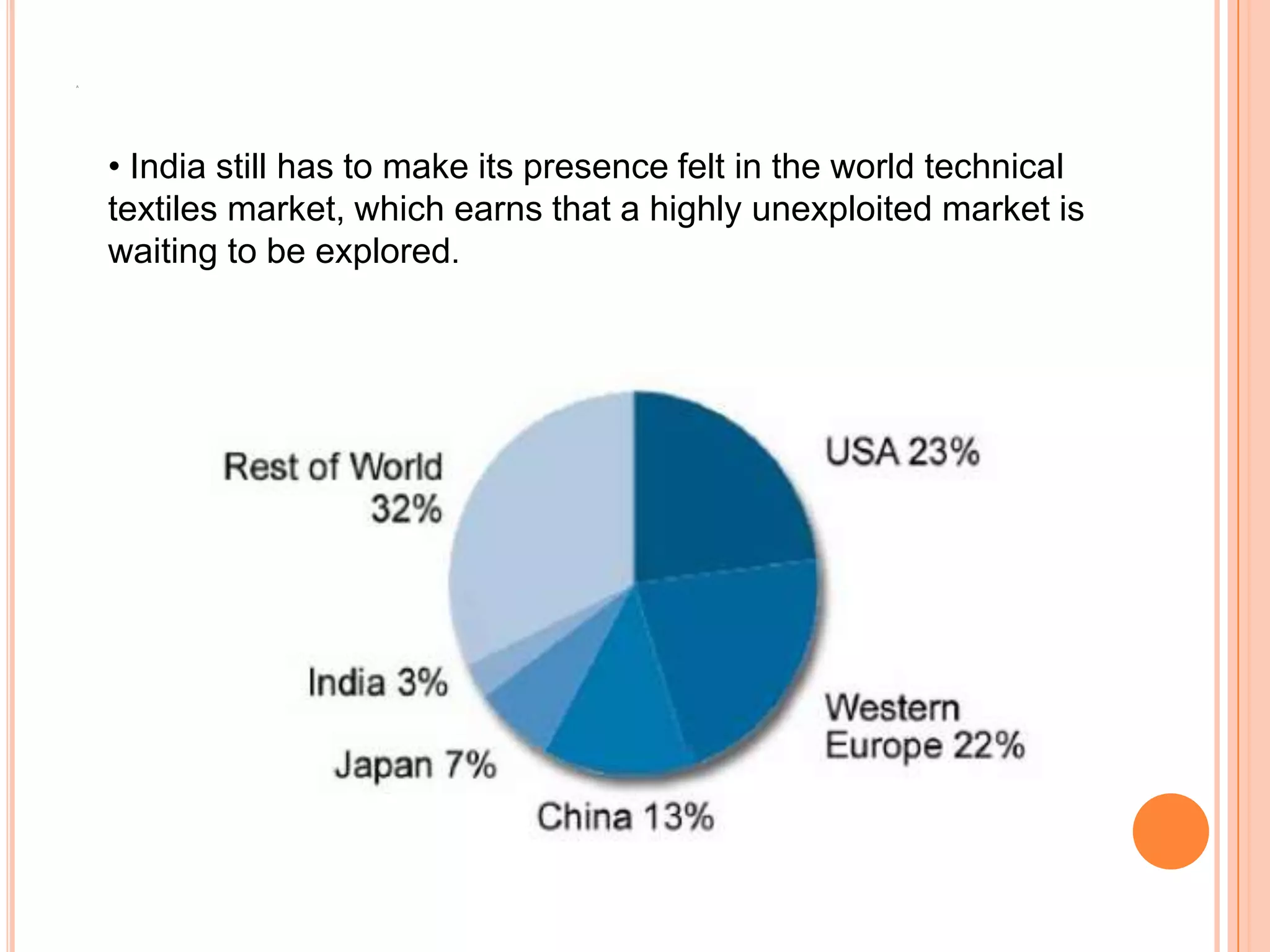

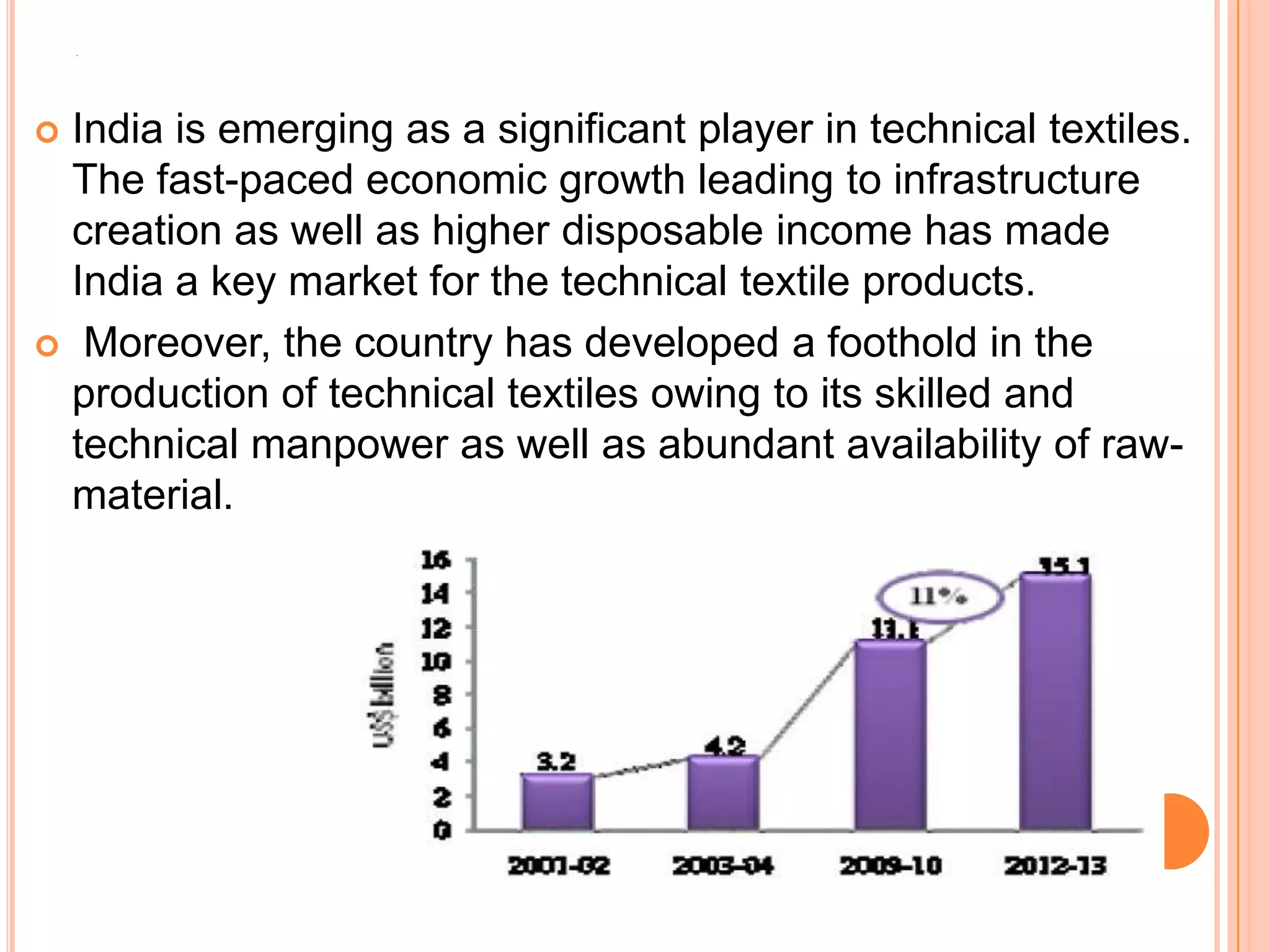

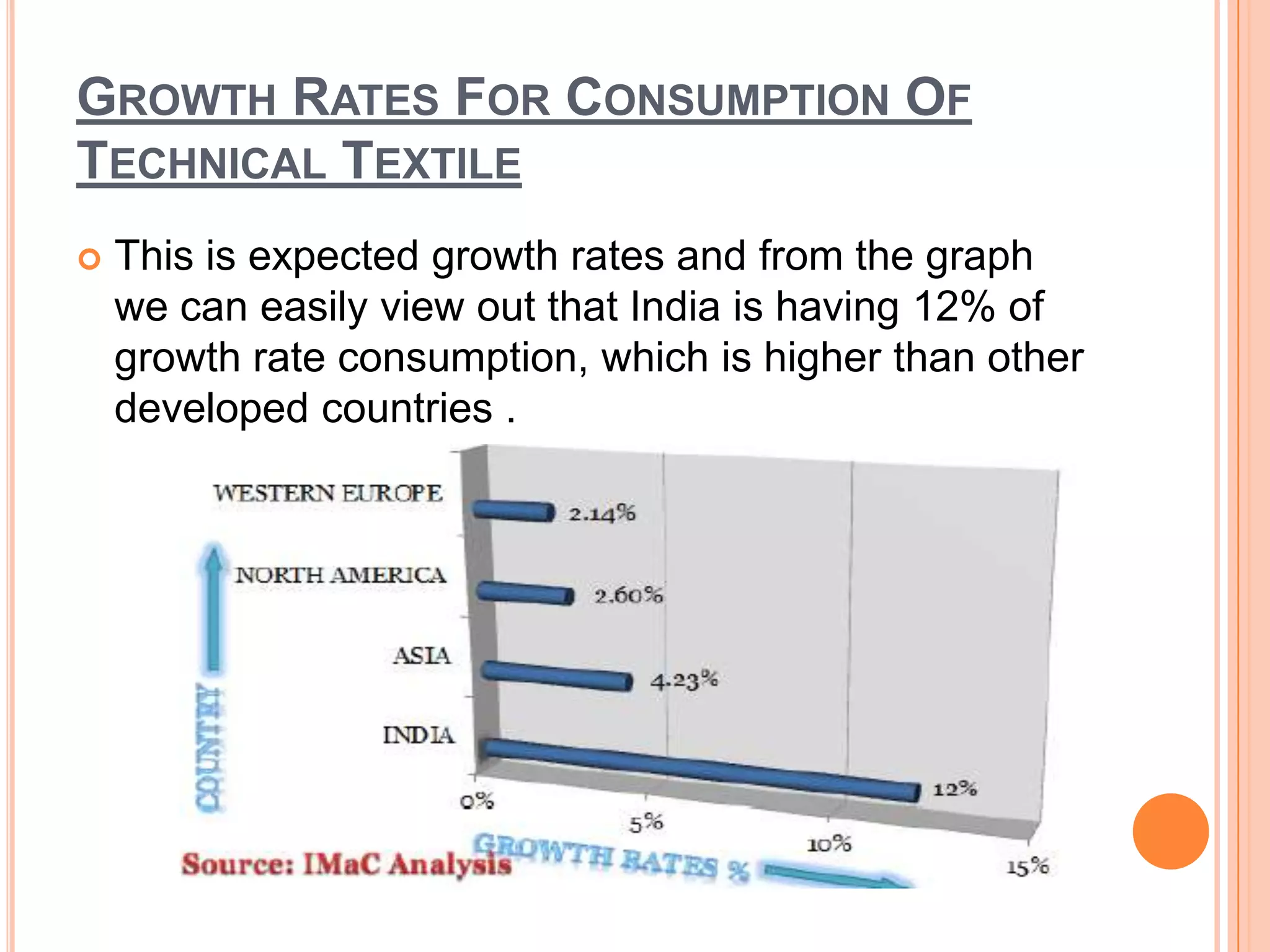

