The document provides an overview of induction motors, including:

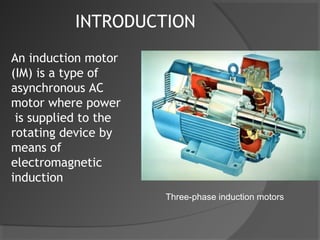

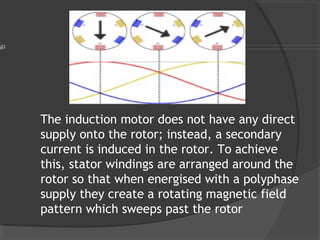

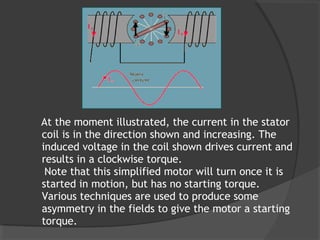

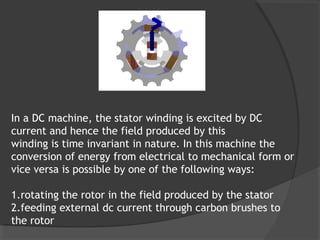

1. It describes the basic operating principle of induction motors, which induce a current in the rotor via electromagnetic induction from a rotating magnetic field in the stator.

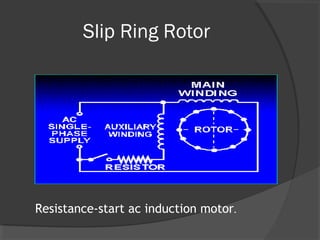

2. It discusses different types of induction motors including single phase, three phase, squirrel cage, and slip ring rotors. Speed control methods like PWM are also covered.

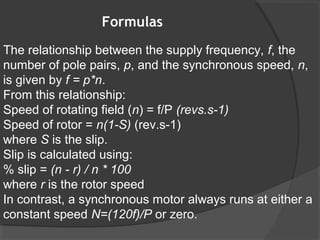

3. Formulas relating supply frequency, pole pairs, synchronous speed, slip, and rotor speed are presented.