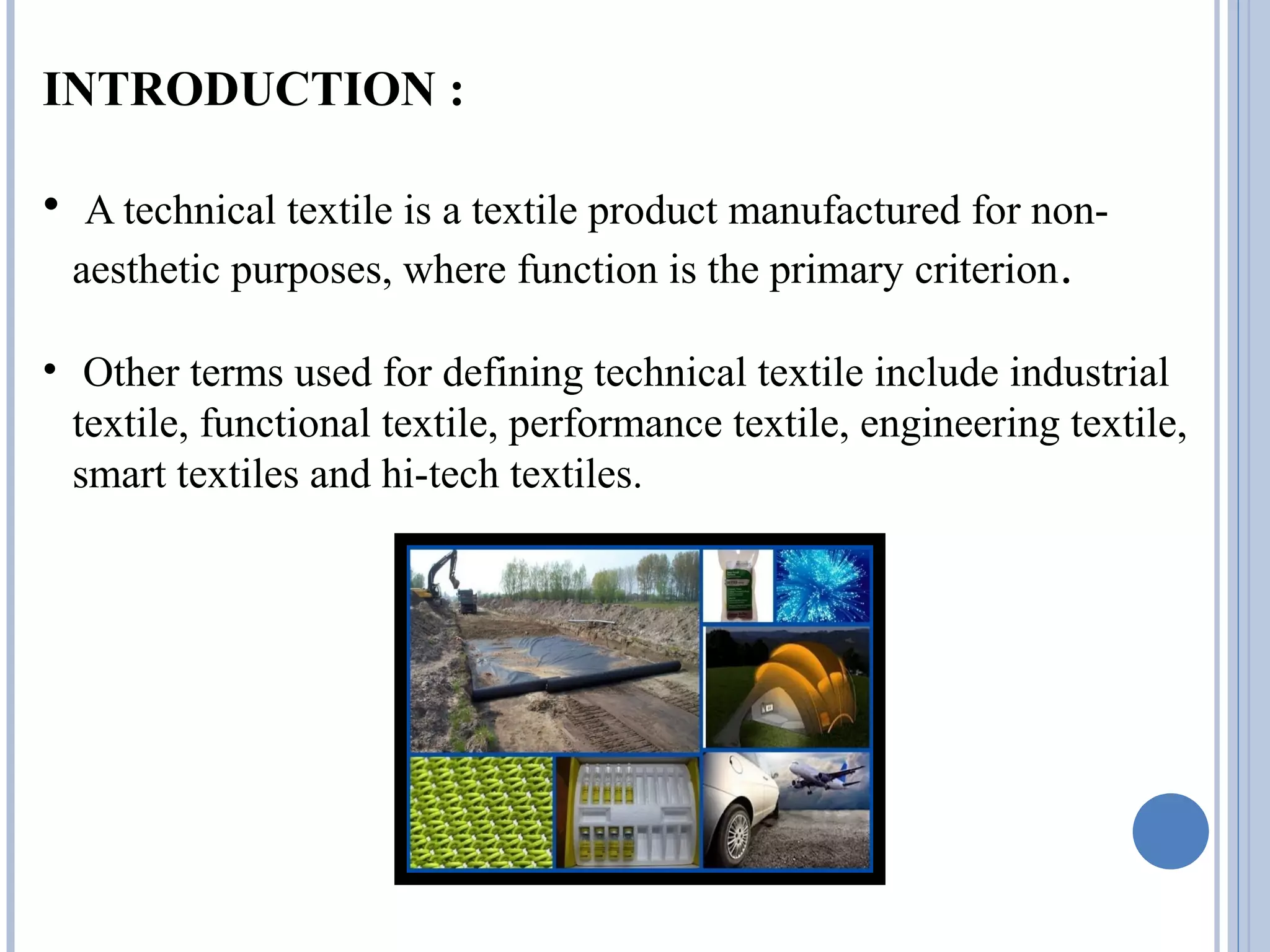

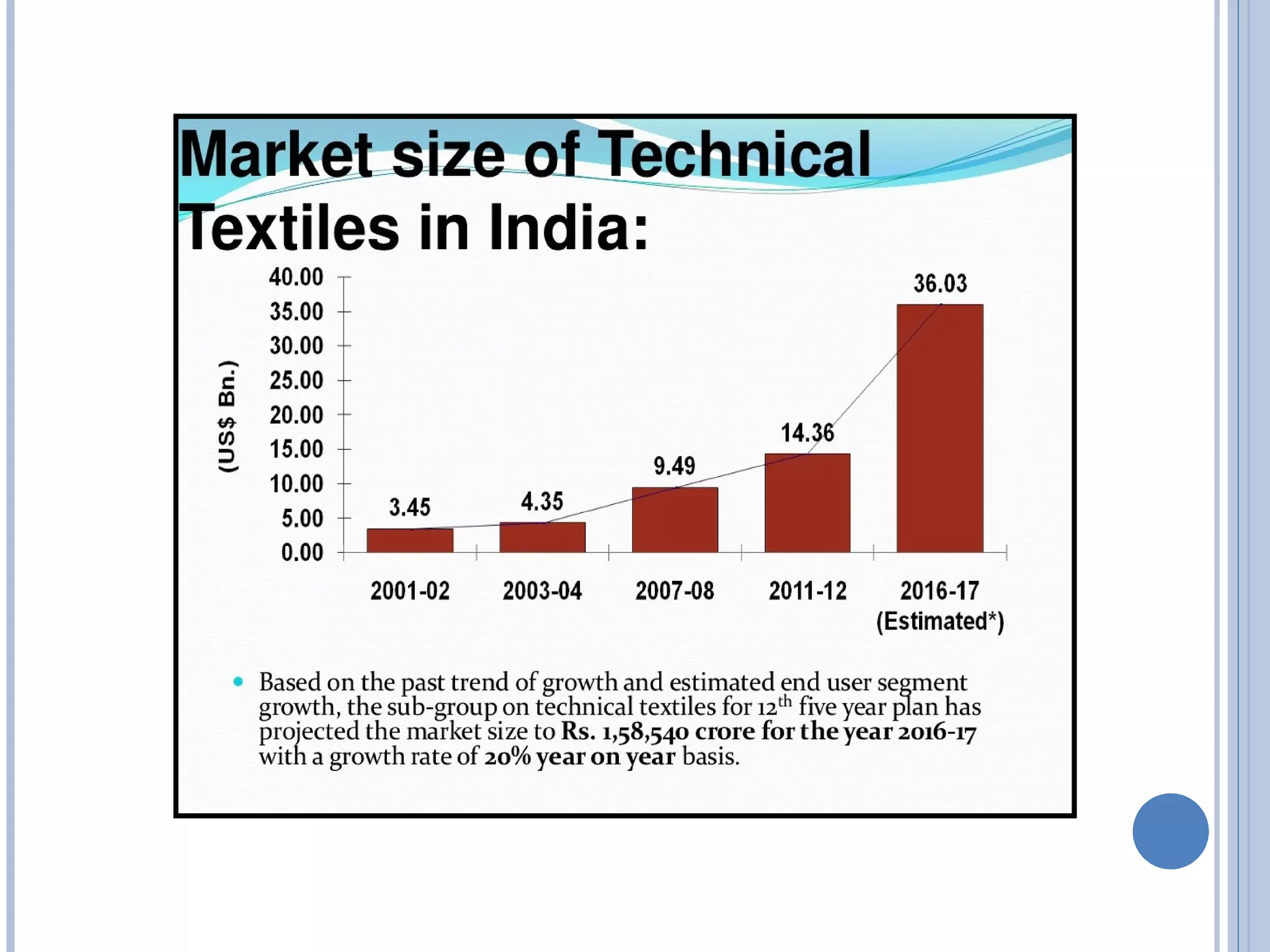