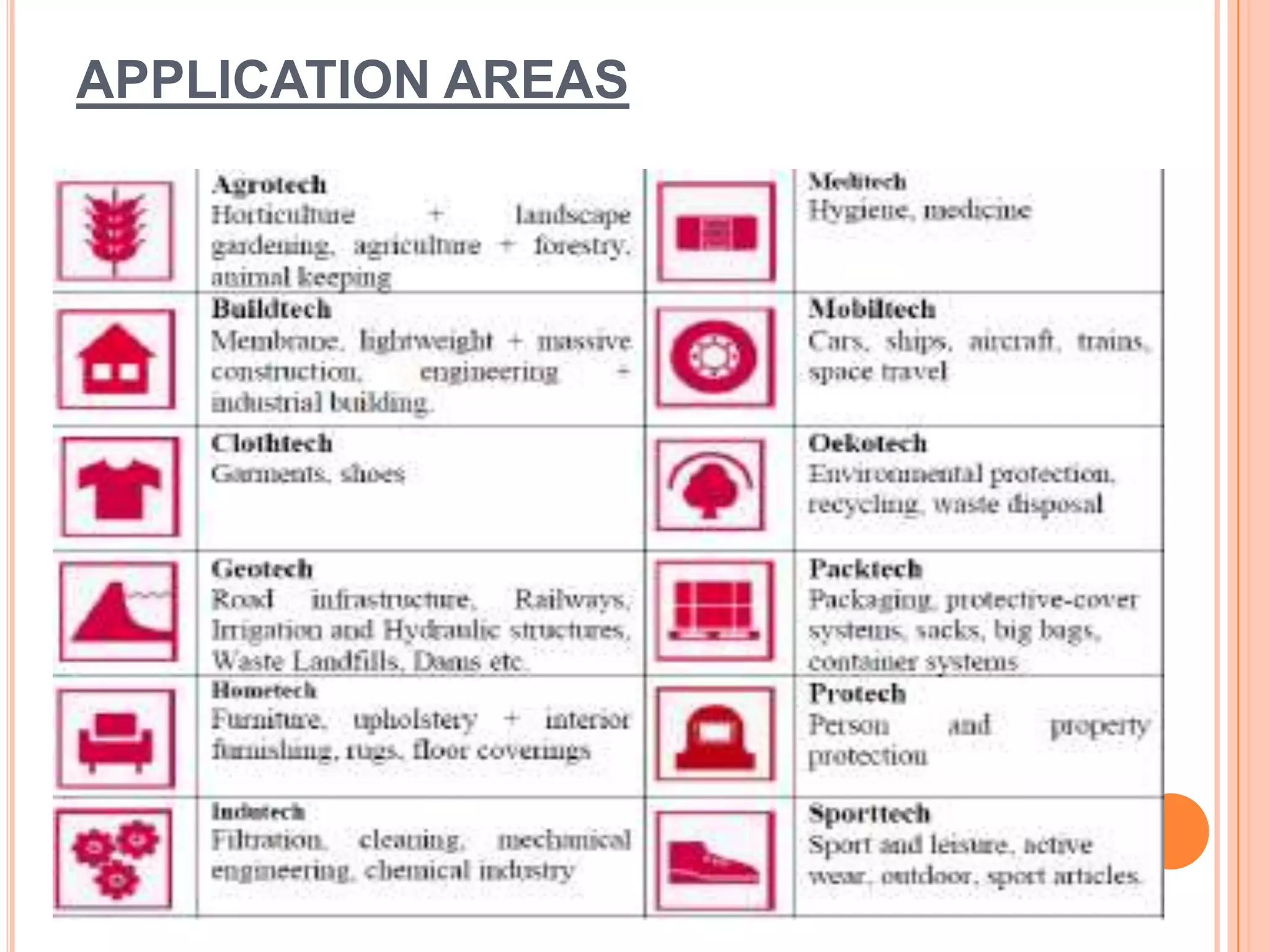

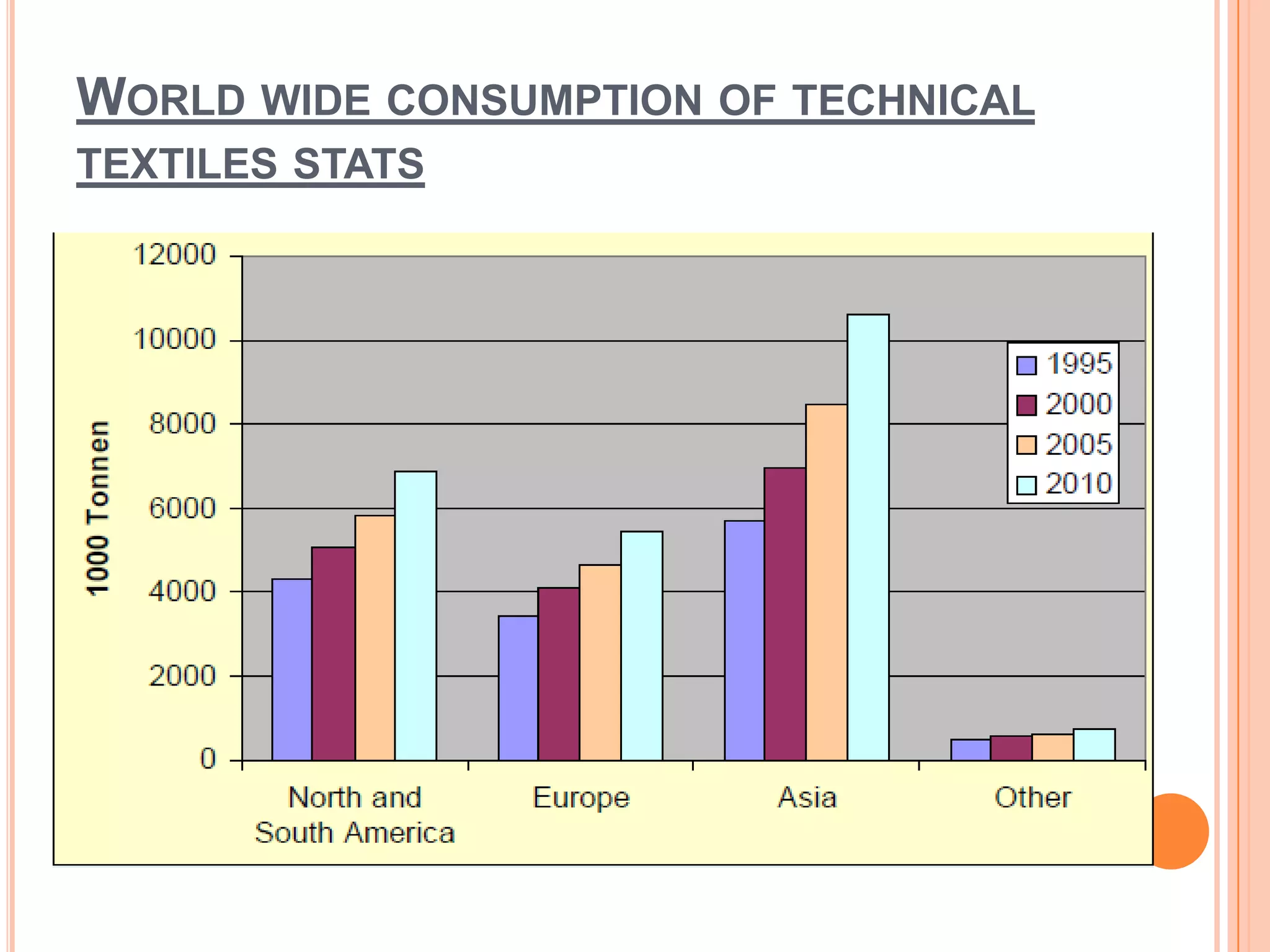

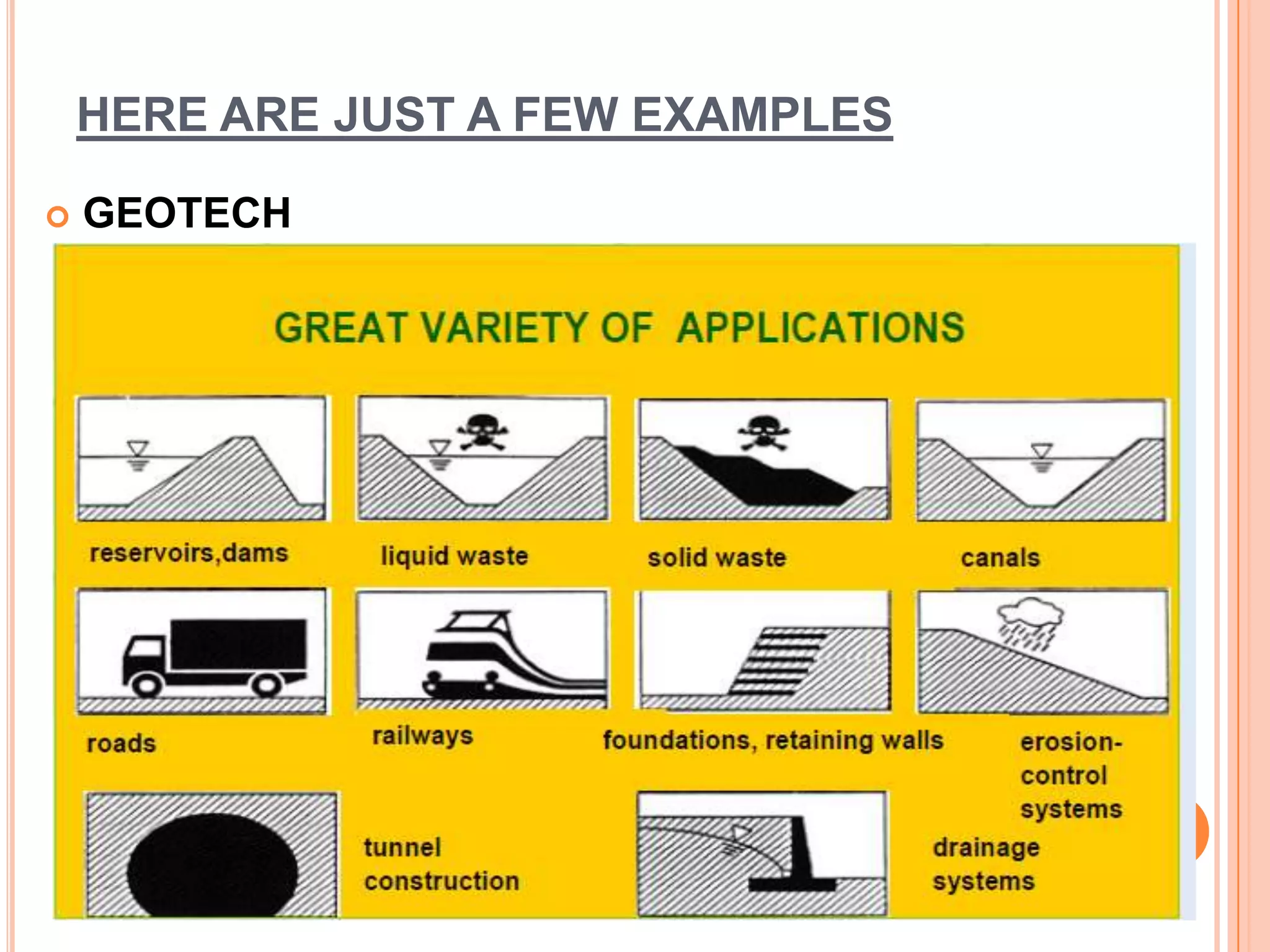

