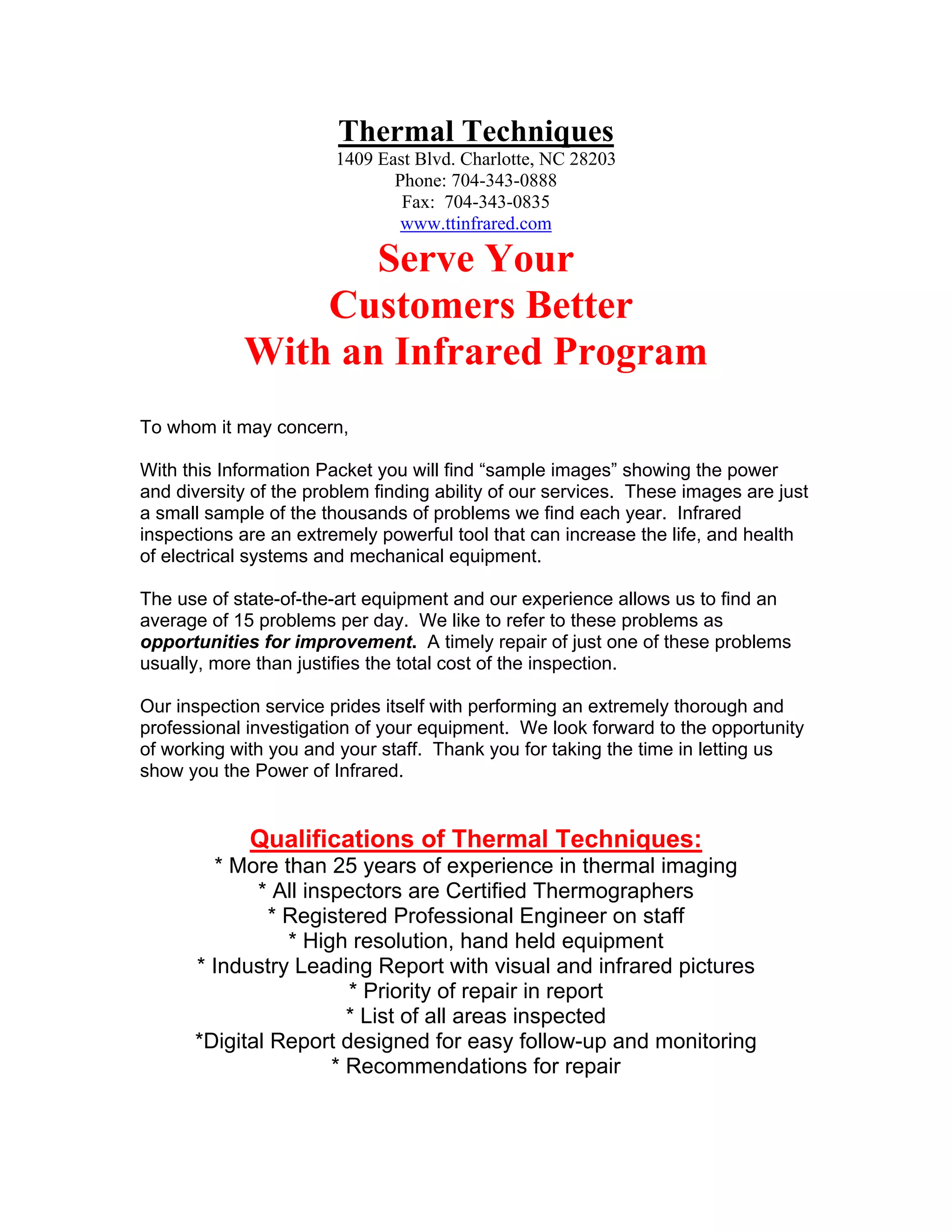

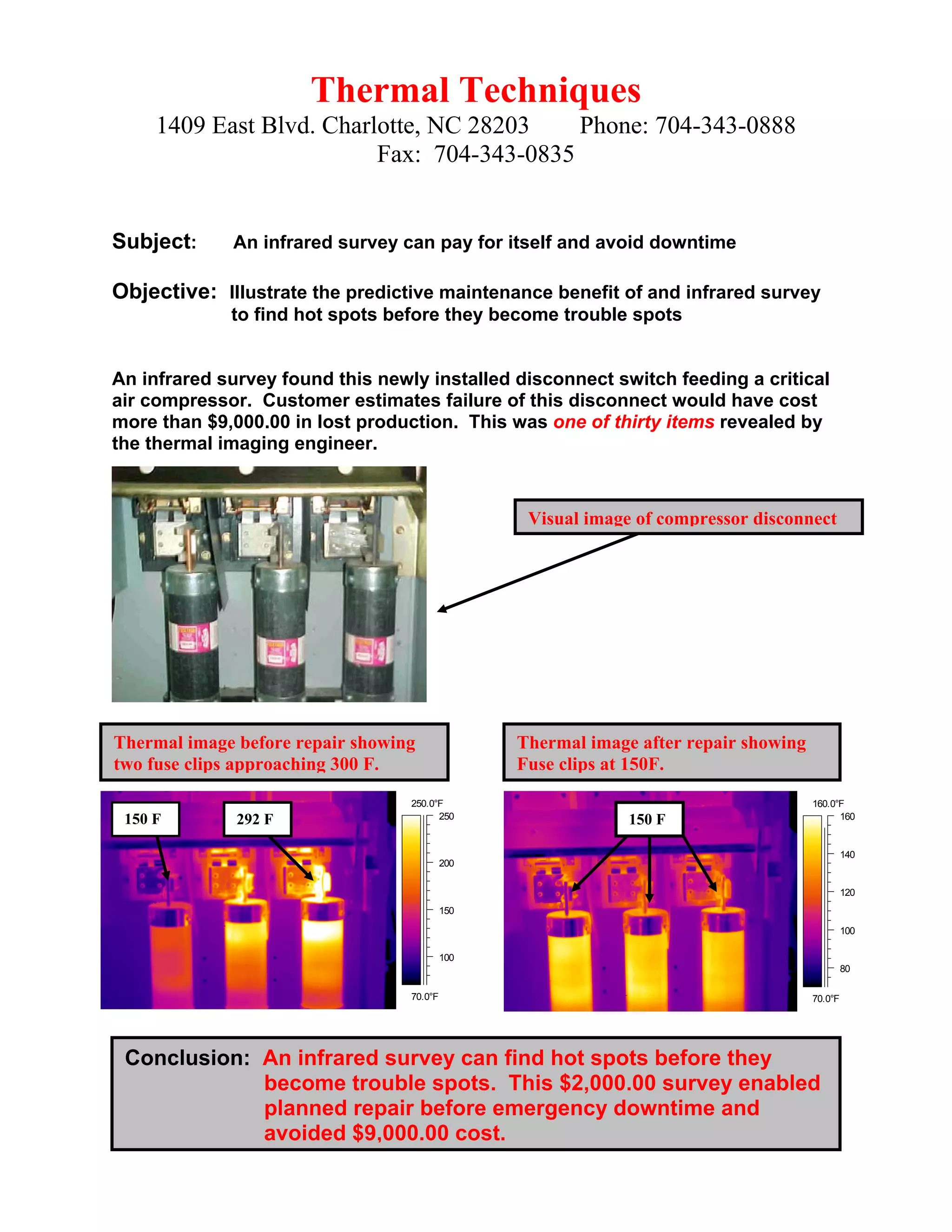

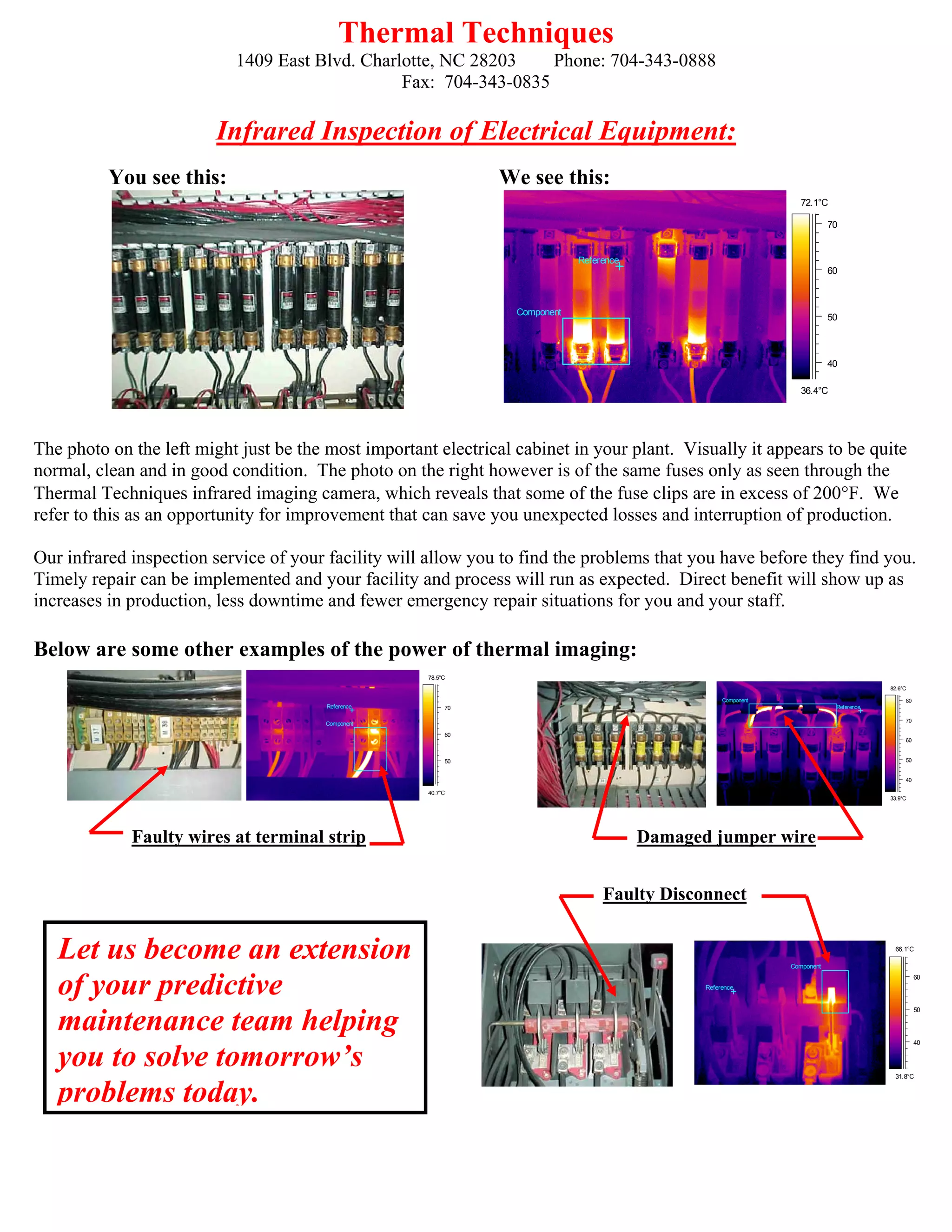