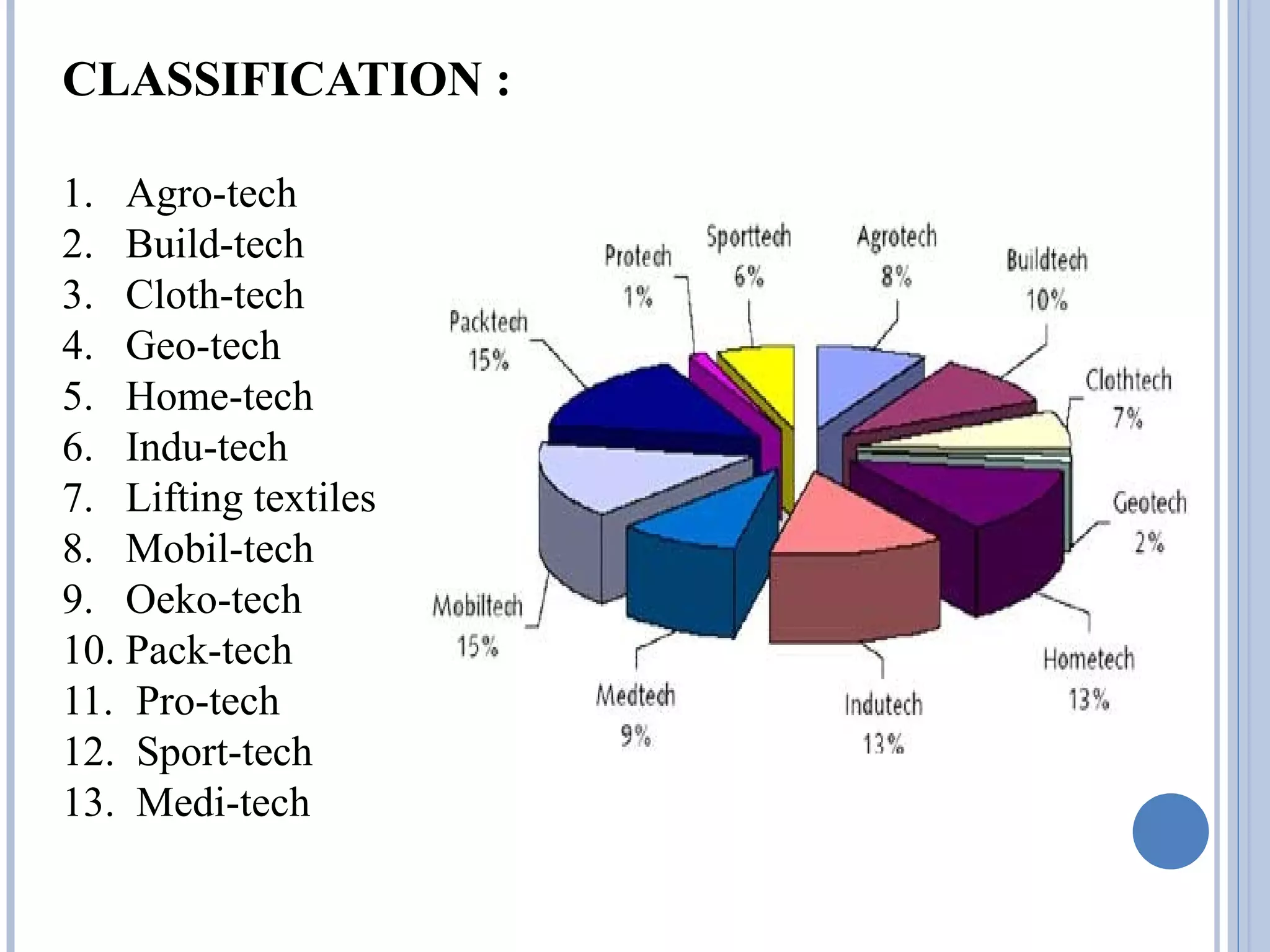

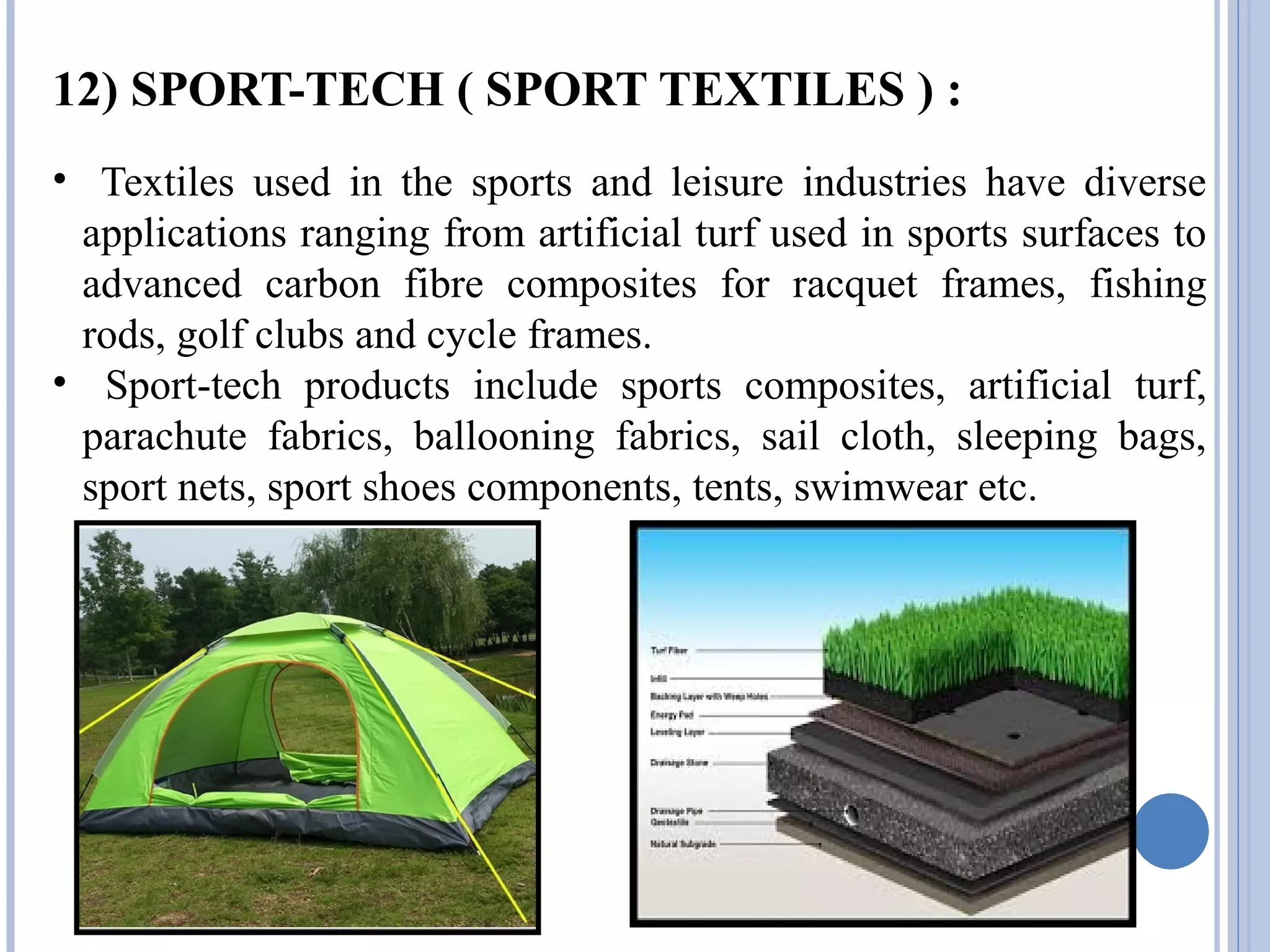

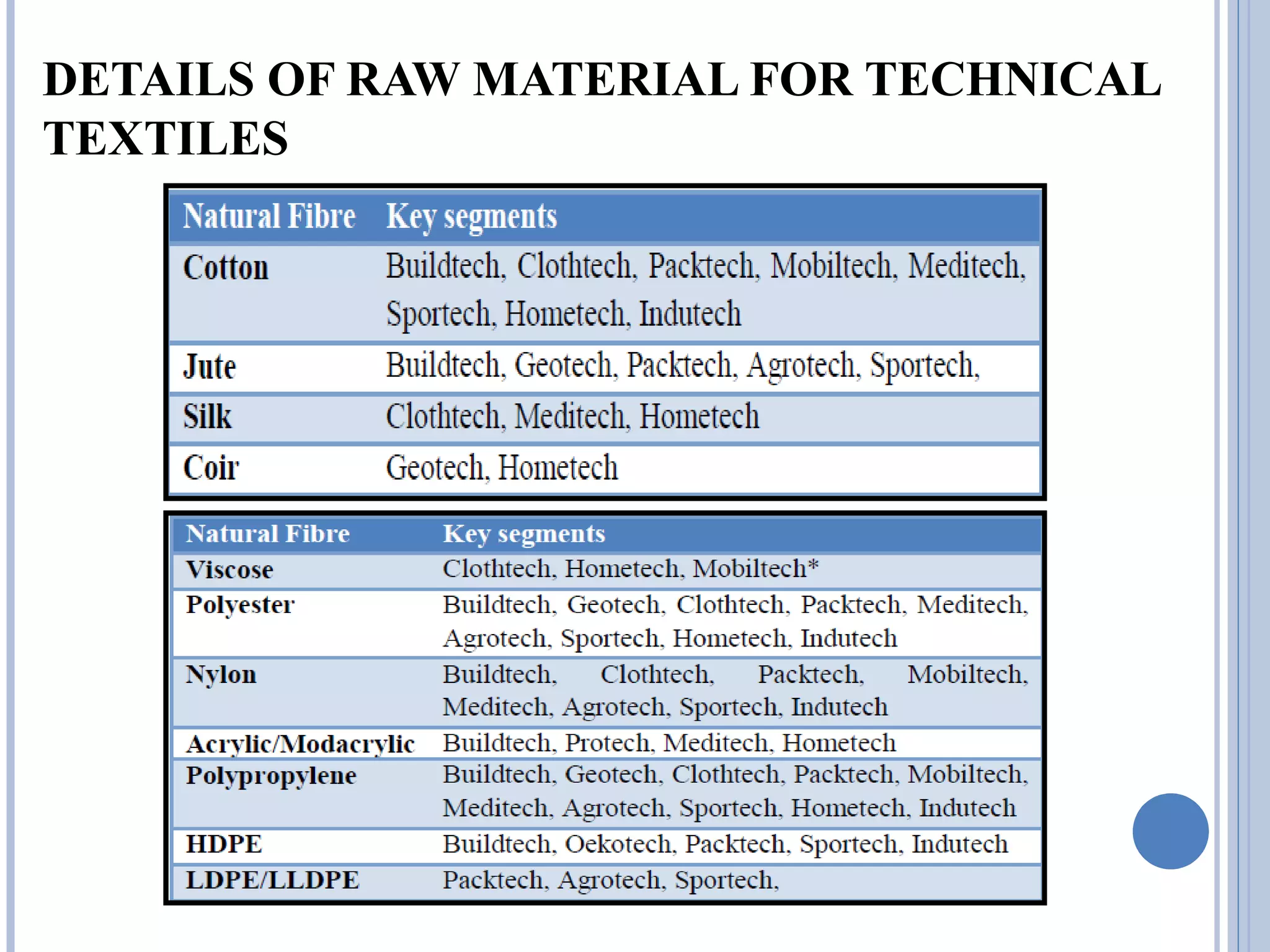

