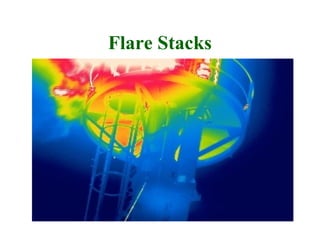

Thermographic testing uses infrared cameras to detect differences in surface temperatures that may indicate issues. It allows non-contact inspection of electrical systems, buildings, industrial equipment and processes. Key advantages are that it is non-destructive, fast, and can detect problems like loose connections, moisture ingress, insulation issues from a distance. Proper equipment, operator experience and understanding emissivity are important to get reliable results. A variety of applications are described like evaluating switchgear, transformers, refractory linings, vessels, flares and detecting manufacturing or process faults.