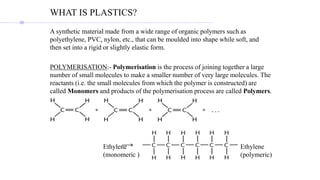

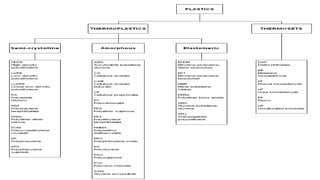

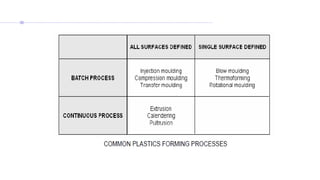

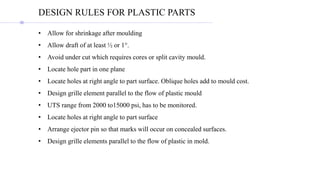

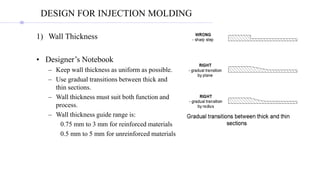

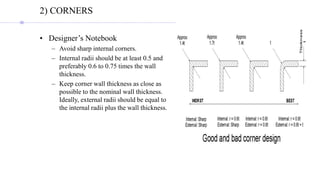

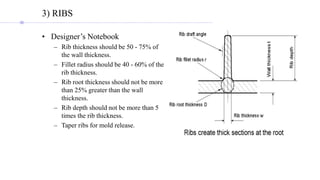

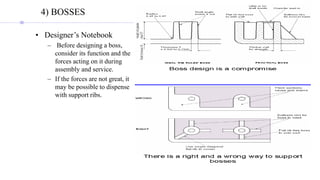

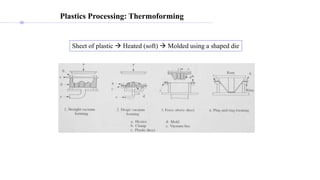

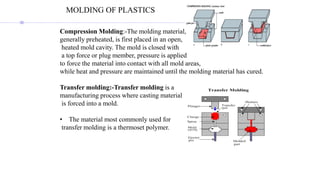

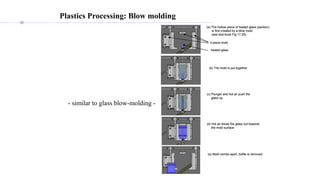

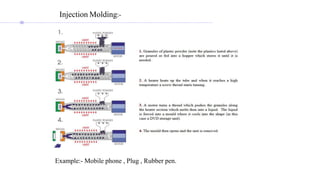

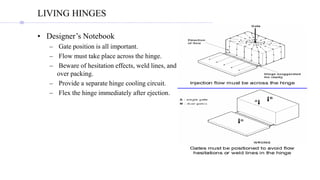

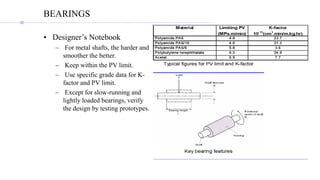

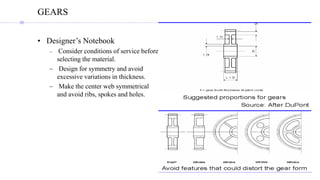

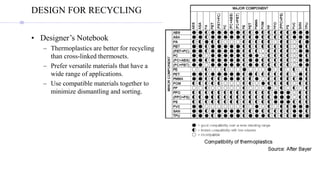

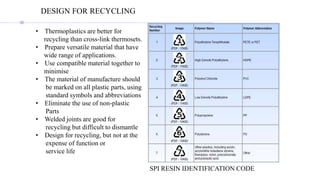

The document discusses various aspects of plastics design and manufacturing. It defines plastics and the polymerization process used to create them. It describes the main types of plastics as thermoplastics and thermosets, providing examples of each. It outlines key considerations for designing plastic parts, such as allowing for shrinkage, drafting angles, and hole placement. Finally, it discusses different plastic molding and forming processes like injection molding, blow molding, compression molding, and transfer molding.