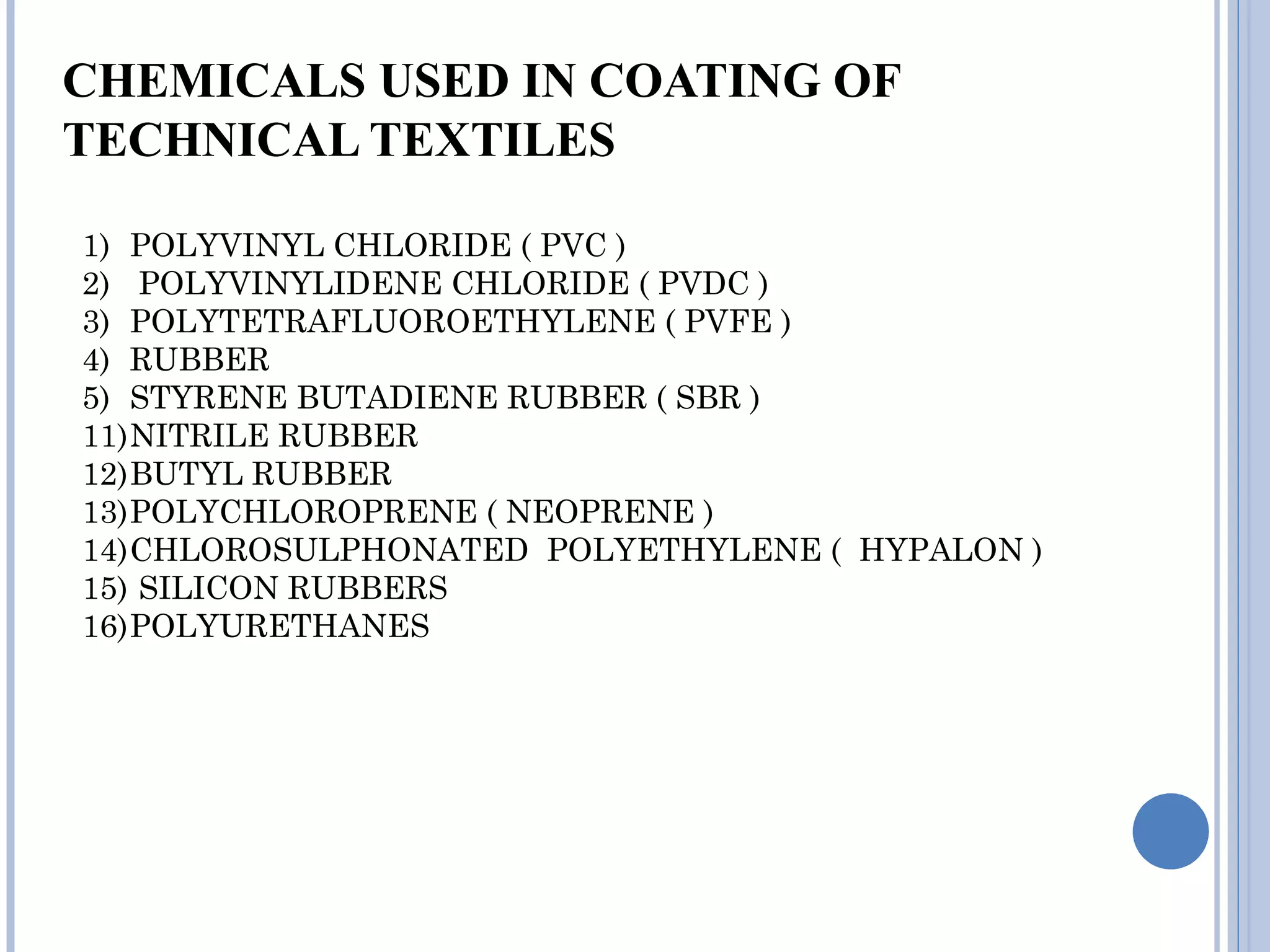

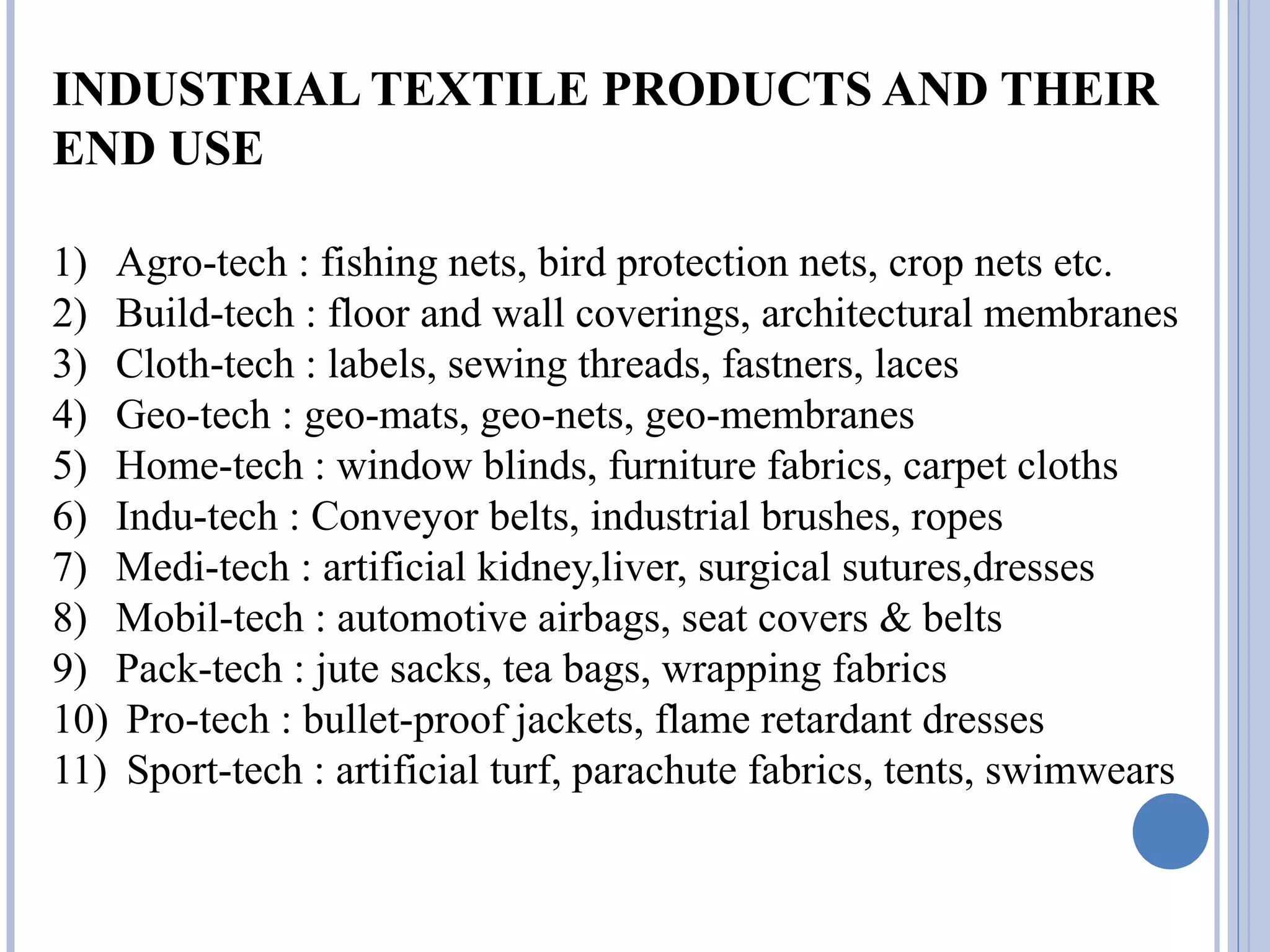