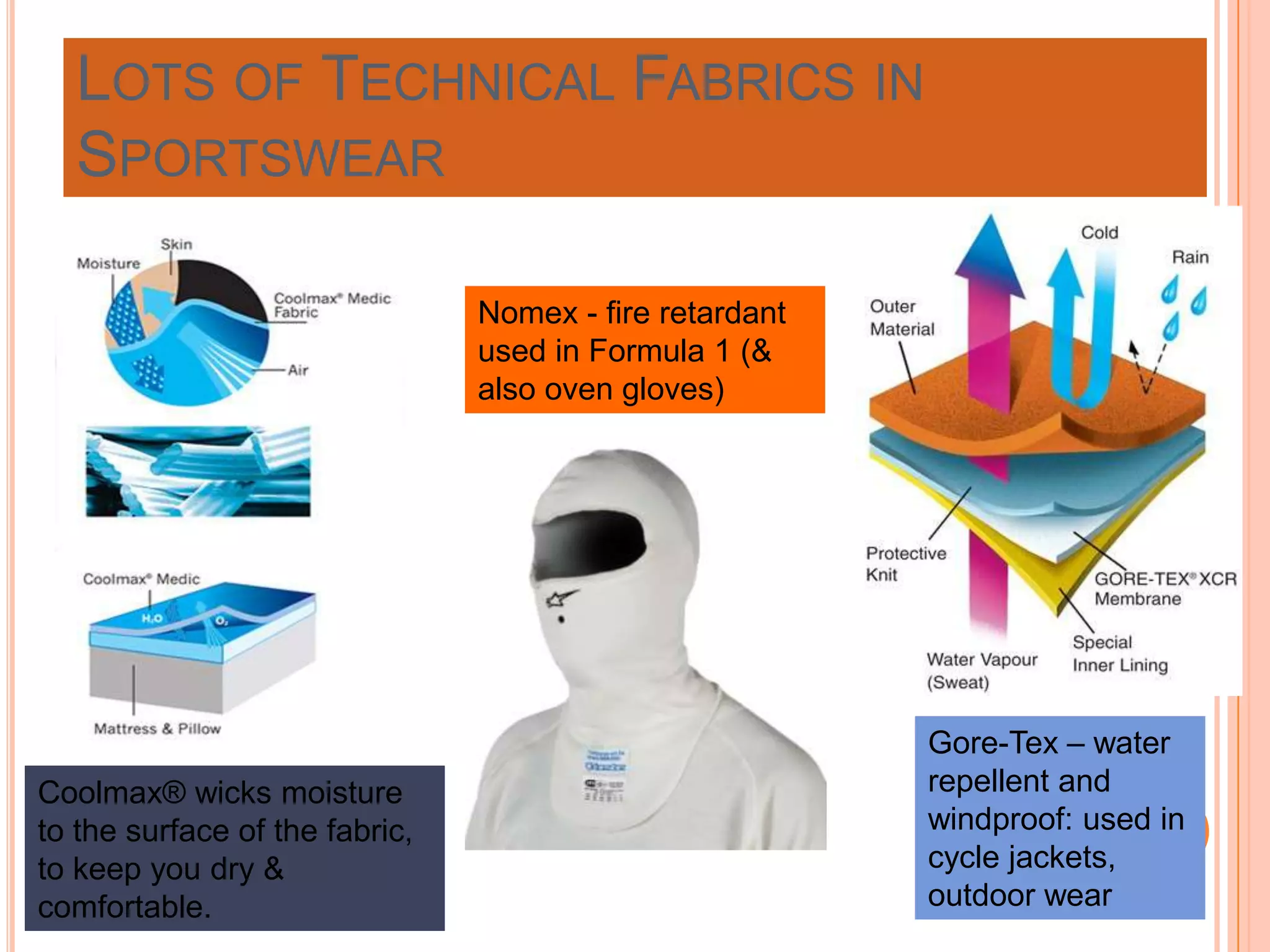

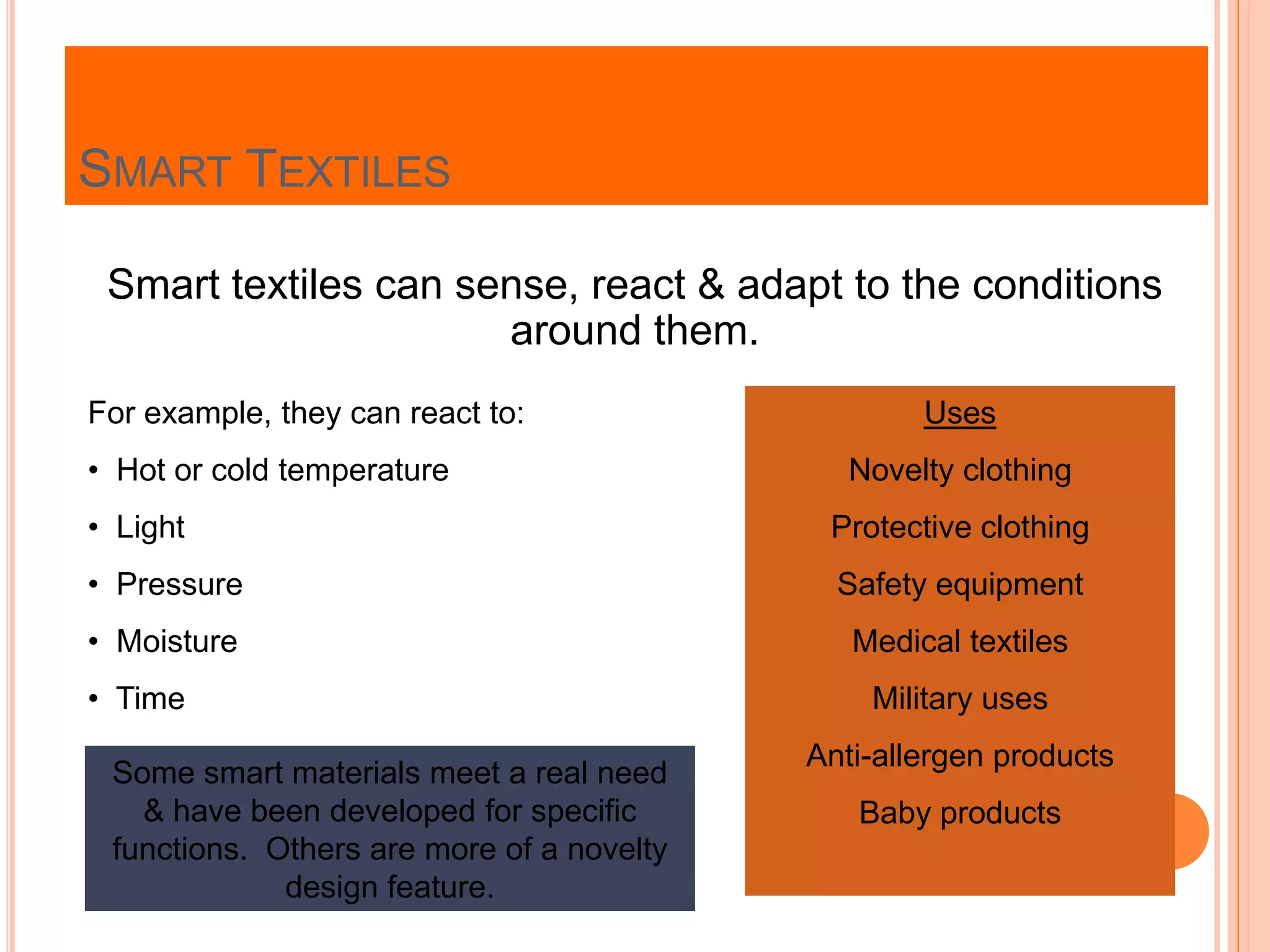

Technical textiles offer new opportunities for growth for the Indian textile industry. They provide functions beyond aesthetics and include materials for construction, agriculture, medical uses, and more. Currently technical textiles make up only 3% of India's textile market but are growing at 12% annually. The government aims to capture 10-12% of the global $6-8 billion technical textiles market in the next 10 years through targeting application areas that use indigenous materials and focus on value-added products. This will help diversify the textile industry and make it less reliant on traditional textiles.