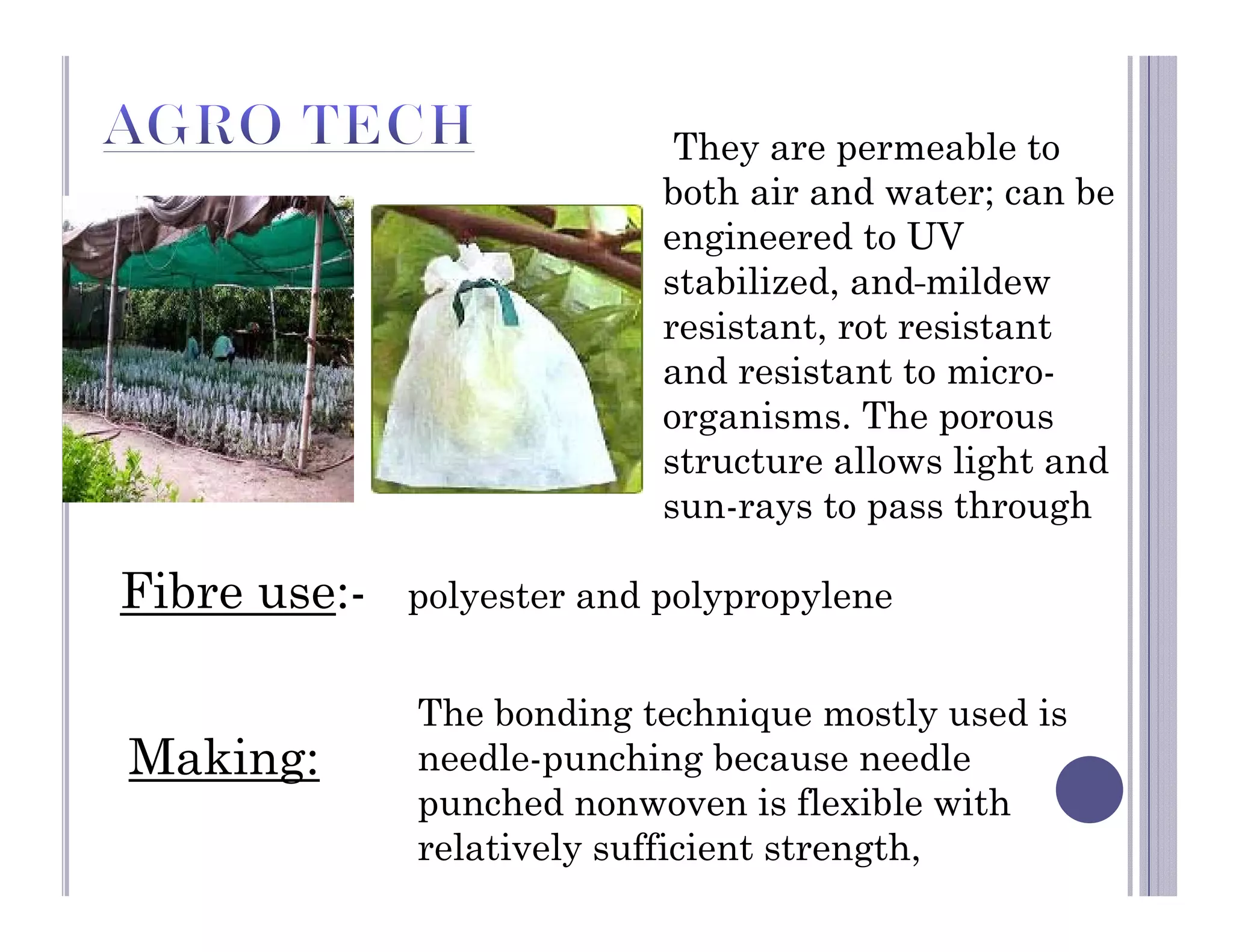

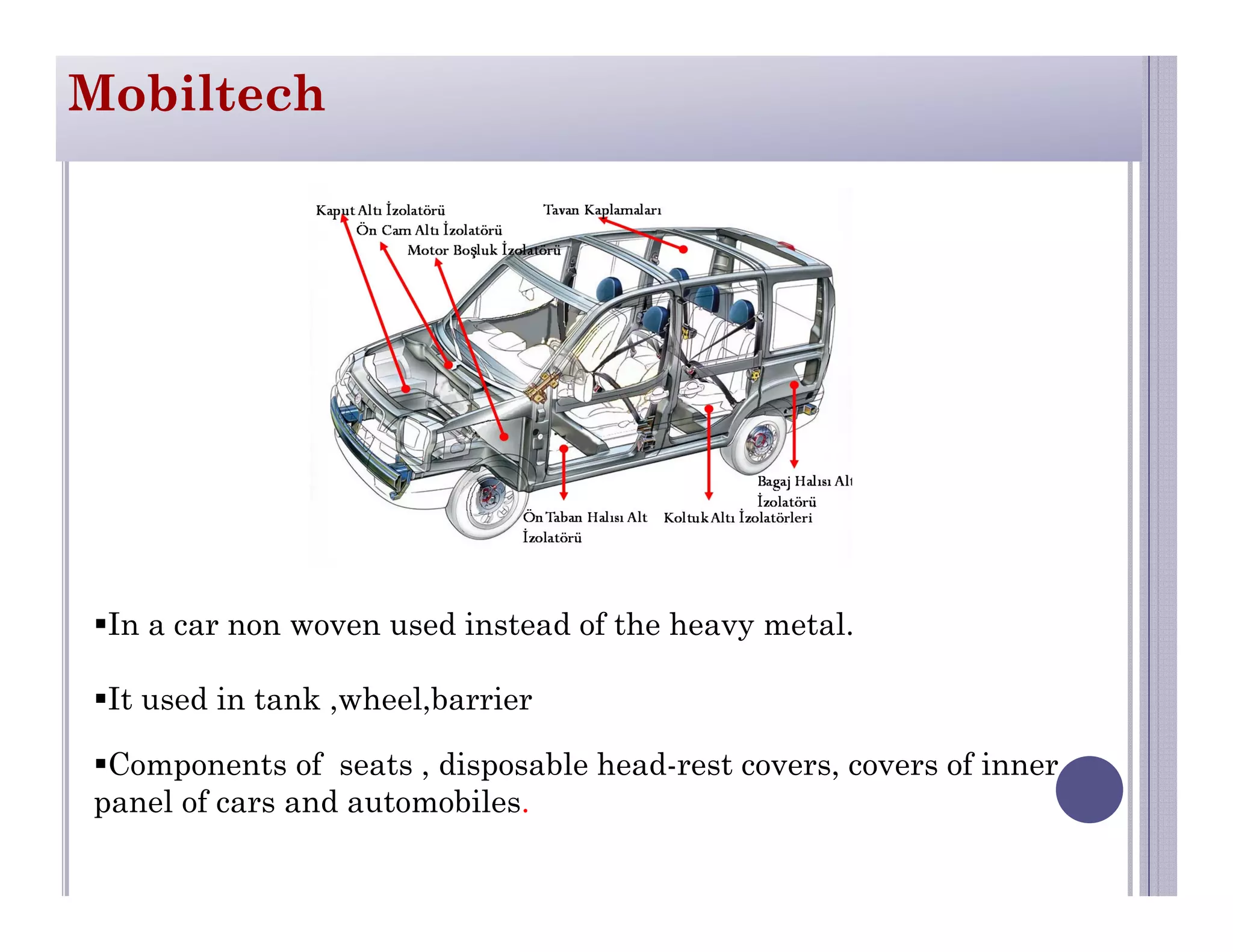

This presentation discusses technical applications of nonwoven fabrics. Nonwovens are made by bonding or entangling fibers without weaving or knitting. They are defined by their technical performance rather than aesthetics. Common fibers used are polyester and polypropylene. Needlepunching is a common bonding technique that produces flexible fabrics with strength. Nonwovens can be engineered to have properties like permeability, UV resistance, and resistance to microbes. They have a wide range of uses including geotextiles, masks, medical textiles, automotive textiles, home textiles, sportswear, packaging, industrial filters, and more. Technical textiles like nonwovens offer cost-effective and high performance materials for