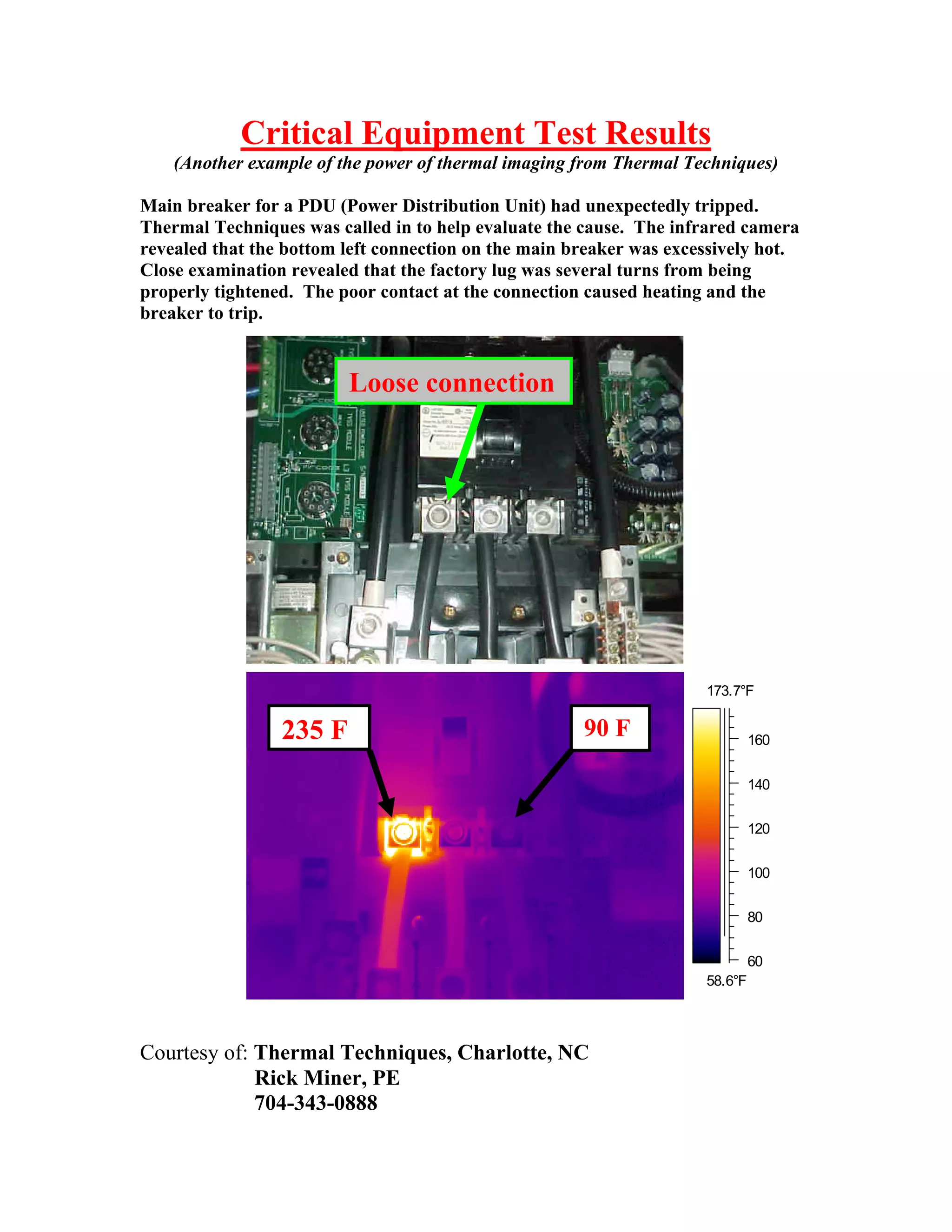

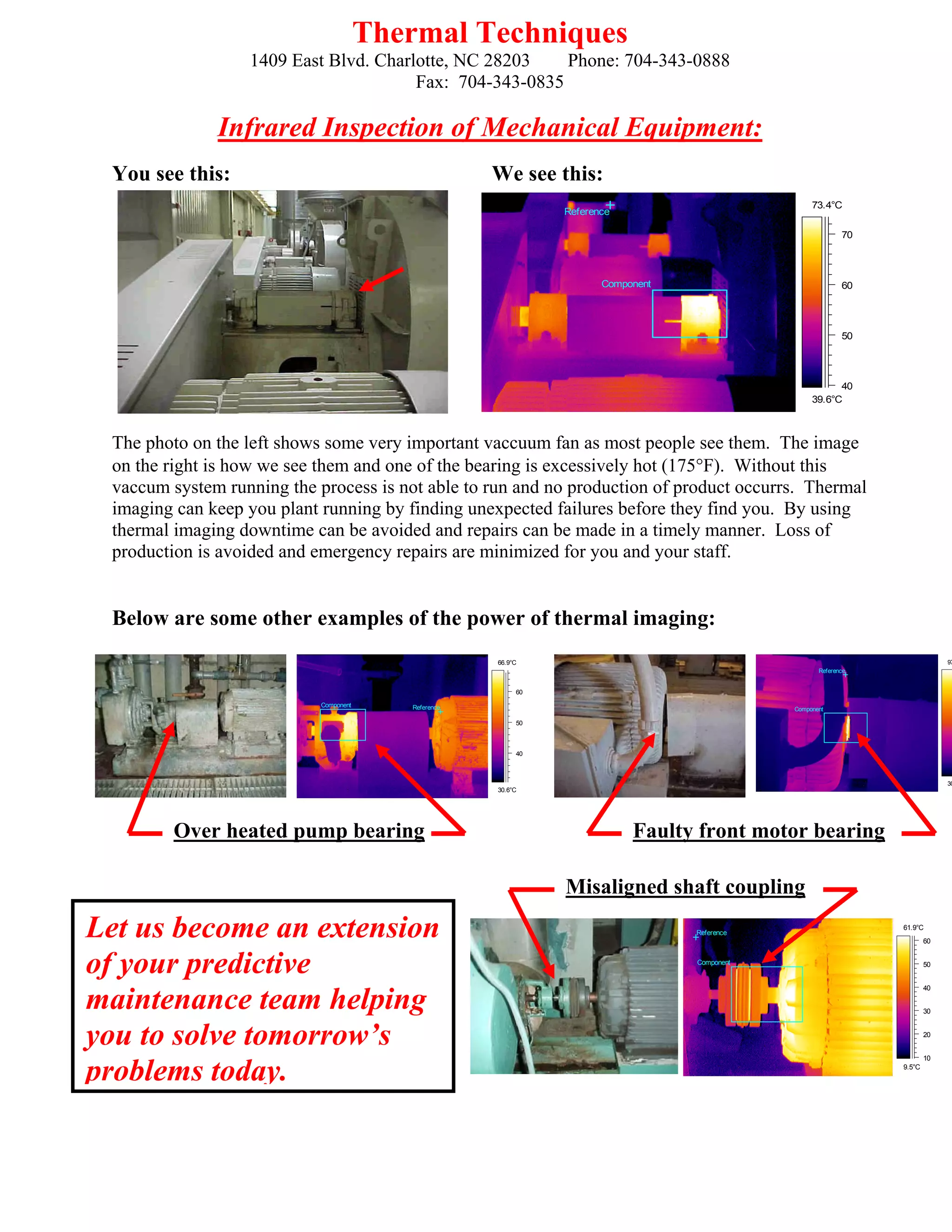

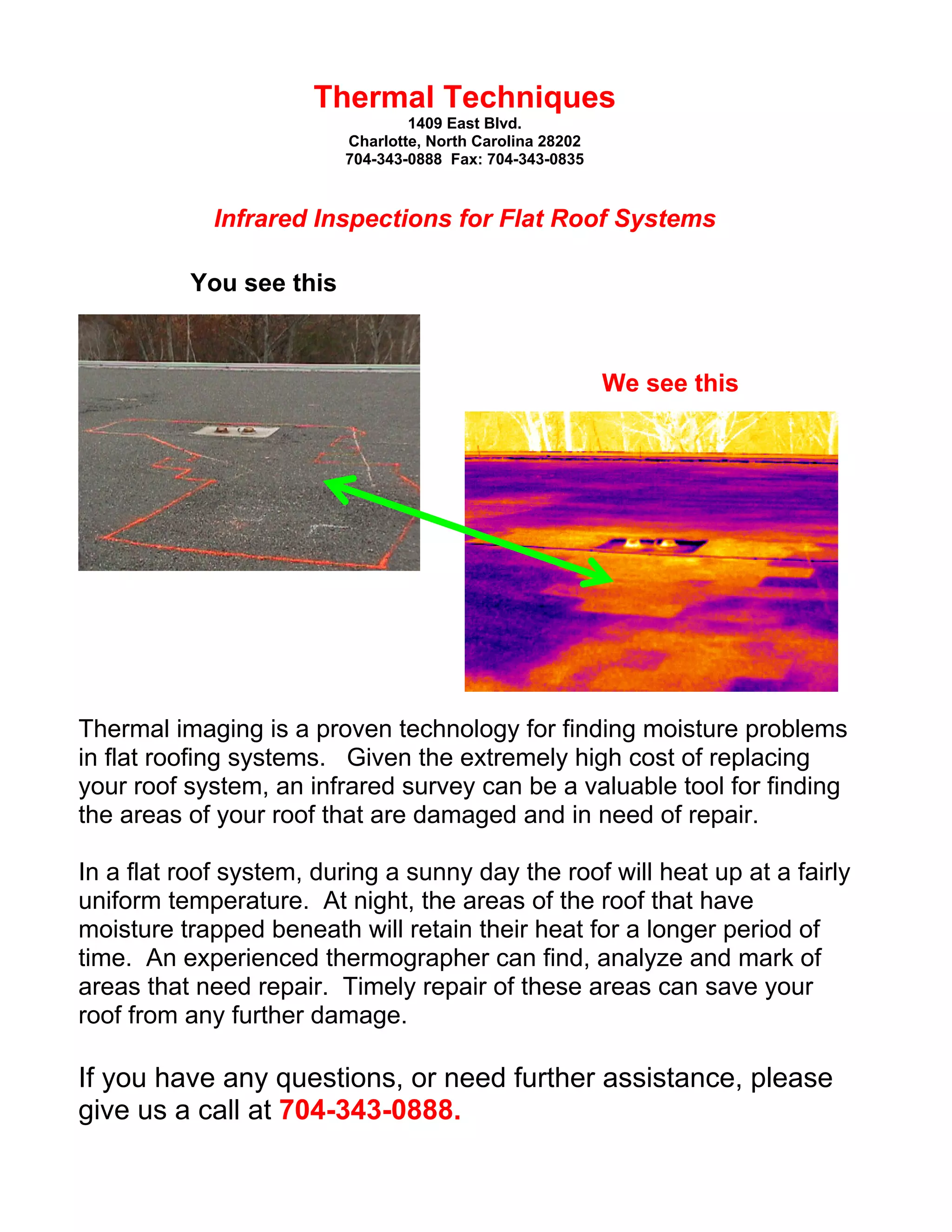

