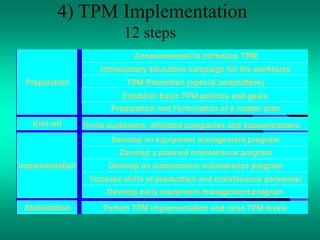

This document outlines the principles and implementation of Total Productive Maintenance (TPM). It defines TPM as a company-wide effort involving all employees to improve equipment effectiveness and eliminate breakdowns, defects, and accidents. The document describes the eight pillars of TPM, including 5S, autonomous maintenance, focused improvement, planned maintenance, and training. It then details the 12 step process for implementing TPM within an organization, including establishing policies, education, equipment management programs, and raising TPM levels over time. Potential benefits are also listed such as increased productivity, reduced costs, higher quality, and improved employee attitudes. A case study of TPM implementation at a bearing company is also summarized.