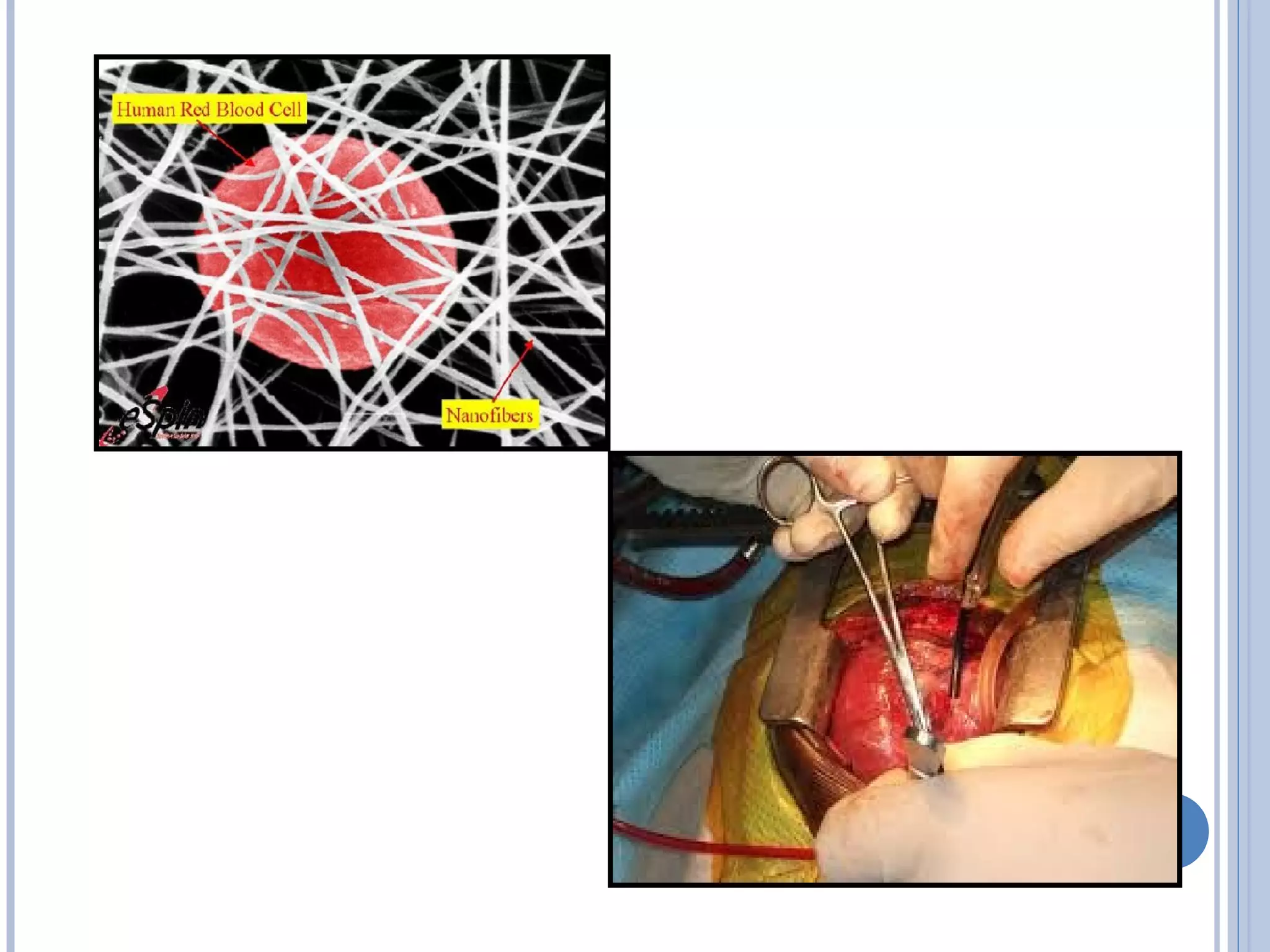

The document discusses the various applications and classifications of technical textiles, which are designed for non-aesthetic purposes with function being the primary focus. It outlines thirteen categories, including agro-tech, build-tech, and medi-tech, detailing their specific uses and properties. It also emphasizes the growing market potential of technical textiles, particularly in emerging fields such as construction, automotive, and medical applications.