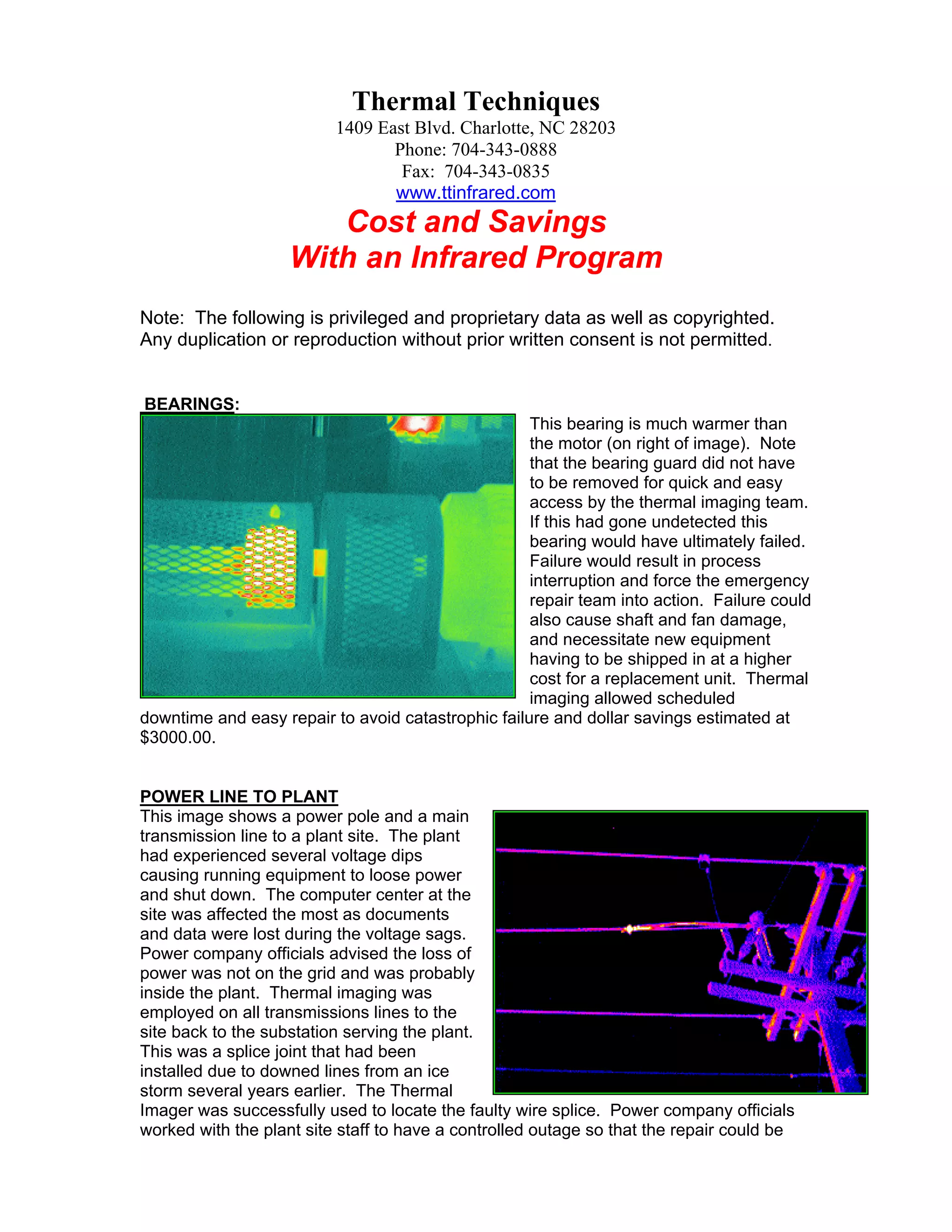

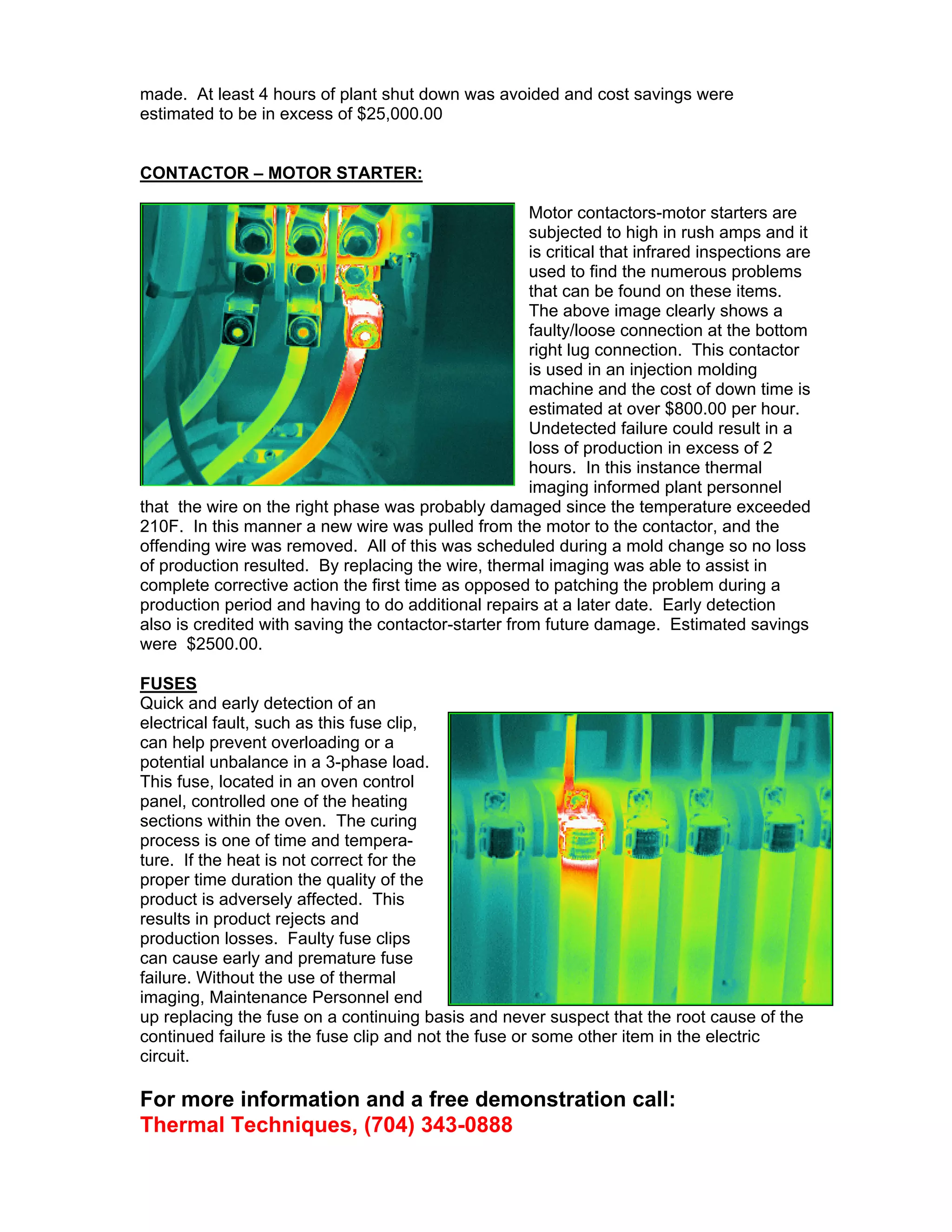

Thermal Techniques provides infrared inspection services to identify electrical, mechanical, and roofing issues before they cause equipment failure or downtime. Their inspections have found problems like loose fuse clips approaching 300 degrees, a faulty disconnect that could have caused a $9,000 compressor failure, and moisture trapped beneath a flat roof. These inspections have helped clients avoid downtime, emergency repairs, and costs estimated from $2,000 to $25,000 by identifying issues for scheduled maintenance.