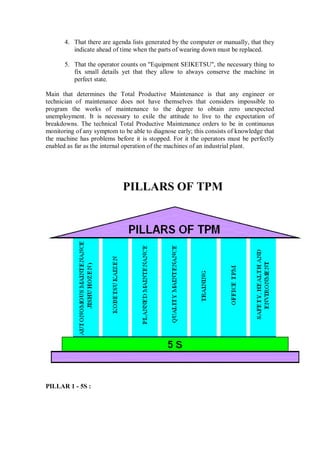

Total Productive Maintenance (TPM) is a philosophy that aims to maximize equipment effectiveness and eliminate waste through autonomous maintenance activities involving all employees. TPM was developed in Japan in the 1970s and focuses on achieving zero defects, accidents, and breakdowns through preventative maintenance practices. The goals of TPM include developing optimal human-machine systems where workers are responsible for daily maintenance tasks, improving workplace quality, and aggressively pursuing prevention over reactive repairs. TPM seeks to rationally manage equipment across production processes to optimize productivity and efficiency through objectives-driven maintenance systems.