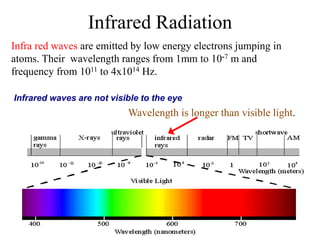

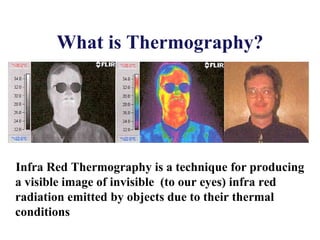

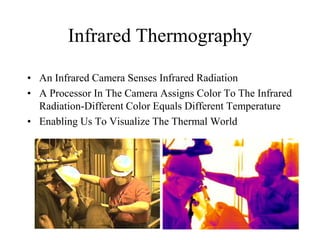

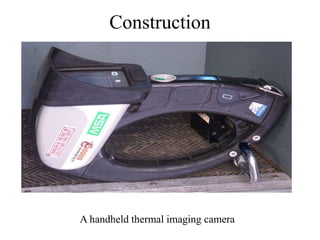

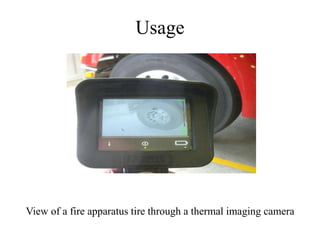

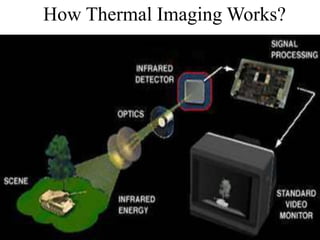

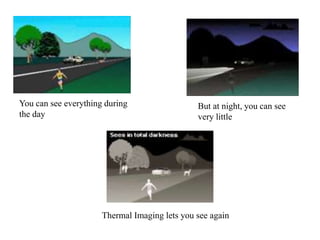

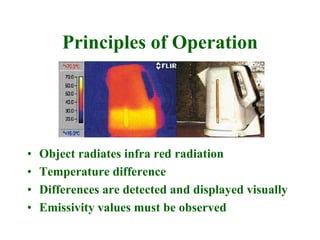

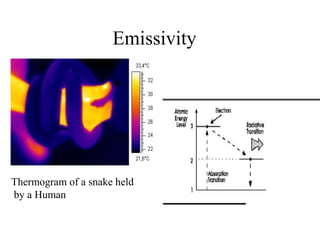

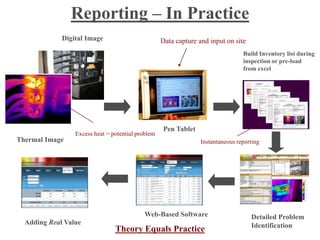

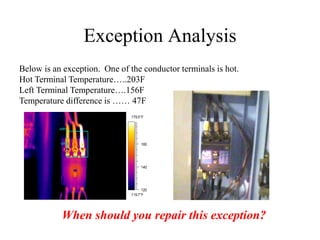

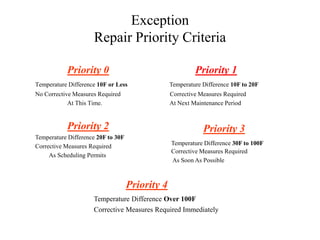

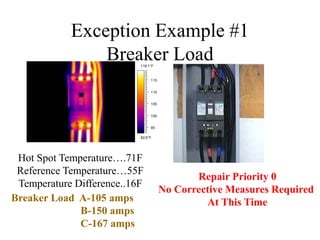

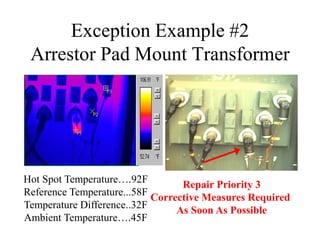

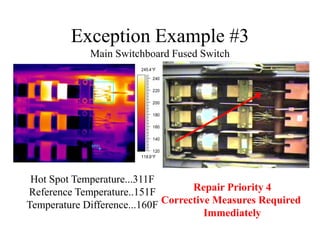

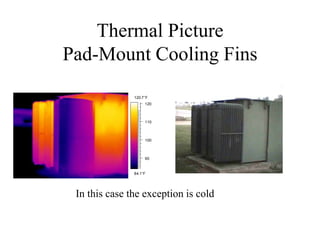

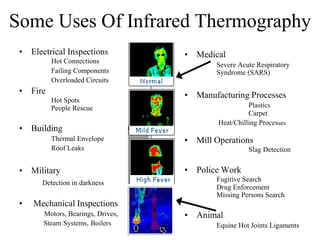

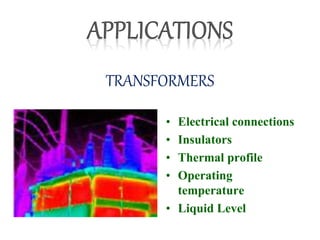

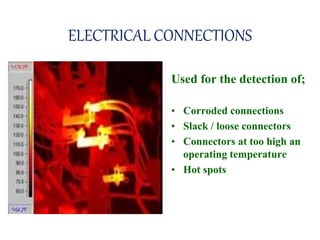

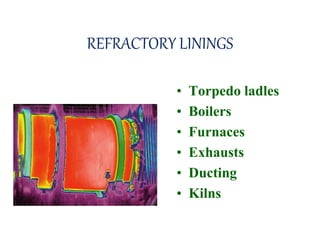

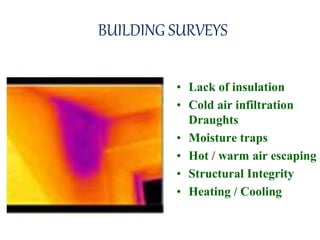

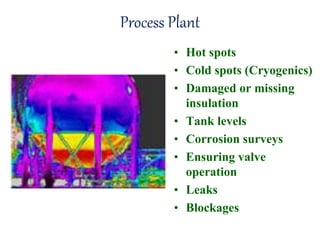

Thermal imaging cameras detect infrared radiation emitted by objects and produce images based on that radiation. They allow users to visualize differences in temperature that are invisible to the naked eye. The document discusses the principles and applications of thermography, including using it for electrical inspections to detect potential problems like loose connections. It provides examples of exceptions found during inspections and a priority scale for when repairs are needed. Thermal imaging has various uses in fields like firefighting, building inspections, manufacturing, and medical and military applications. It is a non-contact, rapid way to scan objects and infrastructure.