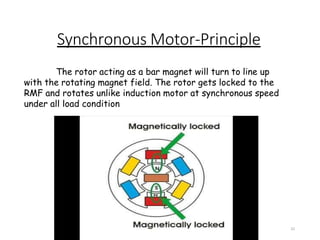

This document provides an overview of AC motors and their types. It discusses the basic principles of how electric motors work by using magnets to create motion. There are two main types of AC motors: synchronous motors and induction motors. Induction motors are further divided into single-phase and three-phase induction motors. Three-phase induction motors are the most common and can have either a squirrel cage or wound rotor. Synchronous motors rotate at a constant synchronous speed regardless of load but require special mechanisms to be self-starting. The document compares the characteristics and applications of different AC motor types.